Eating Watermelon while Watching the Big Shots Quarrel

It is human nature to enjoy watching big shots quarrel with each other.

The story background is straightforward: Yu Chengdong, taking advantage of the launch of the new vehicle of Huawei, claimed that “Range-extended Electric Vehicles (REEV)” is the most suitable new energy model and called for the “rapid elimination of gasoline vehicles”. At the same time, he tweeted to praise Li Xiang for being a pioneer in REEV in China, and Li Xiang retweeted and replied with a business heart.

One who can’t bear to watch the happenings is Li Ruifeng, the CEO of WEY, owned by Great Wall Motor. He bluntly stated that “it is an industry consensus that the range-extended hybrid technology is outdated,” while their own DHT series hybrid technology is “the best in the world”.

When the big shots open their mouth, the “Big Vs” start running. For a moment, various Key Opinion Leaders (KOL) mutually agreed and entered their respective roles…

Yu Chengdong, a well-known figure in the industry for his outspokenness, was not expected to suddenly go berserk as a traditional independent automaker of Great Wall. It turns out that nowadays, it is not only the commoners who are working in cubicles, but also CEOs must be good at arguing and refuting each other to be productive. The joys and sorrows of the contemporary workplace meet in this moment…

Whether it is the advertisement-flavored “call” of Yu Chengdong or the undisguised “opening the quarrel” of Li Ruifeng, friends with a good sense for the Internet can easily see that the proactive marketing of this matter far outweighs the technical debate.

When the big shots quarrel with each other, it doesn’t prevent us from choosing what we want to see. So, ignoring the mouth-additives of both sides, only in terms of the two hybrid technology routes of REEV and DHT, is the “industry consensus” mentioned by Li Ruifeng true that “range-extended hybrid technology is outdated, and DHT hybrid technology is more advanced”?

YES and NO, it is, but it is not.

REEV and DHT, only differ by one cut.

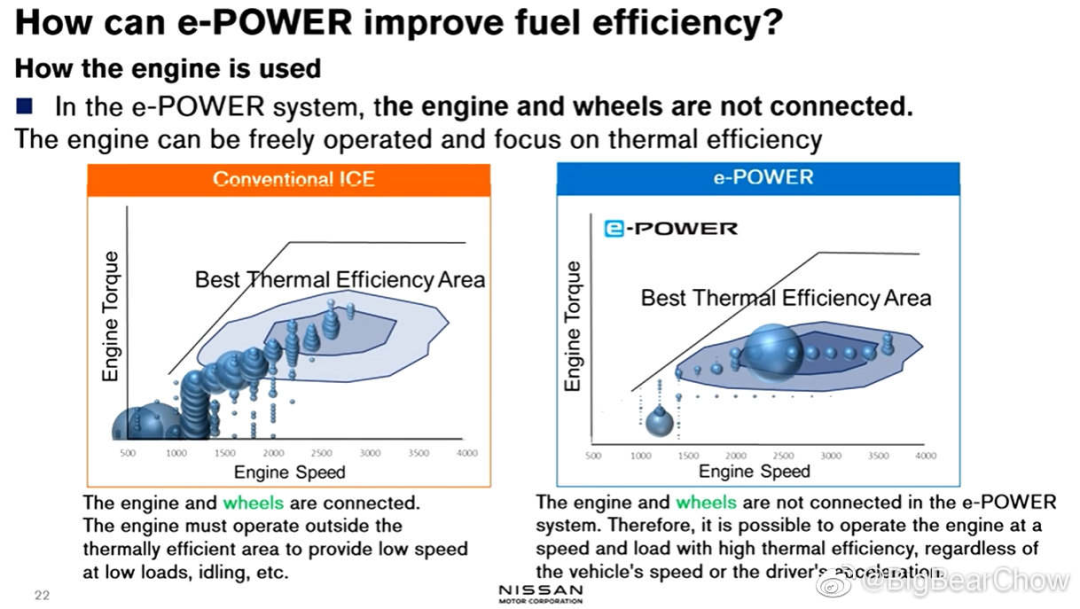

Range-extended electric vehicles (REEV) are easy to understand: The gasoline engine serves only as a generator for electricity, the electric energy can be used for directly driving the wheels of the vehicle, or it can be stored in the battery, and supplied to the electric motor when needed. Since the gasoline engine is always upstream of the electric motor in this path, the oil-electric power is transmitted in a relay-like manner along “one line”, hence it is also called a series hybrid.

