BYD Dolphin officially launched. I know this car is very popular, and our videos, posts, and articles are also comprehensive. Let me summarize this CTB technology.

The Road of Integration

The topic of electric vehicles around batteries has never stopped. As a supplier of automobiles, the status and position of battery manufacturers can be referred to Ningde Times.

The CTB (Cell to Body), CTC (Cell to Chassis), and CTP (Cell to Pack) concepts have since become popular.

Initially, the standards of the power battery industry were different, and CTM (Cell to Module) became the mainstream, generally following a three-level assembly process of “battery cells-module-battery pack” before reaching the car body and chassis.

The CTP technology removes the module in these three levels and can further fit more batteries into the battery pack.

CTB and CTC, in general, have the same concept of cutting the battery pack shell to release more space for batteries.

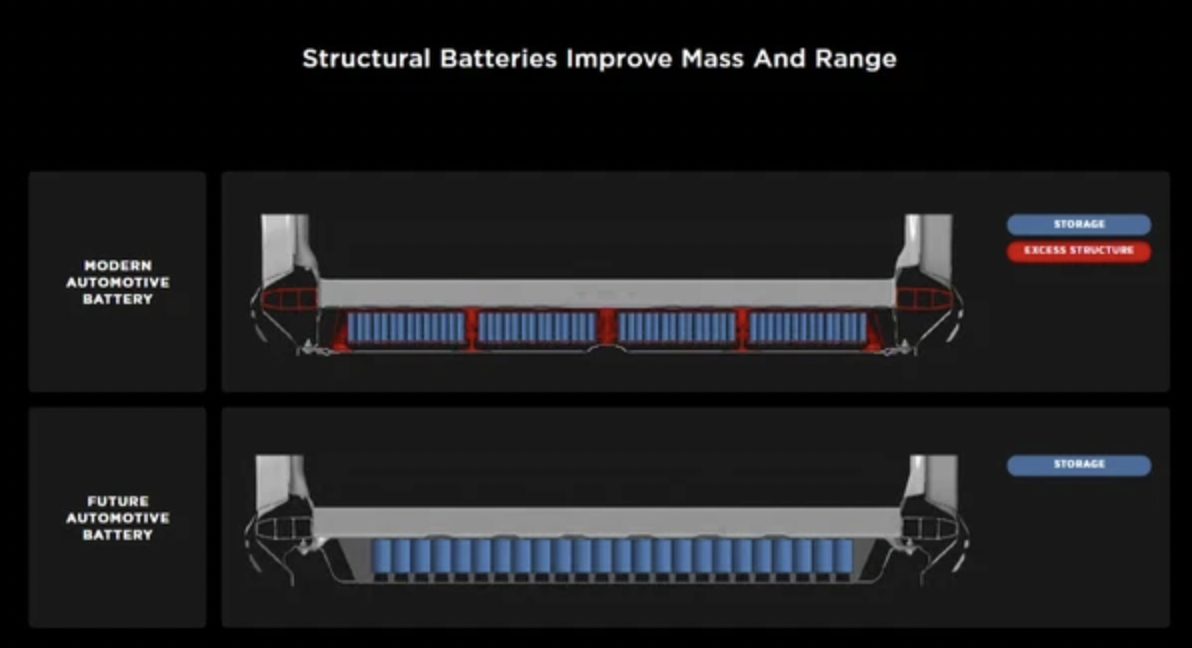

CTC’s fame is closely related to Tesla.

On Tesla’s Battery Day in 2020, Tesla showcased the 4680 battery packaged in CTC (Cell to Chassis). The battery became an integrated structure with the chassis by standing in hexagonal shape, bearing loads.

Due to the disappearance of the battery pack’s support structure, the battery arrangement became more compact. Therefore, the battery can be placed more centrally, with a distribution of weight closer to the center of gravity, smaller moment of inertia, and improved responsiveness to the limit of handling. Additionally, it helps to enhance the battery’s protection against side collisions.

Ma Yilong was afraid that we didn’t understand, so he vividly used “figure skating” as an example: the extension and retraction of the arm during the rotation directly affects the moment of inertia and affects the speed. When the arm is tight, the moment of inertia is small, and according to the law of conservation of angular momentum, the angular velocity increases. In layman’s terms, the more centralized the distribution of weight around the center of gravity, the more agile the handling of the vehicle.

In Tesla’s CTC packaging process, the use of “multipurpose structural adhesives” is crucial; Tesla hopes to have dual features of structural bonding and fire resistance.

Personally, I tend to believe that CTC is more deeply integrated into the battery and body of the car and that the effect of integral die casting is better, so the improvement of the vehicle’s torsion stiffness should be more obvious.

