Author | Pan Jiang

Under the dual motivation of electrification and intelligence in the automotive industry, the maturity and penetration rate of Brake-By-Wire (BBW) technology is accelerating, and the industry is expected to see explosive growth.

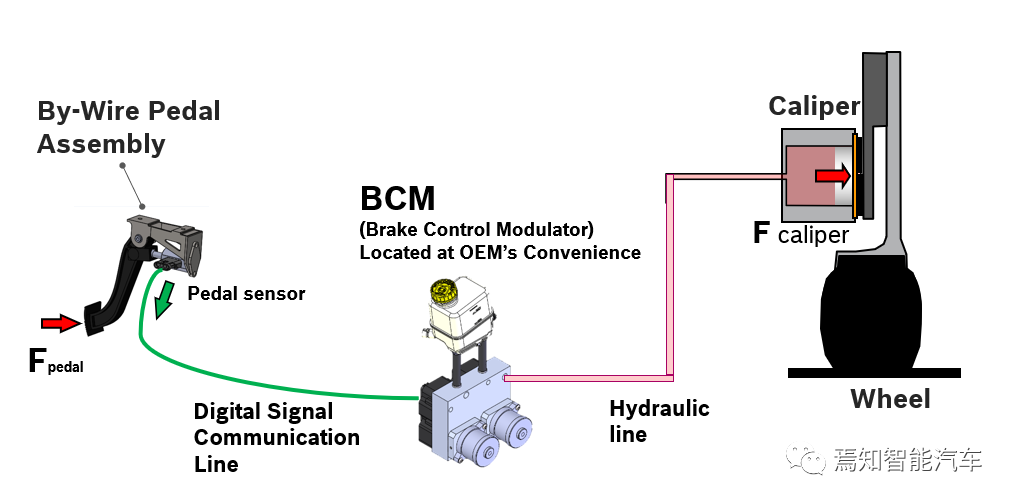

As an electronically controlled braking system, the main feature of BBW is the elimination of the mechanical connection between the brake pedal and the brake actuator. Instead, the system uses a pedal sensor to collect the driver’s braking intention, or receives a brake request from the intelligent driving controller through the vehicle communication network. The electronic signal is then processed by the Brake Control Unit (BCU), which controls the brake actuator output and achieves the desired braking force.

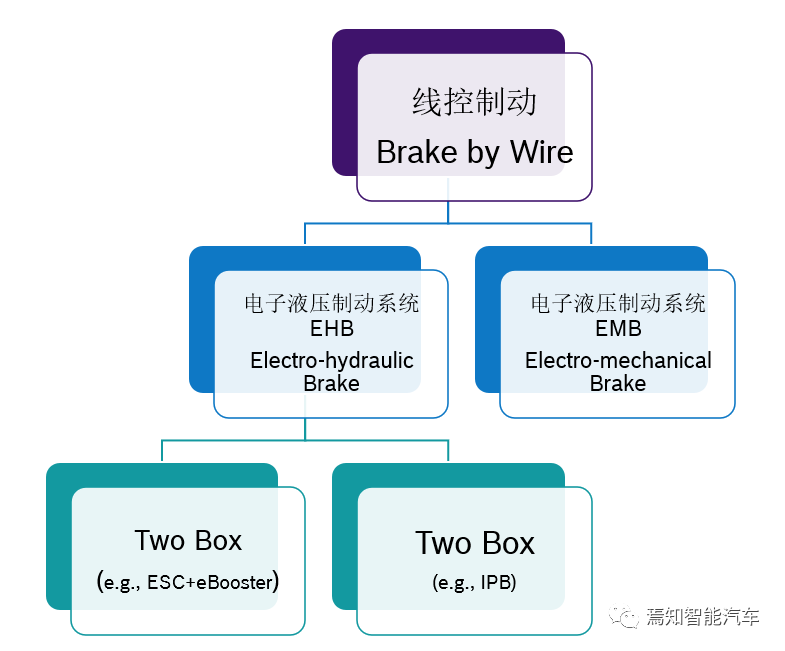

Depending on the brake actuator, BBW can be divided into Electro-Hydraulic Brake (EHB) and Electro-Mechanical Brake (EMB). EHB is based on the traditional hydraulic brake system, and replaces some mechanical components with electronic devices. It uses brake fluid as the power transmission medium and has a hydraulic backup brake system. It is currently the mainstream technical solution for BBW. Moreover, EHB can be further divided into Two-box and One-box solutions based on the level of integration. On the other hand, EMB generates the required braking force by controlling the motor on each wheel end, and achieves stability functions such as ABS through motor control. However, it lacks a hydraulic backup brake system, which poses regulatory obstacles on its way to mass production.