This hybrid mode, which was once considered a “performance without actual effect,” aims to decouple the wheel speed from the internal combustion engine speed. The speed of the internal combustion engine no longer needs to surge with the vehicle’s movement, but instead, it works in a high-efficiency zone as much as possible, so as to improve efficiency and reduce energy consumption.“`

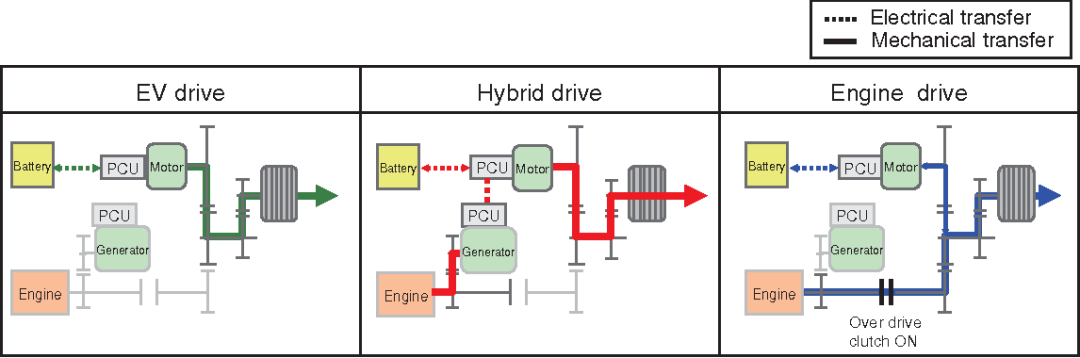

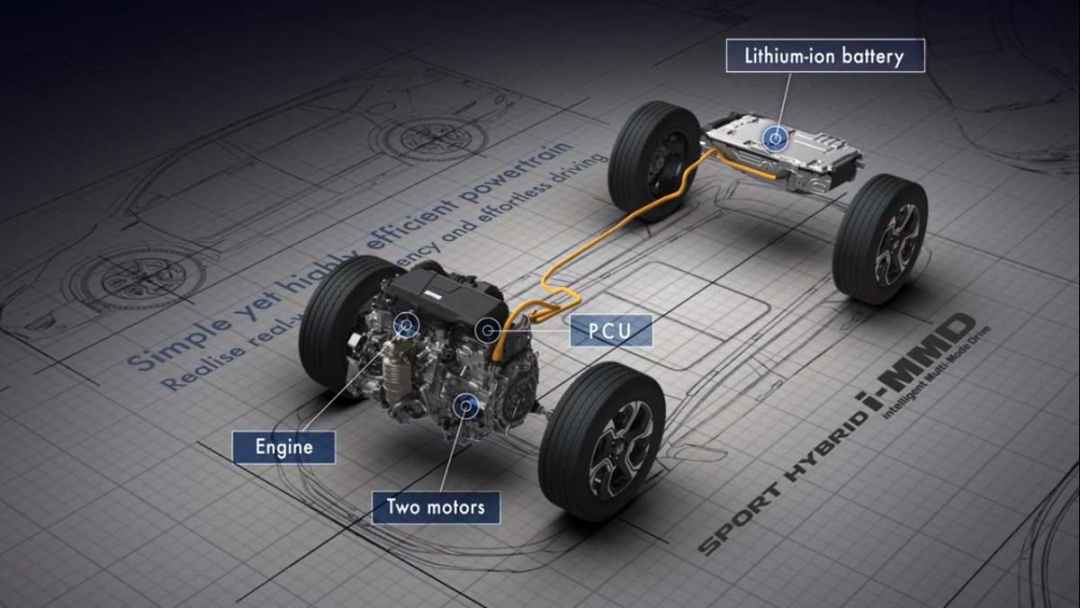

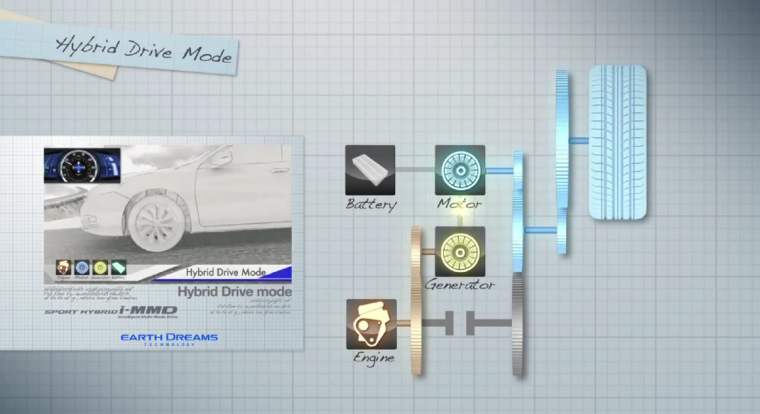

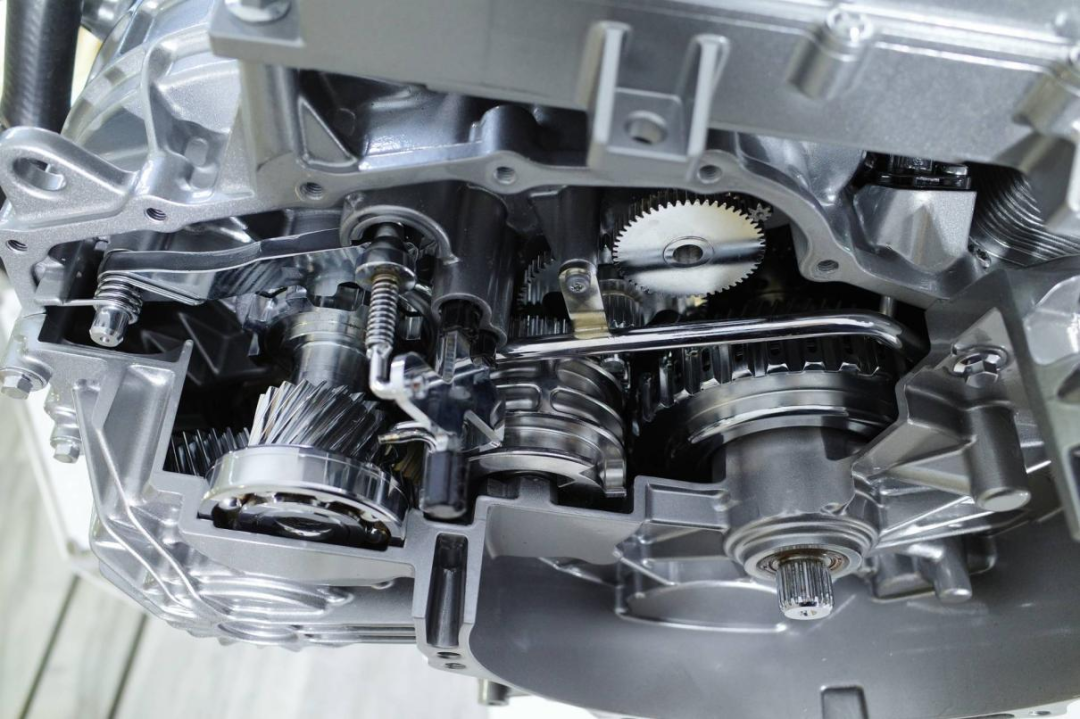

Series Parallel DHT is one of the DHT hybrids, and it is also the most popular DHT hybrid route nowadays. Its source is Honda i-MMD. Series parallel DHT can switch between serial and parallel by opening and closing a clutch.

As shown in the figure below, in the hybrid mode state, the clutch is disconnected and the engine is used for power generation and to provide power to the motor to drive the wheels. This is no different from a series extension hybrid; in the engine drive state, the clutch is closed and the engine power and motor power converge to drive the wheels together, and they are in parallel.

In fact, the reason why i-MMD was amazing at the time was that in the world of parallel hybridism at that time, Honda took the lead in introducing a series working mode by taking advantage of a clutch. That is the originality of i-MMD at that time, which added the “extension” as a working mode to the hybrid system.

So when the ideal ONE was born at the beginning, many Honda fans who were familiar with i-MMD exclaimed familiarly. The final products of the two are quite different: one is a PHEV with a super-large battery, and the other is a HEV (the main promotion at that time); one is a series extension hybrid, and the other is a series parallel DHT, but a part of the internal principle is indeed similar.

If you cut off the mechanical connection structure between the engine and the wheels on a series parallel hybrid like i-MMD (even if you just keep the clutch from closing permanently), abandon the ability of the engine and the motor to drive the wheels in parallel mode, and let the engine be used only for power generation as an extender- abandoning the possibility of direct drive by fuel, what you get is a series, an extension hybrid.

