Author: Frenchfries

The internet always imbues everyday words with more intrigue.

For instance, the catchphrase “screwing screws” that exploded in popularity these last two years has the geekiest tech influencers and average internet users alike participating in this meme.

However, “screwing screws” is no longer just a game of wit.

Who would have thought that the iconic BMW would construct a factory in the metaverse with thick eyebrows and big eyes, and also release a corresponding mobile game called “BMW iFACTORY Experience Tour” yesterday.

Everyone can now happily screw screws in the metaverse.

The Latest Echo of BMW iFACTORY

“Look to the future and define it.“

Attitude BMW Group’s president and CEO Dr. Jochen Goller describes this virtual factory situated within the metaverse’s borders.

But in actuality, it’s more than simply a virtual factory. Quite accurately, in the real world and in Tieling District, Shenyang City, Liaoning Province in China, BMW has built a genuine factory whose 1:1 replicates that in the metaverse, naming it Lida Factory.

“From the beginning of design, Lida Factory is the world’s first automobile factory planned entirely within the virtual realm,” says Dr. Feng Wenjing, head of production for BMW Group. It was “birthed” in the virtual world. In the meantime, Lida Factory has become “the latest breakthrough for BMW iFACTORY,” according to Dr. Norbert Reithofer, head of BMW Group production. It has also become the benchmark for BMW iFACTORY strategy.

Lida Factory covers 2.9 million square meters, with a total project investment of 15 billion yuan, constituting the largest individual investment by BMW in China to date. And with the opening of Lida Factory, Shenyang has officially become BMW Group’s largest global production base.

“Unless there was a computer screen in front of me, I believed BMW’s pride in Lida Factory would have filled my entire desktop.”

But if you ask me what the most direct impression Lida Factory has on me, I think it is four words, “digital twin.”

Lida’s Virtual Reality

If you’ve come across this phrase numerous times and failed to comprehend it just as often, then the BMW Lida Factory will be the ideal opportunity for you to grasp the meaning of “digital twin.”

Digital twinning is essentially creating a digital clone of a physical entity. And isn’t this relationship between Lida Factory and the virtual factory in the metaverse just that?

So why have digital twins? Specifically for Lida Factory, I see two positive implications of its digital twin.

The first is virtual guidance for reality.

For a new factory like Lida Factory, it can be divided into two stages.

First is the construction phase. Since Lida Factory is a factory that has been completely planned and simulated in a virtual environment from the beginning, from factory area planning, architectural design, production line layout to equipment debugging, BMW can create a 3D digital twin model in the metaverse world and perform corresponding preliminary design verification and construction simulation to avoid design errors.

The second is the debugging phase. This step would typically have to take place after the physical construction of the factory in traditional automobile manufacturing. But in Lida Factory, because of the virtual factory in the metaverse, this step can be pre-positioned. Employees can evaluate, verify and identify problems in advance in the virtual world, and make timely adjustments to reduce rework in subsequent steps of actual operation.

The combined results of these two phases have led to Lida Factory being completed and put into operation in just over two years, even under the unfavorable background of repeated outbreaks of the pandemic, which is six months shorter than the normal construction period.

The second is real-world feedback to the virtual.

Lida Factory has accomplished “Data-driven”. BMW said they have interconnected every product, every process, and every employee with the Industrial Internet of Things (IIoT). That is, at Lida Factory, not only the physical building of the whole factory, but also the employees, equipment, production processes inside it, can all be mapped one-to-one with the virtual world because they are connected to IoT.

Taking BMW’s yard management system as an example, the IoT makes real-time logistics data strongly connected to the 3D model. As a result, changes in yard materials in the real world can be reflected in real-time in the virtual factory. The only difference between reality and virtual is that in reality, employees need to count the changes in materials separately; while in the virtual world, we can switch to an aerial view and take a holistic view, which is further combined with heat map analysis to maximize logistics efficiency.

The loading simulation of BMW is connected to the automatic train scheduling system. Thanks to the global planning advantage brought by virtual feedback, nearly 80% of BMW vehicles can be transported away from Shenyang factory by train.

Details Exhibition

Digital twins are always macroscopic, and Dr. Norbert Kovacs brought more details about the Lieda factory.

First is the Lean Production.

“Lean means efficient, accurate, and ultimate flexibility.”

