Author | Wang Lingfang

Editor | Qiu Kaijun

The Ultium platform, which was launched in 2021, marks the comprehensive transformation of General Motors towards electrification.

On July 26th, SAIC-GM held a “Ultium EV Platform Technical Open Class” to provide an in-depth interpretation of the platform’s features.

According to official propaganda, the main features of the Ultium platform are “safer, smarter, and more efficient”.

Of course, no company would think that their own platform is not safe, not intelligent, or has poor performance. Especially in China, there are too many new battery and battery system technologies: CATL’s “Blade Battery”, BYD’s “Blade Battery”, SAIC’s “Magic Cube Battery”, and GAC’s “Bullet Battery” – the names are not enough to express their excellence. Of course, the Ultium platform also includes electric drive systems in addition to the battery system.

Aside from the official propaganda buzzwords, the EV Observer believes that the noteworthy features of the platform are: proprietary cell formulas, ASIL-D system safety level, first-tier motor system peak efficiency, and wireless battery management technology that simplifies processes and maintenance.

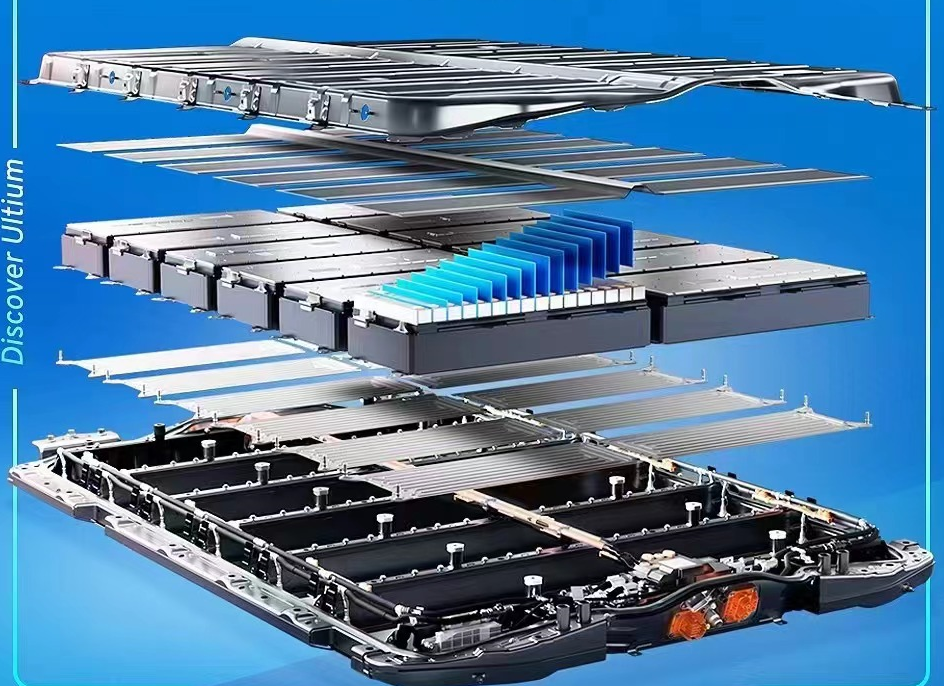

Moreover, the Ultium platform is a vehicle platform based on the skateboard concept, with the goal of achieving a flexible, open platform architecture while balancing R&D and production costs. Therefore, versatility is also a major feature, covering various types of styling with different wheelbases and sizes, including sedans, SUVs, MPVs, and pickups.

As an early platform under development, there are also obvious shortcomings, such as the battery system not adopting a module-free structure, the battery system structure still being very complicated, and the NCM811 cell energy density advantage not being fully utilized.

Let’s analyze each point below.

Proprietary Cell Formulas

General Motors is one of the few companies that can intervene in cell formula design.

SAIC-GM is deeply involved in the design and performance development of cell chemistry systems. The entire cell design and development, as well as verification, are jointly completed by General Motors, SAIC-GM, Pan Asia Technical Automotive Center, and cell suppliers, with deep involvement in five areas of cell material system development, manufacturing processes, performance evaluation, safety abuse, and cost control.

According to Bai Yang, Senior Engineer for Cell Performance Development at SAIC-GM, they have collaborated with domestic cell suppliers to use proprietary formulas on the positive and negative sides of the cell.

On the positive side, SAIC-GM selected the NCM811 system cell with high energy density, which forms a core-shell structure through in-situ coating wrapping and rivets free oxygen by directionally doped rare earth elements.In order to facilitate understanding, the battery cell is compared to a martial artist, with the NCM811 system indicating that this person possesses strong internal force. The in-situ coating is similar to a “golden bell” that prevents internal force from leaking out and reduces oxygen release. The purpose of doping rare earth elements is to stabilize the oxygen element, which serves as the carrier of internal force in the dantian, and also to reduce oxygen release. This further extends the working life of the battery cell, supports fast charging throughout the entire lifecycle, and has little effect on the battery life.

