Text | Roar and Howl

The large integrated cast aluminum body, led by Tesla, gradually has a “word of mouth” trend.

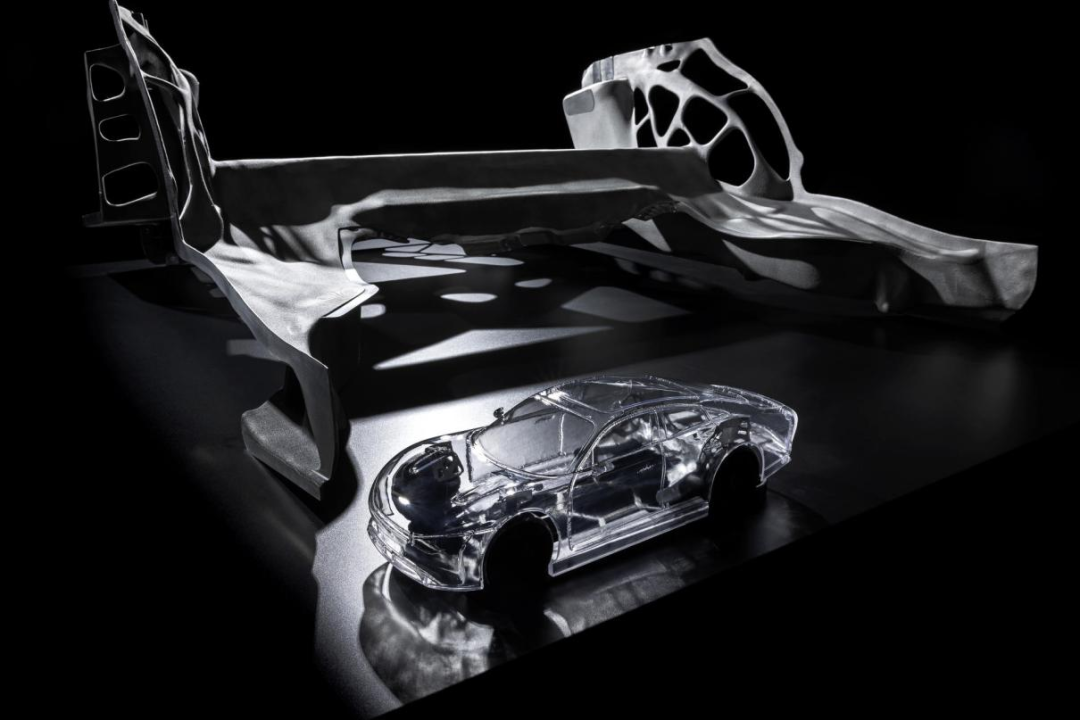

Earlier this year, Mercedes-Benz released the EQXX concept car, and the rear body of the car adopted “BIONEQXX” bionic structure design, which is essentially a large integrated die-casting aluminum alloy component. Volvo announced that it will invest about 7 billion yuan in the next few years to build a new electric vehicle factory, focusing on the production of 8000-ton level die casting machines for large castings. Volkswagen plans to introduce integrated die-casting car bodies in the Trinity project in 2026.

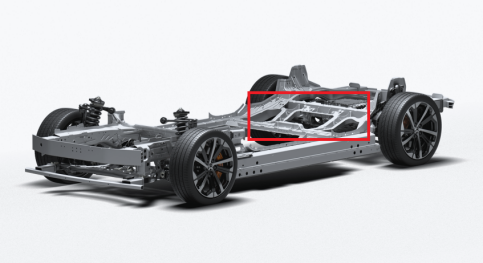

Domestic automakers are moving faster. The new car ET5 that NIO is about to deliver this year uses large-sized cast aluminum parts near the lower floor of the rear lower body. GAC and XPeng have publicly or semi-publicly disclosed that they are developing and introducing large integrated die-casting technology similar to Tesla. Due to Li Xiang’s recent public discussion and praise, Ideal probably also has some ideas about integrated die-casting. Even Xiaomi’s car, which has not yet been launched, recently announced a call for bids for a large-scale die-casting project.

