Ever since BYD officially released its “DM-i Super Hybrid Technology” in January 2021, domestic independent brands have been taking big steps towards plug-in hybrids.

Looking around, the Great Wall Lemon DHT, Changan Blue Whale i-DD, Chery Hybrid System, Geely Raytheon Hybrid, and even the recent Voyah “Lanhai Power,” have all announced their hybrid strategies and accelerated the launch of relevant models.

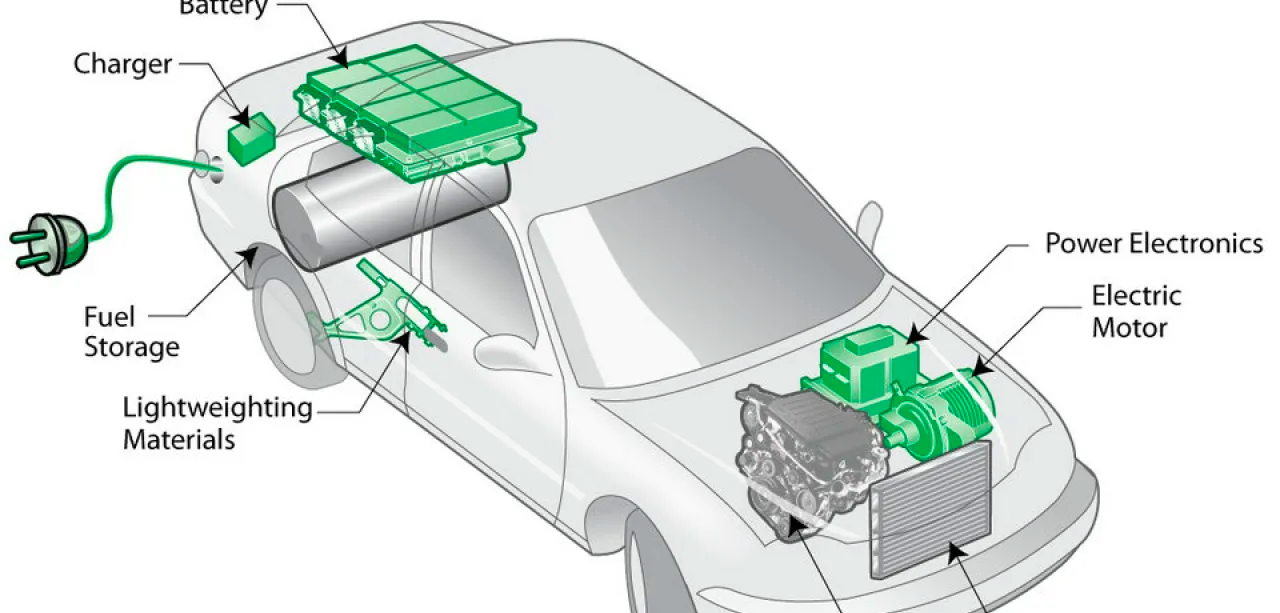

Therefore, it is necessary for us to have a basic understanding of the hybrid system.