With the help of this set of internal martial arts, this formula achieves a 10% increase in thermal stability compared to the basic formula.

On the negative electrode side, high-capacity fast-charging graphite is used to increase the battery capacity. By in-situ construction of a fast ion-conducting ring, the transmission rate of the battery capacity is increased. Particle-level matching eliminates electrode step concentration, which can improve conductivity, ensuring that lithium ions can be smoothly cycled and not easily damage the material’s microstructure.

The OTEV platform battery can be compatible with lithium iron phosphate, ternary lithium batteries, as well as future lithium metal batteries, solid-state batteries, etc.

The highest safety level ASIL-D

In terms of safety, the OTEV electric vehicle platform is designed at the highest level.

According to SAIC-GM’s introduction, the OTEV electric vehicle platform meets the highest level of ASIL-D system safety, which is the highest standard for electronic and electrical system safety in the automotive industry. At the same time, the platform was also developed according to the design standards of the five-star safety evaluation of the electric vehicle in four aspects: voltage, energy, physical protection, and insulation resistance of the power system load end.

High-standard battery cell selection and testing

In the battery cell selection stage, 100% DCR (direct current internal resistance) testing is adopted, which is more costly. Through DCR holistic testing, the consistency of battery cell welding manufacturing, battery cell performance, and offline quality is ensured, thereby reducing the bucket effect of battery cell capacity and improving battery safety and life.

Based on different scenarios such as the whole vehicle usage environment, end users, product positioning, etc., the performance evaluation standards of the battery cells are set, and the battery cells will undergo comprehensive tests such as electrical, thermal, chemical, safety, durability, vibration, and performance. The accumulative testing time exceeds 3.2 million hours.

7-fold thermal management protection

Firstly, an inter-cell thermal wall (patent design) is used, which employs nano-level aerospace materials with a thickened design, where more than 99% of it is air to effectively reduce the heat transfer between battery cells.

Secondly, heat diffusion suppression technology (patent design), which is utilized when a single battery cell is out of control due to high temperature, where a patent-designed fast exhaust channel can be used to quickly discharge high temperature gas. It is supplemented with a liquid cooling plate system integrated into the module bottom, which can quickly release heat inside the package, reduce secondary failure, and minimize the impact on adjacent modules and battery cells.- Three, Integrated Liquid Cooling System (patent design): Each module is equipped with an integrated independent liquid-cooled plate with patent design. Compared to the commonly used battery pack centralized liquid-cooled plate design in the industry, the heat exchange efficiency is increased by approximately 10%. At the same time, the liquid cooling system can control the temperature difference between the battery cells within 1 degree Celsius through unique flow control, ensuring consistent aging of the battery cells and improving the battery life. In addition, a liquid-cooled plate is also placed in the BDU battery disconnect unit. This design is not common in the industry, and it can enable BDU unit to support peak current loads of more than 1200A with a maximum heating temperature below 65°C, eliminating the thermal impact on surrounding components.

-

Four, Fire Protection Design of Modules and Battery Packs (patent): The patent design of the top cover fire protection and built-in aerogel fire blanket provide further protection for passengers and the entire vehicle.

-

Five, Rear Large-Area Explosion-Proof Valve: It is combined with the fast exhaust channel of the module and the battery pack to quickly discharge high-temperature gas.

-

Six, Anti-Arc Design: The high-voltage components inside the battery pack have anti-arcing design to prevent arcing after thermal runaway of battery cells.

-

Seven, Battery Health Monitoring System Combining Car and Cloud: The car side adopts triple sensors of air pressure/temperature/voltage to monitor the battery pack and cell status 24/7 with high frequency. Once the risk of a runaway is detected, quick cooling will be taken to control thermal diffusion and ensure safety.

In addition, based on the battery’s full life-cycle data, the cloud-based data platform can identify potential risk of thermal runaway, such as lithium plating, internal short, swelling, and leakage, in advance, and provide weekly abnormal battery health warnings to prevent hazards before they happen.

Multi-Physical Structure Protection

Regarding the physical protection architecture of the battery, for instance, the Oterpower platform adopts a high-strength battery shell design, a high-strength cross-shaped structure reinforced with multiple 1500MPa ultra-high strength steel beams (five beams for 12 modules, four beams for 10 modules, and three beams for 8 modules). The upper cover assembly adopts 1500MPa super-strong side protection beams, and the pallet assembly adopts 1000MPa bottom protection.

The application of high-strength steel accounts for 61%, and the application of ultra-high strength steel accounts for 37.5%. The entire battery pack has three times the anti-crush performance required by national standards, reaching the highest level in the industry.

