Author | Lingfang Wang, Hui Tian

Editor | Kaijun Qiu

“The entire series comes standard with 8155 chips!”

“Free upgrade to 8155!”

Following CATL’s battery cells, Qualcomm’s 8155 chip has become the new highlight of vehicle promotion. It seems that without 8155, smart cockpits cannot be discussed.

Currently, major players in the industry, including NIO, XPeng, Li Auto, Neta, Weltmeister, Leapmotor, and traditional automakers, such as Great Wall, Geely, SAIC, GAC, Voyah, and Changan, have adopted Qualcomm’s vehicle-grade chip-SA 8155P.

There are precedents for not using 8155 chips, and Great Wall and ECAR have suffered from it. The reason is that 8155 is currently the best performing production-grade vehicle system chip.

However, not using the Qualcomm 8155 chip does not hinder sales success.

Tesla and BYD, the world’s top two new energy vehicle manufacturers, do not use 8155 chips. Tesla uses AMD’s x86 chip and BYD uses Qualcomm Snapdragon chips. Despite not using dedicated vehicle-grade chips, they have achieved enormous sales with few problems.

So, are the 8155 chip and vehicle-grade chips necessary?

Although the performance of the Qualcomm 8155 chip is outstanding among ARM instruction set vehicle system chips, it lags behind other chips in the consumer electronics field.

Built on 7nm technology, with 8 computing cores, and a maximum frequency of 2.84GHz, the Qualcomm 8155 chip boasts a CPU computing power of 105K DIMPS and a GPU computing power of 1142 GFLOPS, twice and four times the performance of the previous 820A processor. In addition, the 8155 chip has a new NPU neural network computing unit, capable of producing up to 8TOPS of AI computing power.

Functionally, it supports up to 6 cameras, can connect to 4 2K screens or 3 4K screens, and supports WiFi6, 5G, and Bluetooth 5.0.

This means that automakers can place more screens in the car, install more cameras, and deliver faster internet speeds.

However, while the Qualcomm 8155 is the “ceiling” of production-grade vehicle system chips, it is only an entry-level chip in the field of consumer electronics.

The 8155 chip is a “modified” version of the Snapdragon 855 chip, which was developed for the smartphone market four years ago. For automotive use cases, Qualcomm reduced the frequency of the CPU, increased the frequency of the GPU and NPU, and further strengthened the processing power of video, images, and other data.

