Recently, a friend who owns a Model 3 complained to me that they couldn’t find suitable tires when it was time to replace them. Tesla’s official aftermarket tires are priced over 2,000 and have high tire noise. Other electric vehicle tires on the market sacrifice handling performance for low rolling resistance, which wastes the excellent chassis quality of the Model 3.

I fully agree with his tire noise issue. We have an imported version of the Model 3 in the company, and the Michelin PS4 tires which emphasize handling performance also bring a lot of road noise due to poor early import assembly technology and ordinary NVH control. In addition, the Model 3 at that time was not equipped with double-layer laminated glass, so the noise suppression performance during high-speed driving can be said to be very average.

I was also puzzled by his dilemma and couldn’t think of a balanced performance tire for electric vehicles. Between grip and low rolling resistance, it seems that you must make a choice.

Ironically, in the scorching July of Jiangsu, Zhejiang and Shanghai, I received an invitation from German tire brand Continental. Unlike usual, the protagonist this time was not a new car but rather the eContact tire specifically designed for electric vehicles.

After test driving it, what surprised me the most was that it improved the Model 3’s tire noise suppression level by one level, without sacrificing other aspects of performance. What surprised me even more was that eContact effectively solved a major pain point for electric vehicles and made a pioneering breakthrough in the field of electric vehicle tires.

So, how was the experience? And what is the pain point that it solved? Don’t worry, let’s keep reading.

Change tires, this Model 3 is really quiet

Interestingly, the experience car provided by Continental this time happened to be a Model 3. On the first day of the test drive, the route was the Hainan Island Ring Expressway, starting from Tufu Bay to the Fenjiezhou Island scenic area, with a total length of 48 km.

