English Markdown

Author: Xiao Long, Xiao Wei

From BYD’s Blade Battery, to CATL’s Cobalt-Free Battery, and to CATL’s Sodium Ion Battery, the power battery industry is experiencing continuous innovation.

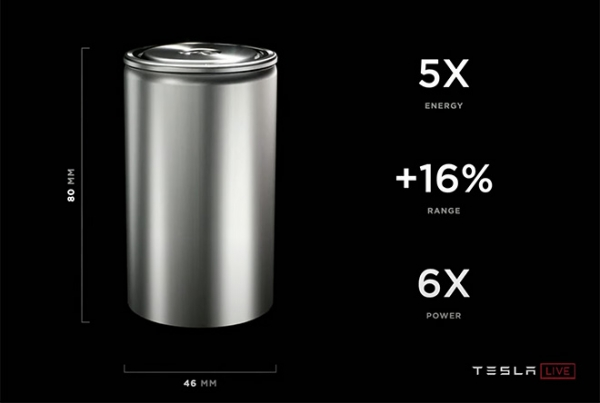

September 23, 2020—Tesla Battery Day. Tesla CEO Elon Musk unveiled a brand new battery, the 4680 battery, to the world.

Previously, the size of cylindrical lithium-ion batteries mainly included two types: 18650 and 21700. The energy of 21700 is 50% higher than that of 18650. The cell capacity of the 4680 battery is five times that of the 21700 battery. The new battery can reduce the cost per kilowatt-hour by about 14% and increase the cruising range by 16%.

Musk said that this battery will make a $25,000 electric car possible.

So, what is this powerful battery all about? Next, we will analyze it step by step.

What is the 4680 battery?

Tesla’s naming convention for power batteries is very simple and straightforward. The 4680 battery is a cylindrical battery with a single cell diameter of 46mm and a height of 80mm.

From the picture, it can be seen that compared to the 18650 and 21700 batteries previously used by Tesla, the appearance of the 4680 battery is like a tall and sturdy man.

However, the 4680 battery is not just about size changes. Tesla has incorporated many new technologies to enhance performance.

New Technologies of the 4680 Battery

Pole-less tab design

Intuitively, the biggest feature of the 4680 battery is its larger size. So why didn’t other manufacturers make the battery bigger before? This is because the larger the volume, the higher the energy, the more difficult it is to control heat, and the greater the safety threats of combustion and explosion.

Tesla has also taken this issue into consideration.

