Author: Chang Yan

Without a doubt, Musk is a man who loves to talk big.

Just a year ago on July 27th, after Tesla’s Q2 2021 earnings announcement, Musk said: ” I won’t be on Tesla’s earnings calls unless there’s something really important that I need to say.”

After waiting anxiously for a few quarters with great anticipation, listening carefully to every word from the world’s richest man, people have come to realize that Musk never really left, and that “goodbye” was just a big talk.

The Q2 2022 earnings call became Musk’s most extensive and profound one in history, which of course brought forth another round of “big talk”.

Unlike in Musk’s many interviews where he repeatedly emphasized his past points, you can clearly feel that now is the time for Tesla’s technological evolution and a new definition of mission strategy for Musk.

There is one sentence that can be regarded as the guideline for the entire presentation: The key to popularizing sustainable energy is to reduce costs, and the two key things are economies of scale and core technology.

Economies of Scale

Today happens to be the 16th anniversary of the release of Tesla’s first product, Roadster.

If you read my article yesterday, you would know that over the past 16 years, Tesla’s veteran factories in Fremont and Giga Nevada have only produced 2 million vehicles.

It is industry consensus that in 2022 alone, Tesla is expected to deliver 1.5 million new vehicles worldwide.

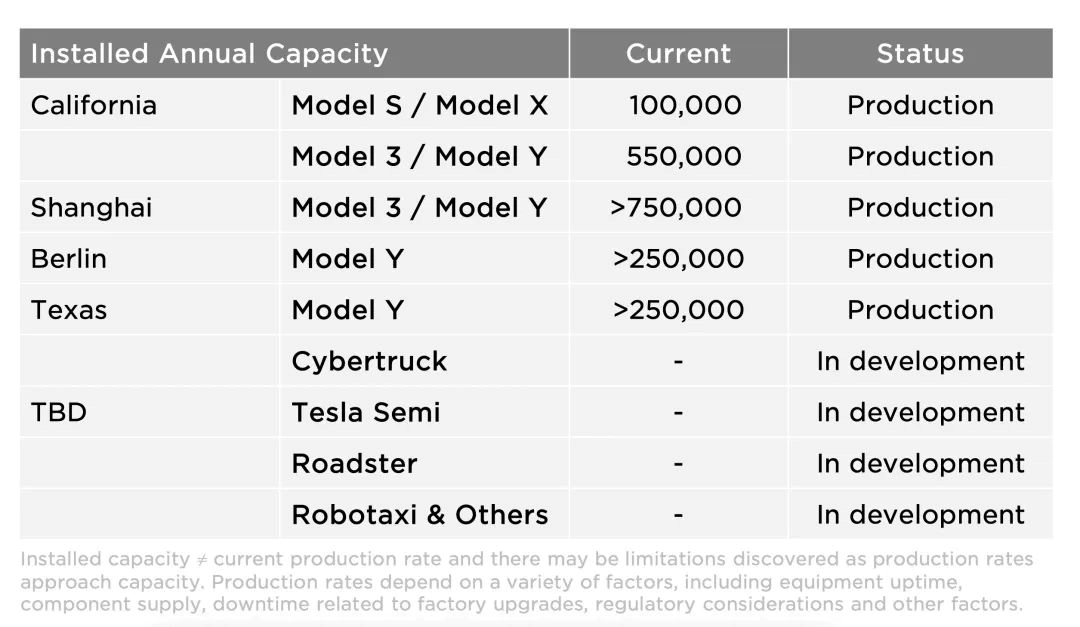

In the Q2 earnings call, Tesla unusually updated the planned capacity of all its factories simultaneously. According to the count, as of now, Tesla already has a comprehensive capacity of 1.9 million vehicles per year.

Perhaps you are familiar with Tesla’s “production hell” in 2018, and Musk now says that Tesla is caught in a “supply chain hell.”

Perhaps you are familiar with Tesla’s “production hell” in 2018, and Musk now says that Tesla is caught in a “supply chain hell.”

“In the past few years, Tesla has encountered many force majeure events, and the second quarter is a unique quarter for Tesla.”

However, it is still one of Tesla’s strongest quarters in history, “in June, we set production records in both Fremont and Shanghai, so we may set new records in the second half of this year.”

For Tesla, several major factories are in a strong upward trend. Giga Berlin surpassed the production capacity of 1,000 vehicles per week in June, Giga Texas is also doing well, and the efforts of Giga Shanghai have moved Musk, prompting him to say, “I am very grateful to the Tesla Shanghai team for their enormous sacrifice in restoring operations and achieving record production in June.”

According to Musk’s calculations, Tesla is expected to achieve a weekly production capacity target of 40,000 vehicles globally by the end of this year.