“`The size of the battery can actually be ignored. The extended-range hybrid (ER-Hybrid) can also develop small batteries, although there are very few cases, such as Nissan e-POWER. Meanwhile, series-parallel DHT hybrid is acceptable for both HEV and PHEV. Honda used to focus on HEV, but in recent years, it has also launched large-battery PHEV based on i-MMD. Not to mention DHT-HEVs and DHT-PHEVs from independent brands nowadays.

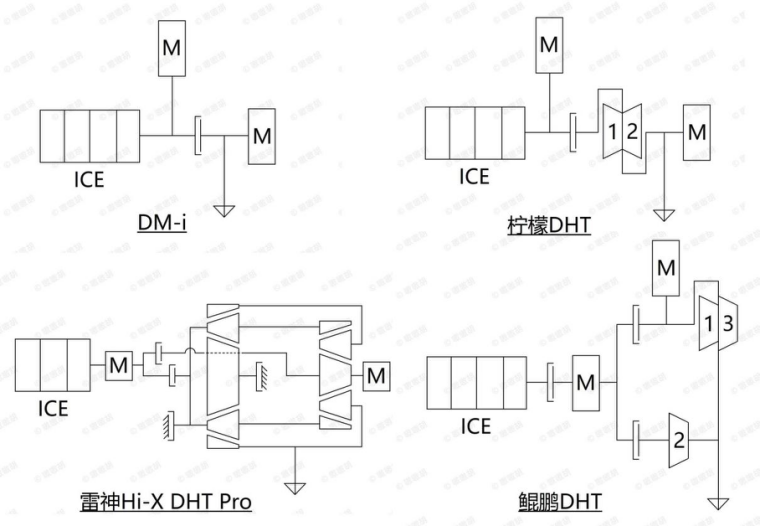

Series-parallel DHT was pioneered by Honda, and almost all independent car companies have followed suit in the past two years. In addition to Great Wall Motors’ Lemon hybrid DHT, there are BYD DM-i, Geely Lynk & Co. 05 PLUS, Chery Tiggo 8 PLUS, Dongfeng Mach and GAC Trumpchi 2.0, etc.

Therefore, success or failure should not be judged by the sales volume alone, and the DHT technology itself should not be underestimated. Even just by the result, there is the BYD DM-i, which has a sales volume that can compete with those in the same camp.

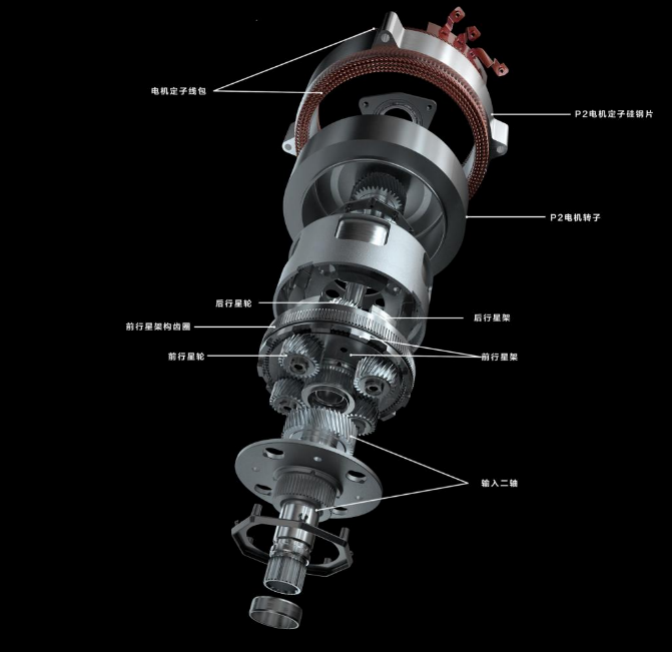

Due to technology selection and patent avoidance needs, the DHT technology of each independent brand mentioned above has many differences, some even “permeated” with some Toyota’s power distribution ideas (Geely). However, the core principle is based on the series-parallel DHT that is similar to i-MMD, and the main difference lies in the number and implementation of direct-drive gears.

For example, Great Wall Lemon hybrid DHT added two direct-drive structures, Geely Lynk & Co. 05 PLUS used two sets of planetary gear sets to achieve three gears, Chery Tiggo 8 PLUS gained the so-called “9-mode 11-gear” structure with a similar 3-gear DCT structure, and BYD DM-i is the authentic single-gear series-parallel. If interested, jump to “Just to Hybrid Better, the DHT Universe Gets Crazy“.