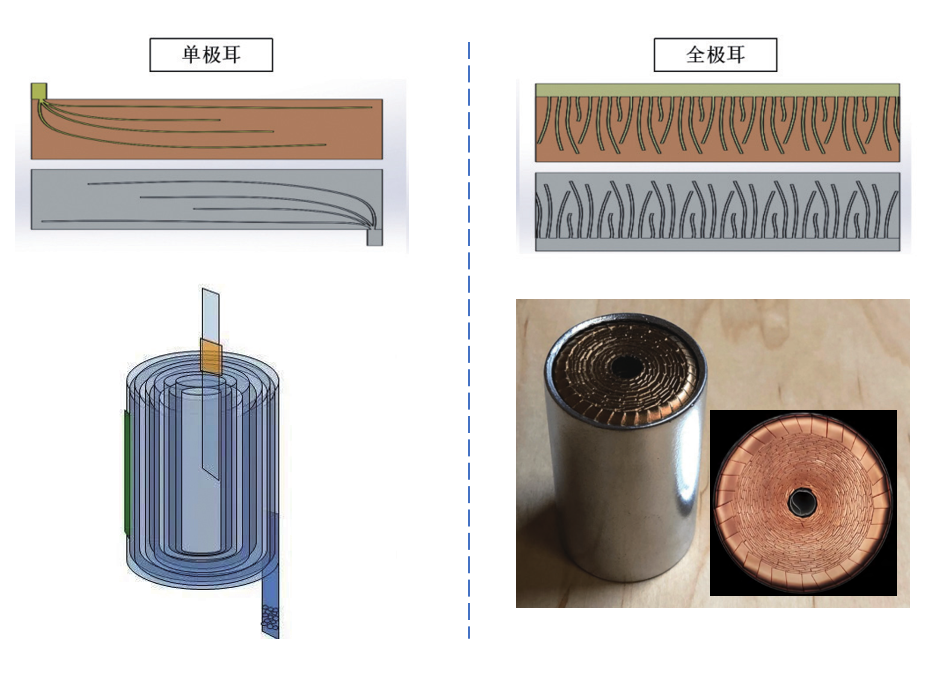

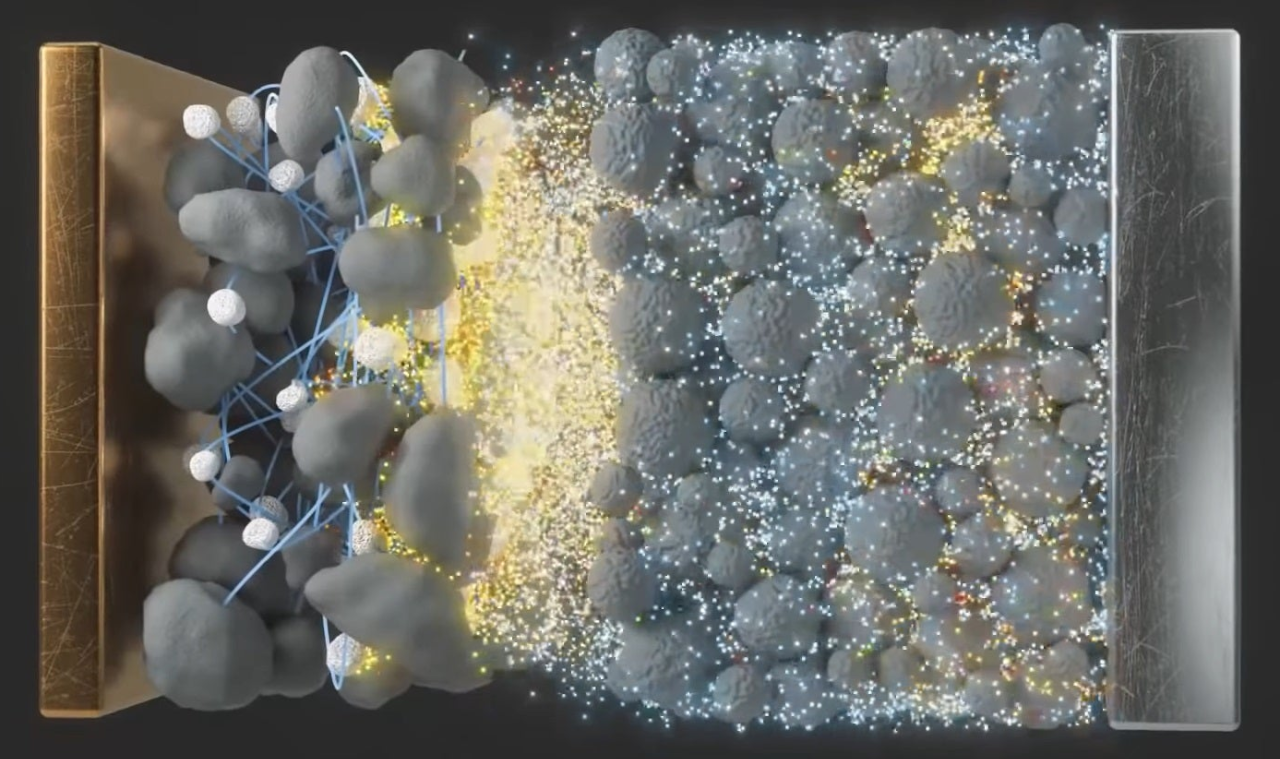

Compared with the previous cylindrical battery, the biggest structural innovation of the 4680 battery is its poleless tab, also known as a full tab. In traditional cylindrical batteries, the positive and negative pole copper and aluminum foils and separator are stacked and wound. In order to lead out the electrode, a lead wire is welded at both ends of the copper and aluminum foils respectively, which is called a tab.