This article will introduce BBW from the following two aspects. In the subsequent articles, we will further explore the characteristics of various types of BBW systems based on this introduction.

- Introduction to BBW types

- Analysis of BBW market

EHB and EMB

EHB (Electro-Hydraulic Brake)

Electro-Hydraulic Brake (EHB) is currently the mainstream BBW solution in the market. Mainstream BBW products such as eBooster and IPB are all examples of EHB.

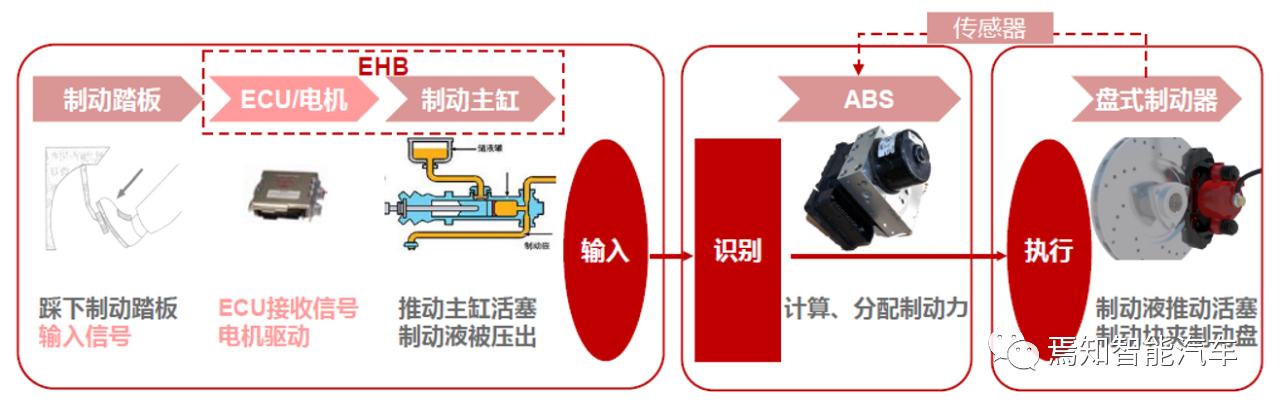

Compared with the traditional braking system, the “BBW” part of EHB mainly lies in the fact that the connection between the driver’s pedal and the braking system’s electronic control unit at the connection point has transitioned from mechanical connection to signal connection. However, the brake actuator unit still retains the hydraulic system.Telecommunication signals are manifested in different scenarios. For driver braking, the electrical signal is mainly the pedal sensor signal that can determine the driver’s braking intention, while for intelligent driving functions such as Adaptive Cruise Control (ACC) and Automatic Emergency Brake (AEB), the electrical signal corresponds to the braking request signal sent by upper-level ECU through communication network.

Compared with traditional braking systems, EHB has the following advantages:

- It cancels the vacuum booster, and the braking force output is not affected by vacuum degree (such as high-altitude areas);

- The pedal feeling can be adjustable, and the host manufacturer can customize the pedal feeling;

- The pressure building response is rapid and accurate, and it is highly adaptable to ACC/AEB working conditions;

- It supports energy recovery function for new energy vehicles.

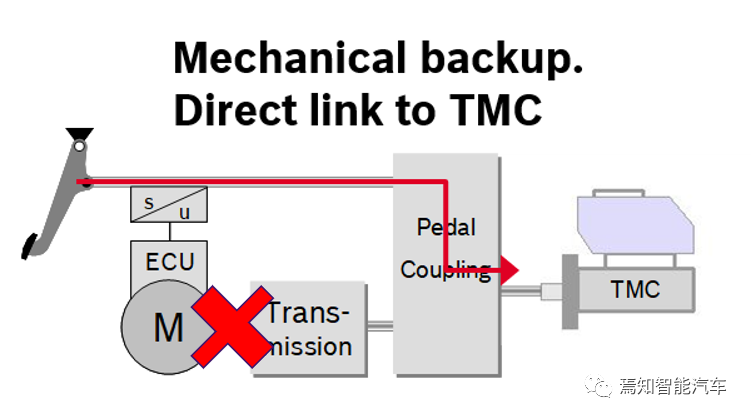

In terms of regulations, according to the requirements of European Economic Commission standard ECE-R13H and national standard GB13594, passenger cars must ensure that in the case of electronic power failure, mechanical components can still generate a deceleration of 2.44 m/s² when the driver uses a 500Nm braking pedal. To meet this regulation, the current mainstream EHB systems eBooster and IPB both retain hydraulic backup. In the braking backup mode, the driver pedal and hydraulic pipeline are mechanically connected to ensure that when the braking electronic control unit fails and the power assistance function is lost, the driver can still push the hydraulic backup system to pressurize the wheel cylinder and achieve emergency braking of the entire vehicle.

