Author: Zhu Yulong

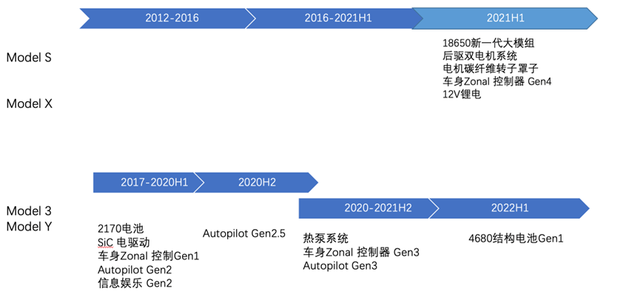

I’ve been reviewing Tesla’s latest developments recently. As shown in the following image, Tesla has made improvements to the powertrain (18650 battery layout and rear dual motors), 12V Lithium battery, AMD series infotainment system, fourth-generation Zonal Body Controller, etc. with the Model S Plaid. Because this car is relatively expensive, there is more room for tinkering. This time, I mainly want to focus on the fourth-generation Zonal Body Controller.

Fourth-Generation Zonal Body Controller

From the Model 3 Zonal Body Controller to the Model Y, there have been three generations of iterations, mainly through layout and functionality optimizations. With the Model S Plaid, the previous Zonal Body Controller was split in two, creating a dedicated power distribution unit and placing the heat pump and other features in a separate controller. This was mainly done to accommodate additional 12V electrical loads, such as compatibility with the Model X’s door control system.

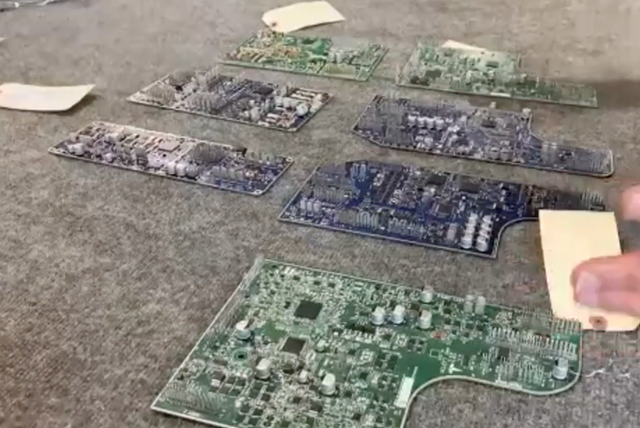

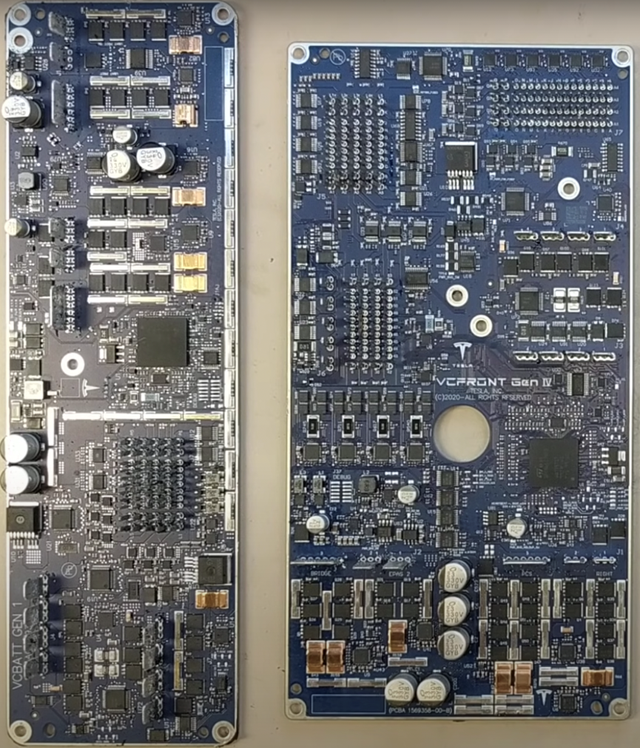

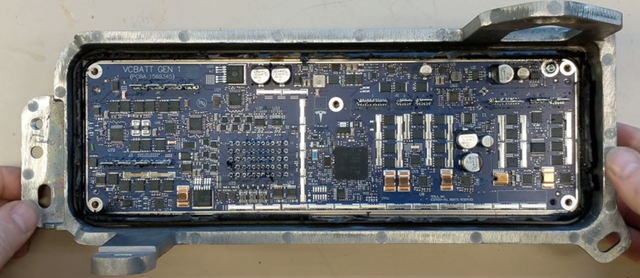

In the above blurred image, the changes in layout are mainly in the purple left and right controllers, with the front being split in two. Now, VCBATT Gen1 is used for power management, while VCFRONT Gen4 is used for thermal management, body management, and some power distribution management. All four body controllers use Press-Fit technology.

This production technology does not require welding, but rather mechanically forces the connector pins into the printed circuit board through pressure-fitting. This method avoids quality issues related to welding, such as cold solder joints, insufficient solder, and poor solder height control. It also avoids damage to the connector body caused by high temperatures during reflow or wave soldering processes, preventing damage or breakage of the connector interface. Additionally, as it does not require solder or flux, it avoids oxidation of the soldering surface, or the use of substances such as rosin, causing oxidation of the metal contact surface inside the connector. Due to the more flexible layout, Tesla and low-voltage connector manufacturers (such as TE and Amphenol) have collaborated more frequently.

This VCBATT Gen1 plays a role in 12V energy management and distribution, and also improves the safety of E-fuse in practical use.

This VCBATT Gen1 plays a role in 12V energy management and distribution, and also improves the safety of E-fuse in practical use.