The winding length of a traditional 1860 battery is 800mm. Taking the higher-conductivity copper foil as an example, the length of the lead wire from the copper foil to conduct the electricity is 800mm, which is equivalent to the current passing through an 800mm long wire.The resistance is about 20mΩ through calculation, and the winding length of 2170 battery is about 1000mm, with a resistance of about 23mΩ. By simple conversion, the same thickness of film needs to be wound into 4680 batteries, with a winding length of about 3800mm.

There are many disadvantages to increasing winding length. Electrons need to travel a longer distance to reach the terminals at both ends of the battery, which increases resistance and makes the battery more prone to overheating. This will degrade the battery’s performance and even pose safety risks. To shorten the distance electrons travel, 4680 batteries use the “tabless” technology.

Tabless technology does not eliminate the terminals but instead turns the entire current collector into a terminal. The conducting path no longer relies on the terminals, and the current transmission goes from the terminals to the current collector plate horizontally to vertically.

The entire conducting length has been reduced from 800-1000mm in length of 1860 or 2170 copper foil to 80mm (battery height). The resistance has dropped to 2mΩ, and the internal resistance consumption has dropped from 2W to 0.2W, directly reducing by one order of magnitude.

This design greatly reduces the battery’s impedance and solves the heating problem of cylindrical batteries.

Tabless technology increases the current conduction area while shortening the current conduction distance, greatly reducing the battery’s internal resistance. Reducing internal resistance can reduce current offset phenomena and extend battery life. The reduced resistance can also reduce heat generation, and the effective contact area of the electrode conductive coating and battery end cap can reach 100%, enhancing heat dissipation capabilities.

The 4680 battery adopts a new tabless technology in terms of cell structure, which can achieve cost reduction and efficiency improvement. On the other hand, eliminating the terminal welding process has increased production efficiency and reduced the failure rate caused by welding.

Combined with CTC technology

Generally speaking, the larger the battery size, the fewer batteries need to be installed in the same car. A Tesla needs 7100 18650 batteries. If 4680 batteries are used, only 900 batteries are needed.

The fewer the batteries, the faster the assembly, the higher the efficiency, and the less likely the middle link will have problems. In addition, the price is cheaper. According to Tesla, the large-sized 4680 batteries can reduce battery production costs by 14%.

In order to improve the energy density of the battery pack, the 4680 battery will be combined with CTC (Cell to Chassis) technology. That is to integrate the battery cell directly into the chassis. By completely removing the module and battery pack, the battery cells become more compact, the number of battery components will be greatly reduced, and the space utilization of the chassis will also be greatly improved.### CTC Requirements for Battery Structural Strength

CTC has certain requirements for the structural strength of batteries. The battery itself needs to bear a considerable mechanical strength. Compared with 18650 and 2170 batteries, 4680 single-cell batteries have a larger and stronger structure. In addition, the general casing of cylindrical batteries is aluminum, but the 4680 casing is made of stainless steel, which naturally ensures structural strength.

In contrast to the shell battery, the layout of the cylindrical battery will be more flexible and can adapt to various different chassis, which can better combine with the ground.

According to the analysis of “Electric Power”, CTC technology is the wind vane of new energy vehicles in 2022 and also a fork.

Integrating the battery into the vehicle body will make vehicle maintenance extremely complicated, and the battery is difficult to replace independently. After-sales maintenance service prices will increase, and these costs will be directly transferred to consumers, for example, insurance costs will rise. Although Musk claims that they have designed repair rails that can be cut off and replaced, the final effect still needs time to verify.

Many automakers have proposed their own CTC technology solutions because it not only re-layouts the battery but also requires changes to the body structure. This involves the re-division of the relevant industry supply chain.

CTC is just a technical route. It is the integration of the battery into the body of the electric vehicle and cannot be disassembled. There is another technology on the other side – battery swapping. The battery swapping technique is convenient to disassemble, but the battery makes a significant contribution to the strength of the battery. Choosing these two routes is a game between battery suppliers and automakers.

