Lithium Battery Technology: Approaching Bottleneck Period?

With the penetration rate of new energy exceeding a quarter, concerns about the future of the electric vehicle and battery industry have emerged. The rapid growth of the electric vehicle market is highly dependent on the development progress of lithium battery technology. However, in the past two decades, lithium battery technology has gone from “jumping start” to gradually slowing down.

Ningde Times, a leader in the industry, has given its answer: Kirin Battery. Three years ago, the company pioneered the Cell-to-Pack (CTP) battery technology, eliminating the intermediate module and directly using battery cells to form a battery pack. By “decentralizing” the CTP solution, Ningde Times increased the utilization rate of the battery volume to over 50%, significantly improving the energy density of the entire battery pack, and enabling vehicles to achieve larger power capacity.

After “CTP 1.0” for three years, Ningde Times has officially launched the third-generation CTP battery system—Kirin Battery. This technology removes the “redundancy” in the battery cell – module – pack structure, and the battery cell “above” is the entire pack. Applying recent advancements in core processes, smart algorithms, and innovative materials, Ningde Times has redesigned the battery structure to further improve space utilization.# Innovation of CATL Kirin Battery System

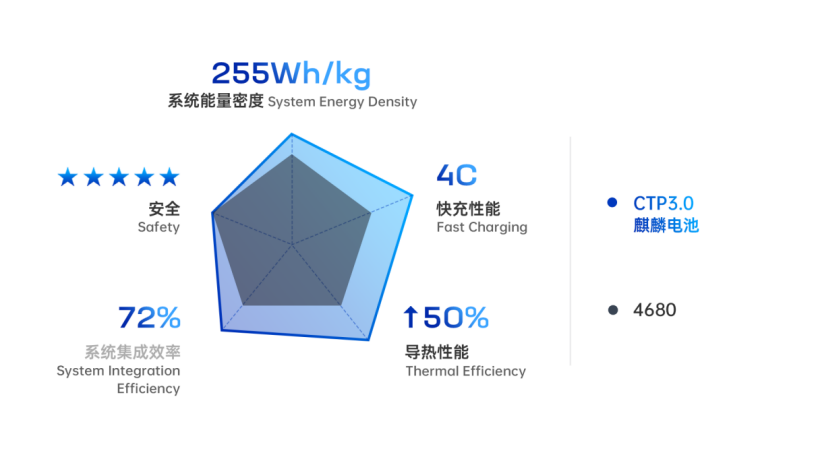

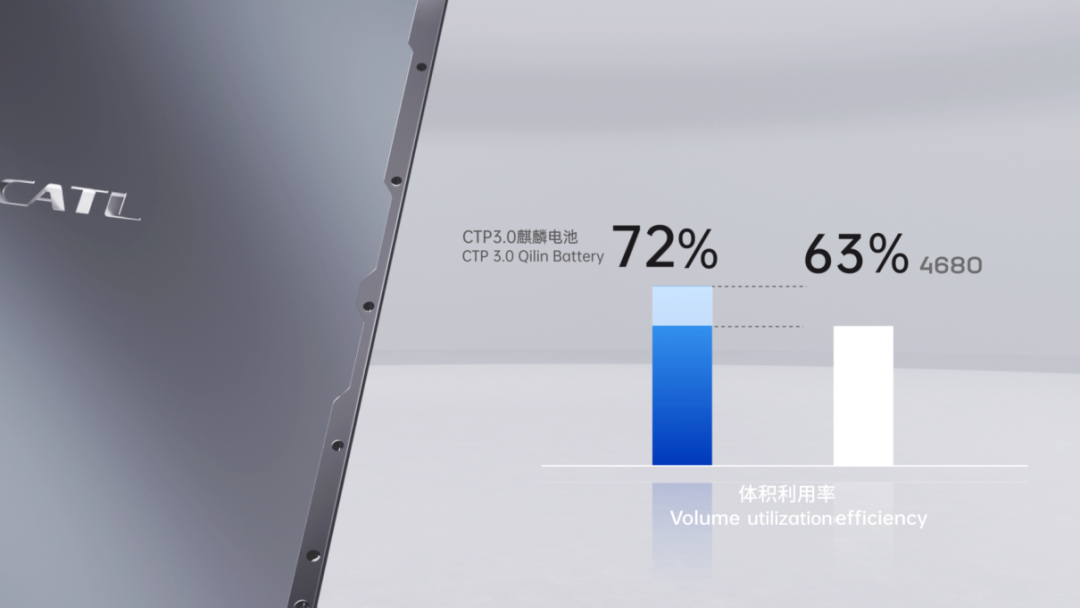

The CATL Kirin Battery System has improved the battery system volume utilization from 50% to 72%, thanks to multiple innovative designs including the three-in-one multi-functional interlayer, original bottom space sharing scheme, and large-area cell cooling technology. When using ternary lithium cell, the energy density can reach 255Wh/kg.

This also means that with the CATL Kirin Battery System, theoretically, a battery pack of only 500kg can have a large capacity of 127.5kWh. Even a 150kWh battery pack weighs less than 600kg. Such high energy density will make it easy for electric vehicles to achieve a range of 1000km, further promoting the pace of replacing fuel-powered vehicles.

Moreover, the innovative structure and design of CATL Kirin Battery System have also improved the reliability of the cell’s entire lifecycle, enhanced the battery pack’s anti-vibration and anti-impact performance, shortened the cell temperature control time, and strengthened the thermal stability and safety in extreme conditions. Even in the future, it can adapt to and upgrade to higher energy density cell materials.

When everyone thought that CTP was already the end point, CATL Kirin Battery System has set a new starting point with continuous innovation and self-surpassing.

“Rethinking” of Creation

How to achieve a new high in space utilization on the basis of CTP?

Although CTP directly forms cell packs, there are still beam structures inside the battery pack, which support the battery pack’s shell and enhance reinforcement in various directions. Because there is a certain degree of expansion and contraction of the cell during operation – the so-called cell breathing effect – heat insulation and cushioning pads need to be arranged between the cells.