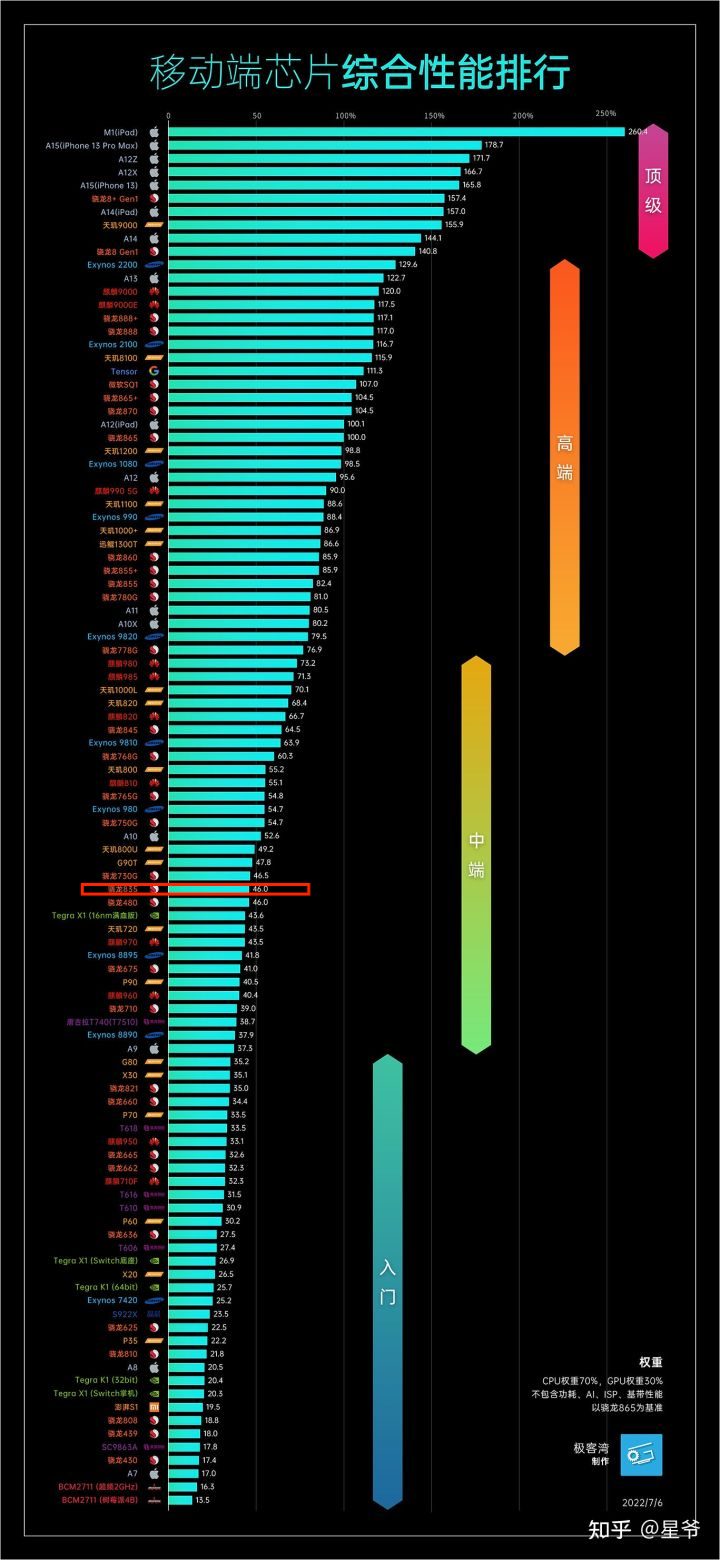

According to the latest CPU performance ladder for phones in August 2021, the Snapdragon 855 chip could only rank in the middle of the field.

And the gap with AMD Ryzen carried by Tesla is also quite large.

Tesla uses non-automotive-grade chips, and AMD Ryzen’s overall performance is far ahead of Qualcomm’s 8155. This chip comes from the desktop-level chip, which is the chip used in desktops, servers, or workstations. It adopts the AMD Zen+ architecture design, 12nm process technology, and the CPU uses 4 cores and 8 threads, while the GPU also has independent 8GB memory.

According to the official statement, the CPU performance of this chip is twice that of 8155, and the GPU is 1.5 times that of 8155.

As can be seen from the chip performance, the Qualcomm 8155 is not the best.

Since Qualcomm 8155 is not the fastest and latest computing chip, why do automakers choose it?

The reason is–automotive-grade.

Automotive-grade chips are more reliable, but not necessary

Automotive-grade chips usually refer to chips certified by AEC-Q testing and are the industry standard in the automotive industry.

By passing the AEC-Q test and certification, it is like obtaining a “university diploma”, which is the threshold for general parts suppliers to enter the automotive industry. However, AEC-Q is not a mandatory certification, and automakers choose whether to use it or not.

For example, Tesla and BYD do not have strict requirements on AEC-Q testing.

However, as a basic threshold, we can feel the importance of this standard during the communication with suppliers.

Chipsee Technology and Jiefa Technology, both engaged in chip research and development, attach great importance to this standard. Especially Chipsee Technology incorporates functional safety. Wei Bin, the functional safety manager of Chipsee Technology, believes that considering AEC-Q100 and ISO 26262 together is the most rigorous approach.

Wei Bin said that as the reliability testing standard, AEC-Q100 is the most basic requirement for placing chips on a car. The level of functional safety must be determined by combining the application scenario and exporting the safety goals through HARA analysis (hazard analysis and risk assessment), and then obtaining the ASIL level.

