Article by: Wu Jingtao

Intelligent and durable, the WM Motor M7 has it all!

In October last year, WM Motor launched their new mid-to-large sized sedan, the WM Motor M7, at their Shanghai headquarters.

With the laser radar placed at the center of the car roof, the design looks like a “unicorn”, which left a deep impression on me during the launch event.

For the past eight months, this “unicorn” has been hidden, practicing and improving its abilities. We haven’t heard any news about it since its launch.

Finally, on August 18th, WM Motor held the M7 performance launch and technical sharing event, unveiling what this “unicorn” has been practicing for the past eight months and providing a more detailed introduction to its intelligent features.

Laser Radar, Over 1000TOPS of Computing Power

The most anticipated feature of the WM Motor M7 since its launch has been its intelligent driving technology.

With 32 sensors, three solid-state laser radars, over 1000 TOPS of computing power, and other hardware that still leads the industry, the hardware at last year’s launch can be described as impressive.

At the technical sharing event, WM Motor provided more detailed information on the “Living Pilot 5.0 FAD Full-Scenario Intelligent Driving System” carried by the M7.

Firstly, the system comes with 32 sensors, including three solid-state laser radars that have autonomous zoom, seven high definition cameras, five millimeter wave radars, twelve ultrasound radars, four surround-view cameras, and one independent and highly accurate positioning module.

With top-of-the-line sensing hardware, their computing power naturally could not lag behind. As the first to use the Orin-X top-tier automatic driving chip, the maximum computing power of the WM Motor M7 can reach 1,016 TOPS, which is on the same level as NIO ET7 and far surpasses its competitors.

According to WM Motor, this hardware configuration belongs to the “ceiling” level of perception hardware for intelligent EVs currently available. Compared to other mainstream intelligent EVs on the market, the hardware capabilities of the WM Motor M7 are indeed unique.With such powerful hardware and computing power as support, the future of WM Motor’s M7 lies in achieving “full-scenario intelligent driving from parking lots, city roads to intercity highways”.

However, WM Motor’s own intelligent driving team lacked experience in developing advanced driver assistance systems before. Therefore, it remains uncertain whether the team can form a quick combat capability and complete the development of full-scene intelligent driving function within the planned time.

Regarding WM Motor’s current phase of intelligent driving experience, we previously conducted a “real-world test” of WM W6’s HAVP self-learning parking function. Interested friends can check the previous test video. “Let the car pick you up by itself, it did it! Testing the WM W6 HAVP self-learning parking”

Intelligent cockpit, steering wheel shifting

As a car model that emphasizes “intelligence”, in addition to intelligent driving, another major highlight of the WM Motor’s M7 is its “intelligent cockpit”.

Different from the knob shift or manual shift commonly used in electric vehicles, WM Motor’s M7 pioneered the steering wheel touch shifting design, allowing users to complete gear shifting without leaving the steering wheel, simplifying the user’s operation and making the cockpit visually cleaner.

At the conference, WM Motor stated that this feature is not for “innovation” sake but is a very practical new design that has undergone rigorous research and actual use testing.

When touching the steering wheel to shift gears, one may inevitably wonder how to avoid misoperation and how to prevent errors.

However, the official presentation did not provide a more detailed explanation of this design, so we also look forward to experiencing this design as soon as possible firsthand to see how it can ensure operational safety while being convenient.

In addition, the WM Motor’s M7 is equipped with the “outdoor voice interaction function” that can achieve voice communication and control outside the car. WM Motor claims that “before boarding, the car will greet the owner through the outdoor speaker”. The description of this feature has a slightly humorous tone.