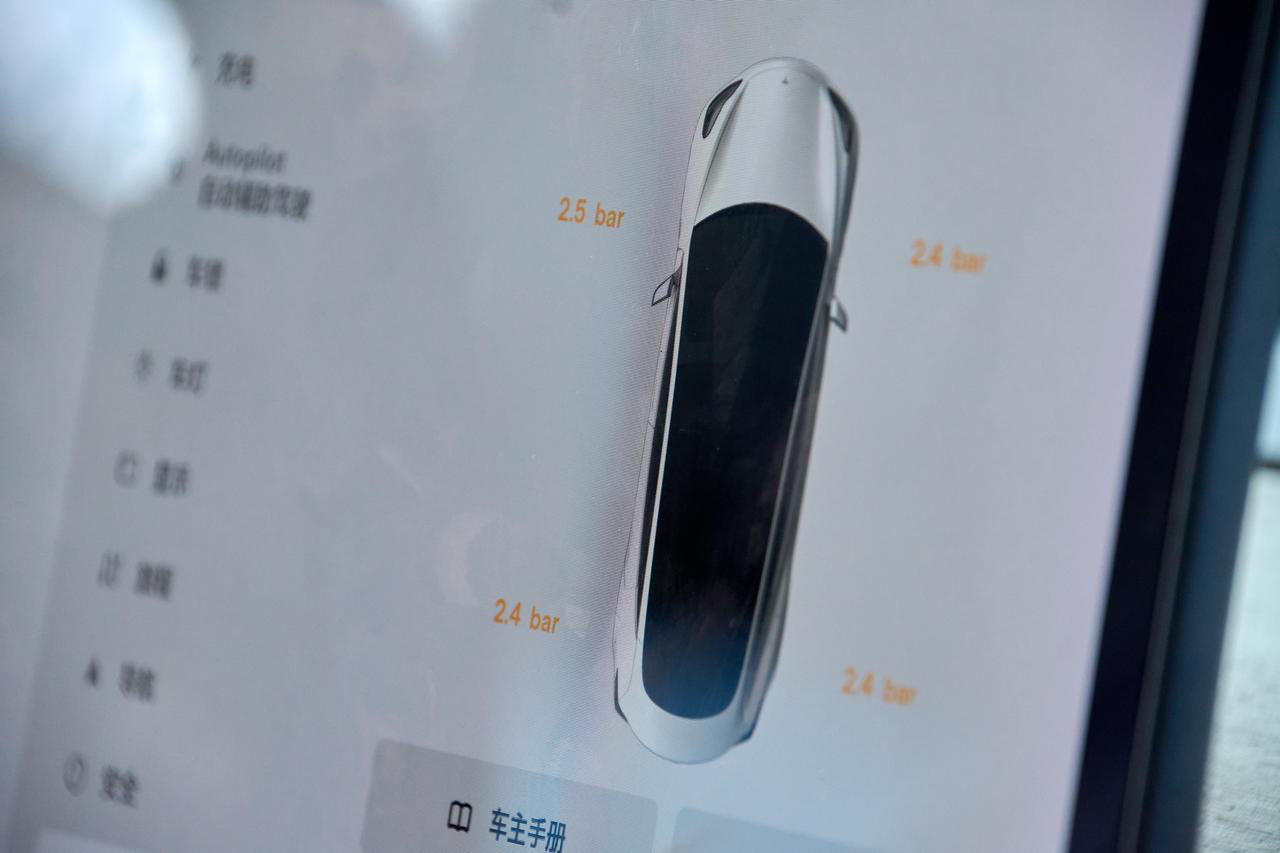

Tesla Model 3 has a recommended tire pressure that is relatively high, reaching 2.9 bar, but after boarding the test drive car, I found that the tire pressure was around 2.4-2.5 bar. In most cases, the lower the tire pressure, the larger the contact area between the tire and the ground, and the more noise it will produce. I prepared to face familiar tire noise while feeling nervous.

Surprisingly, the noise of Michelin eContact tires is much lower than expected. The tire noise from the chassis is not obvious at both mid-low speeds between 40-80 km/h and high speeds of 100-120 km/h. Moreover, this is not just my personal feeling. After reaching the destination, I discussed the experience with friends I traveled with, and everyone expressed that the tire noise of Michelin eContact is much smaller than the original PS4 tires.

Surprisingly, the noise of Michelin eContact tires is much lower than expected. The tire noise from the chassis is not obvious at both mid-low speeds between 40-80 km/h and high speeds of 100-120 km/h. Moreover, this is not just my personal feeling. After reaching the destination, I discussed the experience with friends I traveled with, and everyone expressed that the tire noise of Michelin eContact is much smaller than the original PS4 tires.

