Author: Zhu Yulong

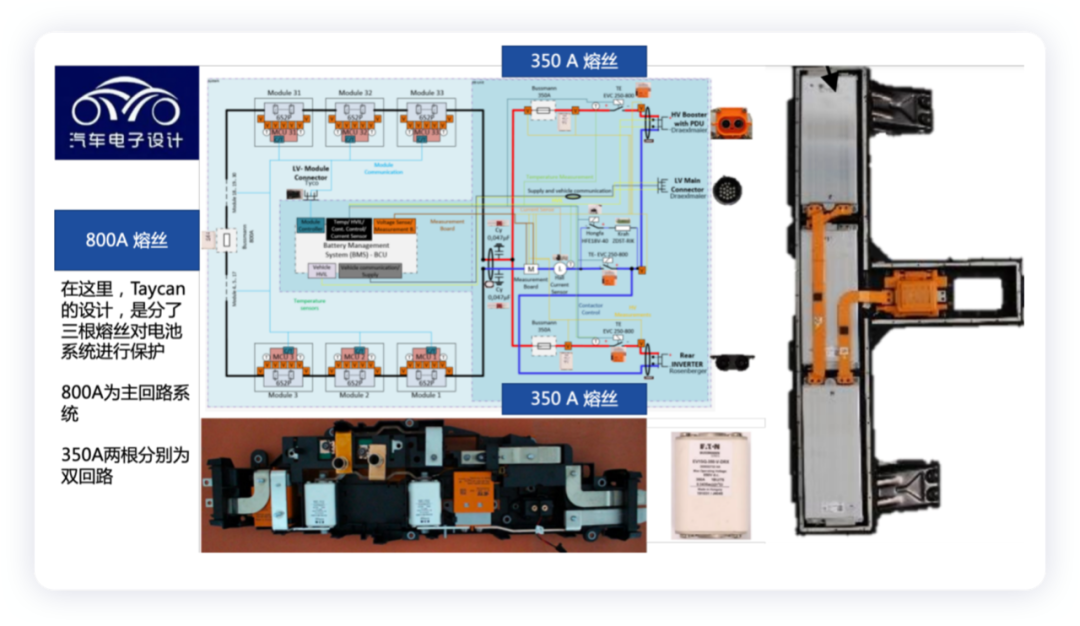

In the 800V whole vehicle system, due to the increase in voltage, the insulation requirements and short circuit protection measures of the entire system have been improved. I think this involves several core reasons related to the PyroFuse and fuses:

-

Under fast charging conditions, the continuous current of high-power charging is larger than the previous design specification, which easily causes premature aging of the fuse.

-

Increasing the specifications of the fuse makes it difficult to match with the high-voltage contactor, which is relatively fragile after 800V.

-

In the design of Tesla Model S Plaid, the design of the entire rear dual-motor greatly increases the peak current of the driving current, which also makes it difficult to match the dynamic current.

That is to say, the steady-state current that the fuse and the contactor need to match conflicts with the fast charging current, and the transient current of the short circuit protection starts to directly match the high-power driving current. The use of electric vehicles by Chinese consumers is relatively gentle compared to the global level. Once this design is used in Europe and the United States, the potential problem is that the protection requirements and extreme working conditions that consumers actually use are easy to coincide. Therefore, in my understanding, to meet these design requirements, we need to consider fast charging from 250A to 400-500A, and design the power of the drive inverter from 150kW to 250kW, or even higher to 300-350kW. PyroFuse is a necessity.