However, it is precisely because of the existence of mechanical connections in the braking backup mode that the layout of eBooster and IPB on the vehicle is limited. From this perspective, neither eBooster nor IPB is the optimal solution for EHB. Currently, mainstream braking system suppliers are developing a new generation of EHB systems, which completely eliminates all mechanical connections between the braking pedal and electronic control unit. This solution not only retains the above-mentioned EHB advantages but also significantly improves the flexibility of the braking system layout on the entire vehicle. Meanwhile, the smaller size of the braking pedal provides the possibility of optimizing the space in the driver’s cabin.The first consideration in the development of the new generation of EHB is how to meet the corresponding regulatory requirements, which is also the current research hotspot. This solution is at least two years away from mass production.

EMB (Electro-Mechanical Brake)

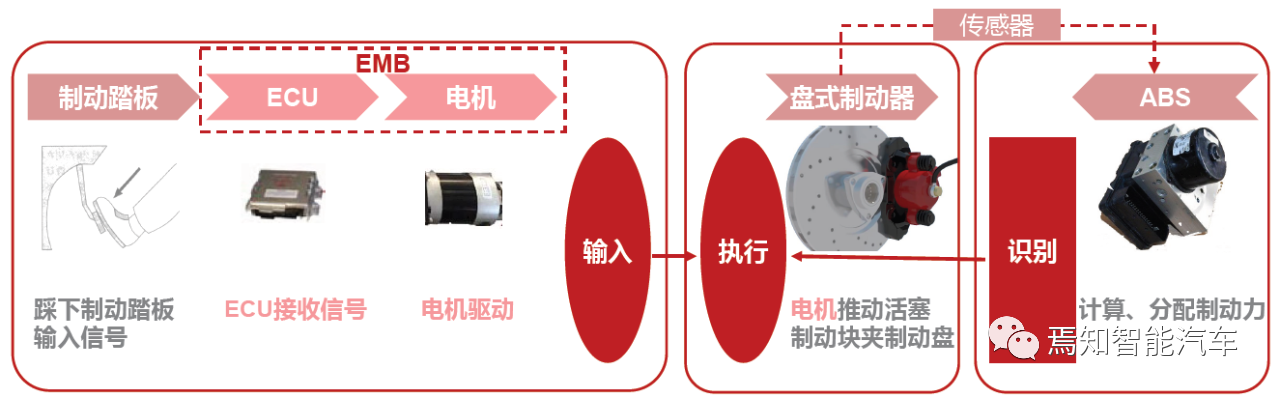

Compared with EHB, EMB uses four wheel-end calipers driven by motors to replace the master cylinder hydraulic system, achieving “fully electronic control”. Due to the significant differences in the brake execution unit, the industry refers to EHB as “wet” electronic control brake and EMB as “dry” electronic control.

While retaining the advantages of the EHB system, the EMB system further releases the layout freedom of brake system components. Meanwhile, the four wheel-end motors and calipers have replaced the relatively complicated hydraulic system, simplifying the process and cost of vehicle assembly and later maintenance.

However, although the EMB technology has many advantages compared to the hydraulic electronic control technology of EHB, the high degree of electronic control also poses higher requirements for the reliability of EMB. EMB still faces many technical difficulties to overcome, such as:

- Pure data signal transmission, how to achieve redundant backup to meet regulatory requirements when a vehicle network failure occurs

- The motor/control unit is on the wheel side, generating high temperatures during braking, and the key parts need to withstand high temperatures and have high heat dissipation requirements

- Wheel-side braking motors require large power and therefore need 48V or higher voltage for driving

- Effective cost reduction is needed to popularize it, requiring control chips and a large number of sensors support