Innovation in Battery Production Technology, Positive and Negative Electrode Materials

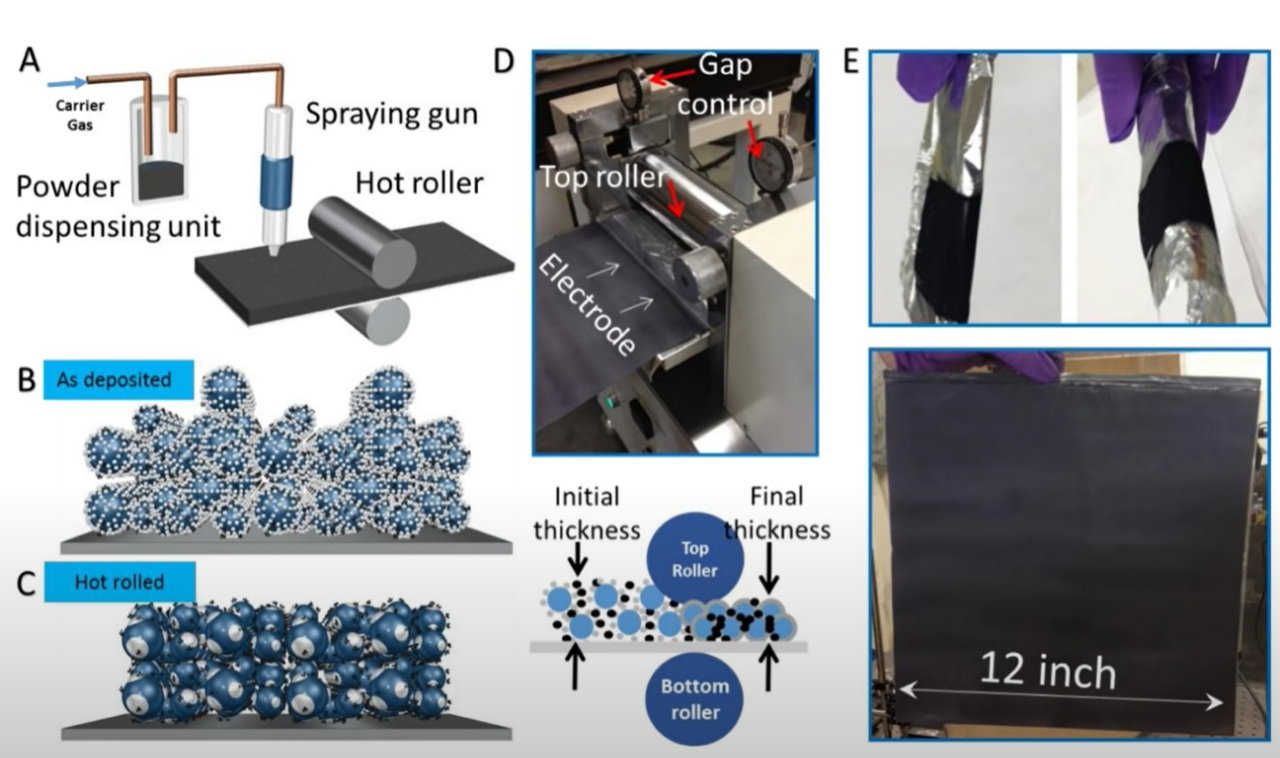

Tesla will use the dry electrode process, without solvents, but rather a small amount (about 5-8%) of fine powdered PTFE adhesive mixed with positive/negative electrode powder to form a thin electrode material strip through an extrusion machine. The electrode material strip is laminated onto a metal foil collector to form a finished electrode.

This method of producing batteries is more environmentally friendly. Moreover, this process is expected to increase the energy density of the battery and reduce production energy consumption by 10 times. Dry electrode technology is likely to become the next generation of technology benchmarks.

Regarding positive electrode materials, Tesla stated that cobalt elements will also be removed from the positive electrode. Cobalt is expensive and rare, and can only be mined in a few countries, including the unstable African country of Congo. If the battery can really eliminate cobalt, it can be said to be a major technological innovation.

