Authors: Lingfang Wang

Editors: Kaijun Qiu

Guoxuan High-Tech has released its first semi-solid-state battery and entered the stage of industrialization.

On May 28, 2022, at the 11th Technology Conference of Guoxuan High-Tech, the company released two new products – a 360Wh/kg semi-solid-state battery and the Yijia Electric intelligent mobile energy storage charging station.

The former is about to be installed in vehicles, and the latter has also signed contracts with partners in multiple locations.

The collaboration between Guoxuan and Volkswagen that has attracted great attention in the industry is also continuing to move forward. Volkswagen has already participated in Guoxuan High-Tech’s daily management work and supported the improvement of its processes and standards. Currently, the standard tri-element and iron-lithium battery cores developed by Guoxuan High-Tech have been acquired by Volkswagen.

360Wh/kg Semi-Solid-State Battery to be Installed in Vehicles This Year

Guoxuan High-Tech has publicly displayed its semi-solid-state battery with a length of 580mm, a width of 120mm, and a thickness of 9mm, a capacity of 136Ah, and a weight of 1341g, with an energy density of 360Wh/kg. Currently, this battery can pass the test of 180°C 30-minute hot box, which exceeds the national standard.

The first-generation semi-solid-state battery from Guoxuan High-Tech passed the 1mm penetration needle test, and the second-generation product passed the 5mm penetration needle test.

This battery will be installed in vehicles this year. Guoxuan High-Tech has provided data for a high-end vehicle model which has a battery capacity of 160kWh, a range of 1000km, an energy density of 260Wh/kg, and an acceleration time of 3.9 seconds per hundred kilometers.

Zhang Hongli, the Executive Vice President of Guoxuan High-Tech Engineering Research Institute, stated that the company’s laboratory already has prototype samples of the tri-element, semi-solid-state battery with an energy density of 400Wh/kg. In the future, they will also iterate through technical innovation by adopting silicon-based negative electrode, lithium metal negative electrode, and pre-lithium technology to accelerate the transition of liquid battery to semi-solid-state, ultimately achieving full solidification.

Guoxuan also revealed that the production line for large-scale production of semi-solid-state batteries is still under construction and plans to be officially put into operation in the first half of next year.

Lithium Iron Phosphate + JTM

At last year’s technology conference, Guoxuan High-Tech released the JTM (jelly-roll to module, canceling the battery cell shell) technology and 210Wh/kg lithium iron phosphate battery. They were experimental products at that time, but these technologies have now entered the industrialization stage.This time, Guoxuan High-Tech has successfully integrated this battery with JTM technology and achieved industrialization. According to Xu Xingwu, Senior Vice President of Guoxuan High-Tech, this battery to be announced soon has a capacity of 47Ah, weighs 710 grams, and has an energy density of 210Wh/kg. The energy density of the battery pack using JTM technology reaches 180Wh/kg.

According to Guoxuan High-Tech, the reason why lithium iron phosphate batteries can achieve such high energy density is due to the significant optimization of the positive electrode material.

Guoxuan High-Tech has continuously improved its capacity and compaction density by doping modification and structural design, reaching 152mAh/g and 2.55g/cc.

Next, thick electrode technology is used. Thick electrode technology is an important way to significantly improve the energy density of batteries. However, the conductivity network problem of thick electrodes must be solved. Guoxuan High-Tech can significantly improve the energy density of the battery and reduce the polar plate resistance of thick electrodes by designing a three-dimensional conductive network, while also considering high energy density and power characteristics.

Of course, pre-lithiation technology is also essential for solving first effect issues.

Guoxuan High-Tech is continuing to explore the potential of lithium iron phosphate batteries. According to the Guoxuan High-Tech lithium iron phosphate energy density improvement technology roadmap, a battery with an energy density of 220Wh/kg will be launched in 2022, and a battery with an energy density of 260Wh/kg will be achieved by 2030.

In addition, with JTM technology, Guoxuan High-Tech has launched the Lishi battery swapping technology. The JTM technology battery is very suitable for staged use, so it is called the “battery designed for staged use” by Guoxuan High-Tech.

Regarding this battery swapping technology, Guoxuan High-Tech did not provide too much information, only mentioning that it is a new business model that integrates charging, swapping, and storage. This product has already received batch orders and will be listed in the new vehicle catalog soon.

