Author: Zhu Yulong

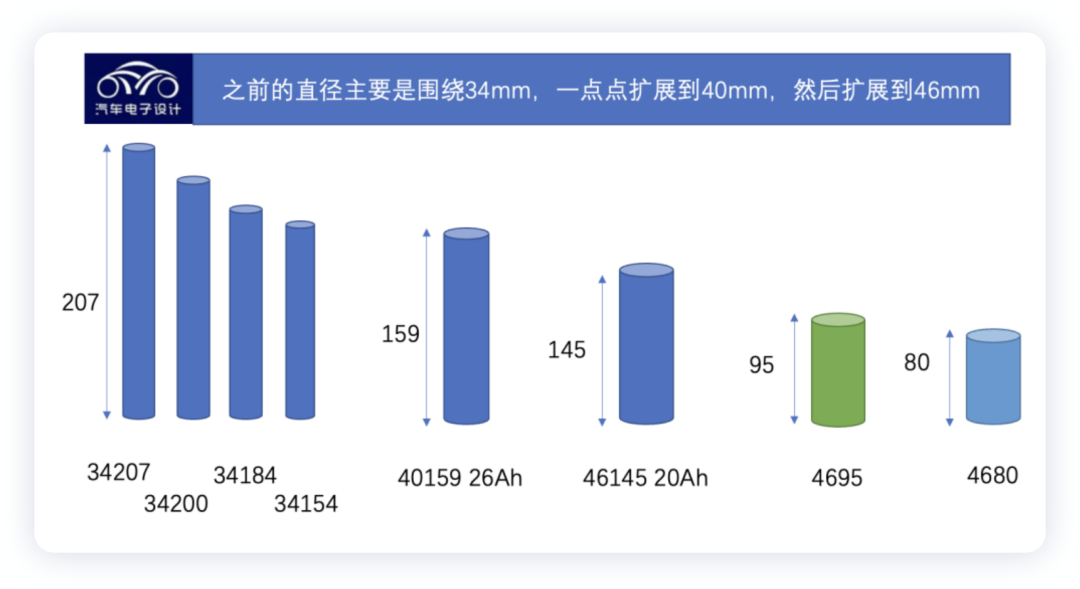

Recently, I came across something interesting regarding the future application of large cylindrical batteries. In C-family’s large cylindrical lithium iron phosphate batteries, the specifications are around 34mm (34154, 34184, 34200, and 34207), 40mm (40159), and 46mm (46145), with the diameter gradually increasing while the length of the cylindrical battery cell decreases, with capacities ranging from 20Ah to 23Ah. In my understanding, C-family employs a large cylindrical iron lithium system as a strategic hedge against small pouches, allowing several mainstream electric bicycles (Harley-Davidson and Xinnuo) to experiment. From the Pack’s perspective, 48v20Ah (0.96kWh), 60v20Ah (1.2kWh), and 109v92Ah (10kWh) are available for different energy configurations, which can be used for micro electric passenger vehicles.

Characteristics of 12V Batteries

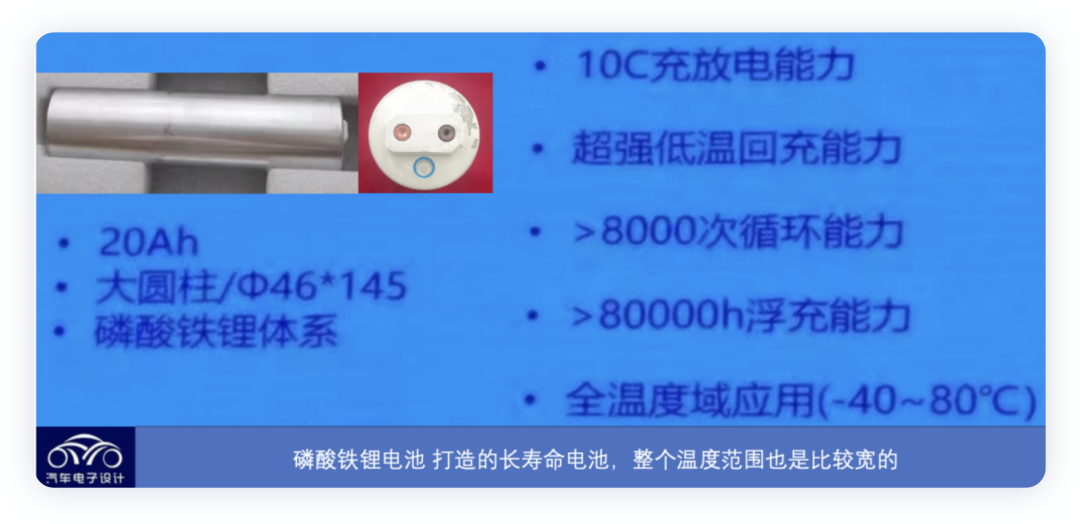

After Tesla and BYD adopted 12V lithium batteries, many companies began to consider them. In previous designs, Tesla used ternary square shells, while BYD used square or pouch-structured phosphate iron. This time, the 20Ah cylinder I saw is C-family’s first extension of a phosphate iron system, using the 46145 system, which happens to have a diameter of 46.

If we look at the evolution of this diameter from what we have seen before in small power batteries, it has gradually changed from 34mm to 40mm to 46mm. We then see news about BMW’s targeted cylindrical battery cells.