Compared with the ER-Hybrid, these DHT hybrids can all drive the wheel directly with the internal combustion engine, and some even use mechanical gears to provide multiple gears when driving electrically. Even compared with the simplest single-track direct drive vehicle members, Honda i-MMD and BYD DM-i, the ER-Hybrid has lost a clutch and the corresponding direct-drive capability.

If only “more and fewer” criteria are used to evaluate, the ER-Hybrid is obviously “lagging behind” series-parallel DHT hybrid. This is probably the basis for Li Ruifeng’s recognition of the “industry consensus.”

The Presence or Absence of Direct Drive Determines Everything

Of course, the debate is not that easy to end.Compared to DHT, it’s more accurate to say that the i-MMD hybrid system simplifies rather than falls behind – and simple doesn’t necessarily mean inferior. Compared to the simplest single-ratio system in a DHT, the key feature that the i-MMD hybrid system lacks is direct drive capability.

The rationale for maintaining direct drive capability is related to the operating characteristics of internal combustion engines. It is well known that the most economical operating condition for a fuel-powered vehicle is steady-speed driving at medium-to-high speeds. At this time, the internal combustion engine runs in the most efficient operating range, and the advantage of the electric motor over the internal combustion engine is minimal.

At the same time, for increased range hybrid systems (as well as the series mode of DHT), the mechanical energy of the internal combustion engine needs to be converted into electrical energy first, and then the electric motor converts the electrical energy back into mechanical energy of the wheel. Compared with the internal combustion engine directly driving the wheels, this will bring about a single-digit percentage of additional energy conversion loss (Ideal ONE once gave a value no higher than 10%).

Considering factors such as cost, volume, and weight, ideal models of such large increased range cars typically choose small-displacement range extenders. Since the best energy consumption range of an internal combustion engine is directly related to the displacement, the power required for high-speed cruising of these large vehicles may exceed the high-efficiency range provided by small-displacement range extenders. That is, the higher the speed, the more likely the generator will deviate from the high-efficiency range.

When these factors are combined, as the vehicle tends to stable high-speed cruising, the relative advantage of electric motors over internal combustion engines in terms of efficiency is not so significant. When Ideal ONE was released in 2019, it admitted that compared to same-level fuel-powered vehicles, there was no advantage in fuel consumption at high speeds as there was in low-speed operating conditions, which was verified by real-world car owners’ feedback later on.

To weaken this disadvantage, ideal and other increased range hybrid systems generally use large batteries (PHEV), with larger “water tanks” to meet high-power demand during high-speed cruising. The cost of this approach is naturally higher battery costs, performance limitations when the battery is critically low and recharging is not yet available, and reduced user experience if the user relies solely on fuel without plugging into a charging station.

Therefore, for consumers who have daily high-speed, long-distance commuting and especially those who have more highway driving and have less convenient access to charging, the Ideal and WENJIE-type increased range hybrid systems are not the best option. Although this type of consumers is not many, it is not just a “small minority.”

另一头,支持舍弃直驱能力的理由,与多数用户的实际需求、车企的发展选择有关。首先,尽管存在一部分数量不可忽视的消费者,明确知道自己高速需求偏多,但如今多数消费者的用车需求,其实是城区拥堵环境居多的日常通勤,只是集中程度不尽相同。

另一头,支持舍弃直驱能力的理由,与多数用户的实际需求、车企的发展选择有关。首先,尽管存在一部分数量不可忽视的消费者,明确知道自己高速需求偏多,但如今多数消费者的用车需求,其实是城区拥堵环境居多的日常通勤,只是集中程度不尽相同。

The reasons for supporting the abandonment of direct drive ability are related to the actual needs of most users and the development choices of automotive companies. Firstly, although there is a considerable number of consumers who explicitly know that they have a higher demand for high speed, the demands of most consumers today are actually daily commuting in urban congestion environments, with varying degrees of concentration.

越是低速拥堵,内燃机直驱的价值就越小。司机师傅们都知道堵车走走停停最费油,即便串并联 DHT 此时也会倾向于串联增程模式。对于只是偶尔走高速的多数消费者,增程式缺少直驱就并非不可接受,高速巡航的能耗偏高也会被大量日常通勤所平均掉。

The value of internal combustion engine direct drive decreases as traffic congestion becomes slower. Drivers know that stop-and-go traffic consumes more fuel, and even in the case of series-parallel DHT, it tends to be in series with extended range mode. For most consumers who only occasionally drive at high speeds, the lack of direct drive in extended-range hybrid vehicles is not unacceptable because high-speed cruising power consumption is offset by a large amount of daily commuting.