Tesla’s Circuit Design

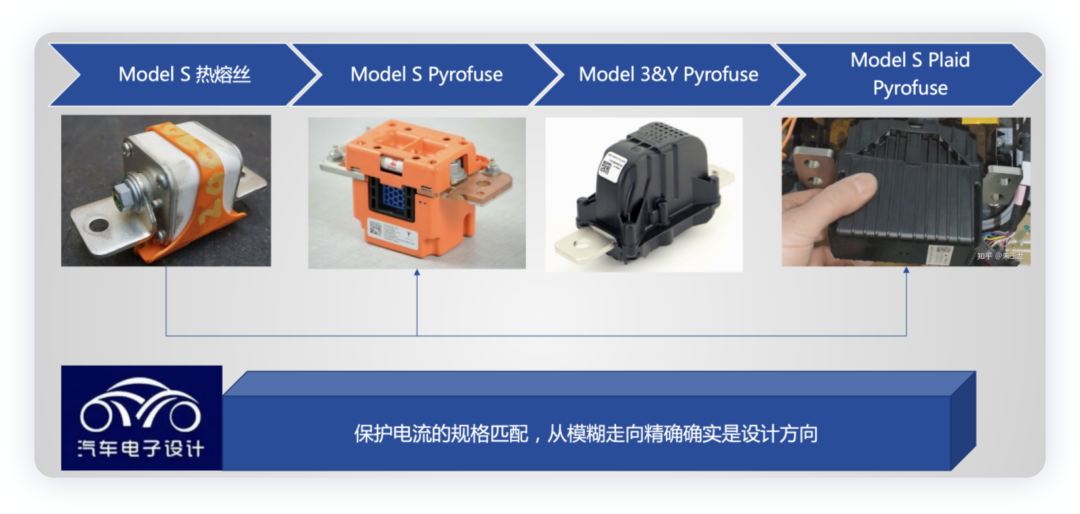

Tesla initially used fuses. From the current perspective, PyroFuse has also undergone three generations of technical iteration:

-

1st generation PyroFuse on early Model S

-

The 2nd generation product that is currently the most widely used in Model 3 and Model Y

-

The 3rd generation solution used in the latest S/X plaid model

This protective design is a microcosm of Tesla’s technological iteration and is actually the main technical direction from fuzzy protection current matching to precise matching. After that, we saw that Volkswagen’s MEB platform also made corresponding designs.

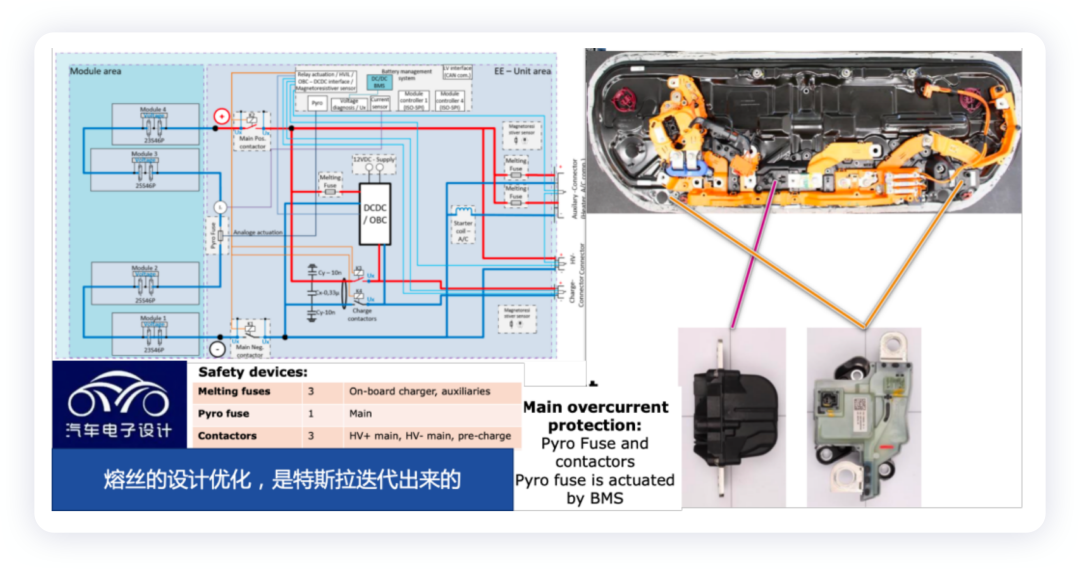

Tesla designed Pyrofuse, which is configured in the middle of the battery in Model 3/Y or Model S Plaid, and is now used as an independent maintenance unit. In the event of an external short circuit or collision in the entire high-voltage circuit, Pyrofuse can timely disconnect the electrical connection, ensuring the entire energy circuit is opened. Pyrofuse can be directly replaced through the maintenance window.

Tesla designed Pyrofuse, which is configured in the middle of the battery in Model 3/Y or Model S Plaid, and is now used as an independent maintenance unit. In the event of an external short circuit or collision in the entire high-voltage circuit, Pyrofuse can timely disconnect the electrical connection, ensuring the entire energy circuit is opened. Pyrofuse can be directly replaced through the maintenance window.