“For the cockpit, the general requirement is ASIL B, because one of the most important functions of the cockpit chip is instrument display, which collects alarm information from various systems in the car and is directly related to human life safety,” Wei Bin said, “If the phone crashes and restarts, it is not a big problem, but if the car instrument suddenly goes blank on the highway, the impact is huge.”

Li Qinglu, the product marketing director of Jiefa Technology, holds a similar view. He believes that AEC-Q100 is the universal test standard for recognized automotive parts, and passing AEC-Q100 is the only way to enter the automotive field. The chips designed and developed by Jiefa Technology meet AEC-Q100 certification.

Since reliability and safety are at stake, this set of automotive standard regulations covers a wide range of tests. Li Qinglu told “Electric Vehicle Observer” that it includes reliability testing of wafers, electrical characteristic testing, packaging defect testing, etc. There are a total of 7 categories and more than 40 testing standards.

However, in the view of Mr. Zhang, the technical director of a smart network-connected car head supplier, AEC-Q100 testing is a relatively low standard, which can basically be considered as a passing score of 60. The testing standards of large car companies themselves are far higher than the industry standard.

Since car companies have their own standards and industry standards are not mandatory, it is not uncommon for car companies to bypass them.

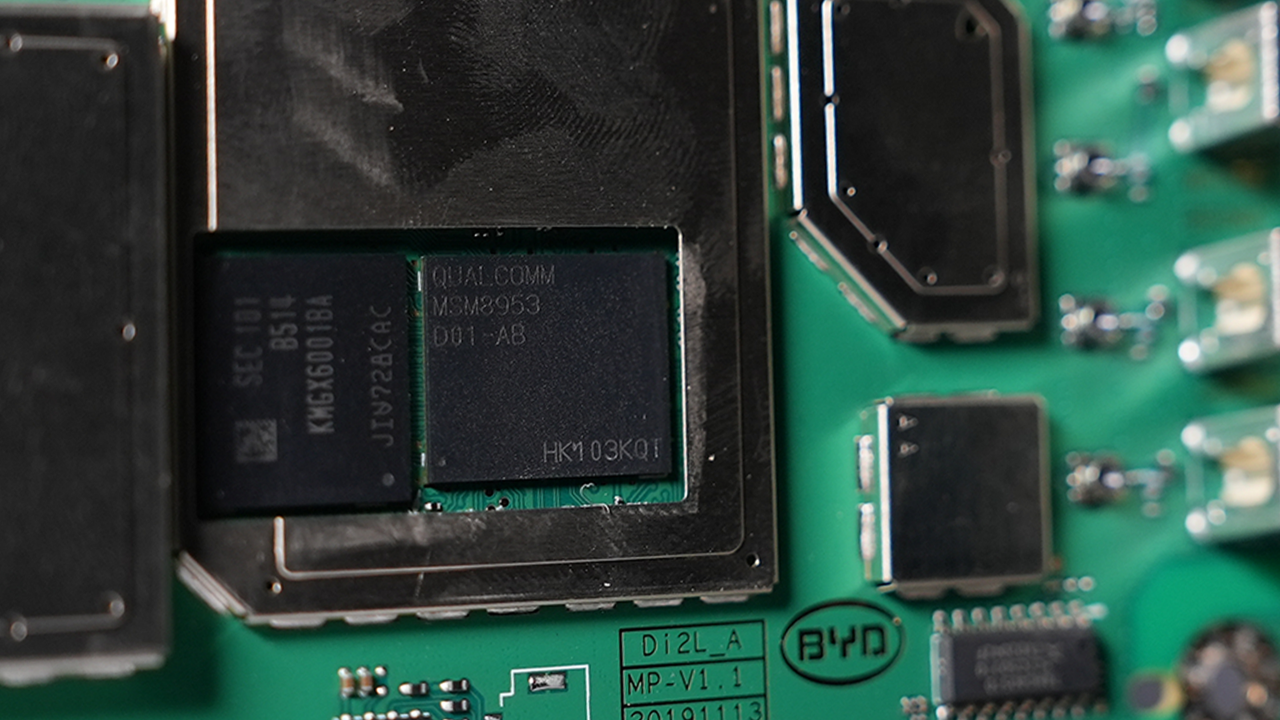

Seeing is believing. In order to verify the chip used in the BYD car machine, “Electric Vehicle Observer” specifically purchased the original car machine controller for BYD Tang DM2021 for disassembly and discovered that it does indeed use the Qualcomm Snapdragon 625, a consumer-grade chip.