BYD’s CTB

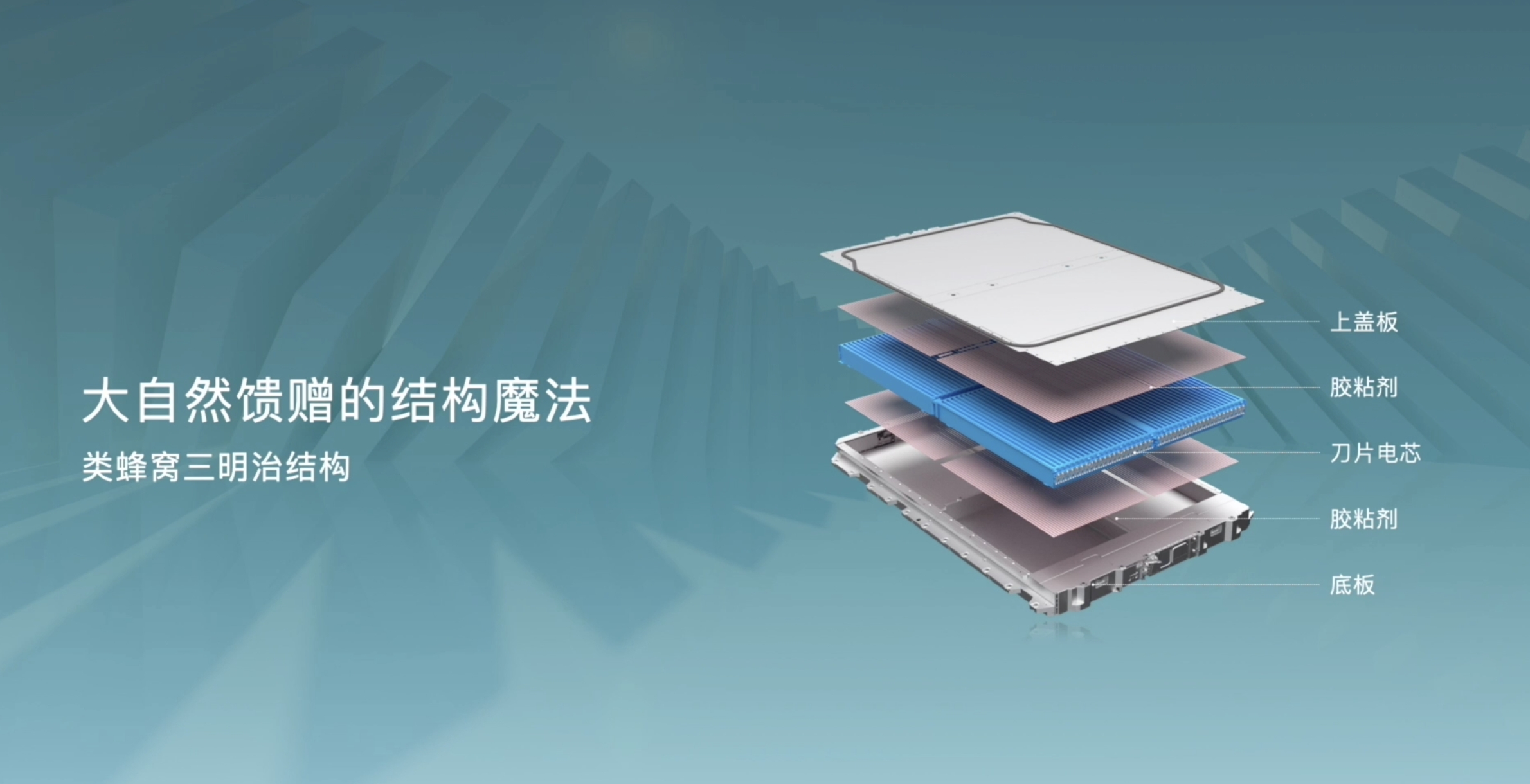

# BYD’s CTB, in their own words, is an “entire vehicle sandwich”, which integrates the body floor panel with the battery pack cover.

# BYD’s CTB, in their own words, is an “entire vehicle sandwich”, which integrates the body floor panel with the battery pack cover.