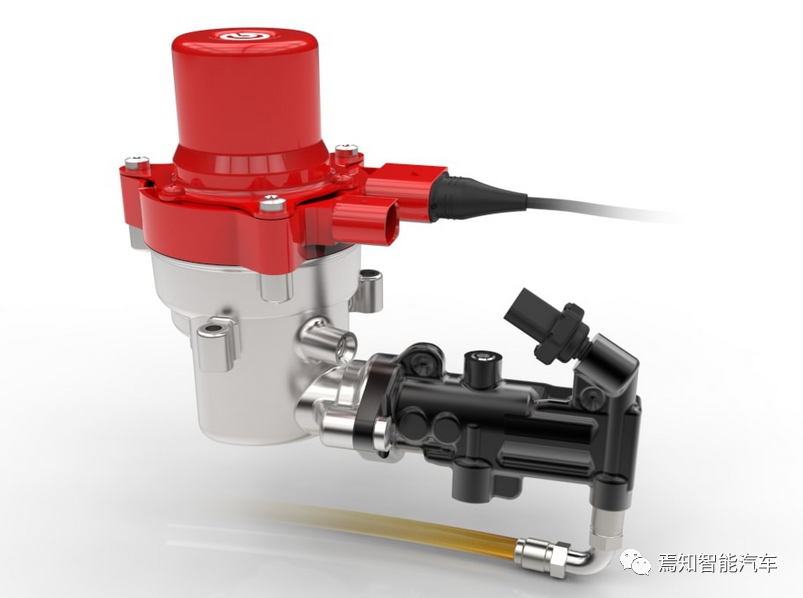

EMB will not be in mass production until these difficulties are overcome. Currently, various companies are in the pre-research stage, and there are also some differences in the scheme. Taking Brembo’s EMB system as an example, its highlight is that the four-wheel motors are not controlled directly by electronic signals. Two front-wheel motors are still driven by small electro-hydraulic execution units to tighten and release the calipers, while the two rear-wheel motors are consistent with the current EPB system, directly controlling the motor to tighten and release the calipers with electronic signals.

From another perspective, as a disruptor and revolutionary in traditional hydraulic brakes, EMB is likely to promote the update of brake-related regulations before it is truly mass-produced, which industry insiders can look forward to.