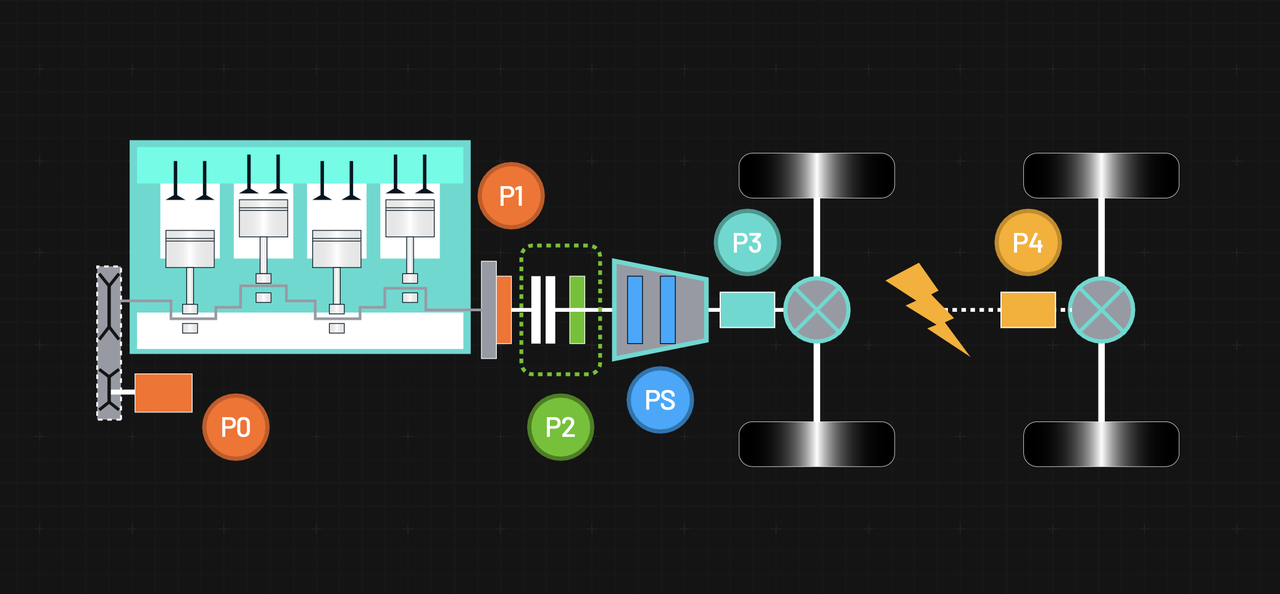

Motor Position

-

P0 motor, also known as the BSG motor. Installed at the front end of the engine, it is connected to the engine via a belt, generally with low power output and cannot drive the vehicle. It is mostly used as a start/generator motor and can also adjust the engine speed to make gear shifting smoother.

-

P1 motor, also known as the ISG motor. Installed at the rear end of the engine, generally integrated into the flywheel or combined with the flywheel through gears, it can replace the starter and serve as a generator with higher power output.

-

P2 motor, located between the gearbox clutch and the transmission. The motor has a relatively large power output and can directly drive the vehicle through the gearbox.

-

P3 motor, also known as the front axle motor. Located behind the gearbox, it is directly connected to the output shaft or main reducer of the transmission, which can directly drive the vehicle for pure electric driving.

-

The position of the P4 motor is not fixed and is mainly different from the engine axis and can support direct driving of the vehicle. Generally located at the rear axle.

Of course, these motors can appear simultaneously according to different layouts. Therefore, the most luxurious configuration is to keep all the P1-P4 motors.

And now the trend is towards integration, so motors in positions P1-P3 that are close to each other have been integrated with the transmission, and even the P0 motor can be further integrated.

P0+P1

After introducing the motor positions, I would like to share some corresponding manufacturer solutions in order.

P0 and P1 motors are essentially unable to drive the vehicle for pure electric driving. Besides assisting with engine start-stop and adjusting the engine speed, their main function is energy recovery. Therefore, models equipped only with these two motors are weak hybrids or light hybrids (24-48V).There are actually quite a few vehicles that only feature a BSG (P0) motor. For instance, in 2011, Mazda, popular among “otaku” (Japanese term for geeks), released the “i-ELOOP” plan, in conjunction with the i-STOP system, which can save 10% of fuel. This is essentially using the BSG motor as the starter motor, which, in theory, can result in less vibration. BYD’s third-gen DM added a 25 kW BSG motor, which has effects similar to those of Mazda’s i-ELOOP.

Honda’s first-gen IMA Hybrid, developed for the Insight, increased the P1 motor. The 48 V Light Hybrid System on the brand new C-Class Mercedes-Benz features the ISG (P1) motor. Meanwhile, the old C-Class uses a BSG (P0) motor.

I view these motors as a way to fix the inherent shortcomings of engines. As electric-only driving is not attainable for vehicles, we won’t delve too deeply in it.