Regarding positive electrode materials, Tesla stated that cobalt elements will also be removed from the positive electrode. Cobalt is expensive and rare, and can only be mined in a few countries, including the unstable African country of Congo. If the battery can really eliminate cobalt, it can be said to be a major technological innovation.

As for negative electrode materials, Tesla will start with silicon materials and use more silicon to replace the graphite currently used. The theoretical specific capacity of silicon-based negative electrode is up to 4200mAh/g, which is ten times that of graphite negative electrode. However, silicon-based negative electrodes also have problems such as easy volume expansion, poor conductivity, and large first charge and discharge loss.

Therefore, improving the performance of materials is actually a search for balance between energy density and stability. The current silicon-based negative electrode products mix silicon and graphite together for composite use.

Tesla plans to fundamentally change the extension of the silicon surface to make it less prone to breakage. This technology not only makes the battery charge faster, but also increases the battery life by 20%. The new material developed by Tesla is called “Tesla Silicon”, with a cost of only 1.2 US dollars/KWh, which is only one-tenth of the cost of the existing structured silicon process.

Silicon-based negative electrodes are seen as the next-generation lithium battery negative electrode material.

A few models on the market have begun to use silicon-based negative electrode materials. Tesla Model3 and other models have already added a small amount of silicon to the negative electrode. Recently, Guangzhou Automobile Aiways AION LX Plus was launched, and the long-range version features sponge silicon-negative electrode battery technology, which can achieve 1,000 kilometers of endurance.

To summarize, the advantage of the 4680 battery technology is that it can reduce costs while improving performance.

The Far-reaching Impact of 4680 Battery Technology

The 4680 battery is not a revolutionary technology in terms of energy density breakthroughs, but more innovation in process technology.

However, driven by Tesla, the production of 4680 batteries will change the existing battery landscape in the current new energy market. The industry will inevitably usher in a wave of large-volume cylindrical batteries.

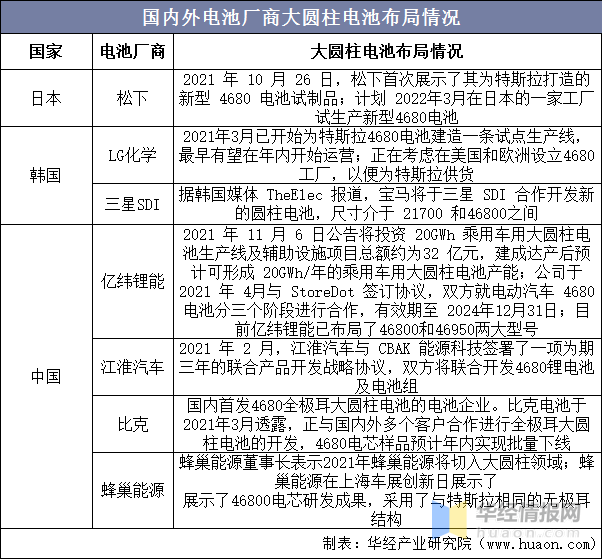

According to reports, Panasonic plans to begin mass production of 4680 high-capacity batteries for Tesla in early 2023. The new investment will be as high as 80 billion yen (approximately US$704 million). Samsung SDI and LG Energy have also joined the development of 4680 batteries.In China, Yiwei Lithium Energy announced that its subsidiary, Yiwei Power, plans to build a 20GWh cylindrical battery production line for passenger cars in Jingmen High-tech Zone. Beike Battery and Honeycomb Energy will also enter the cylindrical battery field. BMW and CATL are also actively deploying cylindrical batteries, and the basic pattern has been established.

The Voice of Electric Power

The structural innovation of cylindrical batteries undoubtedly plays a driving role in the development of the power battery industry. It is not as simple as upgrading from a size 5 battery to a size 1 battery. There is a lot of expertise in its bulky body.

As the cost of batteries approaches 40% of the total cost of the vehicle, the importance of batteries as the “heart” of electric vehicles is self-evident. However, with the popularity of new energy vehicles, the demand for batteries is increasing day by day, and the prices of materials are rising rapidly. Battery innovation has become an important way for automakers to develop.

With the development of battery-related technologies, affordable electric vehicles are just around the corner!

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.