As explained in the article “Your Model Y is being “pressed” out” before, cast aluminum is one of the long-standing forming processes used in the automobile industry, and casting aluminum alloy itself is nothing special. Tesla’s approach on Model Y is to use large-sized integrated cast aluminum parts to replace several connecting components.

Another Point of View

Contrasting with the industry’s positive and optimistic development, some different views or concerns are beginning to emerge in the consumer market.

In February of this year, news of “28 Tesla crashes, repairs cost 200,000 yuan” once topped the headlines of major technology and automotive media outlets. A “Su B” license plate Model Y accidentally collided with a protruding building wall while reversing.

Due to the collision location being too far outside and the overlapping surface being too small, it happened to avoid the rear collision beam, and hit a non-collapsible obstacle such as a wall. The damage to the Model Y almost went straight to the right rear wheel arch–which is part of the integrated die-casting rear body.“`

The reason for the sky-high repair costs is easy to understand: because the rear body (floor) is a single integrated component, although only the right rear side is damaged, the large-size die-casting component that crosses left and right can only be replaced as a whole. Regardless of material or labor cost, this repair cost will not be low.

The huge repair costs quickly make consumers feel the risk. The ¥200,000 repair price list is there, and no matter how auto bloggers argue that “cast aluminum is actually more economical,” it’s just no use. The worry about insurance costs follows, although no insurance company currently differentiates premium rates for models that use integrated die-casting bodies.

Putting aside the controversy over after-sales maintenance, the auto industry’s recognition of integrated die-casting technology is not a consensus. BMW CEO Zipse stated last year that it would not follow Tesla’s so-called “gigacasting” large-scale integrated cast aluminum components because they did not believe that doing so would bring economic benefits.

Wolfram Volk, the director of the Forming Technology and Casting Engineering Department at Munich University of Applied Sciences, also expressed some cautious views on integrated die-casting earlier this year. Overall, he agreed that large-scale integrated die-casting parts are novel, brave, creative, and attractive solutions; but at the same time, they are not as magically cost-effective as car companies promote.

Magical, Not Mythical

Whether it is the concern about repair costs or the puffery of benefits, it has gone too far.

It is normal for consumers to be frightened by sky-high repair bills, and it is not unreasonable to worry that vehicle insurance premiums will rise. After all, it is indeed possible to “replace half a car body structure in one go”-which is usually not possible with a conventional car body.

But as many people have explained, the coverage of the integrated cast aluminum component usually belongs to the main load-bearing structure of the conventional car body as well. In other words, if a conventional car body suffers the same degree of damage, even if it is not immediately scrapped, it is very likely to seriously affect the residual value of the vehicle, commonly known as a major accident vehicle.

Everyone only sees “¥200,000 spent on repairing a Tesla that costs ¥280,000,” but if a conventional car body is damaged to such an extent, after deducting the repair cost paid by the car owner and factoring in the depreciation of the vehicle, how much more can it be compared to “¥280,000 – ¥200,000”?

So the question becomes, are you more willing to pay higher repair costs or bear higher insurance premiums but have the vehicle repaired closer to the state before the accident, or are you more willing to pay conventional repair costs but accept a large decrease in vehicle value?

“`The difference between the two choices is not clear cut at least for now, even though you may have your preference. Similarly, the miraculous effect of die-casting is now overrated. The most widely spread saying goes that it can save 20% to 30% of costs by reducing the process of connections. However, caution and doubt have been raised by experts such as Qiupce and Wolfram Volk, and Li Xiang also expressed that Tesla was trying to improve efficiency, not reduce costs. The claim of cost-saving of 20% to 30% may have overlooked the complex factors in die-casting, such as the service life of the mold, the depreciation of the die-casting machine, waste material losses, and energy consumption. One-piece die-casting may well provide car companies with a new “tool” to reduce costs, but this effect is unlikely to be a qualitative change, such as an instantaneous reduction of 20% to 30%. Moreover, the real cost-reducing needs reasonable planning and utilization by car companies, meaning that low-cost advantages are not “on-demand.”