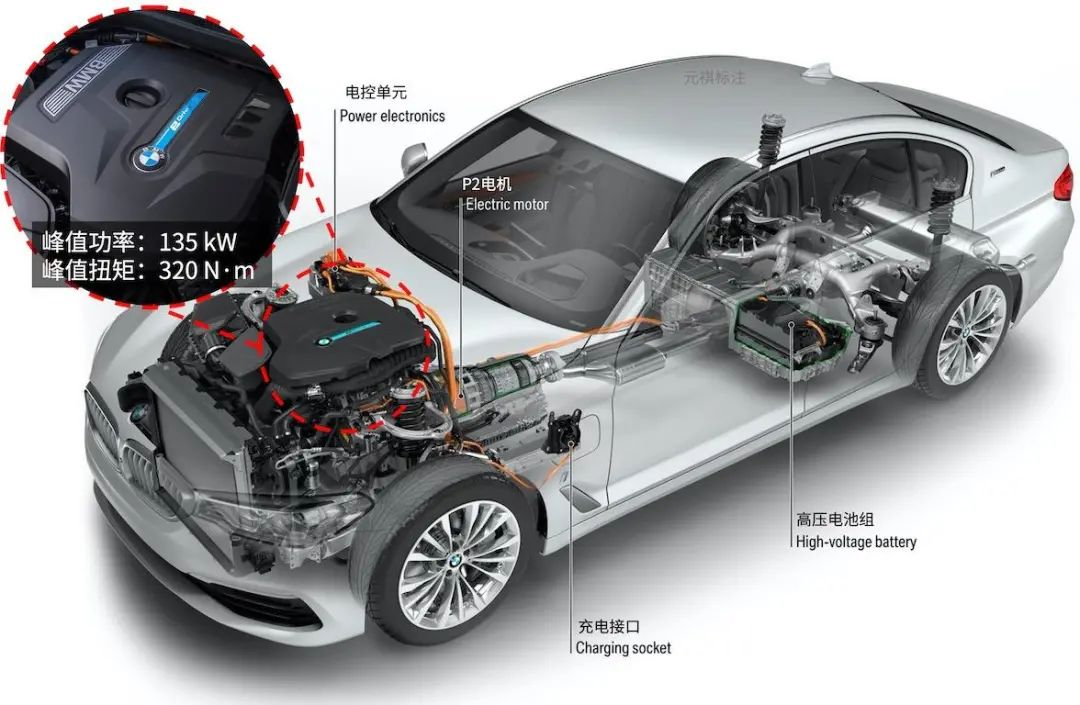

P2

The P2 motor and the engine output end feature a clutch, which makes it possible to directly cut off the hard connection between the engine and the motor, resulting in pure electric driving. The P2 motor can be directly placed on the input shaft of the transmission, which requires minimal modifications to the conventional petrol transmission system.

This means that, for fuel platforms with mature engines and transmissions, adding the motor in the P2 position is an optimal solution in terms of cost.

This is why many European brands, such as BMW, Mercedes-Benz, and Volkswagen, use P2 motors on their plug-in hybrid models.

For instance, Audi’s Q5 Hybrid and Volkswagen’s Touareg Hybrid feature the P2 motor, as does the Audi A3 Sportback e-tron, all of which are brands under the Volkswagen Group.

Tier 1 companies, such as BorgWarner and GKN, have launched mature solutions to meet the market demand. Great Wall’s 9HDCT hybrid transmission uses its own honeycomb drive; the P2 motor features BorgWarner’s product.

The latest Changan iDD follows the P2 route.

-

P0 + P2Generally, the P2 motor is used in combination with the BSG (P0) motor, which is the classic P0+P2 hybrid scheme. For example, the ninth-generation Sonata hybrid version (2016) under the Hyundai Group is equipped with a hybrid power system called “TMED” based on the P0+P2 hybrid scheme.

-

P1+P2

Of course, there is also the P1+P2 scheme. For example, the SAIC Roewe 550 hybrid ride-hailing car that many of us have used, is equipped with a P1+P2 scheme called “EDU” hybrid system. The Roewe eRX5, the Roewe ei6, and the MG 6 hybrid also use this system. The initial DM technology of BYD, the F3 DM model, also uses the P1+P2 scheme.