In addition, remote laser welding is used for 23.2 meters inside the shell and laser wire feeding welding is used for 15.5 meters inside the shell, which is equivalent to winding the battery shell 5 times, providing a solid connection.In the design of the battery shell safety architecture combined with the vehicle system, SAIC-GM has developed multi-position column collision protection ability: simulating column collisions from A-pillar to C-pillar in multiple positions to test the strength of each area of each row of modules and better protect the safety of the battery cells and modules. The international and domestic column collision standards both only consider the single position column collision ability on the side of the vehicle, but SAIC-GM’s design surpasses this standard.

The torsional stiffness of the battery shell body is increased by about 45.8% and the torsional stiffness of the whole vehicle with the battery pack is 35kNm·deg, leading the industry.

In addition to fully meeting national regulations and C-NCAP requirements, SAIC-GM also conducts tests on complex scenarios such as bottom sphere impact and crossing railroad tracks.

Moreover, active discharge can be completed within 5 seconds after the collision to ensure post-accident rescue safety.

In terms of sealing performance, it also achieves IP67 dust and water resistance and IP6K9K high-pressure water protection rating.

Wireless Battery Management System

The wireless connection of the battery management system simplifies battery system assembly and reduces maintenance difficulty.

This optimization reduces the amount of wiring harness in the battery pack by up to 90%, while reducing the weight of the battery pack and improving the space utilization inside it. As a result, the volume of the battery pack is reduced by up to 15%, achieving an increase in energy density.

Li Zhishen, a system module expert at the Pan Asia Technical Automotive Center, believes that the mainstream solutions in the industry currently have the problem of complex wiring harnesses, which can cause very high communication failure rates and easily cause a single communication failure point to lead to the failure of the entire system.

Wireless battery management also reduces the use of connectors, reducing associated costs and the failure rate of these components.

Highly reliable and secure signal transmission. SAIC-GM adopts an adaptive hybrid network architecture. When communication loss occurs in a module group, it will be sent through adjacent modules to prevent signal loss. The 15-channel intelligent random frequency hopping solves the problem of channel congestion. The 112dB RF link budget provides strong anti-interference capability.

In terms of information security, SAIC-GM uses 3 encryption algorithms and key management to protect user privacy and protect vehicles from malicious attacks.

Thanks to the enhanced remote upgrade function of General Motors’ new generation VIP intelligent electronic architecture, the underlying architecture of the battery management system can be updated like a smartphone, continuously optimizing the efficiency of battery management and delivering better performance.

In addition, there are safety measures such as real-time thermal runaway monitoring on the vehicle side and cloud-based thermal runaway early warning.## Maximum motor system efficiency can reach 96%

There are three electric drivers in the Auton platform: the front-drive main motor, the rear-drive main motor, and the rear-drive auxiliary motor.

The Cadillac LYRIQ Ruige rear-drive model uses a 3-in-1 electric drive unit with a peak power of 255 kW, a peak torque of 440 Nm, and a maximum motor system efficiency of up to 96%.

SAIC-General’s inverter IGBT module uses double-sided water cooling, so it can achieve better heat dissipation in a limited space, thereby increasing power density.

The intelligent oil temperature management module’s heat exchanger can store the heat of the gearbox oil and improve the overall system efficiency by utilizing the waste heat of the motor. It can quickly heat up the drive unit during low-temperature start and achieve efficient heat exchange during normal operation, making it an important part of the BEV HEAT efficient comprehensive thermal management system.

The high efficiency is mainly reflected in the motor flat wire technology, motor self-adhesive iron core, full oil-cooled motor and gearbox.

The motor flat wire technology can effectively reduce the winding resistance and thus reduce copper loss, output higher power and torque. At the same time, the flat wire fits tightly in the stator groove, has better contact with the stator core teeth and yoke, and has higher thermal conductivity, which further improves the motor’s peak and continuous performance.

The motor self-adhesive iron core will not cause material pulling caused by the riveting method, reducing the occurrence of eddy currents. At the same time, the fixing strength is greatly improved, reducing the vibration during rotation, reducing wind noise, and having excellent heat dissipation performance, which further improves the motor efficiency and NVH level.

The full oil-cooled motor and gearbox. All Auton platform electric drive units use oil cooling, with built-in oil pumps, which can actively spray oil for lubrication and cooling, improving the overall system efficiency.

Compared with the commonly used water-cooled form in the industry, the motor adopts stator spray cooling combined with rotor oil shedding, eliminating the need for a cooling water jacket. The outer diameter size is small and can bring a higher volume power density.

However, unfortunately, the energy density of the battery pack and battery cells was not disclosed in this public lecture. In terms of structural simplification, except for reducing the harness, there was no obvious reduction in structural components, so it’s unclear what the overall volume utilization rate of the battery system is. Due to the use of NCM811 battery cells, the relevant protection measures will be more cautious, so the energy density of the battery system may not be optimistic.

In any case, as a transformation work of GM electrification, the platform’s later evolution is worth looking forward to.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.