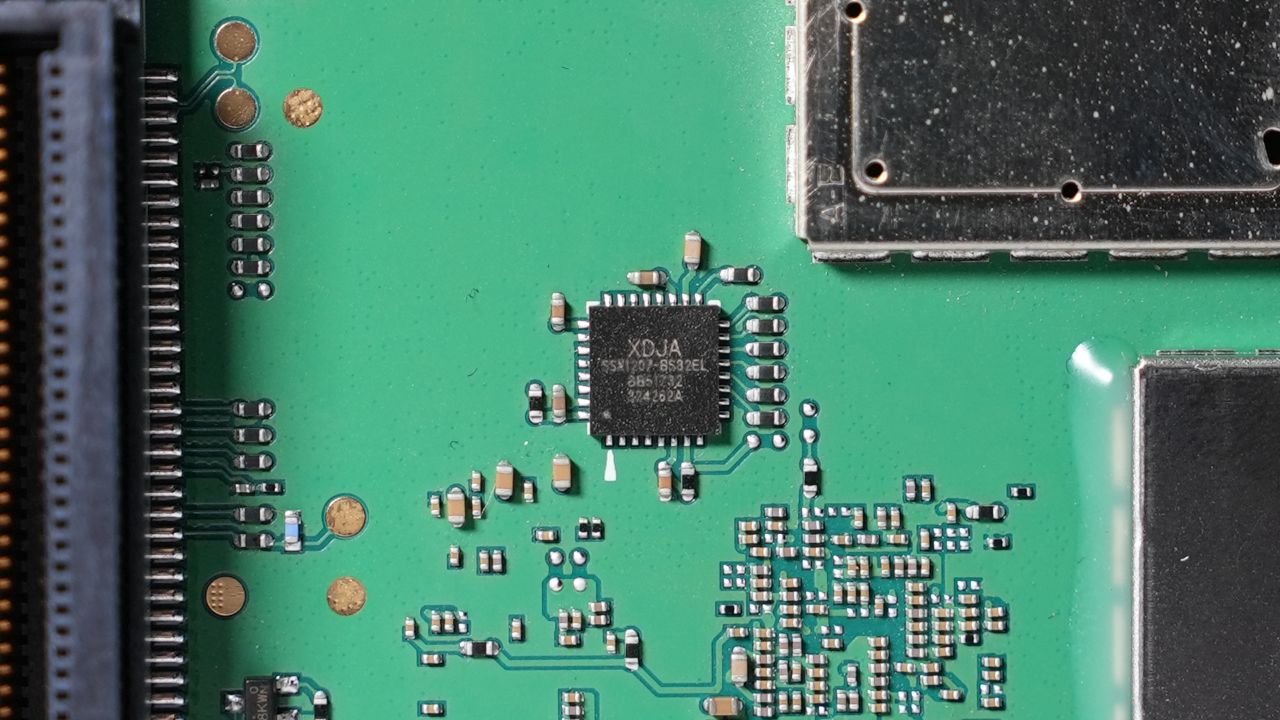

Although BYD’s car machine main computing chip is a consumer-grade chip, BYD has separately deployed a security chip for the car machine system to ensure its functionality and safety.

According to “Electric Vehicle Observer” researching the manufacturer’s website of this security chip, the function of the chip is to ensure the functional safety of the car machine system, which is used to ensure the safety of intelligent network-connected vehicles for remote control and intelligent driving.

This indicates that even if a consumer-grade chip is used as the main computing chip, there are ways to provide higher-level security protection for the entire car machine system from a system-level perspective.