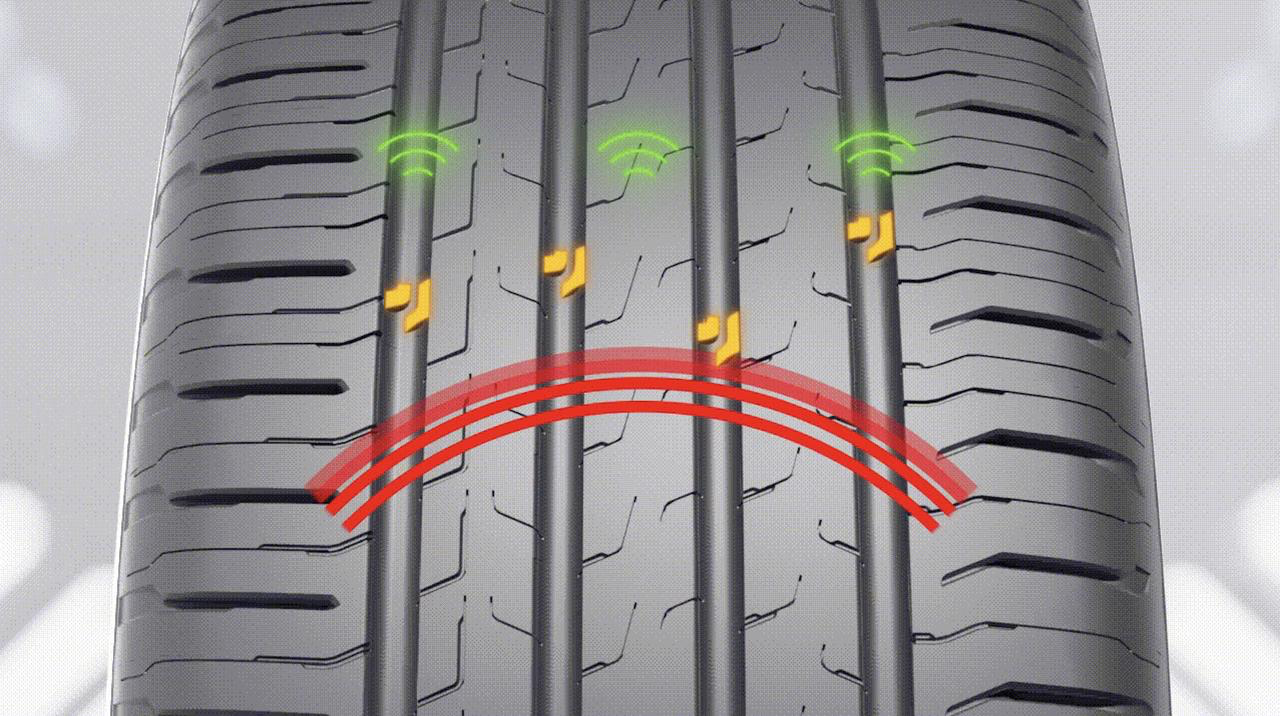

According to the product manager of Michelin eContact, the tire tread pattern of eContact uses a fine needle pattern design that has been optimized through simulation, and while ensuring the grip, the resulting noise and vibration from friction with the road surface are eliminated as much as possible. This significantly improves the tire’s noise reduction performance.

In addition to the optimized tire tread pattern, Michelin engineers also designed “active noise reduction”. Inside the grooves of the eContact tire, in addition to blocks that indicate wear, small bumps can be seen in the middle of the groove. During the tire rolling process, this discontinuous active noise-reducing bump can effectively block the propagation path of sound waves in the longitudinal grooves to further reduce tire noise.

Additionally, we know that the original tires of the Tesla Model 3 have soundproof cotton inside the inner wall. As a replacement tire, Michelin eContact also has soundproof cotton, which Michelin calls “ContiSilent” soundproofing technology. Apart from this, Michelin’s other patented technology also makes a positive contribution to reducing tire noise. As for the details of this technology, we will sell you a cliffhanger here and continue reading below.

Hainan’s weather is very changeable. In just 48 kilometers of highway, the weather has been constantly fluctuating between “heavy rain-sunshine-heavy rain”. Friends who often drive on highways should know that when rolling over the waterlogged road surface at high speeds, if the tire’s drainage capacity is insufficient, the wheel may suddenly lose grip and the car may drift and sway, which is very dangerous.

The shoulder of Michelin eContact tire has blade-shaped guide grooves, which can cut through water film when driving on water-logged roads to prevent slipping. At the outer opening of the Michelin eContact tire, engineers designed large guide grooves, which can quickly drain away accumulated water outside the tire.

On the Hainan Ring Expressway, the heavy rain was so heavy that the visibility was less than 50 meters. Under such conditions, our convoy was driving at 80 km/h without feeling the loss of tire grip. When passing through small puddles, the vehicle body and direction did not deviate or sway.

At last, we arrived at our destination. Behind us was a highly saturated green forest dotted with small villages; beside us was the quietly driving Model 3; and in front of us was a peninsula lying in emerald waters resembling a beautiful woman. This tiny beautiful island is the natural and geographical boundary between the south and north climates of Hainan, the border between Qiongnan and Qiongbei, and the administrative boundary between Lingshui County and Wanning City.

Having enjoyed the beautiful scenery of Hainan enough, don’t forget about the suspense I’ve left: what other special technologies does the Michelin eContact have?

Learn from a Tire How to Stop Internal Friction

It is common for a tire to puncture and leak air. In the traditional gasoline car era, as long as you knew how to use a wrench, you could basically replace the flat tire with a spare one yourself and continue driving within half an hour. But here’s the problem: according to statistics, more than 90% of new energy vehicles sold in the Chinese market do not come with a spare tire. What if an electric vehicle gets a flat tire and leaks air?