直驱所需的机械结构虽然谈不上沉重(尤其是相对于大电池而言),但增加的复杂度是无法忽略的,那些多挡位的串并联 DHT 尤甚,日常维护保养节奏基本要看齐纯燃油车。而无直驱的增程式混动,理论上更容易获得更好的机械可靠性和可维护性。

Although the mechanical structure required for direct drive is not heavy (especially relative to large batteries), the increased complexity cannot be ignored, especially in the case of multi-gear series-parallel DHT, where the maintenance pace for daily maintenance needs to be geared towards pure gasoline vehicles. Extended-range hybrid vehicles without direct drive are theoretically more likely to achieve better mechanical reliability and maintainability.

更具决定性的因素,其实是企业自身的发展路径。

A more decisive factor is actually the development path of companies themselves.

内燃机直驱谈不上什么高科技,但对于全无相关积累的新造车存在门槛。这种门槛并非粗暴的 「不会造 or 不会调」,而是在电动化大趋势下,新造车纵有无限资源,也不会有足够意愿投入到费时费力、却很可能再用不了几年的机械变速器方面。

Internal combustion engine direct drive is not considered high-tech, but it presents a threshold for new carmakers with no relevant expertise. This threshold is not crude “cannot manufacture or cannot adjust”, but rather, in the trend towards electrification, even new car manufacturers with unlimited resources will not have enough willingness to invest in mechanical transmissions that are time-consuming and labor-intensive, but may be of little use in the future.

技术经验积累是如此,生产供应链与售后体系更是如此。新造车企业倘若选择带直驱 DHT,哪怕十年后已经转型纯电,依然要为今天这一小批混动车提供机械传动方面的支持,这种决定的必要性显然不高。本来就有大批燃油车要 「伺候」 的传统车企则没这个顾虑。

The accumulation of technological expertise, as well as the production supply chain and after-sales system, shows this trend. If new car companies choose direct drive DHT, even if they transition to pure electric vehicles ten years later, they will still need to provide mechanical transmission support for this small batch of hybrid vehicles. The necessity of this decision is obviously not high, while traditional automotive enterprises that already have a large number of gasoline vehicles to “look after” do not have this concern.

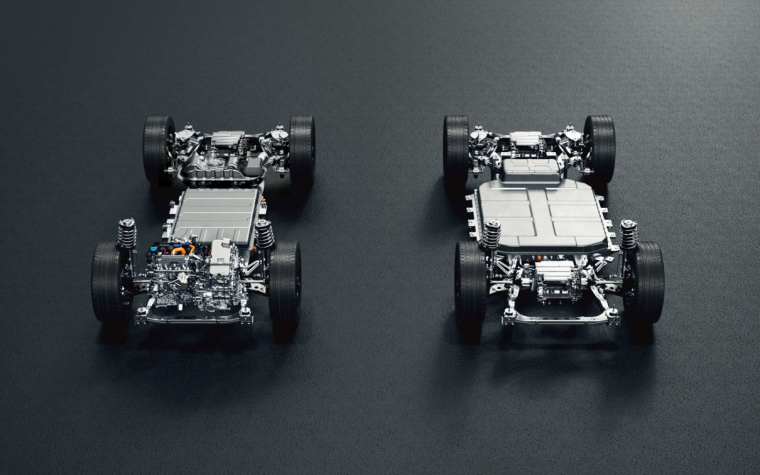

车型平台的发展需要,也让新造车更偏爱方便衍生纯电版本的增程式混动。像问界甚至可以像电动车那样,推出后驱单电机版本;而带直驱的 DHT 混动因为机械传动结构,则必然要以前驱为主。对于 「有根基」 的传统自主车企这没什么,对于白纸起步的新造车则是多了一层茧,于是大可不必。

The development needs of vehicle platforms also make new car manufacturers prefer extended-range hybrid vehicles that are easy to derive pure electric versions from. Like the Wanjie, it can even be launched as a rear-drive single-motor version like an electric vehicle; while direct drive DHT hybrid vehicles must prioritize front-wheel drive because of their mechanical transmission structure. This is not a concern for traditional independent automotive enterprises with “foundations”, but for new car manufacturers starting from scratch, it adds an extra layer of obstacle and is therefore not necessary.

