Who says Chinese people don’t understand romance?

“Shenzhou” spacecraft, “Chang’e” moon exploration. If these are the Chinese romanticism in space, then NETA Motors is the Chinese romanticism in the new energy vehicle industry.

In the world of NETA Motors, the new car NETA S uses a brand new platform called “Shanhai” and is equipped with a battery called “Tiangong”.

Nature creates things, and people create technology.

When NETA uses “Tiangong creation” to describe the battery, is it just showy or truly capable? Safety, range, and lifespan, are there good solutions from Tiangong battery, which are the concerns of most consumers?

Regarding these questions, NETA Motors brought more information about the Tiangong battery this morning.

Is the structure the gatekeeper of battery safety?

Battery safety is still an unavoidable question for electric vehicles.

NETA tackles it by breaking it down into smaller pieces, leveling up gradually, and handling each aspect thoroughly.

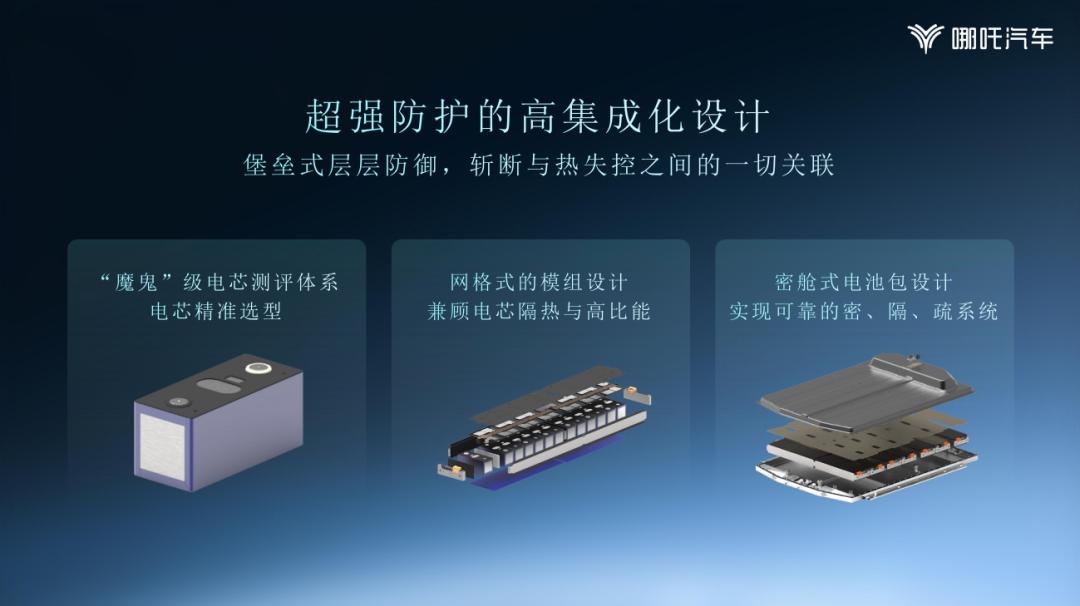

First is the battery cell.

For the automaker, the battery cell is the smallest unit of the battery pack and an important influencing factor for the stability of the battery pack.

However, in the new forces of China, self-making battery cells are probably unrealistic in the short term. So besides selecting suppliers, what can the automaker do?

NETA’s answer is, we have the “devil” level battery cell testing.

As for how “devilish” it is…

Over 400 performance evaluation requirements, over 400 simulation development and strategy algorithm parameter evaluations, over 20 battery cell safety evaluations, over 30 mechanical reliability evaluations, over 30 electrochemical property evaluations, and over 30 thermal performance optimizations and verifications.

It is a bit unfortunate that NETA only provides the general direction and number of testing items for its battery cell testing standard, without specifying which specific contents were tested. Is it because they are worried that the quantity of testing requirements is too large to fit in one PPT?

Beyond battery cells, there are battery modules.

