Author: Zhu Yulong

Munro Live announced that it will dismantle and analyze the Tesla Model Y made in Texas using the Tesla 4680 cylindrical battery, which is highly anticipated. Geeks have already performed teardowns, and on July 4, Qianbei wrote a report on the teardown of the Tesla 4680 cell. Based on his analysis, I will provide some interpretation in the hope that everyone can understand it.

Dismantling and Testing

Is Tesla’s 4680 Cell Housing Electrified?

In previous statements, there was a guess that “the steel shell of the 4680 cell is not electrified, so there is no need to add additional insulation materials, which can maximize the utilization of the battery system volume.” However, looking at the structure, this is incorrect.

Negative Electrode Current Collector and Cover Plate

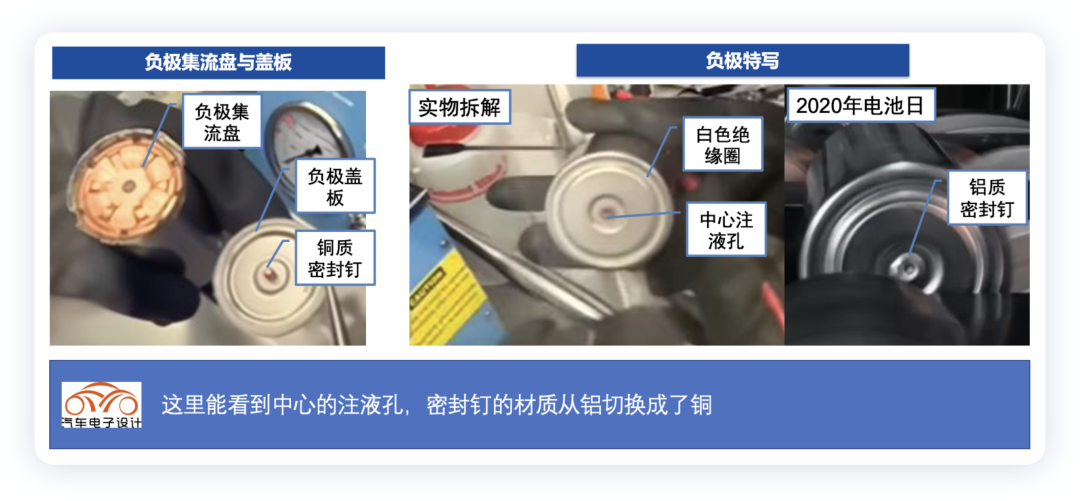

As shown in the following figure, the negative electrode current collector has elastic components, and the negative electrode cover plate is a white insulation material around the cell, with a protruding sealing pin in the center. It is sealed after filling from the center, and the material should be copper sealing pins. In the close-up photo, the white insulation ring of the cell is clearly visible. In the new version, the material for sealing the center filling hole has changed to copper, compared to the battery of the day.

The inside of the negative electrode cover plate has grooves that contact the elastic connecting piece of the restrictor disc, and then it is covered with an insulating ring, as shown in the following figure.