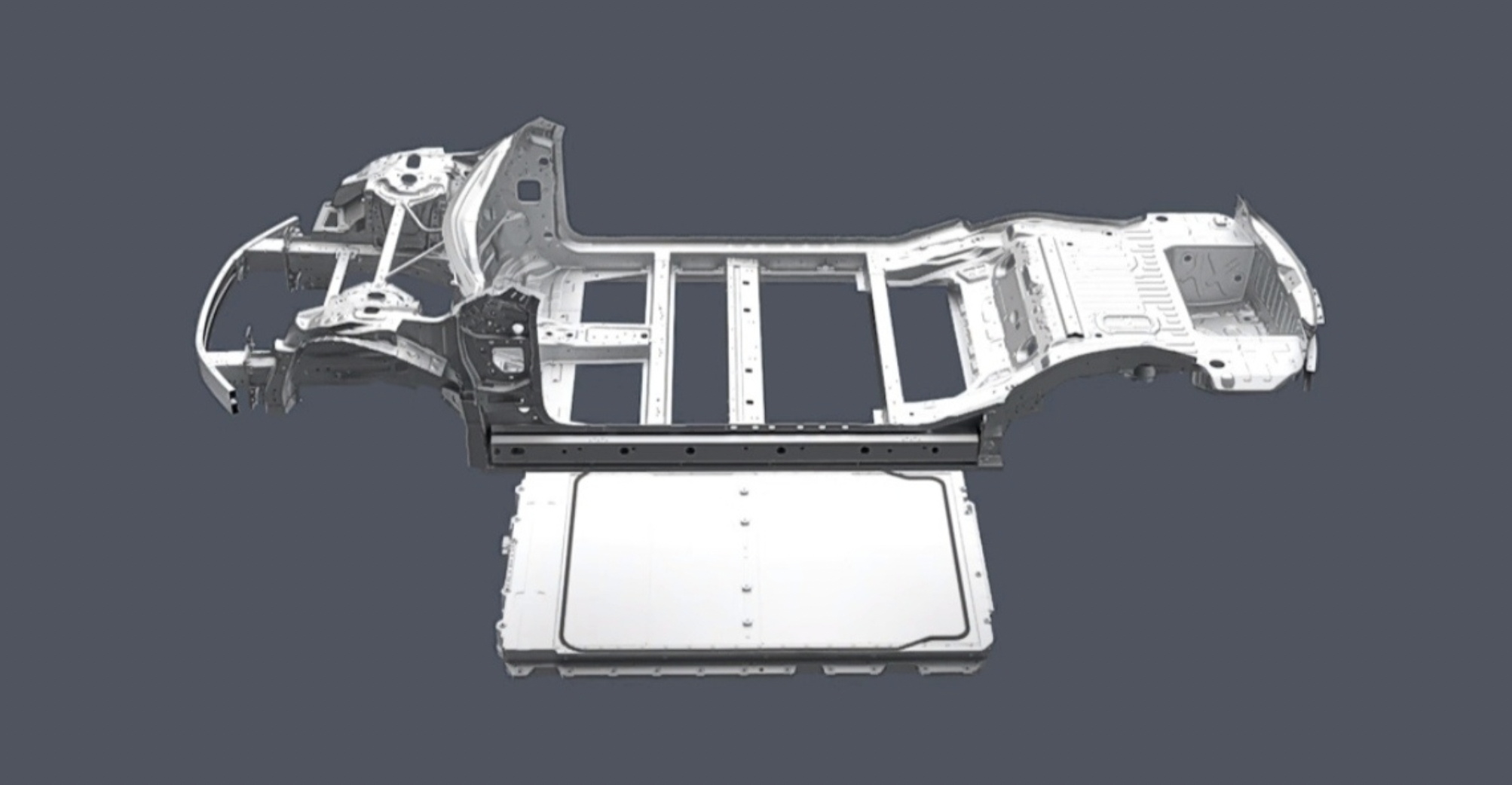

Recently, the design of Road Partner C01’s CTC is somewhat similar to BYD’s CTB, as both have removed the physical existence of the battery pack. Road Partner’s approach, however, is to directly use the body floor as the battery pack cover, integrating the cells and modules from the bottom to the body.

In fact, from the exposed pictures, the bottom of the body still retains cross members to strengthen the torsional rigidity of the whole vehicle. The seats are fixed through these cross members, rather than “directly sitting on the battery” like Tesla.

However, it is obvious that this design will cause the passengers’ feet to come into direct contact with the carpet and battery pack cover, and will inevitably be subjected to impact. I am curious about what material BYD uses to mitigate this problem.

In fact, from this picture, we can also see the vertical blade battery cells. The cells are still divided into four large modules with physical barriers between each module to prevent thermal runaway from spreading.

Effect:

-

Improved battery energy density: Under a wheelbase of 2,920mm, an 82 kWh LFP battery is installed (XPeng P7’s wheelbase is 2998mm, with a maximum 81 kWh battery).

-

Vertical height of battery release: An increase of 10 mm in vertical space reduces overall vehicle height by 15 mm.

-

Advantages for handling: Low center of gravity (467 mm), optimal axle load ratio, low moment of inertia, and high torsional stiffness (40,500 N·m).

-

Disadvantages: Significant increases in repair costs and difficulty. It is expected that battery repair costs will increase significantly. After the implementation of CTB and CTC, this cost may rise, and even lead to car replacement.

Conclusion

In summary, battery integration is a major trend. BYD and Road Partner are trying to explore new ways, while other automakers need to decide on their own strategy.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.