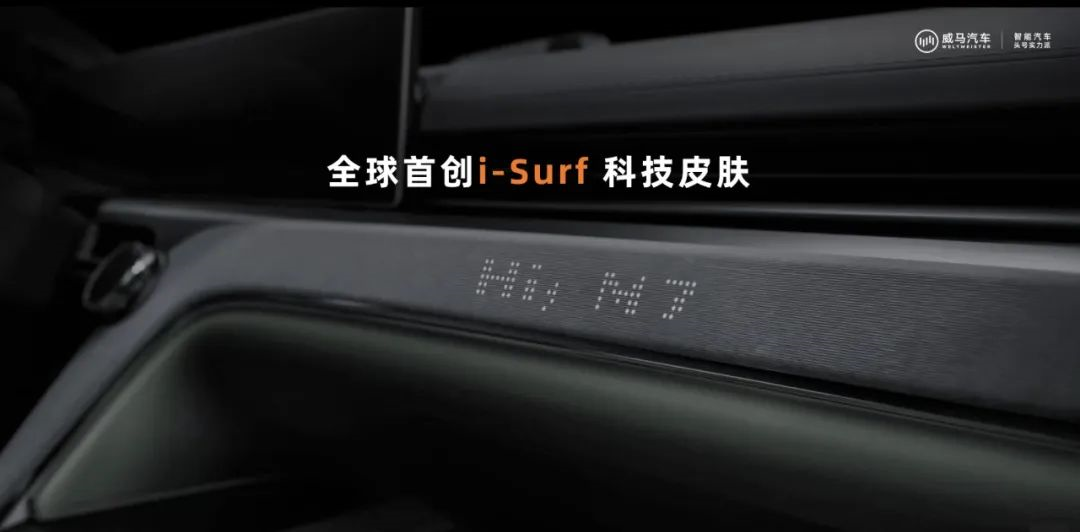

Another highlight inside the cabin is the new design of the i-Surf technology skin and i-Rota Super Dial.# i-Surf Technology Skin and i-Rota Super Dial

The i-Surf technology skin can reflect various lighting atmospheres on the center console fabric and allows users to customize the displayed content. It even provides collision alerts when detecting oncoming vehicles.

Inspired by our smartwatch dials, the i-Rota super dial can display pictures, emoticons, symbols, and other content. It also allows users to control functions with “press, pull, and twist” actions.

After briefly introducing the product highlights of the WM Motor M7, we now move on to the main event of this presentation – extreme heat testing.

Ice and Fire

At the beginning of the presentation, WM Motor compared their M7 to a Nokia feature phone and an Apple smartphone.

Nokia phones are known for their durability and reliability but lack smart features, while the iPhone revolutionized the mobile phone industry with its smart technology but is not as durable as Nokia phones.

As an electric vehicle that emphasizes “intelligence,” the M7 faces a choice between “durability” and “intelligence.” However, WM Motor chose to have both, like “having one’s cake and eating it too!”

During 8 months of “seclusion and practice,” WM Motor conducted comprehensive and rigorous cold weather testing in places like Yakutsk and Heihe using the WM Q100 ultimate verification system, claiming to be on par with a million-dollar luxury car.

Their achievements were impressive, with only 17 kWh of energy consumption per hundred kilometers at -30 degrees Celsius, a comfortable cabin temperature achieved in just 17 minutes, and achieving an SOC battery charge of 30-80% in only 30 minutes, proving the M7’s performance in harsh environments.

Since many areas across China have experienced unprecedented heatwaves this summer, concerns have arisen about electric vehicle reliability in extreme heat. Therefore, WM Motor brought the M7 to Turpan, Xinjiang, for the second round of comprehensive testing and calibration under extremely hot conditions.

Here’s a video of the M7 being tested under extreme heat conditions in Turpan:

<iframe width="560" height="315" src="https://www.youtube.com/embed/BaGJss4f4J4" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe>

“`html

According to official tests under the environment with a surface temperature of up to 60 ℃, the energy consumption of WIMI M7 per 100 kilometers is 15.6 kWh, and it takes 9.5 minutes to reduce the in-car temperature from 60℃ to 26℃, while the charging time from 30% to 80% is 38.6 minutes.

html

This energy consumption level is achieved due to WIMI M7's adoption of a new generation of powertrain system, with the efficiency of its electric drive assembly exceeding 95.3%, the endurance capability being increased by 3%, and the intelligent single-pedal mode further improving the endurance by 4%.

In addition, WIMI M7 also uses an intelligent breathing grille called AGS, which has the function of active open and close, and can autonomously set the opening size according to the vehicle state to achieve timely heat dissipation in high temperatures, and active warmth preservation in low temperatures, further enhancing energy consumption and endurance performance.

html

In response to the pain point that the overheating of the car interior in hot weather greatly affects the car owner's experience, WIMI M7's coping strategy can be summarized as "open source and throttling".

First of all, "open source" is carried out in the air conditioning system. The M7 air conditioning system is specially calibrated for extremely hot environments. At the same time, the algorithm is optimized and calibrated to control the energy consumption of the air conditioning system at 1.13 kWh per hour in high-temperature environments.

html

“`

Secondly, “throttling” is carried out in heat insulation. In response to the problem that the panoramic sunroof does not have heat insulation and affects the riding experience in summer, WIMI M7 adopts a 3-layer coated panoramic sunroof, with a UV blocking rate of 99.99% and a total energy transmittance rate of TTS ≤ 15%. At the same time, the visible light transmittance rate reaches the industry-leading level of TL ≤ 5%, achieving the effect of both heat insulation and light transmission.

