200万!马斯克和特斯拉宣布重大事件

Author: Chang Yan

In the early hours of today, Beijing time, Musk and Tesla each sent a tweet, jointly announcing a major news.

Musk announced that the Fremont Factory + Giga Nevada Factory has produced 2 million cars.

Tesla’s official tweet even omitted the caption and used two pictures to tell us that the offline 2 millionth car was a red Model 3 Performance.

The color and photo layout obviously pay tribute to the scene when Tesla produced its millionth car on March 10, 2020. Oh, by the way, it took 168 months for the Fremont factory to produce the first million cars, and only 28 months to produce the second million.

For a considerable period of time, everyone’s attention to Tesla has been encapsulated in the production process. On the one hand, Tesla’s new models have been delayed in delivery, and on the other hand, Tesla’s factories have been delivering good news one after another.

Whether it is the Shanghai factory’s impressive progress in both domestic and import production, or Giga Berlin and Giga Texas competing to break through the weekly production capacity of 1,000 vehicles, it is enough to make the industry take notice of this behemoth.

But the driving force behind this massive production capacity is still the surge of technology.

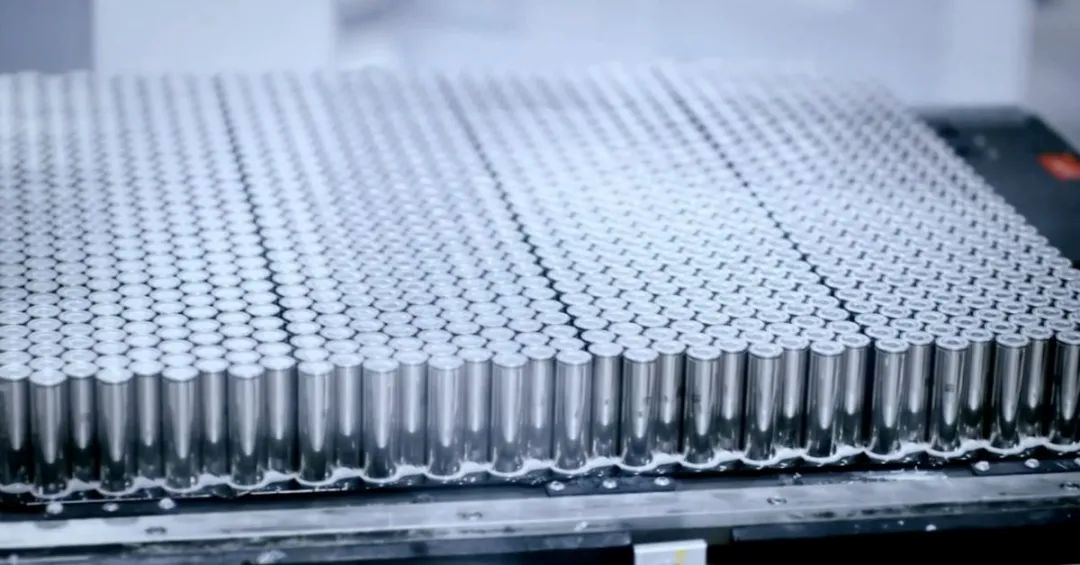

Is the 4680 battery strong enough?The 4680 battery, which was first put into mass production at Giga Texas, has become the starting point of the widely recognized next-generation intelligent electric vehicle structural revolution. After all, the specifications announced by Musk on Battery Day were too impressive to ignore, and Musk also said that the 4680 battery would be a nuclear weapon for significantly increasing Tesla’s vehicle production capacity.

Recently, various core research institutions and media outlets in the United States have sparked a new craze for dismantling the 4680 battery.

The Limiting Factor is a technology channel on YouTube that has long focused on electric vehicle batteries. Recently, they completed an analysis report on the dismantling of Tesla’s 4680 battery, and the story behind it is increasingly intriguing.

The dismantling data confirms some rumors and also reveals some surprising and disappointing findings.

