CTB, the important “backbone” of BYD’s “raise price action”

From CTP to CTC to CTV, now there is another choice for the luxurious lunch with “CTX”. BYD has applied the CTB body and battery integration technology on its high-end product, the Hanxiang (the “Sea Lion”).

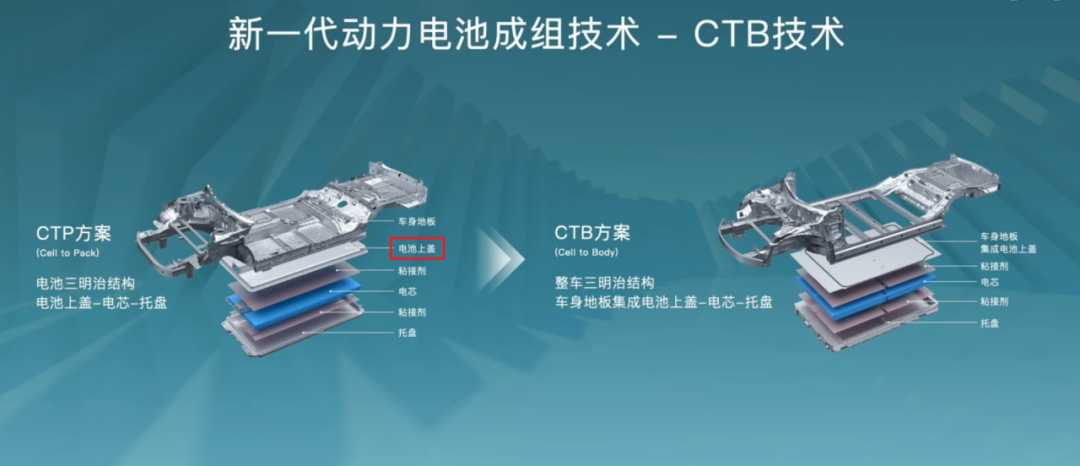

Friends who have been following BYD might have already guessed that “CTX” is simply short for cell-to-X. CTP refers to cell-to-pack, where cells are directly assembled into battery packs, while CTC refers to cell-to-chassis, where cells are integrated into the chassis directly. As for CTV and CTB, we will talk about them later.

The Sea Lion is BYD’s direct response to the Model 3, with a car length of 4800mm and a price range of 210,000 to 280,000 yuan. It features a front-wheel and rear-wheel suspension system with a double-wishbone and five-link setup, as well as a long and short range, rear-wheel and high-performance four-wheel drive models. Its similarities to the Model 3 are obvious, except that Model 3 has not yet applied CTC technology (currently only Model Y has).

At the same time, the Sea Lion is also the first mass-produced car on BYD’s e-platform 3.0 – Yes, our “first stock of electric vehicles.” After experiencing the tumultuous ride of fluctuating stock prices, we finally have our first genuine and exclusive electric platform.

Aside from these little grievances, the Sea Lion is indeed a high-end car that BYD has put its effort into making with its new platform, and it is no longer the same old BYD from before, including the price.

And CTB is one of the important “backbones” in this “price-raising action.”

CTP and CTC have been talked about repeatedly. So far, if we use “CTC-like” as a more general definition, Tesla, Zeekr, and BYD have officially launched cars with this technology, which have already entered mass production. Tesla’s Model Y was the first to use the mass-produced CTC battery technology (4680 cells, not yet available in China), Zeekr recently released its own CTC, and BYD today presented its technology called CTB.

The name is just a personal preference and the letters following CT are not important, just like a little girl dressing up in any way she likes.It is important to understand the specific principles behind each new technology so as not to be confined by a few simple letters. For example, once you understand the new approaches that these three companies have taken with battery packs, you should be able to give them a name without me telling you: Tesla and Zero Run have been introduced in “Tesla apprenticeship taught them to race ahead”.

As the first practical CTC car, Tesla’s approach can be described in layman’s terms as “sealing the battery pack first and leaving the vehicle body open”. The white body is in a “bottomless” state, with the floor, seat support, and middle underbody beams all “together” with the battery pack, and finally, the battery and the body are integrated.

Surprisingly, Zero Run chose a completely different approach, which is described in layman’s terms as “laying the body floor first and leaving the top of the battery pack open.” The white body has a “floor”, but the battery pack “is not covered”. Anything can be put on the body floor, while the battery is like a “tray” with batteries, which only becomes completely enclosed when the two are combined.