Tesla is currently one of the larger customers of the ST microcontroller series. In the Zonal Controller, 6 pieces of the SPC series from ST were used, as shown below. I am making a list, and this series is also used in the gateway.

Battery and Drive System

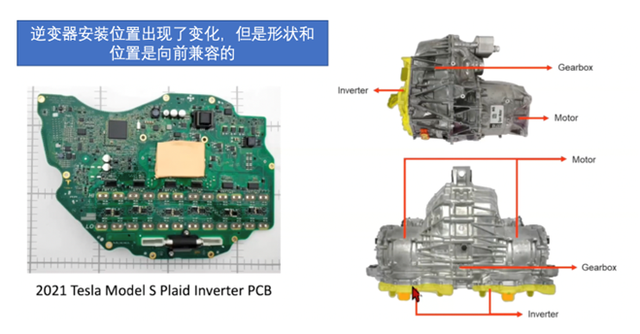

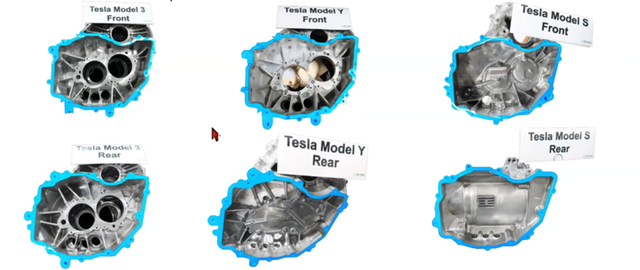

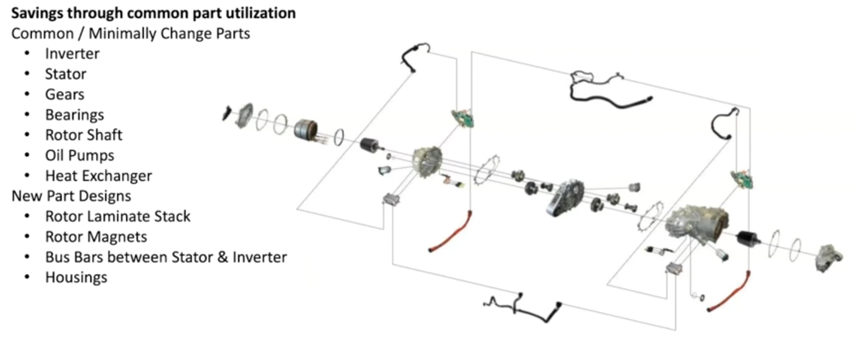

In the electric drive system, Tesla has adopted a basic strategy of implementing motor while reusing inverter. This innovation is based on Model 3 and Model Y, and realizes forward compatibility.

In other words, this achieves a certain degree of modularity, and the matching of the entire electric drive system can reuse the inverter.

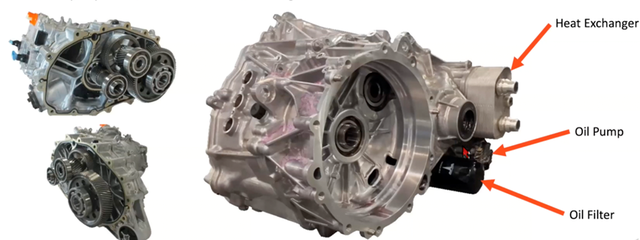

In the electric drive system, Tesla’s all-in-one path is not reflected in OBC+DCDC (already integrated into the battery). It is mainly reflected in other thermal management components, so in the future, all thermal management accessories may indeed be integrated with the electric drive system.

Note: The design that reserves a space specifically for the compressor in the front drive module may be compatible logically.

The newly developed components here mainly include Busbar, housing, and rotor. The development cost is higher, but the BOM cost does not increase significantly.

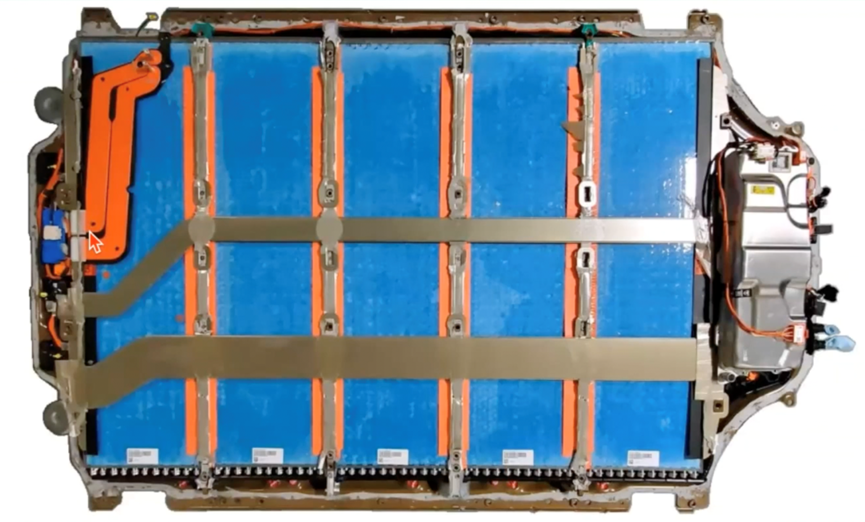

In the battery system, on the one hand, an attempt has been made to design super-large modules, and high-voltage busbars have been used in electrical design.

In the battery system, on the one hand, an attempt has been made to design super-large modules, and high-voltage busbars have been used in electrical design.

Conclusion: Contrary to our previous understanding, after trying new technologies, Tesla has been patching and fine-tuning. This continuous update is very different from our use of a large number of DOE, DV, and PV. The entire design process is a series of rapid iterations and catch-up, and managing the design process is a big project.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.