Two-box and One-box

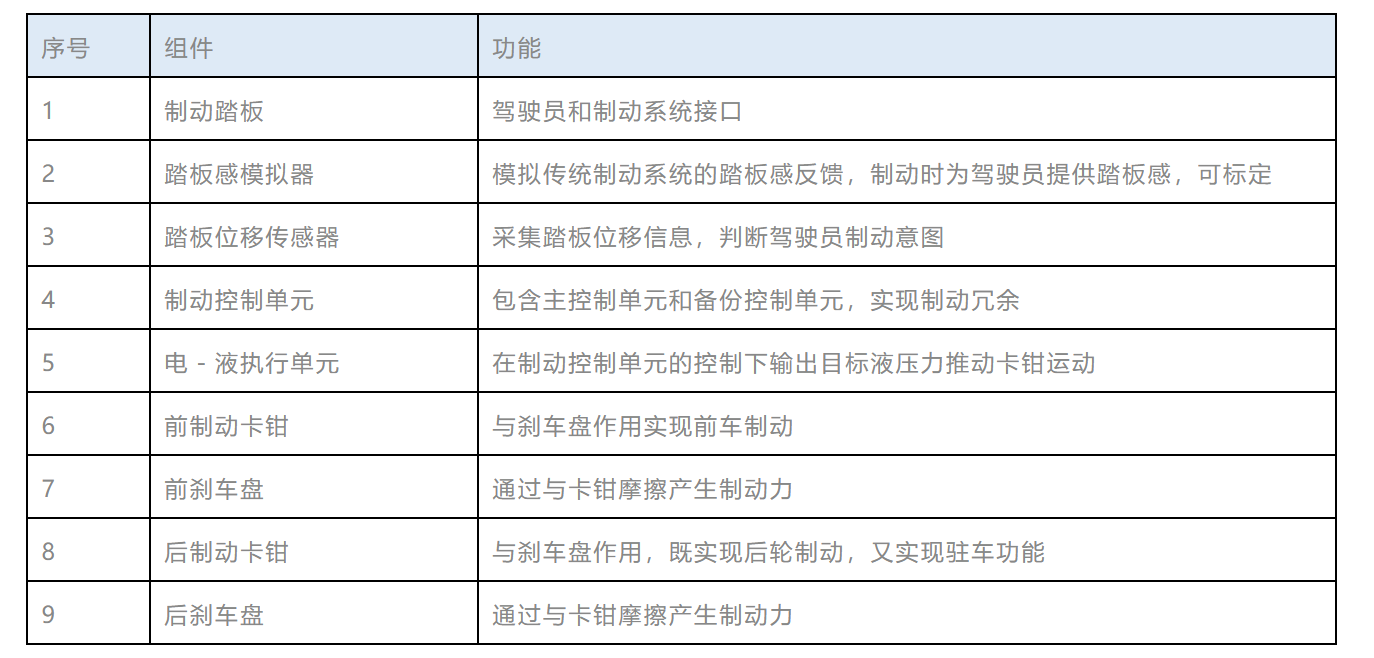

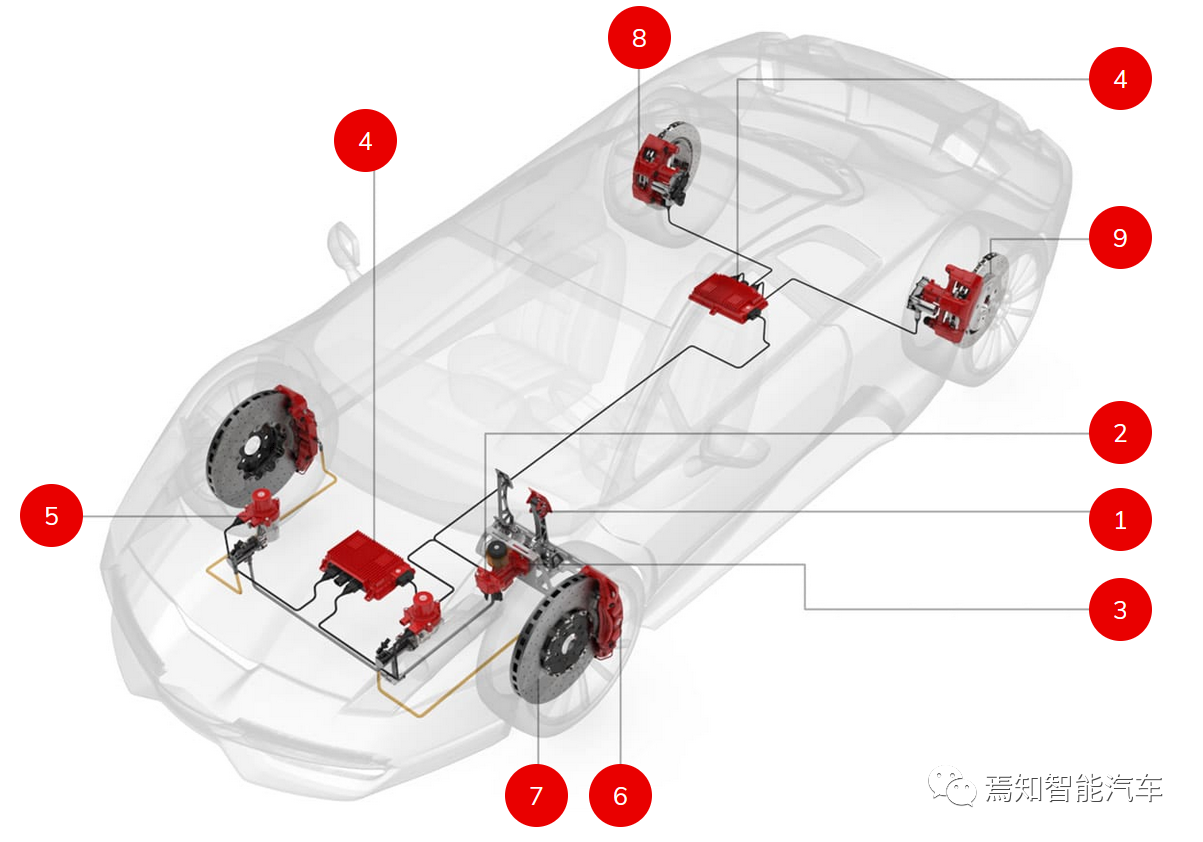

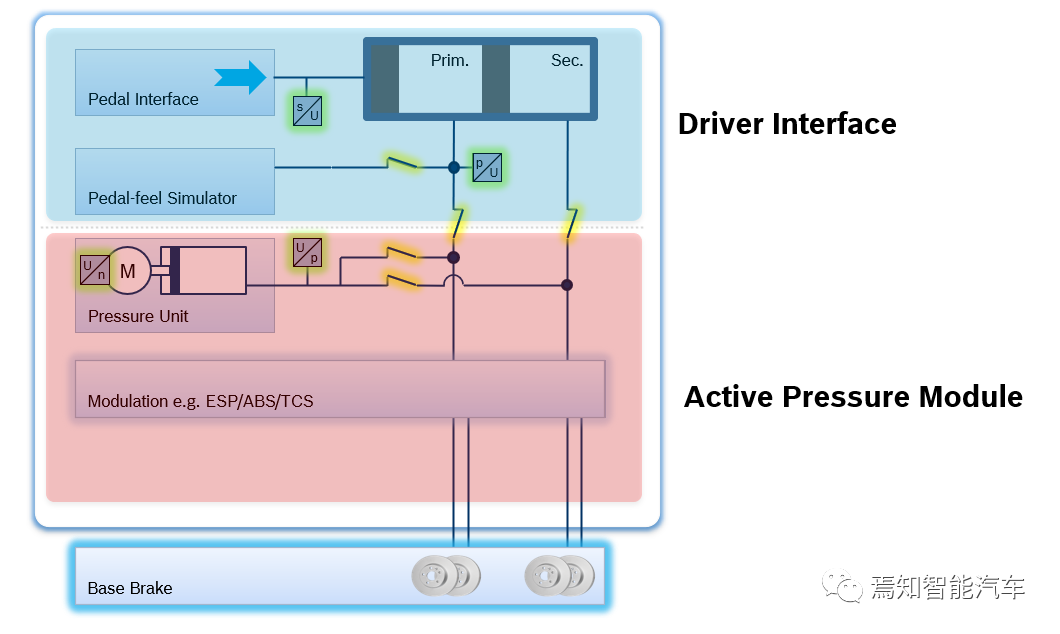

EHB systems are divided into One-box and Two-box solutions based on whether they are integrated with stability control functions ABS/VDC.

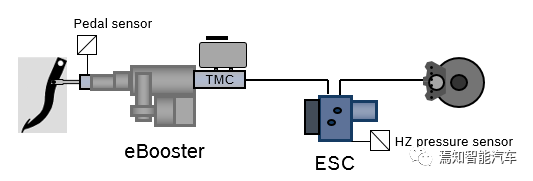

The mainstream Two-box solution currently is the combination of “eBooster+ ESC”, which realizes basic braking function and stability function separately. ESC and eBooster share a set of hydraulic systems on the vehicle and work in coordination, as follows:

- eBooster and ESC share a set of brake oil tanks, brake master cylinders, and brake pipelines.

- The electric motor inside the eBooster generates driving force to push the master cylinder piston, making the brake fluid in the oil tank flow into the master cylinder pipeline and enter the ESC inlet valve. Then, the brake fluid flows into the four wheel cylinders through the regulating valve and inlet valve in the ESC, thus establishing brake force.

- When eBooster is not working, ESC can also independently control the brake fluid to flow from the master cylinder to the wheel cylinder, thus establishing brake force.

- eBooster has a faster dynamic response speed than ESC in pressurization, and its NVH performance is better. Therefore, eBooster is the main executive mechanism in the brake control system.