Even Li Xiang’s conclusion may not guarantee that the large-scale one-piece die-casting is always efficient. Large-sized one-piece die-casting parts, as in the case of Tesla Model Y, obviously lose the flexibility of application for different car models, requiring different molds. The rear of Model Y cannot be used for Model X, and even Model 3 with similar dimensions cannot be directly adapted. Obviously, this brings about the problem of sunken costs of molds. Only the automaker with enough confidence, like Tesla, to rapidly achieve scale sales for its models (commonly known as blockbuster), can afford to introduce large one-piece die-casting components without risk. This also explains Li Xiang’s ideal target, which is to “create a blockbuster for every 100,000 cars.”

Not all automakers have such capabilities. If they cannot anticipate large-scale sales, using one-piece die-casting will inevitably lead to more equipment investment for each vehicle. This will either increase the final selling price or squeeze profit margins. It is not just a matter of ability. The automobile market is a (relatively) low overall concentration and high freedom of choice market. Most of the major automakers offer dozens of car models, which greatly reduces the motivation of car companies to “customize” large-scale die-casting parts for each model. It is rather a exception, as in Tesla’s case, to dominate the market with only two best-selling car models.According to a related person from a car company quoted by Automotive Business Review, “It’s a big burden for a model that sells less than 50,000 units a year.” This number may not be accurate, but it already shows the problem: even large-scale car companies cannot achieve annual sales of 50,000 units for every model, let alone some smaller-scale and new car companies.

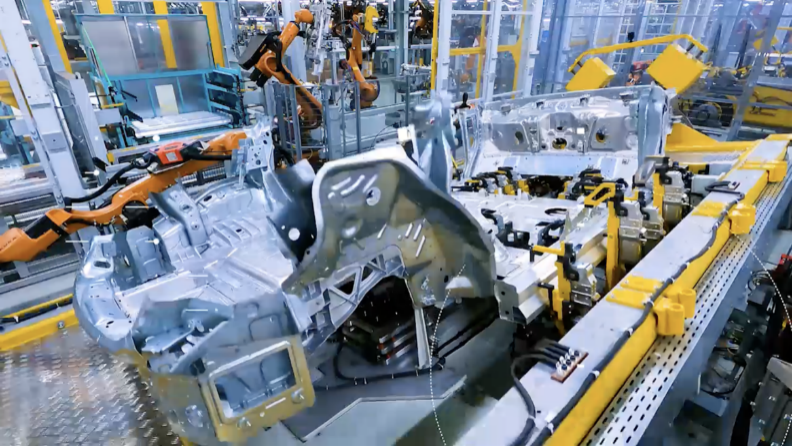

In addition to depreciation and amortization, even if a car company produces multiple models, it will lose efficiency by specifically manufacturing large-scale die-casting parts for each model and replacing the mold to switch production models. Wolfram Volk pointed out that because die-casting machine molds must be vertically replaced with the assistance of cranes, the replacement time for a 100-ton mold is 10-12 hours, while the conventional stamping process changes molds in only 3 minutes.

Small component combinations are bound to be more flexible, and large-scale integration is inevitably more restricted. When large integrated die-casting parts replace many parts combinations, “inflexibility” is an unavoidable byproduct. This is not necessarily a bad thing, but it does indeed restrict the large-scale application of integrated die-casting technology. Tesla took the lead in using integrated die-casting technology, which has some contingency and exceptional circumstances.

Is the world unidirectional?

As Bo Hu often repeats, the evolution of technology is dynamic and there is no absolute barrier once it is formed and settled. It does not mean that when integrated die-casting technology arrives, all conventional process vehicles will become outdated, and the performance of vehicles that do not use integrated die-casting will inevitably lag behind.