The excellent software and hardware facilities of the Lieda factory have further strengthened BMW’s flexible production system. The Lieda factory has extremely high production flexibility, and can achieve up to 100% production capacity for electric vehicles. The first pure electric medium-sized sports car of BMW, the new BMW i3, has been officially put into production here.

Secondly, it is sustainable.

All BMW factories in Shenyang are 100% powered by renewable electricity. One of the major sources of renewable electricity is the 290,000 square meters of solar panels that BMW built in Shenyang. These solar panels can generate 44,000 megawatt-hours of electricity per year, which can support the electricity use of 9,000 ordinary households for a whole year.

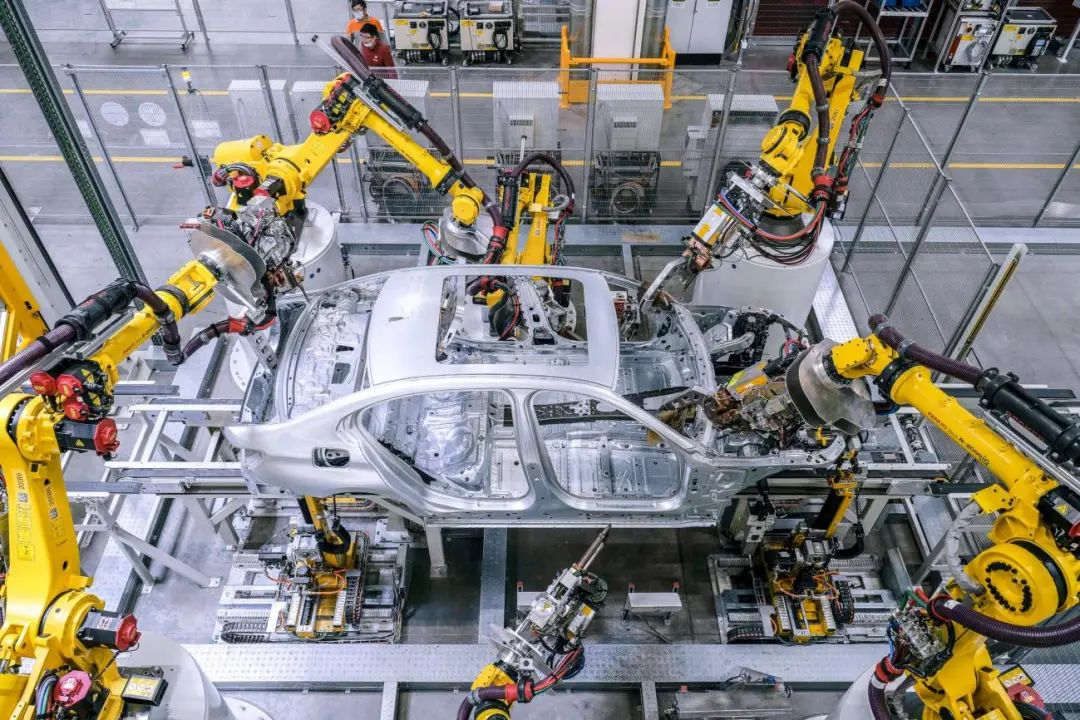

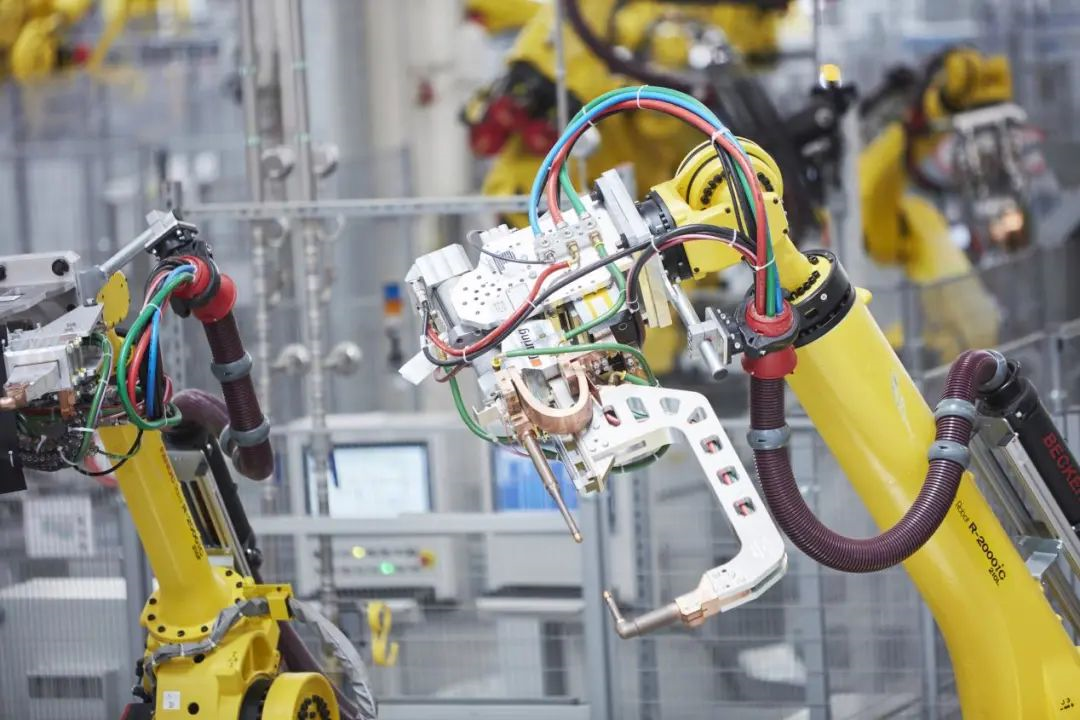

The Lieda factory uses more environmentally friendly new equipment, such as electric servo welding guns used in the body shop, which achieves zero emissions by working with renewable electric power.

BMW’s next goal is to further reduce the carbon emissions of individual vehicles by 80% before 2030.

Moreover, it is digitized.

The Lieda factory originates from the digital world, and digital AI technology has been widely used in actual production. Currently, more than 100 AI applications have been deployed throughout Shenyang Production Base.

For example, the painting workshop of the Lieda factory uses AI computer vision systems, which can take 100,000 photos within 100 seconds, and use these photos to identify tiny flaws in the paint finish.

If you ask what the greatest achievement of modern industry is, I think as long as the industrial kernel remains unchanged in terms of scale production, the answer to this question must be the output.Advanced factories coupled with the effort of BMW employees result in higher production volume.

At present, about one out of every three BMWs worldwide is produced in Shenyang. According to data provided by BMW, with the gradually increasing production capacity of the BMW Brilliance Tiexi plant, the annual capacity of BMW Brilliance will increase to 830,000 vehicles in the future.