This is not as simple as accumulating resources and money in real-time strategy games, but requires a huge investment in the technology tree, so that you can enter the next era ahead of other players.

The same pressure also naturally extends to the supply chain, especially with Musk’s low hum, “If our suppliers don’t solve the problem, then we will.”

Core technology

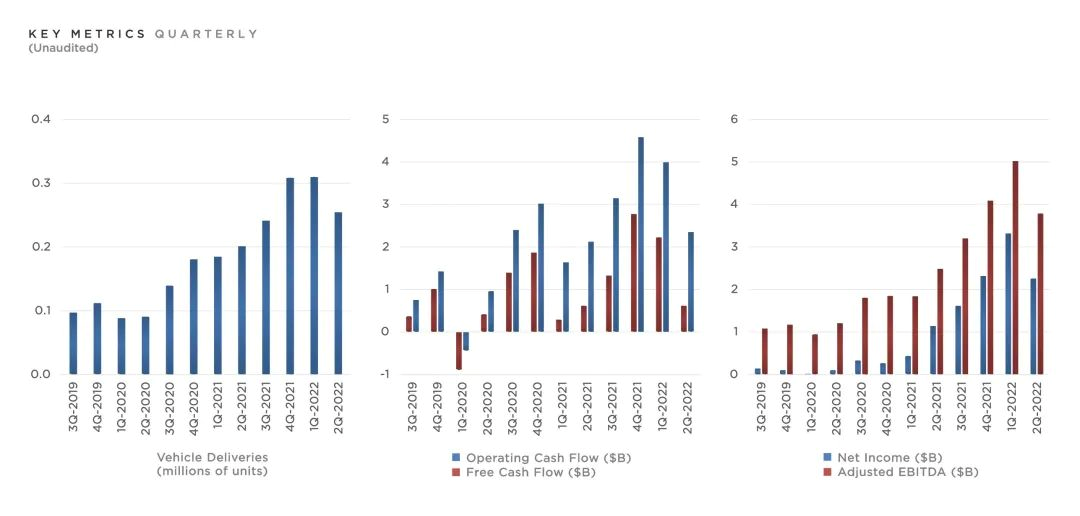

What is more attractive than the factory landscape in financial reports are the many changing curves above.

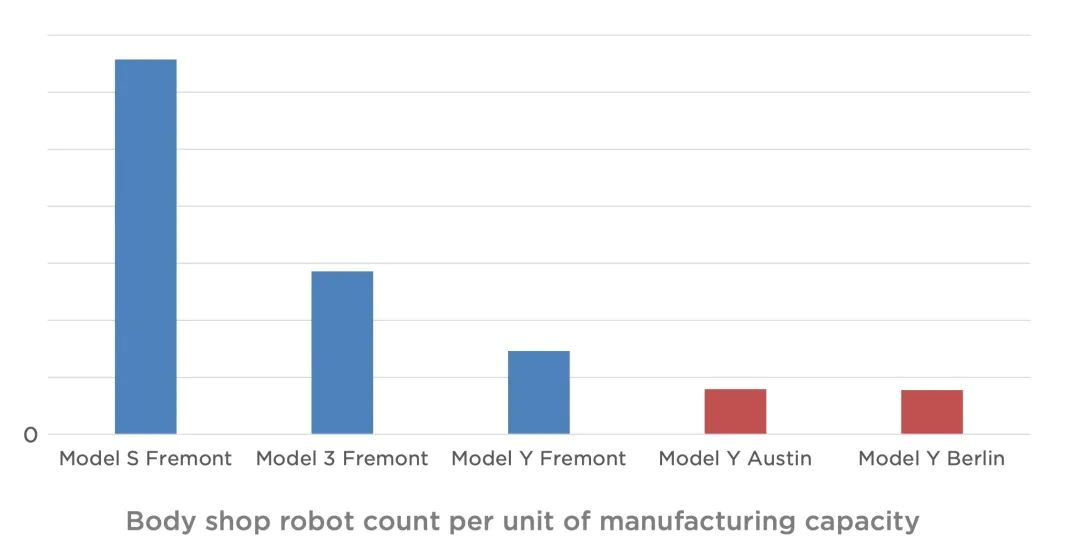

Due to the adoption of technologies such as integrated die-casting body, Tesla has been able to streamline many processes in vehicle manufacturing, allowing “us to reduce the number of body welding robots per unit of production capacity by 70% in Austin and Berlin.”

This is the result of Tesla’s long-term persistence in the past 5-6 years, “about 5 or 6 years ago, we said that we wanted to become the world’s best manufacturer, which was a bit counterintuitive, and for some people, I think this is actually our most powerful competitive advantage.”