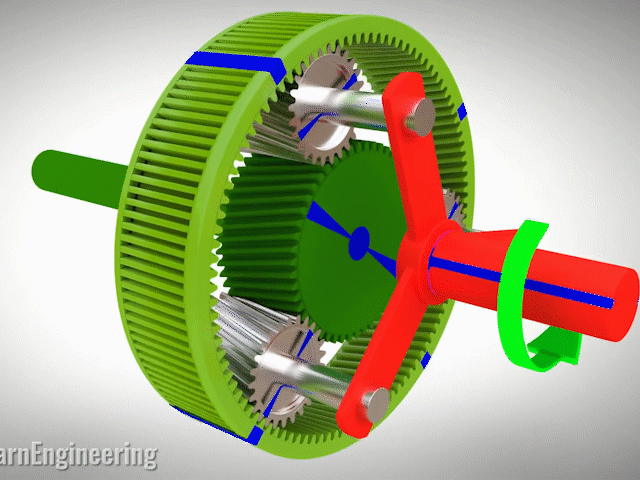

P2.5 (Integration)

What is P2.5? Why didn’t I mention it earlier? P2.5 refers to the design in which the motor and transmission mechanism are integrated. I believe that the integration of P2, P3, and the transmission can be understood as P2.5.

Therefore, from this perspective, almost all new hybrid technology is actually the same.

With the advancement of technology, the P2 motor has been integrated with the transmission.

For example, the well-known Toyota THS-II scheme integrates the P2 motor with the transmission and the core component is the E-CVT. Note that this thing actually has little to do with the CVT and is a power split device composed of a planetary gearset.

The Gauss Wave Power of GAC Group has received the essence of Toyota, so it naturally follows this path. Even the addition of a 2.0T engine has greatly improved the vehicle’s power response.

Another example of this path is the Geely’s E powertrain Hi·X hybrid. Three dual-clutch transmissions are formed through a double-row planetary gearset.