From a compositional perspective, Tesla’s 4680 battery still uses the familiar NCM 811 cathode chemistry formula. Nickel accounts for 81.6% of the composition, and the cobalt and manganese content has not been disclosed. Many people previously speculated that Tesla would introduce aluminum into the 4680 battery to reduce costs, but it did not appear.

One of the core features introduced by Musk on Battery Day was a new electrode technology, but the dismantling shows that this technology is only used on the anode. The battery’s anode active material uses graphite and not silicon.

Therefore, The Limiting Factor points out that, from a chemical perspective, the current 4680 battery does not have a significant breakthrough, so it should still be an entry-level model or an early version.

However, Tesla’s 4680 battery has already reached the cutting edge level of battery performance in the industry.

According to the report, the weight of the battery cell is 355 grams, with an estimated total capacity of 26.136Ah and an estimated total power of 96-99Wh (assuming 3.7-3.8V). Therefore, the estimated energy density is in the range of 272-296Wh/kg.

Will the 4680 battery evolve into its third generation?These data may not be clear to everyone. The Limiting Factor has compared the 4680 battery with the 2170 battery.

One unexpected thing is that the steel shell of the 4680 cell is much thicker than that of the 2170 cell. This may be because the 4680 battery needs to bear more force in the car body structure.

Based on this video, the weight loss caused by the 4680 battery is estimated to be 10-15%.

This weight increase means that when looking at the data alone, the energy density of the two batteries is not as high as expected. The energy density of the 2170 is about 263-276 Wh/kg, while that of the 4680 is 272-296 Wh/kg.

Of course, because the 4680 battery adopts a structural assembly design, when calculating the proportion of the entire vehicle battery, the performance improvement is more obvious.

This has led to two rumors.

One is that the Model Y currently produced by Giga Texas is only called the Model Y AWD, not the Long Range version. In other words, its positioning is actually closer to the Standard Range model. According to Tesla’s consistent product positioning, there must be a long-range version with 4680 batteries.

The existing standard range battery pack consists of 690 4680 cells with a total capacity of 67.620 kWh.

Therefore, based on an increase of about 20%, it is estimated that the long-range version will use 828 cells, forming a battery pack with a capacity of 81.144 kWh.

The second is that there was already an internal rumor at Tesla that the current 4680 battery (98Wh) is only the first-generation technology in the plan, and there will be two generations of updates in the next few years. It will be upgraded to 108 Wh by 2023 (an increase of 10%), and 118 Wh by 2024 (an increase of 9.3% compared to 108 Wh).

Converted into energy density, they are:

Generation 1: 276 Wh/kg Generation 2: 305 Wh/kg Generation 3: 333 Wh/kgPerhaps when we see the 4680 battery in the Shanghai factory, it will already be a stronger version.

The scenery is not unique here

As Tesla’s 4680 battery path continues to grow, more competitors have also chosen this track.

Rimac, who has always secretly competed with Roadster 2 on the track, also talked about their development of the 46 battery family yesterday.

Like Tesla, these battery cells are larger, more energy-dense, and have the same diameter of 46mm, but Wasim Sarwar Dilov, Rimac’s head of research and advanced engineering, said that the batteries they produce will be a large family, and the height will not be locked at 80mm but will be flexible.

The change in height is mainly to adapt to various high-performance car models. Rimac stated that this system is not only for its own use but is currently in negotiations with 5 automakers. In addition to Rimac and its shareholder Porsche, Rimac has identified Aston Martin’s Valkyrie and Koenigsegg from Sweden will use this battery.

Rimac also emphasized that there are a total of 12 collaborative projects in progress, and in order to achieve rapid mass production, they will work with 3 different battery manufacturers.

At the same time, Rimac wants to learn to the fullest, and they stated that they will no longer use the current battery module design but will directly upgrade to a structured battery pack.

Rimac is also working to make the battery provide the best possible conversion efficiency. The efficiency of their flagship model, Nevera, is currently 67%, but their goal in 2025 is to develop a 46mm cell module with 75% efficiency per battery.

The 46 battle is imminent. Whether Tesla can remain competitive or whether other companies can bring the heat remains to be seen.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.