NIO, a carmaker that emphasizes service, has a simple and crude solution: have their staff on standby at all times. But for other electric car owners, it’s not that simple. My colleague Xiao Ding Dang once encountered a situation of a flat tire caused by a nail puncture while driving a certain brand of electric SUV on the highway at 2:00 a.m. After complicated and difficult information registration, the manufacturer finally dispatched staff. However, because it was in the middle of the night, poor Xiao Ding Dang waited until 7:00 a.m. on the side of the highway.Do you think that’s all? Due to the weight of the electric car, the small jack that usually comes with it can’t even lift the car. It took a lot of effort to finally get the car on the trailer with the help of a pulley. As you can see, a small nail can bring such a big trouble, which has become an inconspicuous hidden danger and pain point on the electric car.

Space is precious in electric cars, and spare tires take up too much space. Small jacks can’t withstand the weight of electric cars, which can easily exceed 2 tons. Imagine if tires could repair small punctures by themselves, wouldn’t the problem be solved?

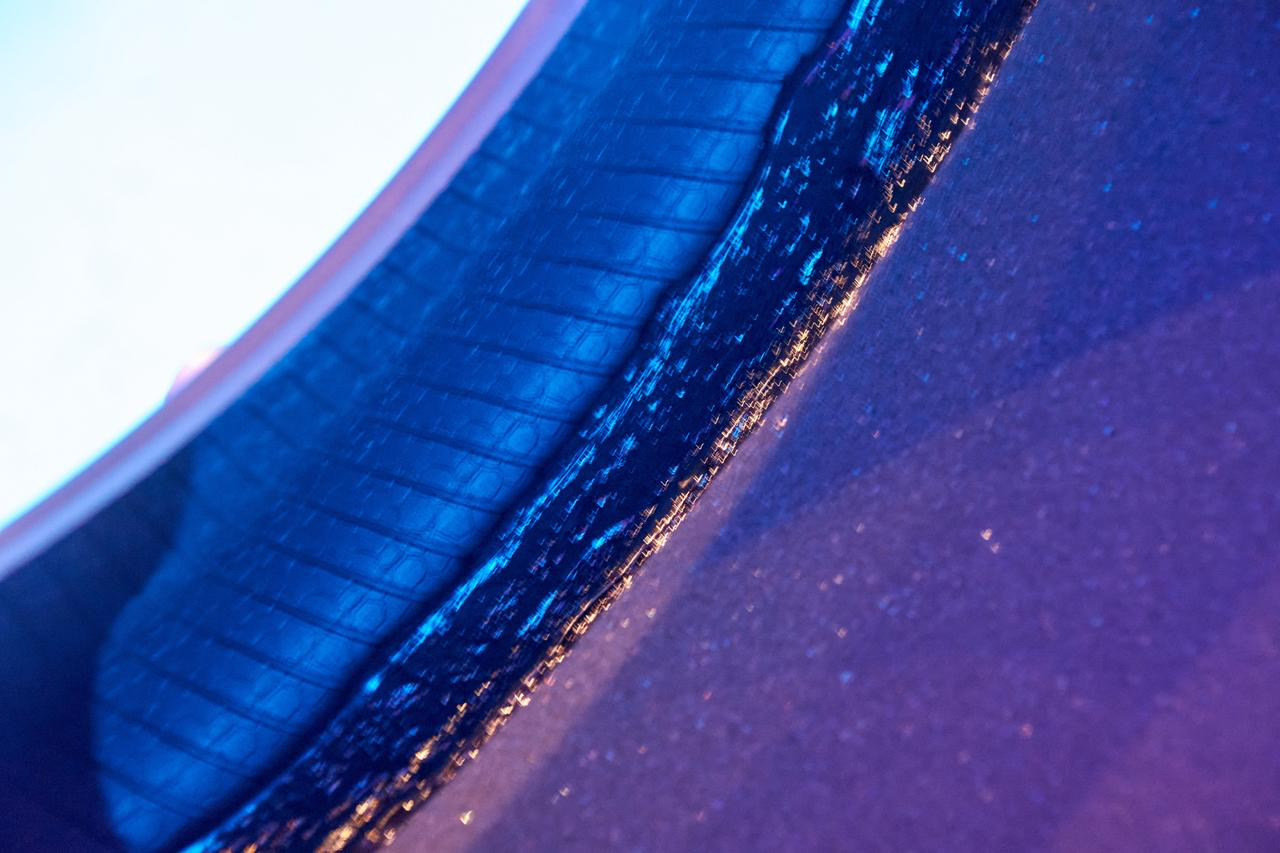

So, Michelin has introduced its Contiseal self-repair technology on the eContact electric vehicle tire. The principle is simple: Michelin applies a thick layer of high-viscosity sealing material on the inner side of the tire. When nails with diameters equal to or smaller than 5 mm penetrate the tire, these sealing materials will enter the gaps and fill the leakage points.