Both of these approaches are consistent with the concept of CTC (“cell-to-chassis”), and to distinguish between them, Professor Ouyang Minggao has referred to Zero Run’s approach as CTV (“cell-to-vehicle”). Because Tesla was the first to mass produce, you can regard it as the “orthodox” CTC, while Zero Run can be seen as a “cruiser” in CTC. However, this term “orthodox” is purely temporal and has no higher or lower status.

Everyone understands that “Tesla-style CTC” and “Zero-style CTV” are both members of the CTC family.

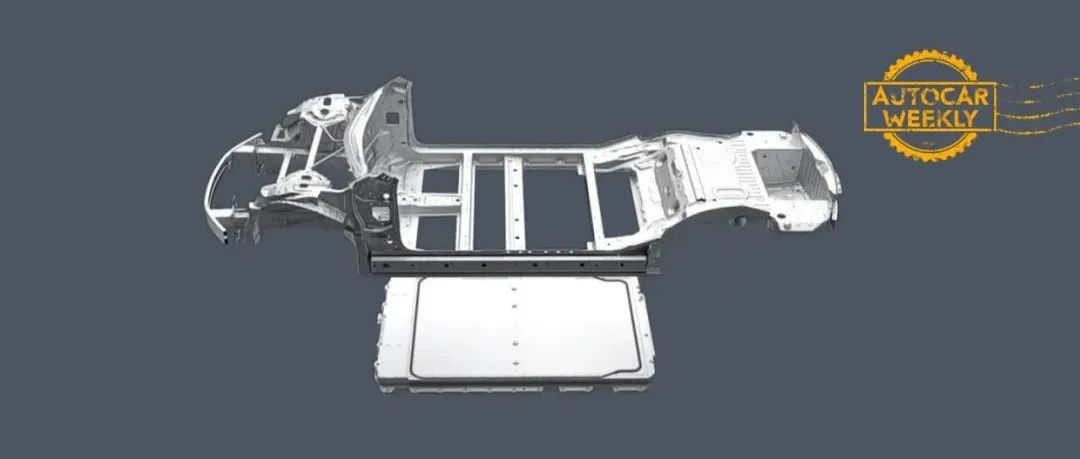

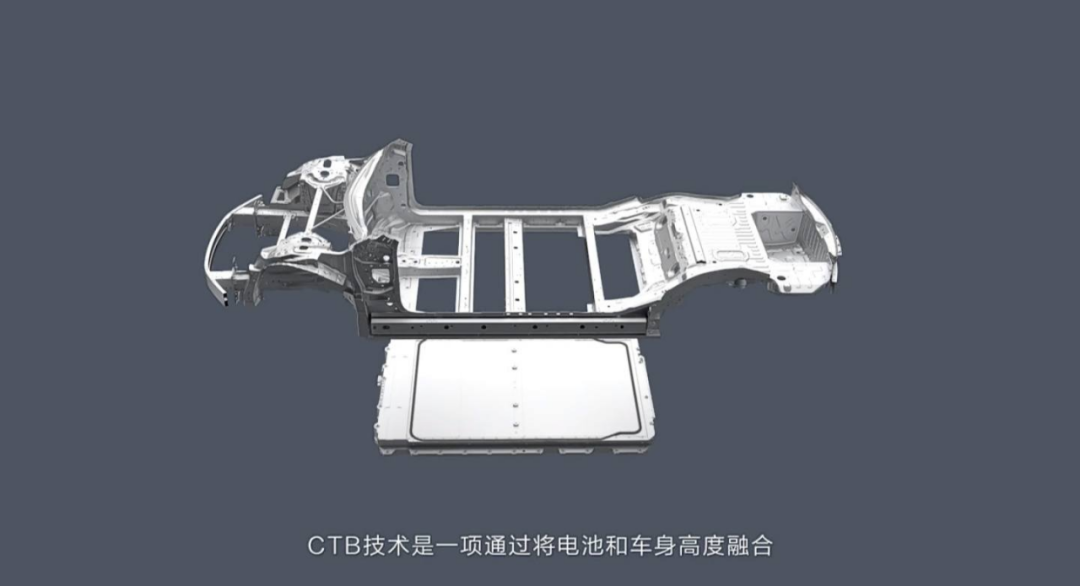

BYD Dolphin uses CTB, which looks like something between CTC (referring to Tesla’s approach) and CTV: the white body has horizontal beam structures and seat support areas, but the flat portion of the floor is hollowed out and is filled by the top of the battery pack, which serves as a cabin floor.Unlike Tesla Model Y’s CTC, the CTB of Heisea’s vehicle does not “give” the seat support and the car’s bottom crossbeam to the battery pack, so the stress structure of the car’s bottom is more complete and there will be no connectivity issue. Compared with the CTV of LeapMotor, the CTB’s battery pack is also encapsulated before being installed, just like Tesla, rather than being sealed with the bare battery pack on the car like CTV.