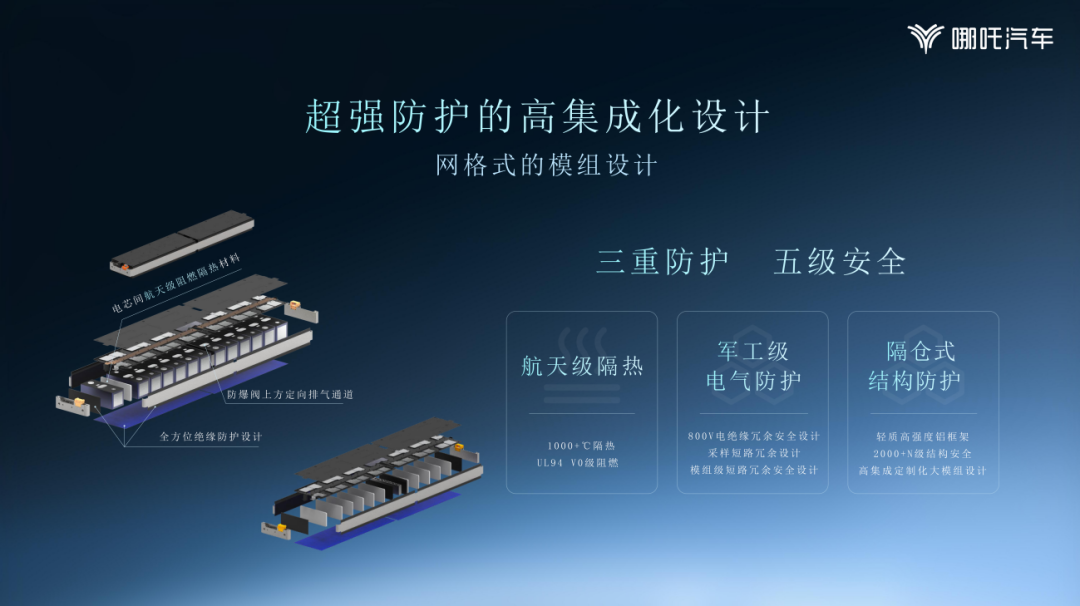

NETA uses a mesh-like battery module design. They set aerospace-grade flame retardant insulation materials between the battery cells in the module to separate the battery cells into a grid-like pattern. These separation materials can withstand over 1000℃ high temperature. Meanwhile, directed ventilation channels are set above the battery cell explosion-proof valve as well.In the part of module electrical protection, the word “redundancy” is the most frequently used term by NETA. 800V electrical insulation is redundant, the sample short-circuit design adopts redundancy, and the module short-circuit design also adds redundancy. In plain language, the three “redundancies” mean that leakage and short circuits are unlikely to happen.

Regarding the design of the pack, NETA believes that it can be understood as an expansion of the module design. It also needs to achieve the functions of gas and heat conduction, short-circuit protection, high-temperature insulation, and short-circuit prevention. This is like problem-solving. Once the ideas are clear, things will be sorted out.

“I anticipated your anticipation”

As for range, besides stacking batteries, what other methods are there?

NETA said, thermal management.

Many years of experience have taught us that batteries are temperature-sensitive and fragile. If you expose them to low or high temperatures, they will lose power, stop working, or worse. But if you take care of them at a relatively suitable temperature, they will release relatively more energy for you.

This is the logic behind NETA’s self-developed HozonEPT 4.0 intelligent temperature control system.

It also uses the popular “scenario” concept.

For the charging scenario, based on the user’s usage habits, remaining battery level, and current battery temperature, it estimates in advance the cooling or heating demand of the battery, so that the battery can maintain a relatively suitable temperature during charging.

As the saying goes, “I anticipated your anticipation,” and the result of anticipation is 2% energy-saving per single charging.

For the low-temperature scenario that batteries are most afraid of, this system also makes corresponding designs.

If your car has low power and you set the destination to a charging station, HEPT 4.0 system will start preheating the battery in advance when you start the journey, so that when you arrive, the battery is already warm enough. Then, you can plug in and charge, and it will be much faster than charging a cold battery. If you have to give a precise number to this “faster,” NETA will tell you that the answer is 20%.Compared with the charging speed, temperature can bring another more important 20% to the battery. In the cold winter, constant temperature liquid cooling can increase the winter range by 20%.

Cloud-based battery management

When it comes to the lifespan of a battery, in recent years, it seems that everyone has recognized one thing, that is, the cycle life of the battery is longer than that of the vehicle.

So why does NETA make this full lifecycle battery closed-loop management system?