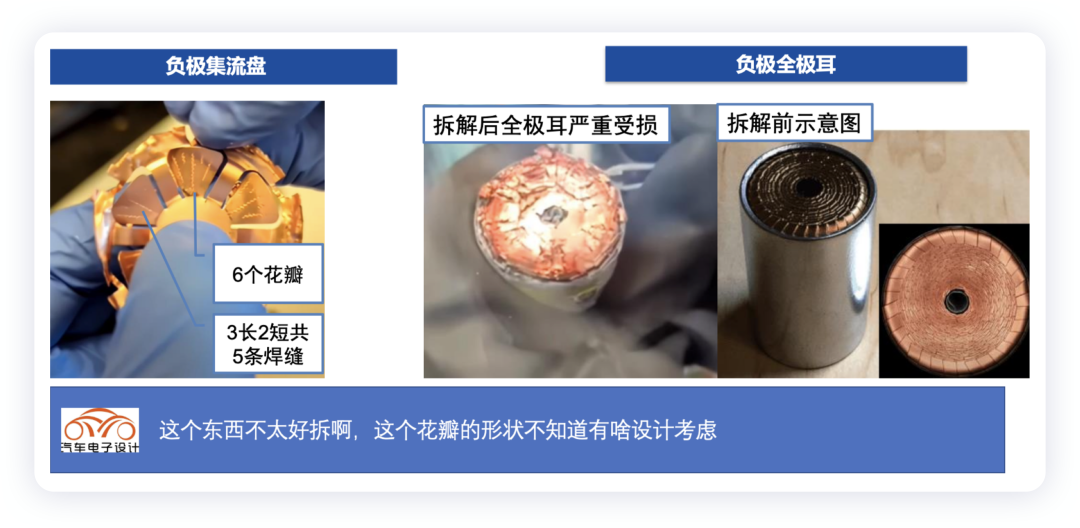

The negative electrode current collector is designed with great features, with a total of 6 petals, each with 5 welds, 3 long and 2 short, and all the earpieces are seriously damaged after dismantling.

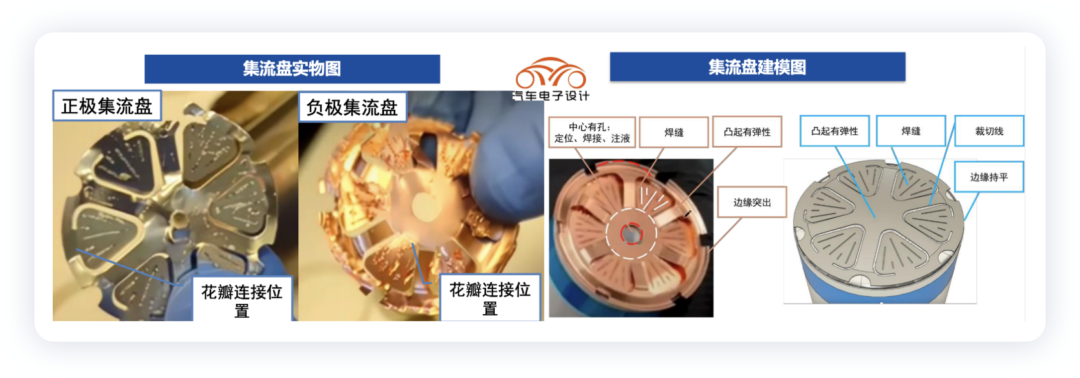

The positive electrode current collector is similar to the negative electrode, with 6 petals, 5 welds each, and 3 long and 2 short.

The differences between the two current collectors are:

- Positive current collector: connected to the petals and edges, with a thickness of 400μm.

- Negative current collector: connected to the center and petals, with a thickness of 260μm.

The two different materials were estimated to have some impedance matching calculations.