Battery size is actually based on the basic requirements of the Pack. Since the previous demand was mainly for the size of the electric bicycles, the large lithium iron phosphate cylindrical solution was compared with 1865 and 2170 in terms of energy. As a result, the overall size uses a horizontal mode. As the demand becomes more and more focused, especially with the emergence of the 4680 and 4695, the need for an entire vehicle where the batteries are standing up emerged. It makes sense to make batteries of different heights around the 46mm diameter.As SGMW’s main vehicle model, the overall demand specification is based on starting at 8kwh. With different battery specifications, interesting battery gradients can be created around 128V 60Ah (3P), 80Ah (4P) or 100Ah (5P), resulting in 7.68kWh, 10.24kWh and 12.8kWh.

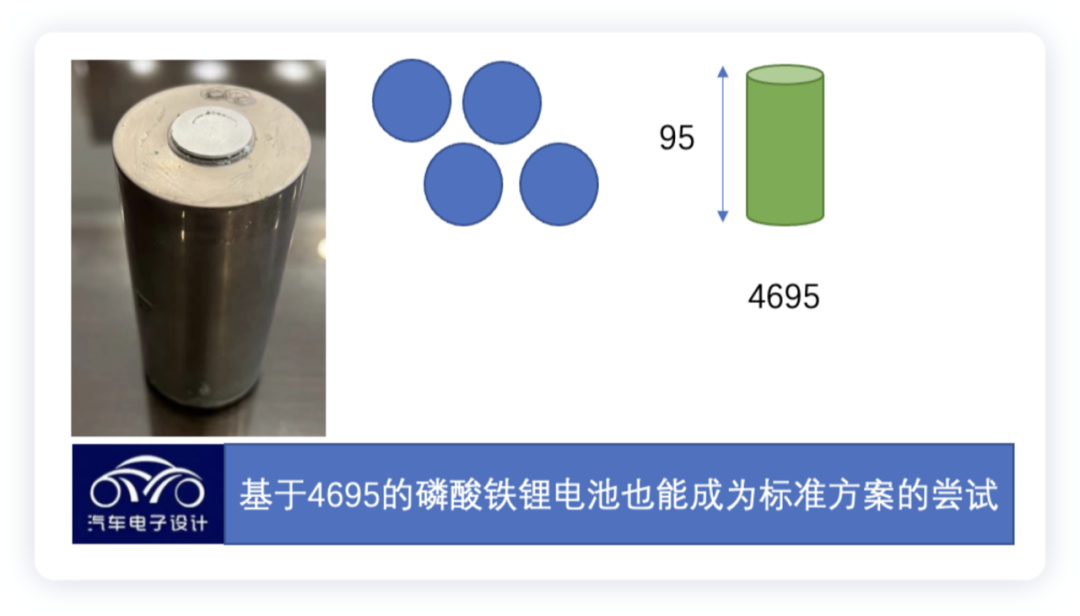

Therefore, we can explore the whole process. If we push the capacity of lithium iron phosphate to the limit, we can make a 13Ah lithium iron battery pack in the size of 4695 that can stand upright. This design does not require a pressure relief base and may be able to achieve a very standardized flexible plan in the A00 scheme.

Expansion of the 46 series

Based on this, we can analyze that in the future, cars may use 4680/4695. If we consider whether SUVs can adopt high-capacity schemes such as 46100-46120 to provide more energy, this means that with the appearance of the 46 specification, adjusting the height of the battery cell can bring more changes in energy.

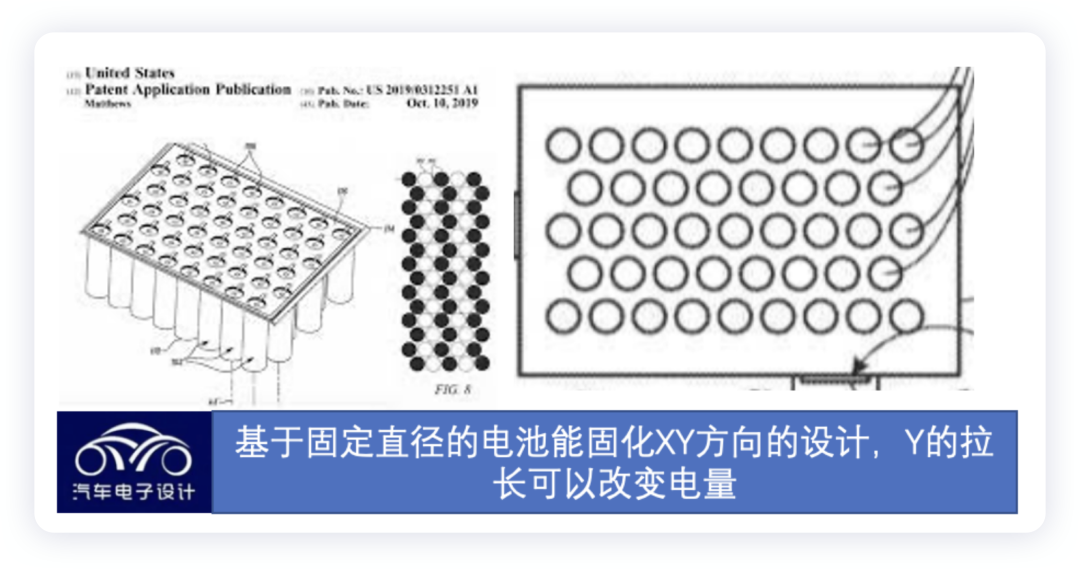

Due to the uniformity of the design of the cylindrical battery cell at the bottom and top, I think this extension can standardize the cylindrical standard battery cells and also make some subtle differences. Because this size specification is compatible with sedans, SUVs and future commercial vehicles, once the design can achieve early warning messages for protection against thermal runaway extension, it will be of great help to the entire industry.

Conclusion: I am thinking about the long-term value of the large cylindrical battery in standardization. It is a solution that can be extended in the Z direction and can replicate applications in different directions. I think it has great potential.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.