Author: Zhu Yulong

Recently, many automakers have begun the large-scale development of new energy vehicles. In this segmented market, where prices are high and brand effects are important, centralized electronic and electrical architecture focusing on technological configuration is the current trend. Some of the recent information released by IDEAL automotive is worth analyzing. Thanks to Xiaokang for sending me the PPT file “Smart Car High Computing Platform Layout – IDEAL Automotive Computing and OS”.

Iteration of EE Architecture for IDEAL Automotive

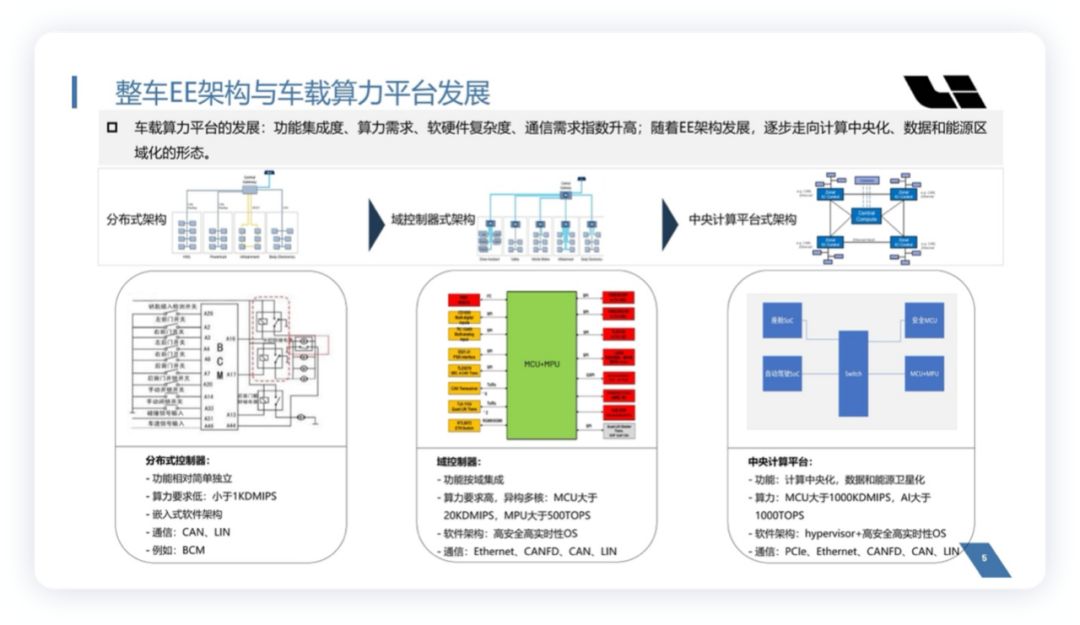

IDEAL Automotive’s electronic and electrical architecture is currently divided into three iterations.

LEEA1.0 is a traditional distributed architecture, which is used in IDEAL ONE. The iteration method of this system is based on the intelligent cockpit controller and ADAS controller.

LEEA2.0 is a domain controller architecture used in IDEAL L9. The whole vehicle is divided into three control domains: central control domain (including power, vehicle body and some chassis functions). Here, the main implementation is the fusion of the body control unit (BCM) and the central gateway, and is developed based on the automatic driving control domain (NVIDIA Orion2) and intelligent cockpit controller (81552). The central domain controller in the LEEA2.0 electronic and electrical architecture of IDEAL is as follows.