We need to clarify a concept that full lifecycle not only refers to how many cycles the battery can use during the platform period, but also concerns whether there is any risk of failure.

In the final analysis, the most direct purpose of this system is still safety.

NETA hopes to use big data comprehensive precise analysis, remote diagnosis, and timely discovery of those outlier or other potential failure individuals, and guide after-sales operation and maintenance to take appropriate measures.

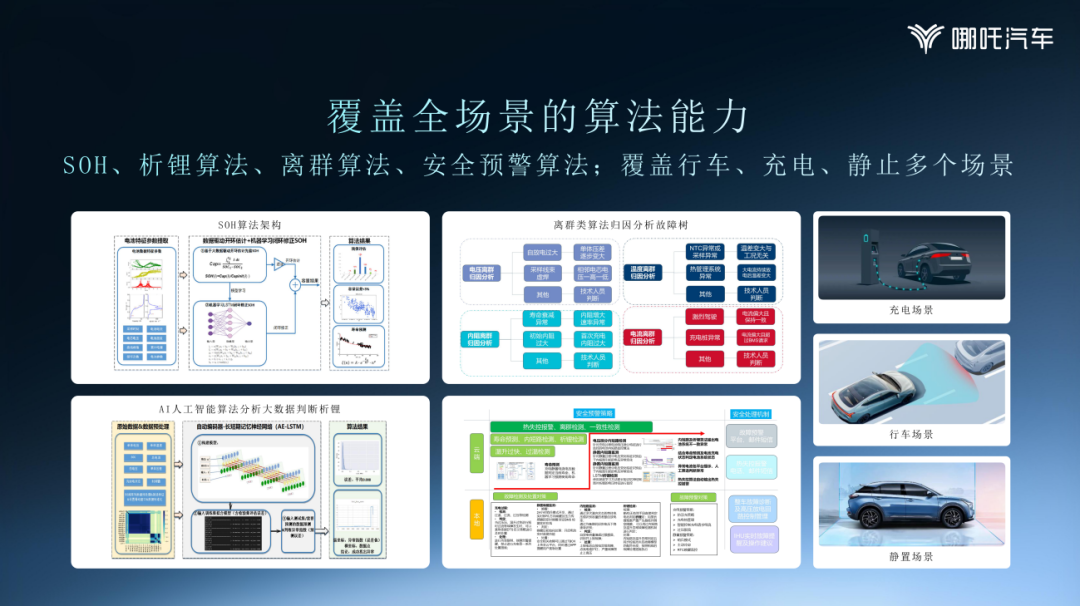

In order to achieve this goal, NETA has introduced algorithms that cover all scenarios.

The SOH algorithm with data-driven open-loop estimation and machine learning closed-loop correction, the lithium analysis algorithm with AI big data overlay analysis, outlier algorithm, safety warning algorithm, etc. cover multiple scenarios such as driving, charging, stationary, and so on.

After calculating and collecting various data by these algorithms, the full-life cycle battery closed-loop management system can formulate an individually exclusive BMS management strategy for different batteries of different vehicles. The appearance of thousands of vehicles with different strategies also provides more imagination space for subsequent other customized functions.

It is said that watching the effect is more convincing than watching the advertisement. How does Tenglong battery perform?

The most direct answer to this question now is the upcoming NETA S.

According to the information released by NETA this morning, the pure electric version of NETA S has a range of CLTC 715 km, and the extended range version of NETA S has a pure electric range of NEDC 300 km.

And of course, the pace of Tenglong Battery will not stop here. According to official revelations from NETA, NETA has collaborated with the head of the supply chain and top universities to complete the research and development of the next generation of Tenglong Battery technology. If you ask what kind of battery it is, I think you should know. NETA also admitted that more information will be released at some point in the near future.

And of course, the pace of Tenglong Battery will not stop here. According to official revelations from NETA, NETA has collaborated with the head of the supply chain and top universities to complete the research and development of the next generation of Tenglong Battery technology. If you ask what kind of battery it is, I think you should know. NETA also admitted that more information will be released at some point in the near future.

As for NETA’s next press conference, I am more concerned about what the next member of the NETA universe will be called, rather than the battery.

Enough talking, I’m going to read the Shan Hai Jing now.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.