In fact, self-repairing tires are not new technology, but this type of product has always had two problems:

-

The adhesive for repairing becomes more fluid at high temperatures. The originally uniformly attached colloids on the inner wall of the tire tend to solidify and clump, causing dynamic balance to be affected.

-

Almost all self-repairing tires on the market cannot be both self-repairing and equipped with internal soundproofing cotton at the same time, only one of the two can be chosen.

Michelin’s eContact tire solves these two pain points. On the one hand, depending on the depth of co-development with automakers, some specifications and models of the eContact tire will simultaneously have the ContiSilent built-in soundproofing cotton and ContiSeal self-repair technology. On the other hand, Michelin has a special patented formula for repairing adhesives that guarantees repairability throughout the tire’s ten-year lifecycle.

According to Michelin’s research, 92% of tire puncture risks on the road come from sharp objects with diameters equal to or smaller than 5 mm, so the ContiSeal self-repair technology is enough to deal with most of the tire puncture risks on the road. This layer of repairing adhesive can also reduce the resonance produced by tire rolling, “saving the country by curve” and improving sound insulation performance.

After talking about the technical aspects, of course, it still needs to be implemented in actual experience. Michelin rudely brought two steel nails and pierced them into the tires of a Model 3. With two slight cracking sounds, the repairing adhesive filled the gaps in the unseen area. We poured water on the puncture points, but no bubbles appeared.

Is it still effective to repair it yourself with a nail in hand on a mountain road?

Good handling also means good range

We took the “injured” Model 3 for a ride on a mountain road. This time, we went to Xinglong National Forest Greenway in Hainan Island. Although the distance is not long, only four kilometers in total, there are more than a dozen sharp bends, and the road has a large variation of height difference. The road was slippery due to recent rain, covered with wet soil and fallen leaves, which posed a considerable challenge to the tire’s control and grip.

I slowed down and kept a safe distance from the car in front. When the car in front disappeared from my sight, I grabbed the steering wheel at 3 o’clock and 9 o’clock positions and pushed the accelerator to the floor. Although the Model 3’s chassis limit is very high, I had to cautiously accelerate through the first few bends as I was not sure about the limit of the tire’s grip at that moment. (Note: The entire journey was within the speed limit.)

Despite the damp and slippery leaves on the ground, I didn’t hear a squeak from the tire, nor did I feel any slippage when driving through the bends. Encouraged by this experience, I bravely stepped on the accelerator when exiting the bend. The tires held the Model 3 in a good grip, and the support in the bend was also adequate without dragging the chassis.

At the end of a straight road, I stepped on the brake pedal hard. Under this violent attack, the tires only slightly lost grip. When it comes to the ability of the Michelin eContact tires to maintain good grip in wet conditions, it has two aspects:

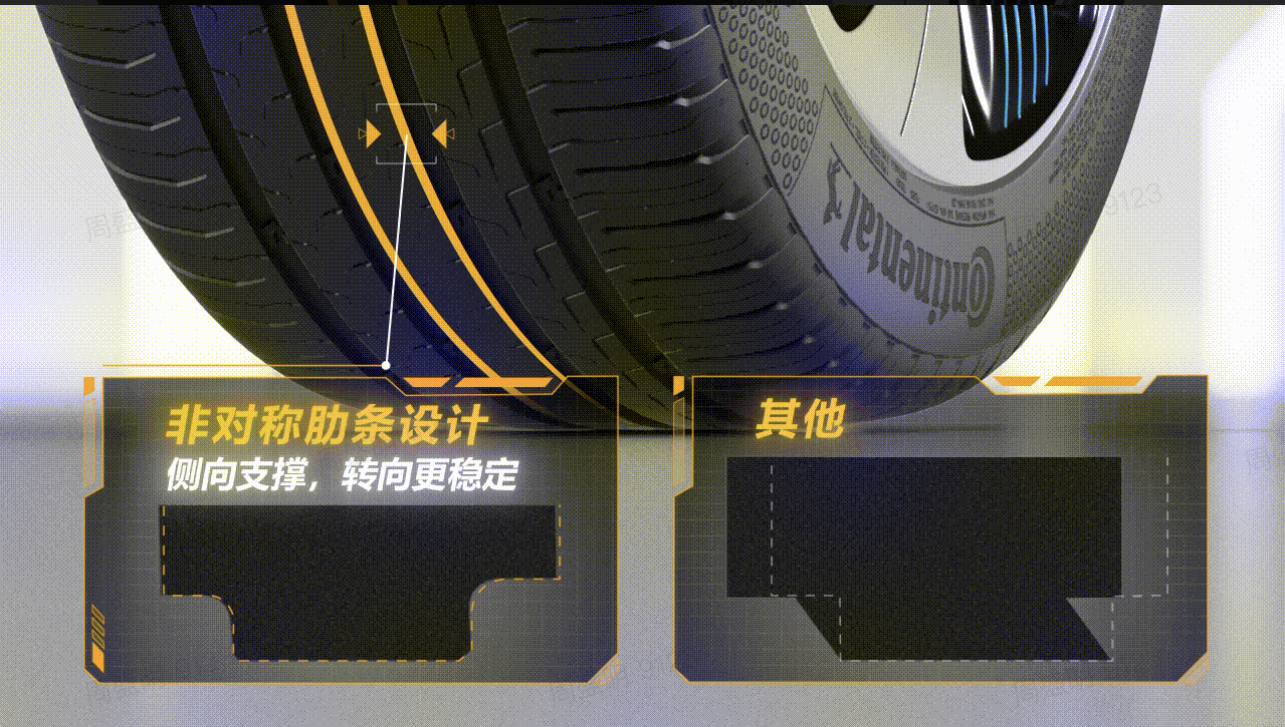

On the one hand, as mentioned earlier, the shoulder-shaped directional grooves and the large drainage grooves on the outer side can tear and quickly remove the water film from the surface of the tire. On the other hand, Michelin did not forget about its sports genes, and brought the non-uniform rib profile from its sport tires to this new energy-specific tire.

Symmetric ribs will experience significant lateral deformation during turning as they resist the tearing force. This will cause a loss of grip. Asymmetric ribs can maintain the maximum contact area of the tire when it resists the strong ground frictional force in turning.