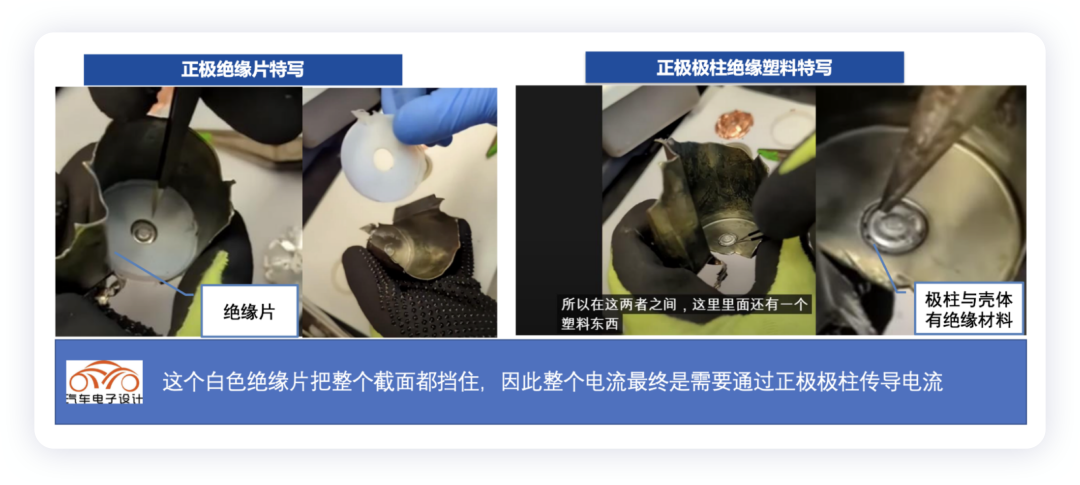

Here we also see the issue of insulation design. The positive insulation sheet covers the entire cross-sectional area of the cell, thus all current flows are eventually collected at the positive electrode column, and heat is concentrated in that location. This is also the main reason for the subsequent top heat dissipation (through the external busbar).

Then the 4680 casing was measured, with a wall thickness of 635μm, and the estimated mass of the cylindrical side is 58.2g.

Winding

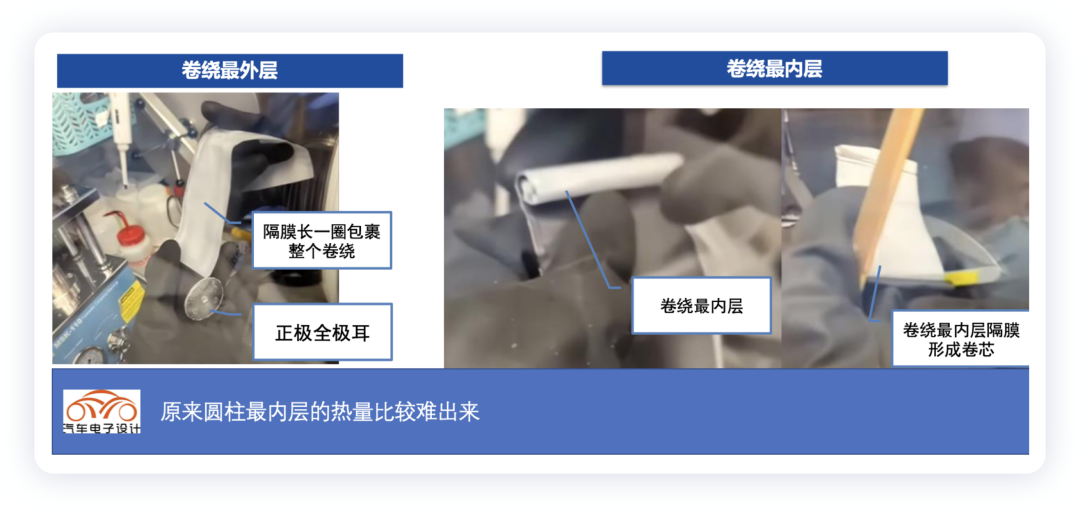

The 4680 winding uses two kinds of insulating tapes, yellow and green, as termination tapes. From the design perspective, there is a safety gap between the positive electrode coating and the aluminum foil edge, and the positive foil tab is clearly visible and tightly arranged.

- Outermost Layer of Winding: The separator wraps around the entire winding for one circle.

- Innermost Layer of Winding: The separator of the innermost layer forms the winding.

Here, we also see that Qianye summarized:

-

Basic information we are interested in was not disclosed in the disassembly video, such as capacity, voltage, mass, and energy density.- The OCV test was abnormal when tested with a basic multimeter. The voltage was too low.

-

Without seeing any relief valve inside, it is difficult to ensure the battery venting downwards. Physical testing is necessary here.

-

The insulating plate on top of the positive electrode reduces heat transfer efficiency. Currently, in the old design, all current paths are concentrated on the positive electrode column for insulation. This hampers the advantage of the entire polar ear.

-

From the exterior, the positive electrode column seems too small. Whether the impedance can meet the requirements depends on Tesla’s calculation. I am skeptical whether it can meet the future Super Charging V4 heat dissipation and internal resistance requirements.

Conclusion: The research on the new battery pack is solid, and Mr. Huang and Mr. Qianye make a great combination. Mr. Qianye did most of the overall analysis and organization work, while I contributed a bit. We hope our efforts can be helpful to our readers.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.