People often focus only on the most obvious point, ignoring the situation before and after that point, so they attribute all the reasons to that point itself. All those popular stories are like this: “Nokia fell” in such a way, “iPhone rose” in such a way, “integrated die-casting” if it eventually becomes the future, it may also be the same.

But the result does not necessarily lead to 100% causal relationship.

BMW CEO Zipse expressed distrust of Tesla’s large-scale integrated die-casting approach, but in fact, BMW also attaches great importance to the large-scale aluminum casting parts, but the method is not as extreme as Model Y. The front and rear body of iX both use cast aluminum parts, but they do not span the left and right body.

The largescale aluminum casting of aluminum cast parts requires heat-treated aluminum alloy materials as a support to bypass the problem of thermal deformation of largescale aluminum cast parts. But even if Tesla claims that heat-treated materials can achieve the required performance, naturally hardening aluminum alloys are still significantly weaker in strength than conventional aluminum or steel, which means that to achieve the same performance, large-scale cast aluminum parts may need to increase thickness and weight. This will partially offset the lightweight opportunities brought by the casting process, and the weight advantage will be reduced, accompanied by the difficult benefit of raw material costs due to the casting process (it is impossible to achieve the goal with less aluminum).In the previous article, we mentioned the requirements of aluminium casting technology for the tonnage performance of die-casting machines. One important reason why Tesla introduced aluminium casting before the body structure, and recently began producing the aluminium-cast front body of the Model Y at its Texas factory, is that the weight of the front body is significantly larger and requires a die-casting machine with a higher level of performance.

Considering that large aluminium castings require heat-treated materials, which have a disadvantage in strength, and that the strength disadvantage requires increased weight reinforcement, the front of the car requires higher strength. It is not difficult to understand why car companies’ “integrated die-casting dreams” all start with the rear body.

The order of using die-casting for the front and rear body is not the focus. The key point is that due to a series of reasons, the application scope of integrated aluminium castings as replacements for conventional body parts is limited and cannot be changed if needed. Furthermore, it is not realistic to expect “whole-vehicle integrated die-casting shaping” in a short period of time.

If the above text is summarized, the application scope of integrated die-casting in the entire automotive industry is obviously limited. This is because, surprisingly, the main material for most car bodies is still steel, even for the most economical vehicles. Aluminium is a rarity, let alone aluminium casting and large integrated die-casting parts.

At the end of the last century and the beginning of this century, all-aluminium bodies were also popular. From any perspective back then, all-aluminium bodies were the inevitable future, and it was a familiar phrase to say “the general trend”. However, the result today is clear. The answer is mixed-material body structures dominated by aluminium, with only a few still insisting on using all-aluminium structures.

In retrospect, the judgement at the time was not wrong. People saw the potential of aluminium, but some mistakenly thought it would dominate the market completely. Integrated die-casting is also the same. It is a new thing that has given automobile production new opportunities, new methods, new thinking and new freedom. However, viewing it as an infallible hexagonal warrior without any shortcomings or limitations, as if it were the ultimate answer to the automobile production industry, is somewhat naive.

We are the generation brainwashed by “over-simplified narratives”. We grew up with “Occam’s Razor” and witnessed the rise of “first principles”. It seems that this world is full of one-sided immutable truths. Once we understand it, the road is straightforward. We just need to charge forward in that direction with our heads down.

This is simply a cyberpunk thing of the 21st century.

We used to think that the internet would change the world. Today, we find that the world is changing the internet.

We used to think that online communication would replace offline communication. Today, we find that staying at home in person is impossible.

We used to think that globalization was irreversible. Today…

Willful standardization is never the true direction of the world.

If there is an arrow-like guidance that is easy to follow without thinking but guarantees to never go wrong, then the world will become too easy and effortless, without the need for careful consideration and balancing.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.