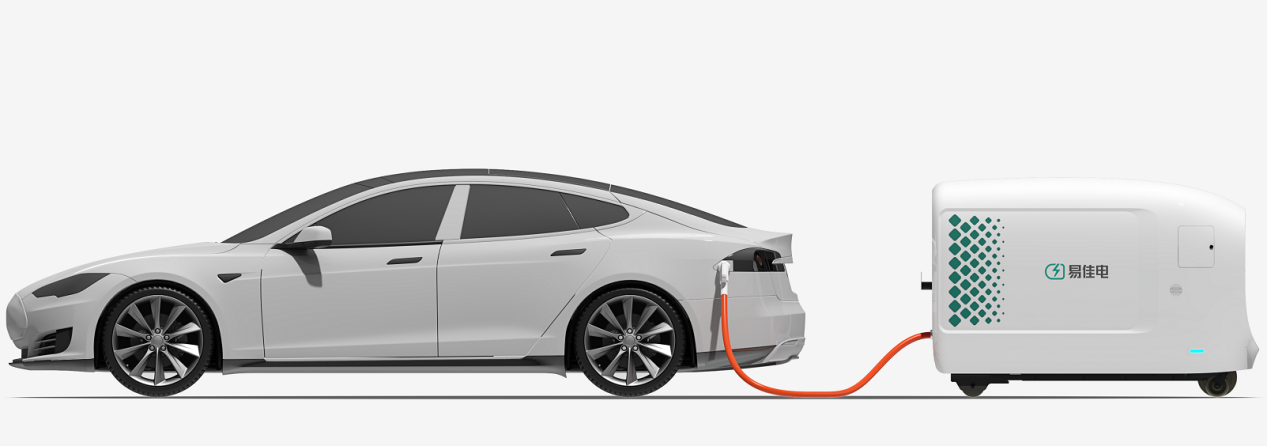

In addition to batteries, Guoxuan High-Tech has also released a mobile energy storage and charging station, priced at RMB 350,000 per unit.

The Yijia Electric Intelligent mobile energy storage and charging station is independently developed by Guoxuan High-Tech and has characteristics such as easy layout, multi-scene adaptability, large capacity, and high power.

Xie Faqiang, General Manager of Anhui Yijianeng (a subsidiary of Guoxuan), believes there are three scenarios for electric vehicle charging in the future: the most common fixed charging piles, newly emerging battery swap stations, and mobile energy storage charging.

Mobile energy storage charging has three major advantages: from the perspective of electricity usage, charging is not constrained by the power grid, achieving peak shaving and valley filling, reducing the burden on the grid and making charging safer and more secure; from the perspective of space, charging breaks the limitation of space, requiring no infrastructure construction, and offering more flexible deployment options; from the perspective of application scenarios, charging breaks through the conventional thinking of a charging pile or an energy storage station, achieving direct economic benefits.

To demonstrate its economic benefits, Xie Faqiang did some calculations: for example, taking a shopping mall or hospital as an example, it is difficult to find suitable land or receive fire protection approval to build a small, 2MW energy storage power station. However, using Yijianeng’s products, ten units can be conveniently deployed in corners where it’s hard to install chargers, each with less than 200 kWh, with strong affinity and high safety level as independent units, helping to make up for the shortage of chargers. The cost can be recovered in 4-5 years by integrating charging and energy storage.

The cooperation between Guoxuan and Volkswagen is of great concern to the industry. During the meeting, Frank Engel, Executive Vice President of Volkswagen Group (China), introduced in detail the cooperation between Guoxuan and Volkswagen. Engel believes that Guoxuan is an important strategic partner of Volkswagen Group, and also a technology partner of Volkswagen Salzgitter factory. For Guoxuan, Volkswagen Group is both a shareholder and a consultant as well as a customer.

“As a shareholder, Volkswagen has participated in Guoxuan’s management work, supporting the establishment of the board of directors and management committee process, to enhance corporate management capabilities; as a consultant, Volkswagen has dispatched experts to support the improvement of Guoxuan’s processes and standards; as a customer, Guoxuan has made products tailored to Volkswagen’s standards. The two sides have maintained an open and friendly cooperation.”

According to information provided by Guoxuan, the total number of personnel for the Volkswagen-Guoxuan joint project team exceeds 100, covering all functions including battery cells, manufacturing processes, project management, quality, and testing. Guoxuan’s lithium-ion and iron-phosphate standardized battery cells have both been approved by Volkswagen.

Currently, Guoxuan is not only deepening its technology development in the battery field, but also expanding into the charging and battery swap field. Recently, the trend of battery companies extending upstream and downstream of the industrial chain has become increasingly apparent. Under the trend of battery swapping, battery companies are actively releasing standardized battery products. It is believed that in the future, there will be more charging and battery swap products and layouts from Guoxuan.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.