Pressures and Blessings

Regarding production volume, I fully trust BMW, but my concern lies with their products.

Although I personally love BMW’s electrified products, and the BMW i4 is even my number one choice for the driving experience of an electric car, in fact, BMW’s new energy products have not received good feedback in the consumer market.

On the one hand, this issue makes me examine the defects of the current communication methods, as we cannot find a way to directly demonstrate the advantages of BMW electric car driving experience to the audience. On the other hand, in terms of architecture, endurance, and other aspects, BMW’s electrified vehicles lag behind the new forces in the most intuitive data comparison.

The ultimate result of these problems is sales, and we cannot say that the sales are satisfactory.

And the essence of business is profitability. BMW invested 15 billion yuan in Shenyang to build such an advanced factory and expand so much production capacity. BMW certainly hopes to recoup these costs through sales.

BMW stated that the Tiexi plant, after the ramp-up of production capacity, could increase the annual output of BMW Brilliance by 130,000. In 2021, BMW delivered about 48,000 new energy vehicles in China. Assuming that the Tiexi plant operates at 100% capacity for electric vehicle production, the annual production capacity of the Tiexi plant exceeds the demand in the Chinese market for two years.

Therefore, the cost pressure on the production side has suddenly shifted to the sales side.

Of course, Guo Jie, President and CEO of BMW Group Greater China, said that BMW will offer 13 pure electric vehicle models to Chinese customers by next year. At the same time, BMW will also launch a “new generation” of pioneer models in 2025.

What will happen with these new products? As a hardcore fan of the BMW i4, I just hope that BMW can make money from electric cars.

After all, a profitable BMW can bring us more electric vehicles that drive as well as the i4.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.