Author: Zhu Yulong

After finishing the first part of the consolidation, the main focus will now shift to the second part, which includes enterprises mainly engaged in SiC power semiconductors. More details will be added.

- Gao Jinping, Senior Marketing Manager of Automotive Electronics Business Division, Greater China, Infineon Technologies (China) Co., Ltd.

The application of silicon carbide focuses on the automotive industry, and it has different voltage and power demands in different application scenarios.

-

Silicon-based devices have the widest coverage in power and voltage, with high technological and business maturity, and better cost-effectiveness. It will still occupy a mainstream position for a long time.

-

Silicon carbide has a relatively high frequency resistance, and its medium and high voltage power is also relatively large.

-

Gallium nitride is suitable for low-voltage and ultra-high frequency applications, such as the 5G base station and the 4C power supply (laptop charging plug).

Automobiles have limited space and are relatively difficult to handle thermal dissipation. They are also exposed to high temperature, high humidity, and high heat scenarios, which will bring high power density and high temperature resistance to electronics. For OBC and DC/DC, the switch from 3.3-6.6kW to 11kW and 22kW, silicon carbide can reduce the volume of the entire passive device (inductor, capacitor, transformer), reduce the heat loss of the entire system, and comprehensively reduce the cost of the entire system. The core pain point for the main drive is the longer cruising range and higher power density. The use of silicon carbide can also improve the current high battery costs and increase the cruising range.

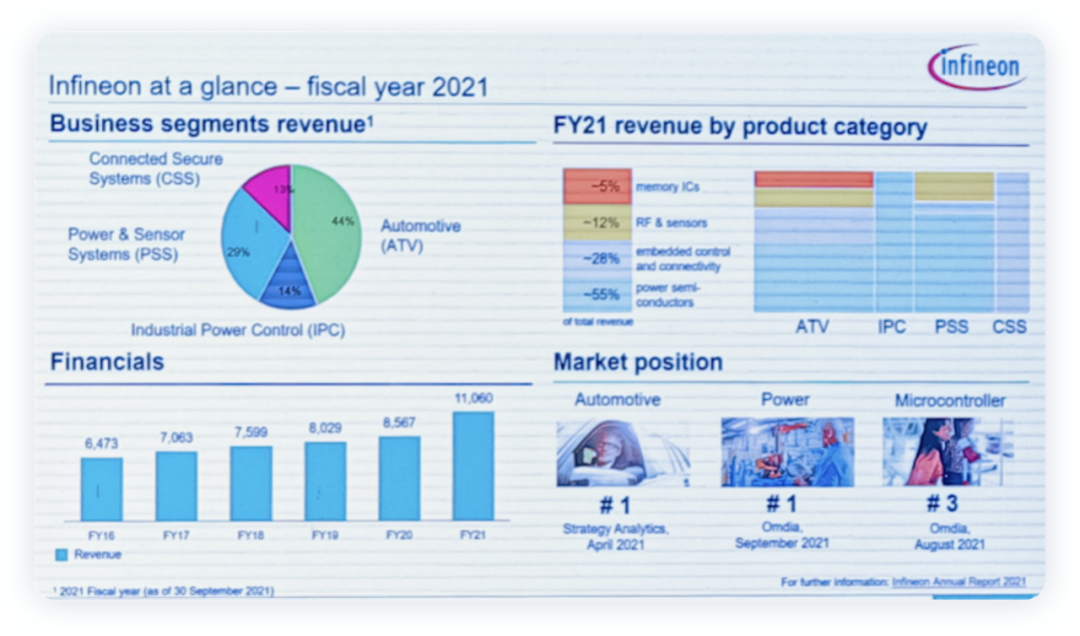

The compound growth rate of the entire power semiconductor market should be around 28%. Now, the momentum of the entire new energy industry may be faster than we imagined. The compound growth rate of silicon carbide is relatively higher, and it is predicted that its share will exceed 32% by 2025. The domestic development of silicon carbide may be faster. Hybrid will focus on IGBT, with higher power density and cost requirements. For high-end electric vehicles with a high amount of assembled batteries, especially those with over 70-80 degree electric drive, silicon carbide is usually used on the main shaft that works for a long time, while IGBT is still used on the auxiliary drive shaft that is not commonly used.