The difficulty in significantly improving the volume utilization rate of the battery pack is because a large amount of space is occupied by various functional components. CATL Kirin Battery System eliminates the original structure and replaces the beam, water-cooling plate and insulating pad with an integrated, multi-functional elastic interlayer, which is placed between the cells.

The elastic interlayer has a micrometer bridge connection device inside, which can stretch and shrink with the cell breathing effect, replacing the buffering heat insulation pad. At the same time, the interlayer is combined with the cell, forming an integrated energy unit that jointly bears the vertical stress, improving the battery pack’s anti-vibration and anti-impact capabilities.

In the vertical direction, CATL Kirin Battery System boldly adopts the unique design of inverted cells, which brings a space release of 6%.

In the traditional battery pack, the positive electrode of the battery cell is placed upward and the high-voltage connection is arranged on the upper layer of the battery pack. The channel structure for exhaust in case of thermal runaway is also arranged on the upper layer, while a ball-hitting protection structure needs to be arranged on the lower layer of the battery pack. These functional modules are stacked up and down like a sandwich, increasing the vertical dimension and squeezing the available space for the battery cell.

In the traditional battery pack, the positive electrode of the battery cell is placed upward and the high-voltage connection is arranged on the upper layer of the battery pack. The channel structure for exhaust in case of thermal runaway is also arranged on the upper layer, while a ball-hitting protection structure needs to be arranged on the lower layer of the battery pack. These functional modules are stacked up and down like a sandwich, increasing the vertical dimension and squeezing the available space for the battery cell.

Kirin Battery inverts the battery cell, so that complex functional modules such as high-voltage connection lines, ball-hitting protection structures, and thermal runaway exhaust channels can all be integrated into the shared space below the battery cell and at the bottom of the battery pack, reducing the space occupied by the functional modules and leaving space for the battery cell or reducing the external dimensions of the battery pack.

Through precise calculation and AI simulation, CATL has obtained the optimal intelligent distribution of each module, thereby integrating multiple modules that used to occupy separate spaces into a shared space at the bottom while still meeting the national standard testing requirements for ball-hitting protection, etc.

Based on the changes in the structure of the battery cell and battery pack, Kirin’s battery cooling system also breaks the original boundaries. Traditional battery packs often use water-cooled plates placed at the bottom for cooling, while Kirin Battery integrates water-cooled plates into the multi-functional elastic interlayer between battery cells. The change in the cooling position expands the heat exchange area of Kirin Battery by four times.