现实面前,理论请往边靠

In the face of reality, theory should be put aside. This is actually a very typical “simple system vs complex system” problem.Does simplifying a system and removing some components necessarily mean poorer performance? If the answer is yes, how can we explain why the simplest BYD DM-i has been sold out despite the fact that other domestic independent brands have more complicated DHT hybrid technology? If market results don’t necessarily correspond to product performance, is i-MMD/DM-i the worst DHT? Probably not.

No matter how sophisticated a design principle is, the ultimate result depends on the subsystems and components that determine and affect it. Even if the principle is perfect, it needs material and technology to make it real. The principle of gas-powered automatic rifle is more advanced than that of bolt-action semi-automatic rifle, but if you use soft plastic 3D printing to make an AK-47, you won’t dare confront someone using the original 98K.

Applying the extreme method of thinking, if a series-parallel DHT has more direct drive than an extended-range system, but the vehicle weight is increased by one ton, does this direct drive still have any meaning? If the thermal efficiency of the internal combustion engine matched with this DHT is 10% lower than the extended-range hybrid’s range extender, can the direct drive help overcome the disadvantage of this DHT? Such examples are abundant.

Of course, in reality, most people are roughly equivalent, without black technology, and not too inferior. Therefore, the final product result depends on the superposition of the subsystems and components’ excellence. The lack of direct drive in an extended-range hybrid can be compensated by higher efficiency range extenders or motors, and a series-parallel DHT having more work mode options may still experience low transmission system efficiency enough to drag the entire system down.

Even if the parts’ manufacturing process is excellent, the final product’s software and tuning can still affect it. Simple systems provide fewer combinations, which theoretically limits the system’s maximum potential, but also makes available paths simpler to navigate. An extended-range only needs to consider electric drive because it provides electric drive only, while a DHT needs to consider all possible combinations of direct and electric drives.

More complex systems offer more possibilities, and theoretically, precise differentiation can lead to greater efficiency, like some multi-gear DHTs providing double-digit work modes. However, on the one hand, the patient and time required to calibrate the system dramatically increase, and on the other hand, even if the best operating map is determined theoretically, actual execution does not necessarily match the simulated software. Therefore, insignificant execution motions need to be eliminated.

All these require time, resources, and increase risk. This is a balancing act that cannot be judged in absolute terms, and the optimal choice should vary among different manufacturers according to their abilities.

Whether to eat ads or not, everyone knows to check if it works.Even if there are performance advantages realized through technology, one still faces a problem that is beyond their control: whether these advantages are easily perceivable and noticeable in actual user scenarios. To illustrate with an extreme example: suppose a user has a built-in traffic-jam-inducing effect like Chinese singer Xiao Jing Teng; no matter how much Direct Hybrid Transmission (DHT) is involved, the user’s driving speed will never exceed 40km/h.

In reality, in the world of hybrid vehicles with varying degrees of complexity, more gears and more complex DHT technologies often correspond to a stronger tendency towards Hybrid Electric Vehicle (HEV) models. This is similar to how Direct Hybrid Transmission (DHT)-less Extended Range Electric Vehicles (EREVs) have largely evolved into Plug-in Hybrid Electric Vehicles (PHEVs) with larger batteries nowadays.