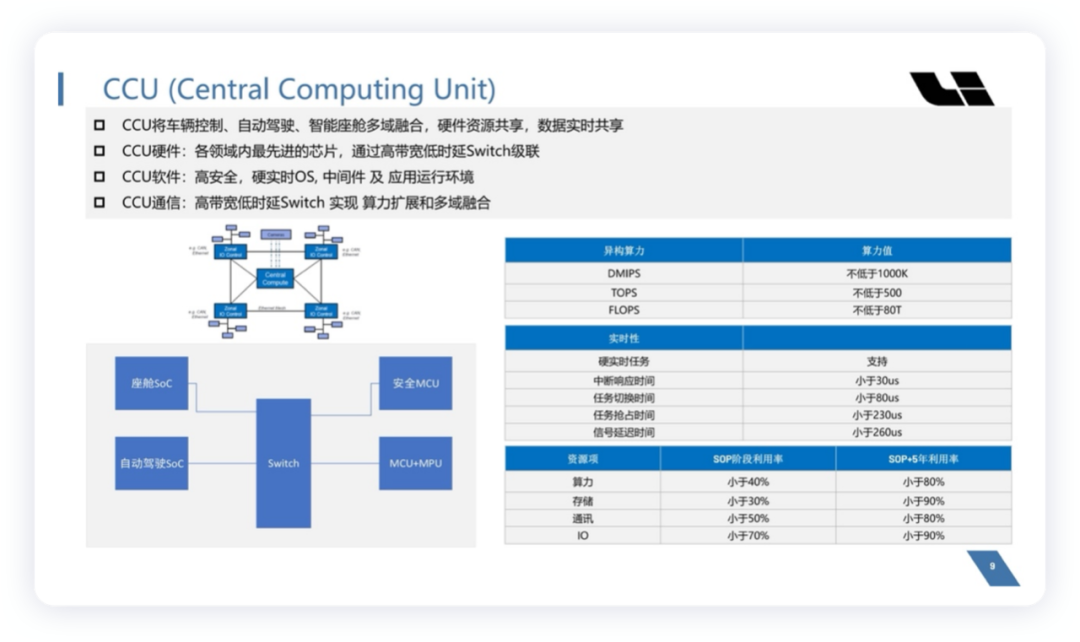

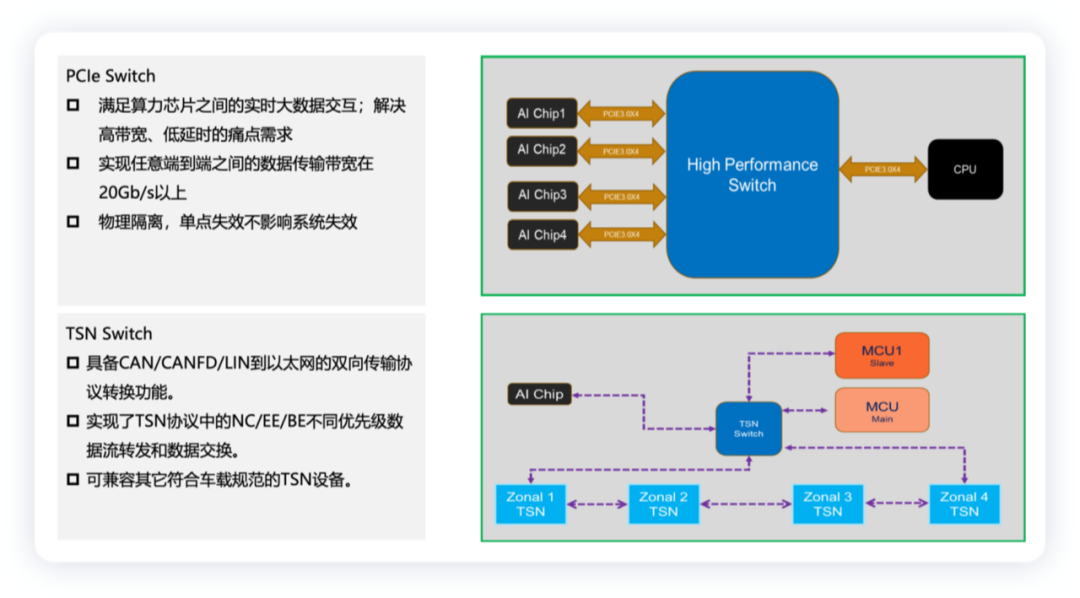

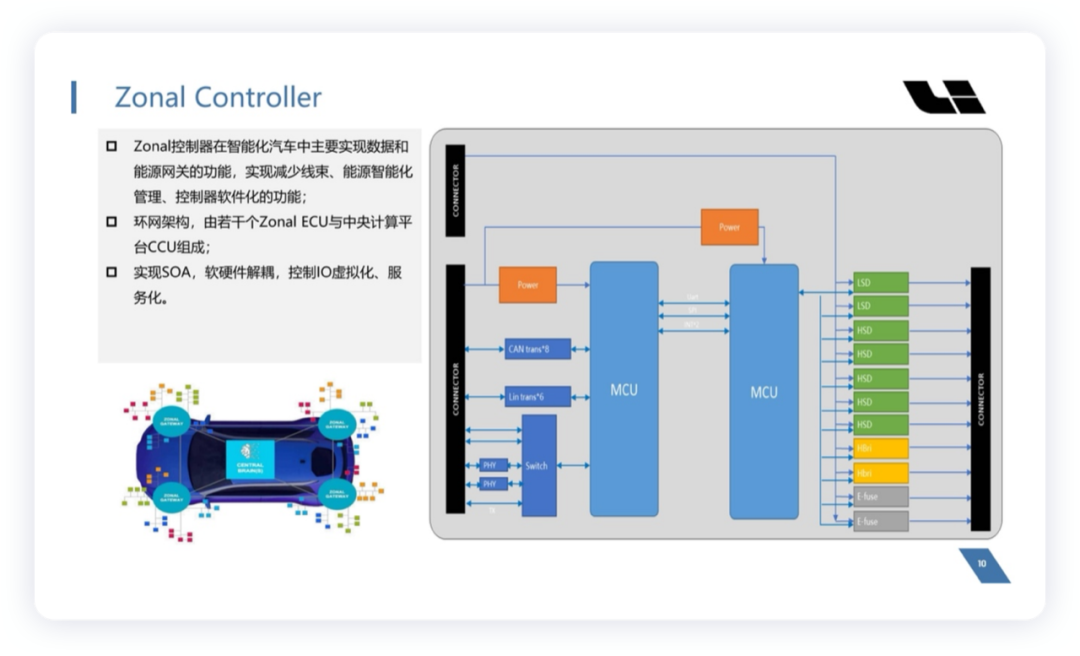

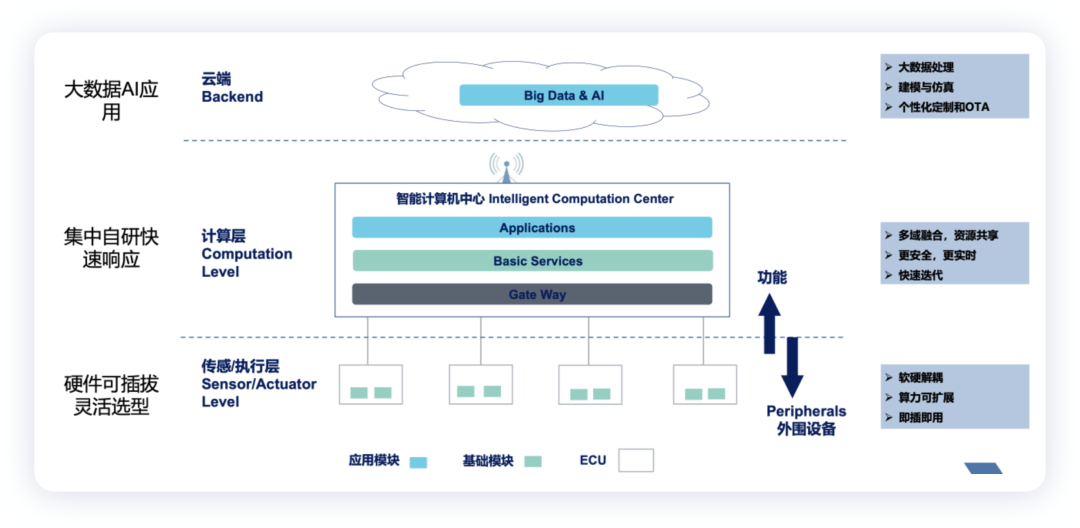

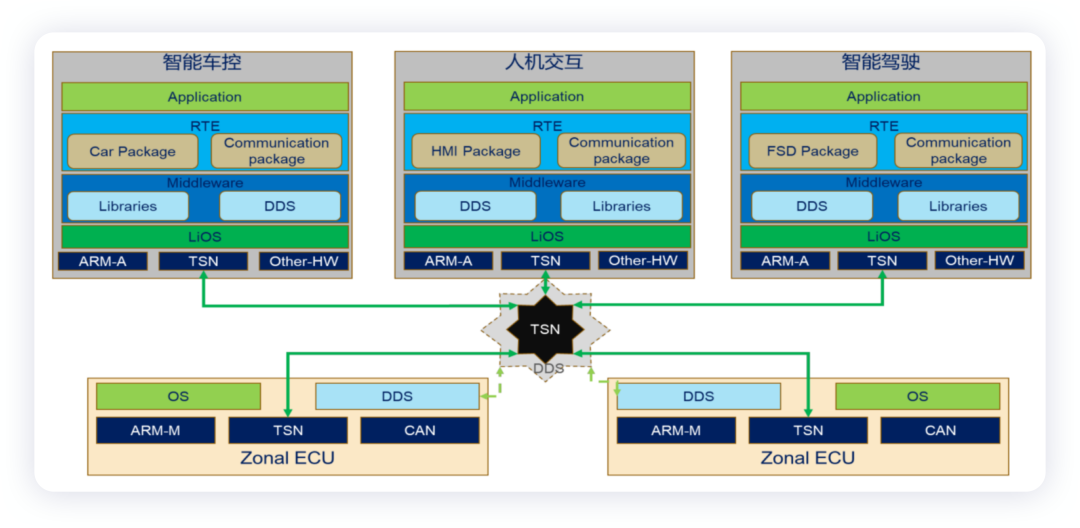

LEEA3.0 is a new model (800V pure electric platform) that is expected to be launched next year, where the central computing platform + regional control architecture will be used. Currently, according to the information available, it is possible to use the design concept of industrial control computers, and connect the three boards of intelligent vehicle control, automatic driving, and intelligent cockpit using PCIe in a OneBOX structure. The goal of this generation is to achieve centralization of computing, system abstraction of data and energy zones, and locally integrate and control all kinds of physical sensors that are close to each other, while outputting various controls to the motors. Then, after packing the data, they will be returned to the computing center.

In several sections, a large board can be integrated as a whole, but logically the individual blocks of the boards are separated due to the high cost of all SOC chips. Then, the interconnection effect is better achieved through PCIe Switch and TSN Switch.