With a larger cooling area, the temperature is easier to control during normal use, and the temperature control time for the battery cell is shortened to half that of the original cooling system. Kirin Battery can support 5-minute quick start in low-temperature environments, greatly improving the user experience. Its powerful cooling ability for fast charging means that 10-minute fast charging can become a reality.

In extreme cases, the four-fold heat exchange area significantly enhances the ability to suppress thermal runaway and thermal diffusion. The water-cooled plate located between the battery cells can more effectively block heat conduction between cells, making the entire battery system more stable and safe. The larger temperature control capacity also means that Kirin Battery can adapt to new battery cells with higher energy density in the future.

Breaking the “4680 Myth”

Kirin Battery will be officially mass-produced and launched in 2023, inevitably becoming one of the representatives of the new generation of battery systems. When it comes to new battery technologies in the near future, the 4680 battery system recently produced overseas by Tesla has occupied the industry and market’s attention.

Due to the backing of Tesla, the name 4680 has been mythologized in the market and has cast a shadow over the industry for many people. However, in reality, it is just a physical specification. Even Tesla’s 4680 battery pack, Kirin Battery has a 13% energy advantage.It is well-known that 4680 represents a cylindrical cell with a diameter of 46mm and a height of 80mm. In fact, cylindrical cells are no longer mainstream and are not widely used in applications other than Tesla. The adoption of the 4680 system by Tesla is more like an inertia development along its own path, rather than representing the optimal solution for cell form factor.

Compared to the small cylindrical cells with specifications of 1865 and 2170, the three-dimensional dimensions of the 4680 cells have greatly increased. Quantitative changes have produced qualitative changes, resulting in many difficulties in production, manufacturing, and reliability. For example, the production process of the polar ear for the large cylinder and the inconvenience of electrolyte injection are the main reasons why Tesla has been difficult to mass-produce for a long time.

Compared to the square cells that other manufacturers prefer except Tesla, cylindrical cells have extra weight from the cylindrical steel shell. Although the 4680 cell volume has increased, the large cylindrical shape is not conducive to compact arrangement in the battery pack. The increased volume also puts greater pressure on water cooling system heat dissipation, and these contradictions make it necessary for the 4680 battery to make trade-offs between energy and fast charging. In fact, in recent years, Tesla has also begun to introduce more and more rectangular cells.

CATL’s Kirin cell has a volume utilization rate of up to 72%, which is significantly better than the 63% of the 4680 system, thereby achieving a 13% energy advantage under the same battery pack volume. At the same time, the discharge rate of up to 4C, higher unit weight energy density, and stronger thermal conductivity of the Kirin cell also surpass the 4680 system.

Over the years, CATL has once again reaped the benefits of its rich experience in high-performance battery technology. By using the innovative method of the industry’s first CTP technology to break through the original boundaries and rethink and reshape the design, CATL has achieved twice the result with half the effort, and has achieved self-transcendence through the Kirin cell.

Conclusion

The Kirin cell is compatible with both ternary lithium and lithium iron phosphate cells. Through the three technological innovations of the multi-function elastic interlayer, the bottom space sharing scheme, and the large-area cooling technology for the cells, the energy density of the ternary lithium battery pack can be increased to 255 kWh/kg and the lithium iron phosphate battery pack can be increased to 160 kWh/kg, while achieving comprehensive performance improvements in endurance, fast charging, safety, and reliability.

CATL will launch the Kirin cell into the market in 2023, and many leading automakers including Ideal and Lotus have already expressed interest. The birth of the Kirin cell has once again expanded CATL’s advantages in the battery industry and consolidated its leading position in the industry.

After leading the industry trend in CTP, the third-generation CTP Kirin battery from CATL once again proves that the company is not only a manufacturer of battery cells, but also possesses innovative technology strength in the entire battery system, and can directly help whole vehicle enterprises to rapidly improve their competitiveness as a innovative technology company.

CATL’s self-exceeding and innovative actions allow car companies to have a more solid energy foundation. It is because of the breakthrough new battery technology of Kirin battery that breaks down old boundaries, that new energy vehicles can replace fuel vehicles at a faster pace, and the global historical transformation towards sustainability is just around the corner.

And CATL will be the founder of all of this.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.