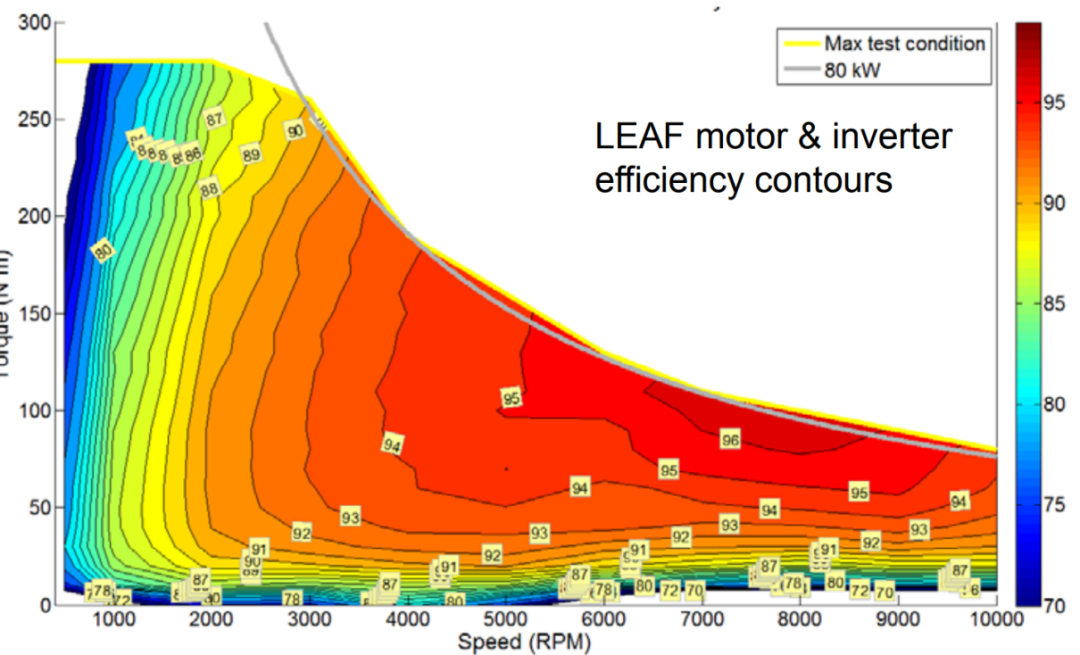

Many people know that motor efficiency can reach over 90%, far exceeding the thermal efficiency of the most efficient internal combustion engines at 40%. However, similar to internal combustion engines, the efficiency of electric motors may drop in certain working conditions such as low speed and high load, and sometimes it can fall below 80%.

Therefore, for HEVs or non-plug-in PHEVs, where battery energy is entirely obtained from burning oil by the internal combustion engine, if there is no direct drive, the energy utilization efficiency of fuel in low-speed operating conditions may be as low as 40% ( thermal efficiency of the internal combustion engine) x 90% ( oil-to-electricity conversion loss) x 80% (low-speed motor efficiency) ≈ 29%.

Of course, this is just an estimate, but the order of magnitude is sufficient to explain the problem: series hybrid mode may have a low fuel utilization rate after one round of oil-electricity conversion, and sometimes it may even be low enough to warrant consideration of whether direct drive would be more economical.

Therefore, manufacturers such as Great Wall, GAC, and Chery, who need to consider the HEV market, have added direct drive gears to their DHT to expand the speed range where the engine intervenes. By using a more diverse fuel-electric hybrid drive force and flexibly allocating the load ratio between the internal combustion engine and the electric motor, they aim to achieve the lowest possible comprehensive energy consumption performance.

The BYD DM-i completely disregards HEVs; for PHEVs that are charged by connecting to the grid, since electricity is much cheaper than fuel, energy utilization efficiency is no longer a metric that needs to be counted meticulously. Although car owners may get anxious about the numbers on the gas gauge, they are less concerned about a couple extra dollars on their electricity bills. As for PHEV users who find it inconvenient to charge, they have their own expectations of higher fuel consumption; this is tactical abandonment.

In the debate of range extender vs series-parallel hybrid, for a group of users who spend 99% of their time stuck in city traffic, the energy efficiency advantage brought by the range extender may be so small that they don’t even notice it. If they have a certain level of charging convenience (without the requirement of a fixed charging pile), then except for occasional long-distance trips that may shock them with fuel consumption, the range extender may not be the best choice for them.

For this group of users, the “advanced” advantage brought by the series-parallel hybrid’s direct driving ability has become unnecessary. On the other hand, for another group of users, who may have longer commuting distances, may not encounter traffic jams in their cities, or may not have any charging facilities at all, the series-parallel hybrid may be the more suitable choice.

A basic principle that must be explained is that people are different. Different consumers have different needs, and therefore the most suitable products for them are also different. However, we usually define “advanced” based on the usage needs of the majority of ordinary users. At this point, the question changes from “who is more advanced” to “what is considered the majority?”

Whether a consumer product will be recognized by the public is not determined by how flashy or avant-garde the technology is, how advanced the concept is, or how superior the performance is. It depends on whether they meet the needs and preferences of most ordinary people. Is the flashy technology user-friendly enough? Does the avant-garde concept have practical use? Can the more superior performance benefit the user?

Consumers never buy technology itself, but the results brought by technology. Even if it is a 6.0L V12 engine, as long as you can achieve 1L/100km, the online ride-hailing drivers will abandon their Nissan Sentra and Toyota Corolla for it. Our curiosity about technology is to understand “how to achieve this result”, rather than just focusing on the process without considering the result.

We value technology tactically, but we should ignore technology strategically. Whether it is Garfield or Maneki-neko, as long as it makes people happy, it is a good cat.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.