There are two main advantages of silicon carbide:

- Switching Loss: especially at 800V, silicon carbide has faster switching speed and reverse recovery characteristics, and its switching loss is much better than IGBT.- Conduction Loss: Silicon carbide is not always superior to IGBT in every field or every current point. IGBT and silicon carbide will have a turning point in terms of loss, with typical working conditions of 400V and demand for less than 100A current for about 95% of the time. When the current exceeds 300A under a rated current situation of 75%, the advantage of silicon carbide’s conduction loss becomes very obvious.

Infineon’s double-sided water-cooled IGBT and double-sided water-cooled silicon carbide, based on silicon carbide technology, can achieve a reduction of 75% in conduction loss and over 60% in switching loss across the entire operating range, resulting in an overall loss reduction of over 60%. Simulations have been conducted for WLTP working conditions for systems of 400V and 800V, which show that adopting silicon carbide products for 400V systems could increase the cruising range by approximately 4%-5%.

The foundation of 750V IGBT itself is relatively good.

In the 1200V system, the IGBT itself does not perform as well under high voltage as that of 750V, so the baseline will be pushed back, and the 800V seems to be more promising.

750V silicon carbide is still necessary. As the silicon carbide industrial chain becomes more mature and commercially mature, 750V will bring better cruising range (overall reduction in battery cost), which, of course, depends on the industry’s battery cost and the maturity of silicon carbide.

Infineon has been doing silicon carbide for almost 30 years, even more than 30 years, gradually penetrating from the earliest industrial field to the automotive field. We started mass production of vehicle-level silicon carbide products in 2019, and they have been adopted by many car manufacturers for OBC, DC/DC, and silicon carbide modules. Currently, they are maturely running in Hyundai Kia’s 800V platform. There is basically no more controversy in the entire industry. Basically, international big companies have all announced that they will enter the field comprehensively after 2023 or 2024. Infineon’s first-generation mass-produced product is Trench technology. For the first-generation IGBT 750V, we replaced the chip with silicon carbide, verifying the chip technology before updating to the next-generation product. The second-generation silicon carbide module is expected to be launched comprehensively in 2023.

Traditional power modules will use magnetic rings or three-in-one current sensors. In order to solve the problem of better power density, modules can be equipped with current sensors from third-party collaborations, which can greatly improve our power density and save 8% of volume in space. Using non-magnetic technology, the entire life cycle has high accuracy, and it is integrable for installation with good usability.The module with dual-sided liquid cooling adopts a comparatively high aluminum nitride substrate on the bottom surface to achieve good heat dissipation. Copper block technology is also applied on the upper surface, which can improve the heat dissipation up to about 40%. For silicon carbide products, it is important to dissipate heat due to the wafer area, and the surface heat dissipation is also critical.

In order to facilitate installation and integration, stray inductance and power electronics are on one end while signal electronics are on the other, which is not suitable for silicon carbide products. The next-generation dual-sided liquid-cooled silicon carbide module will adopt a DC side three-terminal structure, which will further reduce system loss. Compared with the same single-sided module, the overall heat dissipation advantage is increased by about 40%.

DCM modules with 750V silicon carbide chips have been mass-produced, and DCM1000X with 1200V silicon carbide chips will be mass-produced by the end of this year. The future plan is DCM500, which adopts a six-in-one package form and has a smaller size.

-

The voltage resistance that DCM1000X module can withstand has been increased from 900V of the original DCM1000 to 1200V, and the maximum current that it can achieve can reach 800A.

-

The module adopts direct liquid cooling technology, and the number 1000 actually represents the area of available semiconductor chips covered inside it.