Because the original two-layer board (car bottom plate + battery top cover) is reduced to one layer (the battery top cover also doubles as the cabin floor), CTB reduces the occupied longitudinal volume by 10mm. This number is exactly the same as the contribution to reducing height of LeapMotor’s CTC (or CTV). In this aspect, CTB and CTC can be considered to play almost the same role.

However, whether it’s CTC or CTB, the 10mm difference, which is probably thinner than a pinky finger, obviously cannot have any qualitative change to the interior space or body height of the car. CTC or CTB cannot eliminate the too-high effect brought by the thickness of the battery pack, and only removing the thickness of one layer of steel plate can be said to have a negligible effect on the longitudinal dimension, which is better considered as the “complimentary” role of CTC/CTB.

Let’s take a look at the strengthening effect of CTB on the vehicle body. BYD claims that CTB makes the entire vehicle torsional rigidity of the Heisea exceed 40,500 Nm/degree. This is indeed a high number. Those who pay attention to electric vehicles should remember that NIO ES8 has a torsional rigidity of only 44,140 Nm/degree, despite having a full aluminum body.

However, it is not clear how much CTB has contributed to this rigidity achievement. A big feature of electric vehicles is high torsional rigidity, and the battery pack, as a steel box with a more regular shape, can often significantly improve the rigidity of the body. Even for some “oil-to-electric” models with a pre-existing sturdy body, after adding a battery pack, the rigidity can often be greatly improved.

It is important to focus on the results, not the implementation method.The strength of the vehicle body, or the more reliable passive safety performance, may be the advantages of CTB. CTB only removes the floor of the vehicle cabin, but does not modify the lateral beam structure of the bottom of the vehicle used to resist side collisions. The Tesla-style CTC, integrated with the bottom beam of the battery cover, is not integrated with the side frame of the vehicle body, which reduces the contribution of the beam to the strengthening of side collision. This requires taking other measures, such as ensuring the strength redundancy of other impact-resistant structures, to ensure that the overall vehicle safety performance is not weakened due to CTC.

In contrast, the entire body structure of CTB is intact, and there is little difference from the traditional body structure. The vehicle safety design can be more conventional, and the actual strength performance is more likely to meet the design, which ensures the reliability of the vehicle passive safety.

However, the other side of the coin is also because the main force-bearing structure is not integrated with the battery like Tesla, nor is it like LI’s one-piece body floor that also serves as the battery pack structure, so the weight reduction effect of Haima’s CTB may not be so significant. BYD did not mention weight-related issues at the press conference, so we have no way of knowing.

The issue remains the same as with CTC, which is the sealing reliability risk and the difficulty of after-sales maintenance. The CTB structure does not have the extra battery pack sealing risk, but the sealing performance when using the battery pack as the “back cover” of the vehicle body still needs time to be verified. CTB may not require more than 300 steps to disassemble and assemble the battery like Tesla, but battery replacement still involves interior structure and will cause more trouble.

Compared with Tesla and LI’s solutions, Haima’s CTB achieves a certain degree of electric vehicle structure optimization in a way that is more integrated and lower risk and higher reliability. However, because CTB does not directly change the core of the vehicle body strength structure, the maximum optimization effect it can achieve will be relatively limited.

As previously stated when introducing LI’s CTC (CTV) solution, in fact, whether it’s CTC, CTV or today’s CTB, these structural optimization technologies are not as magical as people imagine, nor are they competitive barriers that others cannot break once achieved.

Technology itself is just a way to achieve performance, and it does not absolutely lead to better performance. They ultimately obtain every aspect of the vehicle itself, rather than the way they implement these aspects. The purpose of understanding technology is not to distinguish between “good” and “bad”, but to use one’s own thinking to understand the causes of product differences and characteristics.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.