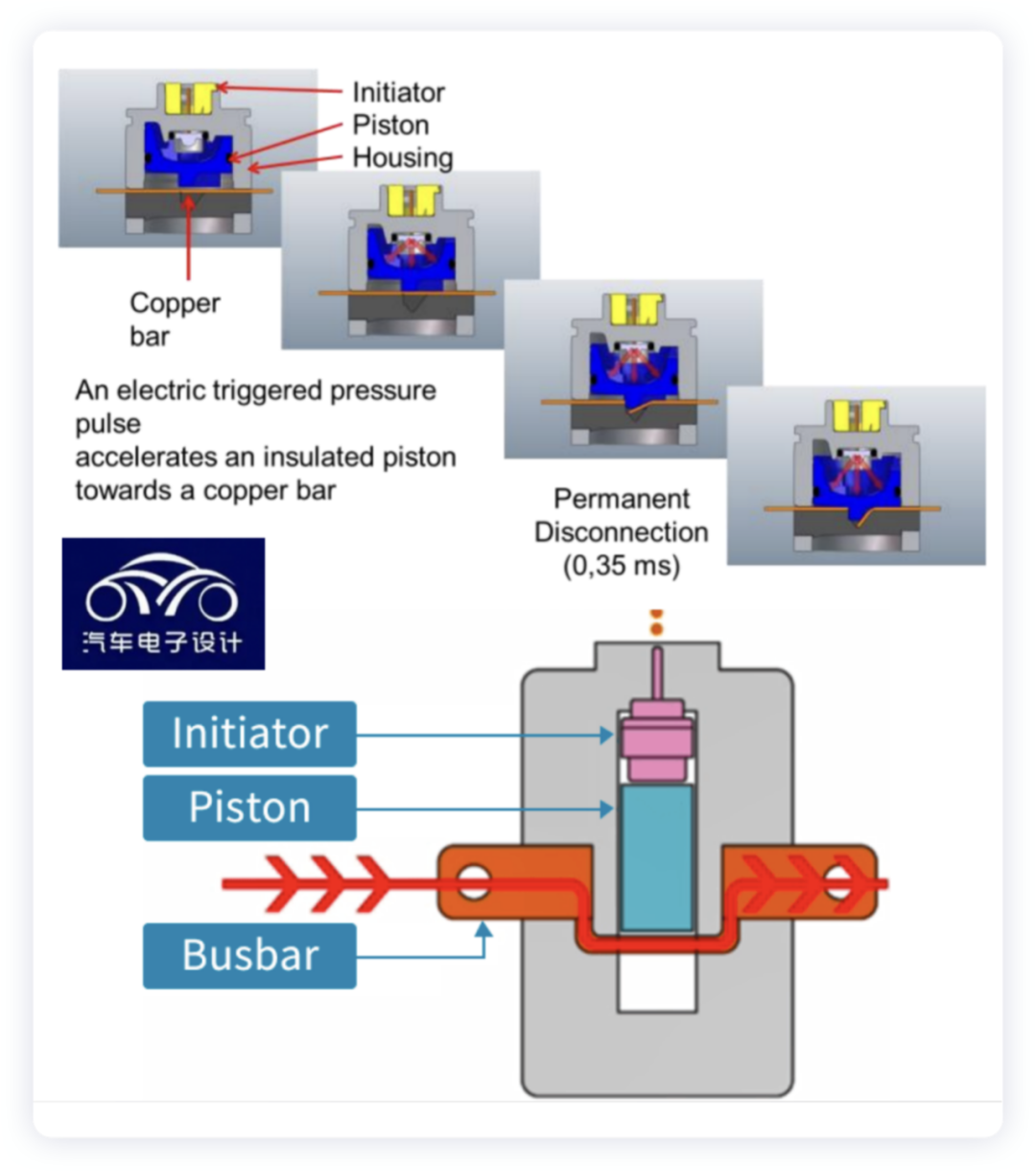

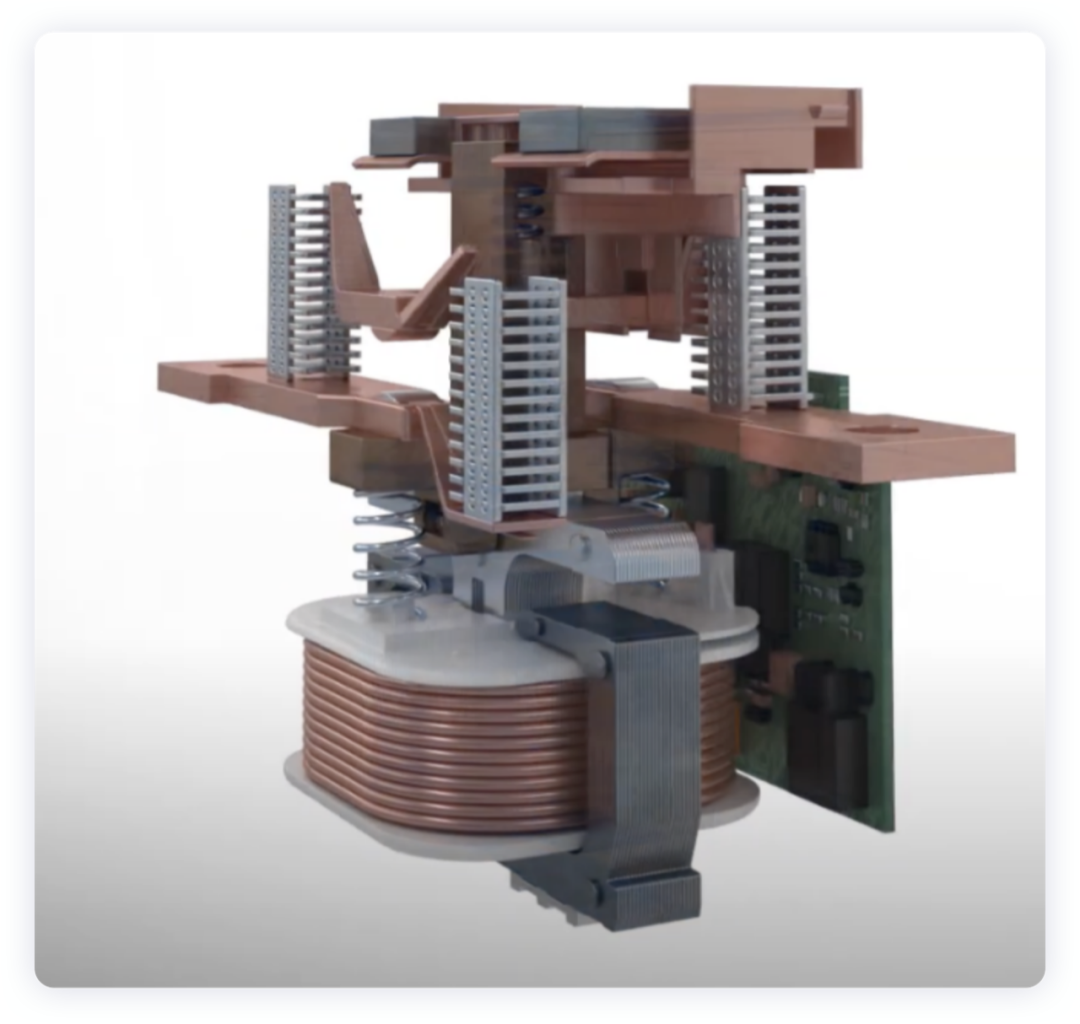

Pyrofuse was first introduced by Autoliv in the 12V system and includes several basic components:

- Igniter: This is the execution structure, which disconnects the connected circuit through the propulsive force after receiving the driving signal.

- External detection of current and circuit judgment usually requires a current sensor. There are two ways to handle this, one is that BMS is responsible for it, and the other is that Pyrofuse itself has current detection.

- Arc suppression device: Cutting off high-voltage current will generate a huge arc, so it is necessary to consider how to deal with the arc. Small arc suppression fuses can be used to attract and absorb the energy of the arc.

In terms of cost structure, the BOM of this Pyrofuse is relatively simple, and the structural components mainly include Busbar and arc absorption. Note that in order to switch connections, Busbar must be designed to be “weakened”. By designing a reasonable structural strength, Busbar can be disconnected when triggered. As for the arc absorption chamber, power equipment professionals should be familiar with it. This is a typical stacked design, guiding and absorbing the arc (including white composite material pads, mainly for flame retardant purposes).

The signal is transmitted through the lead at the top cover when triggered.

Circuit Design Cost

Tesla’s Iteration

-

Tesla uses BMS main control to let the high functional system of BMS arbitrate whether to disconnect the circuit, especially after using Bosch’s driving chip to improve this functional safety design.

-

From attracting the arc with parallel small fuses to using stacked arc extinguishing chambers later (dividing the arc into multiple small arcs, increasing the total voltage, thereby suppressing the current and interrupting the circuit).

-

On the triggering method, two triggers are used, configured in the trigger storage tank, one of which is to disconnect the busbar and release solid particles and heat energy. By triggering twice, the airflow is released to blow the arc (realizing the offset arc).

Therefore, let’s go back to Eaton’s breaker. If this breaker can really achieve the function of contactor + Pyrofuse, the entire electrical design will still undergo a significant change. This is equivalent to making the Pyrofuse work multiple times to cut off the circuit, and the disadvantage is that the arc extinction design needs to be very strong.

Summary: In terms of the design of the three-electric system, overall, electric vehicles and the entire electrical network familiar to us are actually integrated.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.