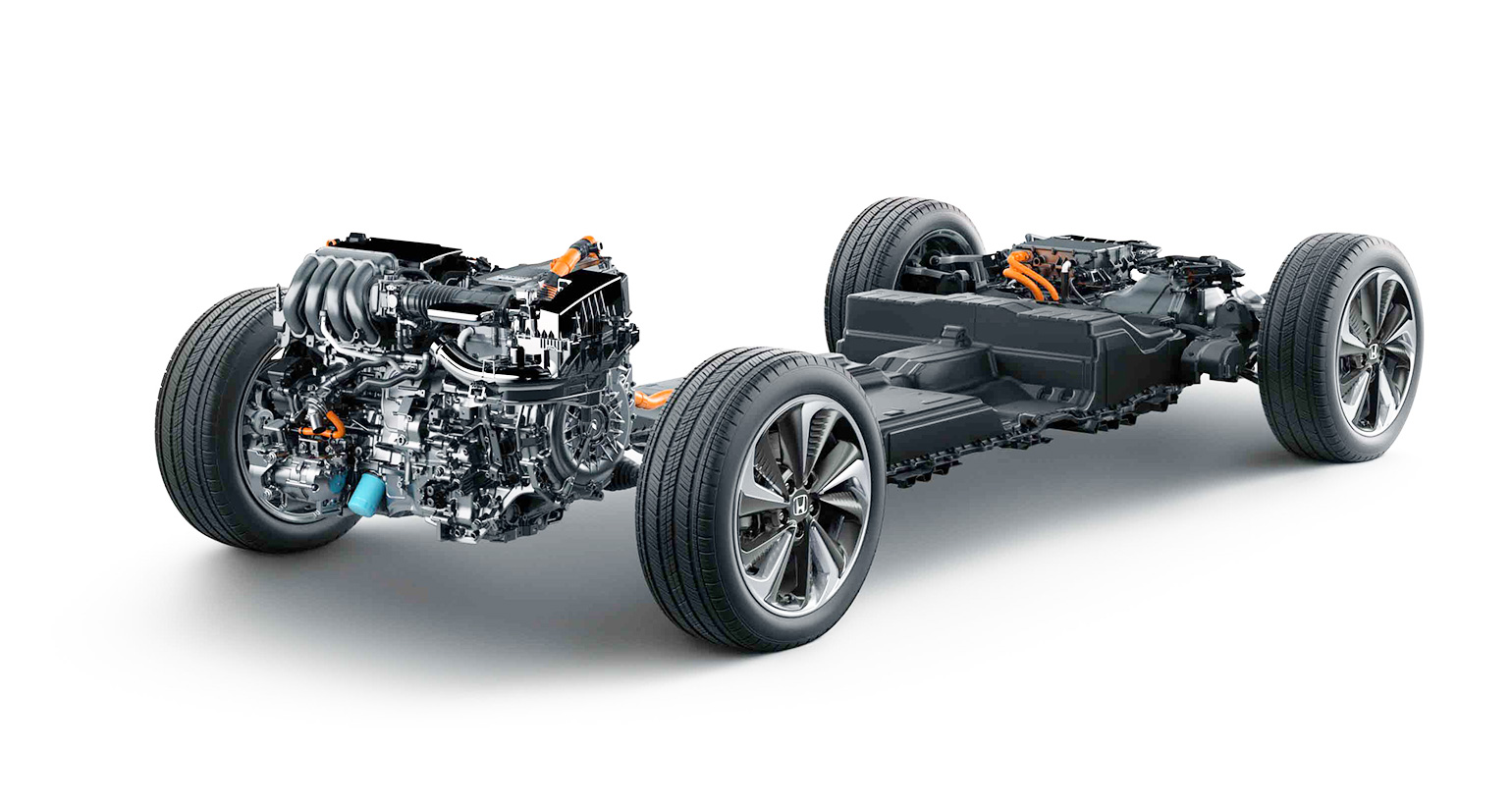

For example, Honda’s i-MMD system integrates the P3 and transmission. However, in the high-speed range, the motor can be completely eliminated, and the vehicle can be directly driven through a single-gear transmission, which is more efficient.

Most domestic automakers follow the i-MMD route, making them all disciples of i-MMD because this structure is simple and efficient.

For instance, BYD’s latest DM-i can engage the engine for direct drive at a speed of 70 km/h.

The hybrid version of the “Lanhai Power” of the Land tu dream also follows the i-MMD principle, with an additional P4 motor on the rear axle.

Chang’an’s latest Lemon DHT hybrid adds a direct drive gear on the basis of single-gear direct drive.

There is also a relatively special self-owned hybrid, Chery’s Kunkun DHT. Officially, it adopts a dual-motor three-clutch with P2 and P2.5, which is relatively complicated.

P3

There are not many hybrid models using P3 motors. The P3 located at the output end of the transmission needs to drag the gearbox in pure electric driving, which wastes energy. Also, P0-P2 can serve as a starter motor to help start the engine, but P3 cannot.

Of course, there are some models that use the P3 scheme, such as BYD’s second-generation DM, which has motors located at the P3 and P4 positions and is called “three engines and four-wheel drive,” with extraordinarily violent acceleration.

P4

P4 motor is generally located on the rear axle, like P3, it does not have any effect on the engine, so it can be used in combination with all the above motors.

P3 and P4 motors are more commonly used on electric vehicles. Of course, we can simply differentiate them by calling them front and rear motors. However, there is also a P5 motor that has not appeared, which refers to the hub motor. Currently, there are no mature products, so we will not discuss it.

Conclusion

The above is a comprehensive analysis of mainstream hybrid systems. For some detailed technical explanations, I did not go into depth. In the future, I will explain the hybrid technology of a certain brand one by one.

However, we need to be clear that although there are always pros and cons in theory for any type of hybrid system, the actual performance may be completely different. This places high demands on the algorithm management of the electronic control system, and it is also difficult for us to eliminate variables and say which hybrid technology is the best. Everyone should remember that all data from actual mass production tests of a single vehicle model should be used as the basis.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.