But this is only the first step in Tesla’s manufacturing process evolution, and the second step will arrive just one year later.“`markdown

“Our team continues to focus on the production preparation of Cybertruck and some future platform design. We look forward to starting the delivery of Cybertruck in the middle of next year.”

“We will bring the next level of simplicity and manufacturing improvement through Cybertruck and future products that we are not ready to discuss yet. This will be very exciting.”

“I think Cybertruck could actually be our best product ever.”

As for the aforementioned indescribable product, Tesla’s Robotaxi has already appeared in this earnings report, and we will dig a hole for it and write another article.

If we split a Tesla into two parts, top and bottom, the iteration of the top part lies in the manufacturing process of the body, while the iteration of the bottom part lies in the 4680 battery.

Regrettably, Tesla is still using 2170 batteries to manufacture cars this year, even though “we have enough 2170 batteries to meet all vehicle production for the remaining time this year”.

Musk emphasized that “we (this year) do not rely on 4680. 4680 is important next year, but not this year”, “we have installed second-generation manufacturing equipment for 4680 batteries in Texas. We are also continuing to expand our cell capacity in factories such as Fremont and Shanghai.”

The obstacle to the rapid production of 4680 batteries involves dozens of processes related to anode-cathode materials. “When something is revolutionary, many unknowns must be solved. So we are confident in solving these unknowns, but it is very difficult.”

But this is what Musk calls “doing the foundations really well”.

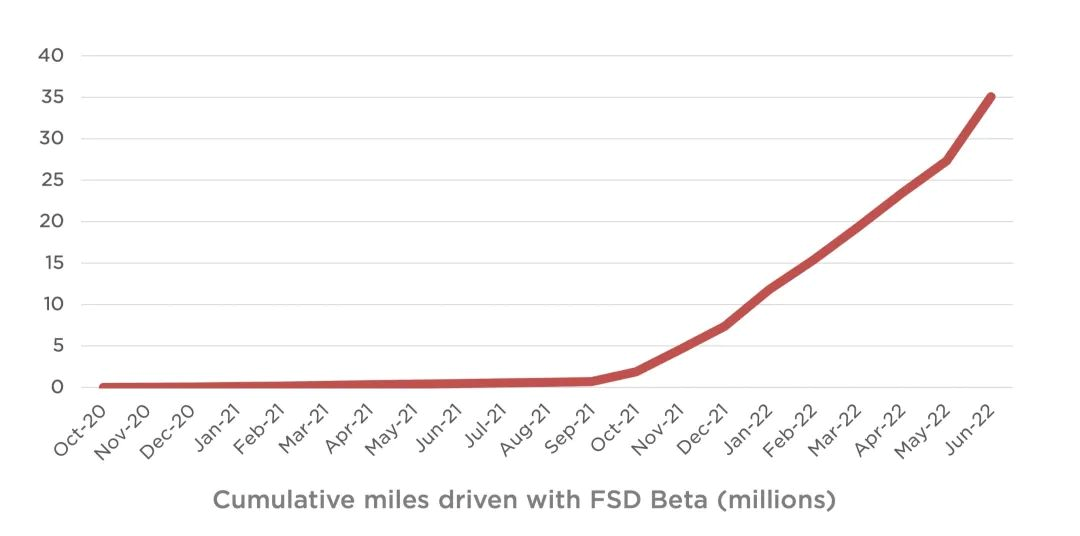

Another foundational work is FSD, which constitutes the cornerstone of Tesla’s software value.