At the same time, WM Motor has also optimized the charging experience for “extremely hot” environments.

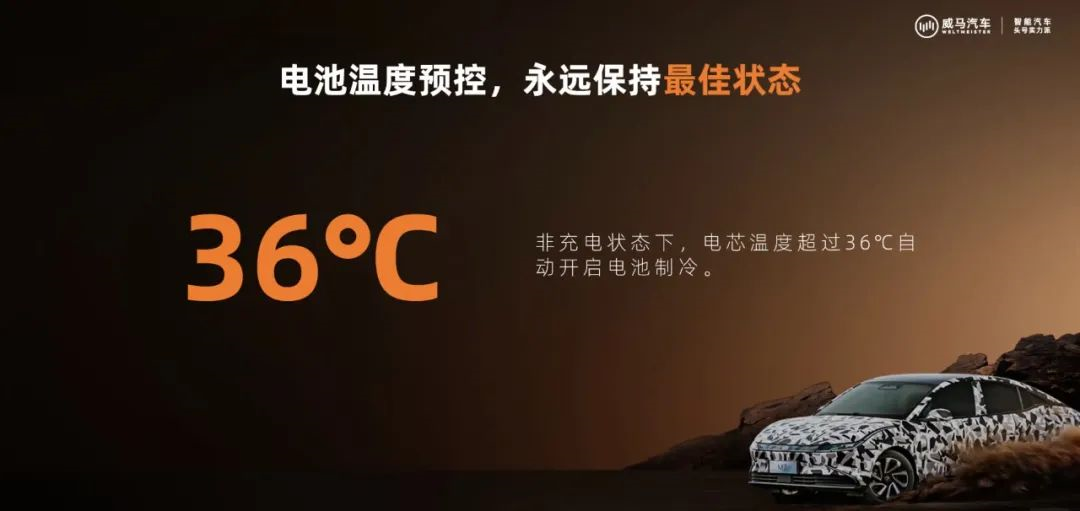

In a non-charging state, the temperature control system will use temperature pre-control to keep the battery cell temperature at 36℃ to ensure the vehicle’s power performance and prepare for charging.

During charging, the temperature control system will turn on battery cooling when the cell temperature reaches 33℃ and turn it off when it drops to 31℃, keeping the cell temperature within the optimal working range.

For battery safety in “extremely hot” environments, the WM Motor M7 uses the BMS3.0 management system, which can monitor individual modules and accurately determine the battery status. It can also provide an early warning 5 minutes in advance for battery thermal runaway to ensure the safety of personnel and vehicles.

Admittedly, these extreme climate conditions are not the normal driving conditions for ordinary users. Therefore, test results under “extremely hot” environments may not be sensitive to regular users.

But for a brand, it is worth recognizing that it is willing to spend a lot of cost and time on such testing. It also reflects the confidence of WM Motor in its own technology and the M7 product.

If WM Motor can present these technologies and results in mass-produced models and improve the actual driving experience for users in the winter and summer seasons, it is believed that it will help change consumers’ perception of electric vehicles being “fragile” to cold and heat.

In conclusion

Recently, there has been news that WM Motor’s M7 is expected to be launched in the fourth quarter of this year.

To create a good product, in addition to having the courage to face difficulties and challenges while maintaining excellence, one also needs to have a good understanding of the market trends and opportunities.

From being listed in the first tier of new carmakers and “the three heroes of WM,” to now needing to catch up, the WM brand has been silent for a relatively long time.

Therefore, the importance of the M7 model to the current WM brand is self-evident. WM Motor has high expectations for M7, hoping it can help improve the brand image, further increase attention and sales.

However, in the current market for new energy vehicles, the segment where WM Motor’s M7 is located has seen many strong models. Facing these competitors with excellent product quality and higher brand awareness, the “highlights” of M7 at its launch have become increasingly dim with the passage of time.

However, in the current market for new energy vehicles, the segment where WM Motor’s M7 is located has seen many strong models. Facing these competitors with excellent product quality and higher brand awareness, the “highlights” of M7 at its launch have become increasingly dim with the passage of time.

How to accelerate the pace of M7’s entry into the market is a key issue that WM Motor urgently needs to address.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.