-

The most important feature of the module platform is the independence of the chip, which allows customers to choose the desired chip to use, in order to meet their considerations for performance, cost, and process safety.

-

The current output capacity of the module can be configured according to the performance and quantity of the selected chip, and the internal electrical optimization of the module can be configured according to the selected module.

-

The module’s connection method can be customized (providing DBB technology = using copper binding instead of traditional soldering), which can significantly improve the module’s power cycle capability.

-

The module’s heat dissipation performance provides ceramic substrates with different performance according to the current level and heat dissipation requirements of the module.

-

Danfoss provides direct cooling technology, and the number and shape (material) of water channels can be customized to achieve a balance between thermal resistance and water resistance.

Silicon carbide chips are very expensive, and the module price does not generate a lot of profit (most of the profit goes to chips, which are made with sweat and toil).Denver offers a differentiated packaging solution, which includes Denver’s DBB patented technology plus a water-cooling technology that removes bubbles. These technologies can quickly improve the module’s cooling ability and achieve higher power density and mechanical reliability. The junction temperature of the chip may be further increased to 250 degrees, and the cooling temperature in actual customer applications is probably around 65 degrees. The junction temperature of the chip may experience temperature fluctuations above 130K. DBB increases the melting point from the ordinary solder of 220 degrees to the silver sintering of 960 degrees through silver-bonding technology, making it an excellent partner for future silicon carbide applications.

3. Mao Sijun, the General Manager of Chengxin Technology (Shanghai) Co., Ltd.

The dynamic characteristics of silicon carbide power modules are capable of high-precision testing, and we will not excerpt them here.

4. Lu Tao, the Manager of the Electric Drive Power Module Product Line in the Power Solution Division of AMS

The focus of silicon carbide inverters is mainly in the range of 150-160 kW, while below that is basically IGBT. In 2023 and 2024, the vehicles launched are basically rear-wheel drive using silicon carbide, while front-wheel drive is mainly IGBT. 120 kW or still IGBT, basically from 160 kW to 250 kW, it will switch to silicon carbide. Currently, silicon carbide can bring more than 5% efficiency improvement at 400V.

AMS is currently one of the few companies in the world that can provide the ability to develop from the substrate to the module to the system, with around three or four other companies. In terms of cost, the promotion of 6-inch substrates will continue to 8 inches. By around 2024, it should be able to enter 8 inches. The development of M1, M2, and M3 is to increase the density of the solid and the future development of some modules.

5. Ren Yadong, Deputy Director of the R&D Center of Zhuzhou CRRC Times Semiconductor Co., Ltd.

How to achieve the optimal choice of power density for high-voltage modules from the chip level and how to continuously reduce losses in the device. In terms of reliability, the trend is towards reducing the maximum power density in the trench direction, taking advantage of the characteristics of silicon carbide materials.The challenge of packaging for silicon carbide is to work at a junction temperature of 175 degrees or even higher. All material systems must meet the challenge of higher junction temperatures. If the device is to work at 175-200 degrees with a water temperature of 65 degrees, the entire power cycle will become much larger, equivalent to increasing by 20 degrees, 30 degrees, or even more, posing a significant challenge to the overall lifespan.

As for high-temperature insulation materials such as silicone, working at 175 degrees or even higher junction temperatures for a long time will cause degradation and aging, including embrittlement and discoloration. It is no longer suitable for conducting research at higher temperatures. One solution is to develop materials with higher tolerance to insulation or to use packaging schemes to solve the challenges brought by high-temperature insulation materials. Silicon carbide has a high hardness. Replacing the silicon in the chip with silicon carbide will reduce the lifespan by about half.

Improving the lifespan of the bonding wire system without aluminum, which affects chip connection and heat dissipation, can enhance our cycle lifespan. By using some direct terminal interconnections, the entire power cycle ability can be increased to 4 to 5 times on traditional technology.

Summary: Some content is quite detailed, and I have extracted some important viewpoints. I will share my opinions on Si, SiC, and GAN if there is an opportunity in the future.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.