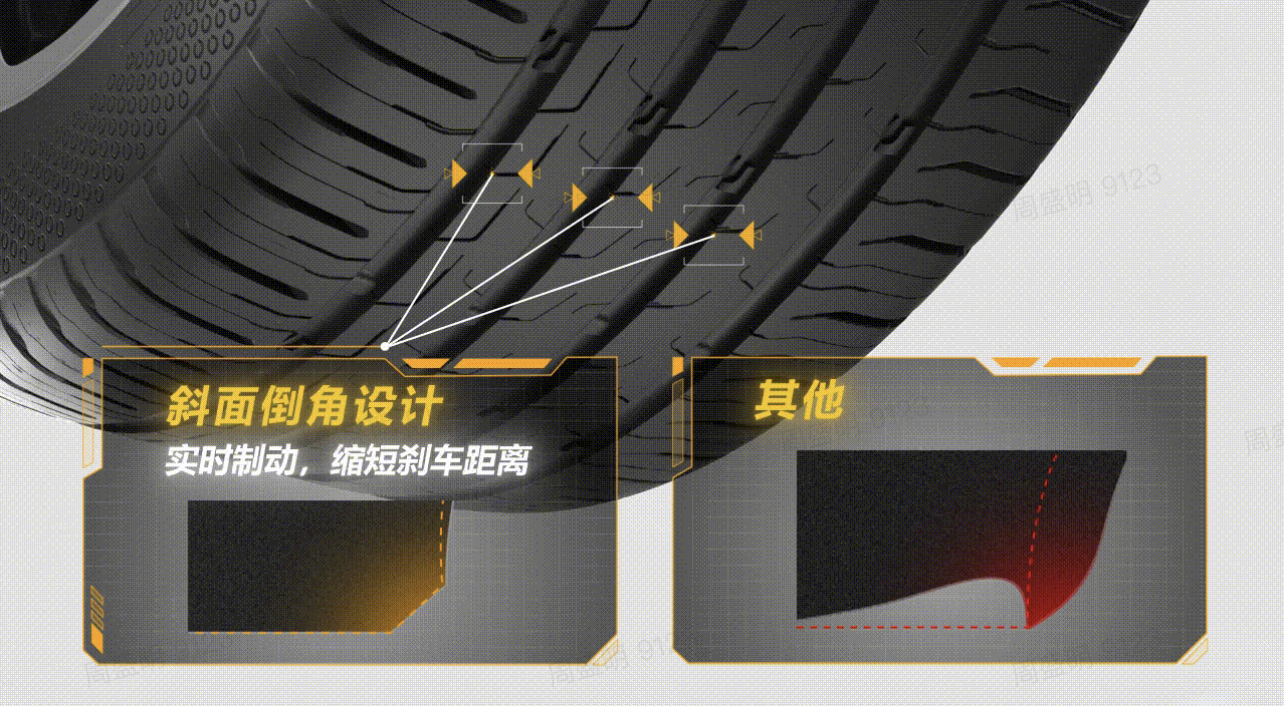

In addition, engineers designed the chamfers on the surface of the tire. If compared with an eraser, a square eraser is easy to curl or even tear during vigorous wiping. Chamfers ensure the contact area of the tire and reduce abnormal wear of the tire during braking.

As a new energy tire, Michelin eContact needs to consider optimizing its endurance when designing. We find that eContact is covered with tiny depressions on the surface. Does it resemble a golf ball?

The rough surface of the golf ball can make it travel five times the distance of a smooth ball. The small dimples on the surface of the golf ball make the surface air tightly adhere to the surface of the ball, reducing the downstream swirling airflow resistance, which enables the golf ball to fly farther and faster. Michelin engineers found inspiration in this and designed similar depressions on the outer side of the tire to prevent the inbound airstream from forming turbulence but instead flow smoothly against the tire surface.

Today’s test drive is coming to an end. I looked at the energy consumption data of Model 3 after the 200 km test drive: 15.4 wh/km. Although the weather in Hainan is very suitable for lithium batteries to work, our driving style has been very aggressive, basically driving at the road speed limit and there are many high-speed sections. Such energy consumption performance has already proved that Michelin eContact, as a new energy tire, will not drag down the endurance of the vehicle.

Back at the hotel, the staff removed the two nails stuck in the tires earlier in the morning. At this point, the dashboard still showed a tire pressure of 2.4-2.5 bar, but the punctures were automatically repaired by eContact’s self-repairing capability, and you couldn’t even find the damage without carefully examining it with a flashlight.

Back at the hotel, the staff removed the two nails stuck in the tires earlier in the morning. At this point, the dashboard still showed a tire pressure of 2.4-2.5 bar, but the punctures were automatically repaired by eContact’s self-repairing capability, and you couldn’t even find the damage without carefully examining it with a flashlight.

Wrapping Up

Currently, eContact from German manufacturer, Continental, has only one specification available on the MA-PAI app, which is a 235/55 R19 tire priced at CNY 1,199. The 18-inch tire model that we tested, which is compatible with the Model 3, is expected to hit the market next month. As for other specifications, MA-PAI plans to release 1-2 specifications next month, with all specifications planned to be available by the second quarter of next year as shown in the figure below:

As the only component in direct contact with the ground, the importance of tires cannot be overstated. While new energy vehicle-specific tires have not undergone radical changes like those in new energy vehicles and traditional fuel-powered vehicles, developments in tires for electric vehicles have to keep up with the times in response to the pain points such as the absence of spare tires and the need to balance rolling resistance and handling, among others.

Whoever solves the pain points first will win the incremental market. You see, it’s not just the new energy vehicle market that’s booming; the battle has spread to tire manufacturers.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.