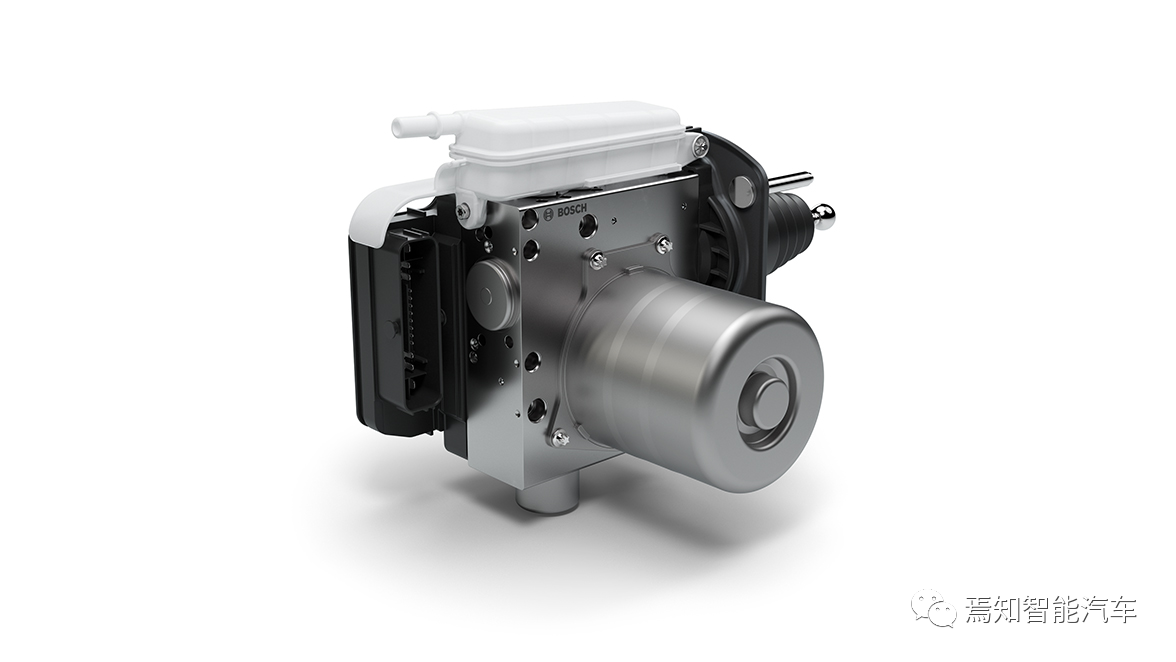

To further reduce costs, the “One-box” solution, which integrates basic braking function and stability function in one body, has begun to be favored by automakers.

One advantage of the “One-box” solution over eBooster is that it decouples the pedal. The driver’s pedal force does not act on the master cylinder. The pedal feeling is achieved by the simulator, while the brake force is achieved by the servo motor, and therefore there is greater freedom in adjusting the pedal feeling.

For autonomous driving systems, there is a demand for braking redundancy in the braking system, which means that the backup braking system needs to ensure the vehicle can still enter a safe state (such as stopping by the roadside) when a single fault occurs in the main braking system. The Two-box solution can meet the braking redundancy requirements for autonomous driving. The One-box solution requires an additional independent brake unit RBU (Redundant Brake Unit) to be added to form the Two-box solution that supports braking redundancy.

Market Analysis of Wire-Controlled Brakes

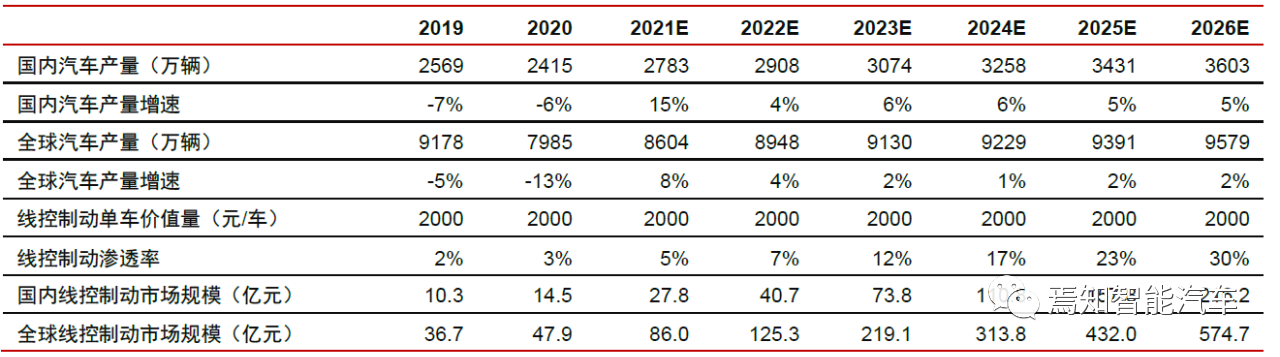

In terms of market size, the wire-controlled brake market is steadily increasing. According to Citic Securities’ forecast, with the demand replenishment after the gradual end of the global epidemic, the global automobile production is expected to increase by 8% and 4% year-on-year in 2021-2022, and the global automobile market production is expected to increase by 1%-2% year-on-year in 2023-2026. With the development of intelligent automobiles, the penetration rate of wire-controlled brakes will rapidly increase, reaching 30% in 2026. Based on the current market performance of wire-controlled brakes, with a value of around 2000 RMB per vehicle, the domestic and global markets for wire-controlled brakes are expected to reach 21.6 billion RMB and 57.5 billion RMB respectively by 2026, with enormous potential.