From this figure, the ideal design is to iteratively upgrade based on the NXP S32G. On top of this, the low-side switch, high-side switch, E-fuse and half-bridge circuits can be configured. Each Zonal controller is equipped with 8 CAN channels, 6 LIN channels and 2 Ethernet channels.

The Software Advantage of New Players

At present, the software capabilities of new players have not yet been fulfilled, mainly because the systems are based on relatively old architecture. In the new-generation development based on the physical architecture of Central Computing Unit + Zonal Control Unit, the SOA design concept is adopted to define and deploy multi-level services inside the vehicle. This process is a great challenge for the team and it is difficult to handle the power of suppliers. In other words, the automakers need to rely on external software suppliers and their own software teams to do this.

Logically speaking, automakers need to build a highly extensible, real-time and secure microkernel-based operating system for vehicles. Then, improve the user experience through optimization of computing resources. Finally, meet user needs for new features through the development of an application development ecosystem. Ultimately, the open software-hardware integrated computing platform facilitates the automaker’s innovation and competition.

Note: We need to further confirm where the in-house development is reflected here based on subsequent research.

Because of my understanding, interpersonal interaction needs an ecosystem. Your base is still based on Android’s practice, while this system is based on Qualcomm’s chip system. I don’t understand why there is no Qualcomm logo here. The ideal application uses Infineon’s high-end MCU, including NXP, NVIDIA, Horizon and Arm.

Conclusion: In the current environment, I have learned that automakers may need to focus on their own development because new forces may need three generations of models and three different electronic and electrical architectures, which will bring great maintenance pressure in the future. However, I understand that moving towards a new direction will be more sustainable. As the hardware and electronic and electrical architecture gradually solidify in the future, the software capabilities will be fully compared.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.