In Mr. Zhang’s view, it is indeed possible to make up for certain deficiencies at the system level, such as strengthening the protection of hot and cold environments through heat dissipation design and special process design for components, which can also improve the system’s reliability, stability, and durability.

Using consumer-grade chips in car machine systems ultimately depends on the probability of the entire car machine system malfunctioning. If the failure rate of car machine systems using consumer-grade chips can be reduced to the same level as car-standard grade chip systems, then the impact is not significant. Even if there are problems, such as navigation cannot be used or the display screen freezes, it will not directly affect driving safety.

It can be seen that car-standard grade car machine main computing chips are a more reliable choice, but they are not necessarily a necessary choice. The reason why various car companies promote the 8155 chip is mostly due to commercial considerations, with implications of mutual promotion with Qualcomm.

The reason why some car companies do not use car-standard grade car machine main computing chips may be directly related to testing time and cost.Li Qinglu told “Electric Vehicle Observer” that chips need to pass the vehicle-level test, and the time and cost are indeed high. The fastest and most smooth also takes 3 months, and it is common to exceed one year.

The raw materials, IP and packaging testing of vehicle-level chips are relatively more expensive than consumer-grade chips. Wei Bin gave an example of packaging testing. Due to the unique three-temperature limit scenario testing of vehicle-level rules, the cost of testing alone is about 5 times that of consumer-grade chips.

The requirements for safety, reliability, and long-term effectiveness of vehicle-level chips are much higher than those of consumer-grade chips. Wei Bin said that the two environments of high temperature and low temperature are extremely harsh, and more considerations need to be made in design than consumer electronics. In addition, to achieve functional safety requirements, various safety mechanisms will be considered in chip design, which will increase the chip area and thus increase the explicit cost of the chip. In addition, there are hidden costs brought by functional safety personnel training, process construction, and product certification.

Li Qinglu also gave two examples, for example, in the simulation of 85-degree ambient temperature, if you want to ensure that the chip works normally, you need to use more expensive or better heat-dissipating materials, and the cost will increase. In the case of simulating aging testing, vehicle-level simulation aging usually takes 10-15 years.

From some data, it is normal for the cost of vehicle-level chips to be 20%-30% higher than that of consumer-grade chips. Of course, this is closely related to the demand of enterprises.

Putting Server Chips on Cars May Be a New Trend

The disadvantage of automotive-grade chips is that their iteration speed is too slow.

Currently, in the field of intelligent cockpits, various car companies are still competing for large screens and UI interactions, and they have not widely entered higher-level AR guard or 3D three-dimensional interaction stages. However, this is definitely the future development direction. NIO and Ideal’s new cars ET7 and L9 to be launched in 2022 have already carried related functions.

NIO ET7 will support AR experience interaction, and its core is a camera sensor. Ideal L9 is equipped with a 3D ToF sensor to sense human motion posture.

The more sensors, the greater the demand for computing power. Therefore, NIO directly uses the Nvidia Orin chip for AR functions; Ideal deploys 2 high-performance Qualcomm 8155 car chips on the L9. Both are to meet the computing power requirements of intelligent cockpit software.

As the computing power requirements of intelligent cockpit software surge, more car companies are beginning to consider using higher computing power chips in the field of intelligent cockpits.

On August 5th, AMD announced a cooperation with the intelligent car industry company ECARX Yikatong Technology, and the latter will use AMD Ryzen series processors and RX 6000 graphics cards to create a digital cockpit.

The difference between AMD and Qualcomm lies in the difference in chip core architecture.

Qualcomm uses ARM architecture, mainly in the field of mobile phone chipsets, while Intel and AMD’s x86 architecture are mainly used in the PC field.## Translation Below (Markdown Format)

x86 architecture CPUs have a high demand for computing power, therefore they are super strong, with a relatively high core frequency, and have a high requirement for heat dissipation.