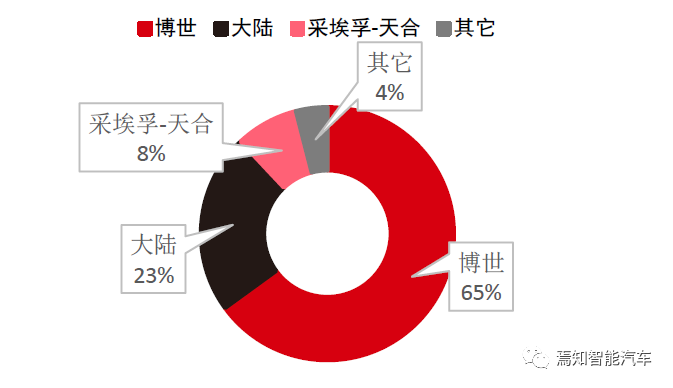

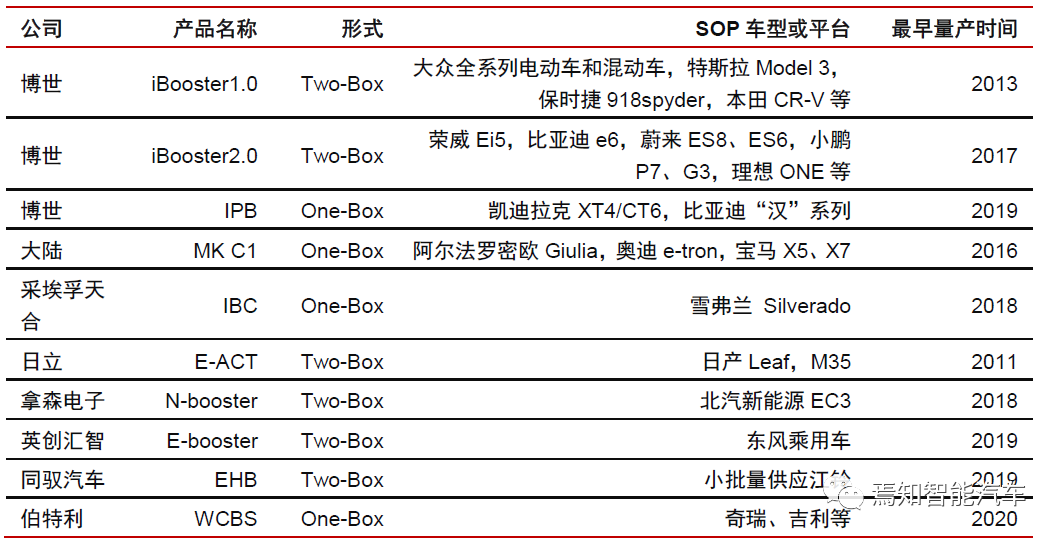

On the other hand, the wire-controlled brake market is still dominated by foreign suppliers. The world’s major wire-controlled brake system suppliers are Bosch, Continental, ZF, and Akebono. Among them, Bosch was the first to independently develop and lay out wire-controlled brakes, occupying a leading market position. Its main products are the iBooster+ESP of the Two-Box technology route and the IPB of the One-Box technology route, among which the iBooster+ESP product was launched earliest and is currently the most widely used, and the IPB product was the first to match with the BYD Han in China. Continental’s MK C1 wire-controlled brake product has a complex manufacturing process, and its mass production progress is relatively lagging. At present, it mainly targets the European market and gradually began to target the Chinese market at the end of 2020. Akebono acquired the wire-controlled brake technology for passenger cars and commercial vehicles through mergers and acquisitions of Nissin Kogyo and Webco, and its passenger car wire-controlled brake product IBC began mass production at the end of 2018, and its commercial vehicle wire-controlled brake product EBS was launched in 2012.

Surprisingly, there are many domestic players participating in the wire-controlled brake market, including Bertelli, Top Group, Nason Electronics, etc. Among them, Bertelli, a leading supplier, has been deeply cultivating the brake field for many years, with strong product capabilities. For example, its One-Box style product, WCBS, performs excellently in key product performance parameters such as lightweight level, braking pressure speed, and braking energy recovery efficiency. In addition, Bertelli has deep technical accumulation in ABS, ESP, and EPB fields, as well as rich data accumulation and supporting experience. It is currently the only domestic manufacturer that can mass-produce One-Box style wire-controlled brake products, and is expected to stand out from domestic suppliers with its first-mover advantage.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.