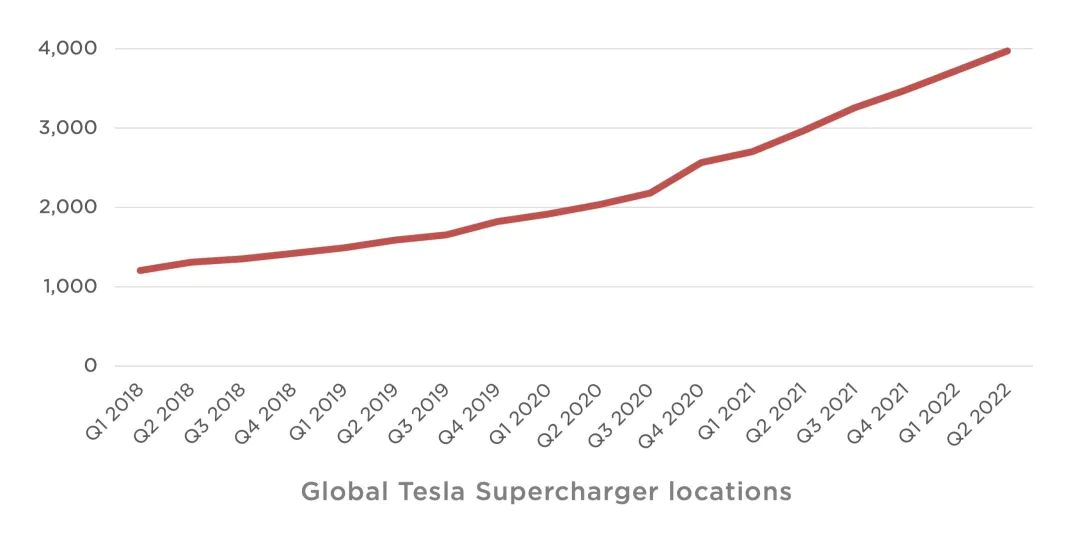

“`Now, in North America, Tesla has 100,000 test users. “We have now driven over 35 million miles with the FSD beta, which is more autonomous driving miles than any other company known. A lot more miles are needed for a fair comparison, but it should be at least an order of magnitude higher than any other company.”

“We will raise the price of FSD later this year.” “FSD is a lot more valuable than people realize. If FSD capabilities are real, people will be amazed how great it is. It is ridiculously cheap right now.”

“The FSD beta is expected to be released to all North American customers by the end of the year. If we get regulatory approval, we are also hopeful to be able to release it in Europe and other parts of the world.”

This statement raised many questions at the financial results conference, especially because one of the key figures in Tesla’s FSD, Andrej Karpathy, recently resigned.

Unexpectedly, Musk said, “Since Andrej wrote all the code himself, it naturally stopped there. But we have a very talented AI software team of about 120 people, and I am very confident that we will solve full self-driving, and it seems like we still might do it this year.”

The 2nd day of Tesla AI Day, which is just around the corner, will be the best window to solve this puzzle.

Global economic indicators

Musk seems unconcerned about whether Tesla can sell all the cars it produces, and his judgment is: “As we increase production, Tesla obviously has more demand.”

Of course, there are still many people in the world who are dissatisfied with Tesla, especially those who have placed orders.

Customers who ordered the Model 3 and Y will have to wait 4-6 months, while Model S and X customers in China and Europe have been waiting for nearly two years for delivery of the same models they ordered.

Musk understands that “currently ordered Teslas have a considerable wait time, in some cases up to six months; in some cases up to a year,” “we don’t want long backlogs. It’s frustrating. It’s like going to a restaurant, ordering a hamburger, and waiting three hours for it. It’s annoying. You want your hamburger right away. So, we want to shorten delivery times.”

Don’t think that having a ton of orders is a happy problem; on the contrary, it could be a financial risk.

“We see car orders coming from all over the world every day, and, in fact, it’s like a barometer of people’s economic confidence.”

Tesla must “predict the inflation rate that could occur during the long period between ordering and delivery” to prevent the cars produced from being sold at a loss.

This is because the continuous increase in costs at the supply chain terminal. Musk stated that the cost of refining the metal materials used for manufacturing car bodies and the cost of refining required to manufacture batteries are all increasing continuously, which greatly increases the industry’s uncertainty.

Musk even encourages more people to join the lithium refining industry.

Chips are also new sources of energy, “We have been working with our suppliers. We are not currently planning to manufacture our own chips. We don’t think it’s necessary to produce chips, but we’re working closely with many suppliers.”

In fact, due to the uncertainty of the Shanghai factory, Tesla announced in this quarter’s financial report that it has sold the 75% of Bitcoin it held, and to maintain its dignity, Musk emphasized, “We have not sold any Dogecoin yet.”

All of this makes us feel Musk’s anxiety about the global economy.

Of course, this anxiety also comes from Chinese competitors. Although he proudly declared that “now, Tesla is the best electric car maker in China,” he also said, “But I have great respect for the Chinese, especially electric car makers. I think they will become an unstoppable force in the world. They are very smart, and they work very hard.”

For the future, Musk even revealed a more obvious pessimism:

“I think it’s tough to predict anything 10 years from now. Frankly, I hope civilization still exists.””Hopefully, by that time, we will not have had the third world war.”

However, Tesla’s financial performance does not seem to be the focus of Musk’s attention. Instead, he continues to focus on “transitioning the world to sustainable energy.” “What we’re working hard to do is to manufacture electric cars, solar power, and stationary battery packs. These are the three pillars of the sustainable energy future.” “If we solve these three things, we have a sustainable civilization future.”

Fortunately, “as long as I can effectively promote sustainability and autonomous driving, I will work at Tesla.”

Hopefully, that’s not just talk.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.