In comparison, CPUs under ARM architecture are not so powerful in performance, with a relatively low core frequency, but have the advantage of being small in size, just 1% of CPUs under x86 architecture. They can also be combined with GPUs to become an SoC and used in mobile phones.

Mr. Zhang believes that, with the continuous improvement of vehicle intelligence, the main chip from the consumer electronics sector may no longer be able to support the development of vehicle intelligence.

Tesla uses AMD because of its strong server capabilities. Cars have surpassed mobile phones as the best carrier for intelligence. Their consumption of computing power and electricity will be higher. Because there is space in the car, large batteries, especially for electric vehicles, there is a demand for this computing power. Therefore, in the future, the chip for car intelligence will be from servers, not from mobile phones.

The Trend of Vehicle Compliance

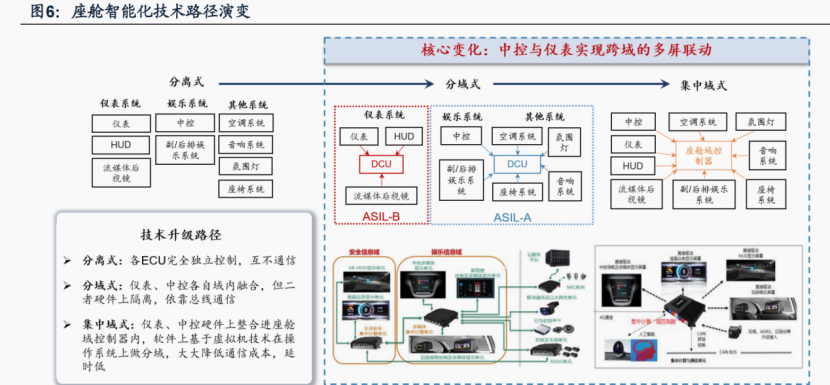

Looking back at the evolution of car cabins, we can see a trend in which functions have moved from being decentralized to being centralized, and controls have moved from being independent to being integrated.

In the last century, Bosch joined Intel in developing the CAN bus system for in-car ECU data communication. Since then, the types of in-car embedded electronic products have gradually increased and in-car operating systems have been widely used.

In 2001, BMW introduced a central display, marking the official entry of LCD screens into car cabins. In 2018, Visteon launched the SmartCore intelligent cabin system at CES, marking the start of mainstream domain control solutions entering the market. From 2020 onwards, intelligent cabin solutions have gradually come onto the market, with automakers, suppliers, and technology internet companies entering the intelligent cabin field one after another.

In terms of product forms, the central control and instrument panel have been integrated to achieve multi-screen linkage, while the application ecology of mobile phones has gradually been transplanted to the cabin.

At the technical level, software is moving towards soft and hardware decoupling. The various electronic control units (ECUs) are moving from traditional separate units to domain-centralized units and then to centrally centralized units across domains.

With the trend of cross-domain integration, there is a trend in the driving domain of gradually integrating the cabin domain, the body domain, and other functional domains. The CCU, a full-vehicle computing platform dominated by the driving domain controller, may be realized in the near future.

When the entertainment system is integrated with the intelligent driving system that is closely related to safety, the security and reliability requirements of the main control chip will further increase. Chips that meet vehicle compliance levels and functional safety standards will become a necessity.The reason is simple: when multiple functions are integrated into one device, the main control chip must meet the strictest automotive-grade standards. This is why AEC-Q100 and ASIL-D certifications have become standard requirements. Therefore, even less demanding components can achieve automotive-grade safety as long as the electronic architecture of intelligent vehicles continues to develop towards centralization.

Currently, automotive-grade chips may only seem attractive for entertainment purposes, as they may not be required for safety. However, in the long run, as cross-domain integration develops, automotive-grade chips will become necessary for intelligent cockpit chips that involve safety, ADAS and other functions as they have lower failure rates and higher safety levels.

Qualcomm 8155 is currently recognized by consumers as the best choice for intelligent cockpit main chips, but the competition in terms of computing power and automotive-grade standards is just beginning. Whoever can achieve both objectives will gain a competitive advantage in the next stage of the competition.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.