Markdown Output

文 | Ao Ao Hu

Since XPeng made an unpleasant incident with Tesla, Zeropark has become the most “Tesla apprentice” one.

In early April, Tesla just held the Cyber Rodeo opening ceremony at the Texas super factory. The new version of Model Y, which switched to 4680 cylindrical battery cells and central terminal connectors (CTC) battery pack, was the highlight. Only half a month later, Zeropark on the other side of the ocean announced that the CTC battery technology will be mounted on the new C01 model, showing a gesture of snatching the master.

Improvement, Improvement, or Improvement by XX

The so-called CTC (Cell-to-Chassis) refers to directly connecting the battery cell to the chassis or underbody of the vehicle, just like what has been mentioned in “naming the hardest part in making batteries”. The battery pack is thus integrated with the vehicle chassis so that everything is interconnected.

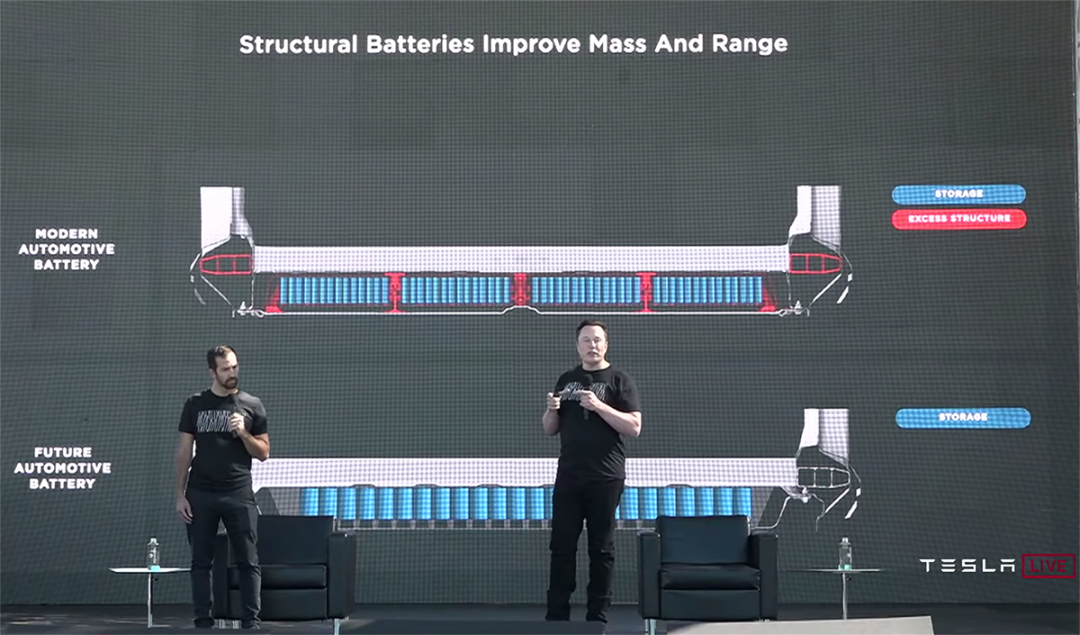

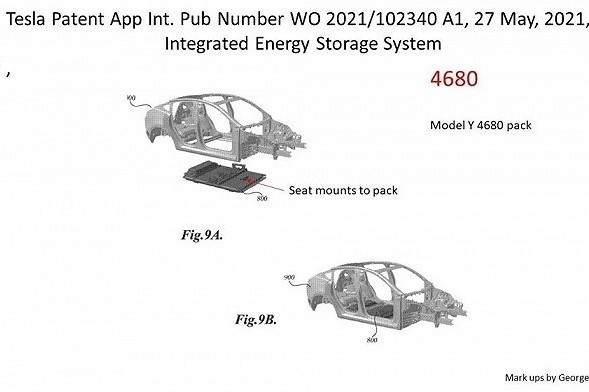

Removing the redundant structures always improves efficiency, weight, space, etc. Tesla claimed that by leveraging one-piece casting of the front/rear body, 4680 cells, and CTC packs in the new Model Y, the weight was reduced by 10%, and the cruising range increased by 14% (it was not solely attributable to CTC, of course).

Zeropark also presented beautiful data about CTC: a 10% improvement in cruising range, a 10mm increase in the vehicle’s vertical space, a 14.5% increase in battery layout space. In addition to these, Zeropark’s CTC improved torsional rigidity by 25%, and weight reduction by 20%. These were not mentioned when Tesla promoted CTC. We don’t know whether they just ignored these improvements or didn’t want to reveal them.

In short, it’s impressive.

What if there is No CTC?

Whenever a company (not limited to car manufacturers) proposes a groundbreaking new technology, facing those dazzling and beautiful data PPTs, you need to calmly ask yourself:How did everyone in the industry do before this new technology appeared? Why did nobody think of doing it before? Is it that others did not think of it or that there were reasons why others were unwilling to do it? Will there be any cost or compromise after doing this? If there is no cost and compromise, why are you the only smart one? (The recent case is “Skateboard Chassis Solves Car Anxiety?“)

This is not to denigrate innovation. There are certainly historical cases that can be answered one by one and still look reasonable and promising.

It is just to emphasize that only by raising and considering these questions and sorting out the most basic development of the field, can you – obviously not omniscient – possibly (just possibly) make a preliminary judgment on whether an explosive or seemingly explosive new technology is a true industry revolution or a heartless PE/VC harvester.

The latter is also known as the “dropout pseudo-nerd” vs. the “highly educated sea turtle” reverse harvester.

Going back to CTC.

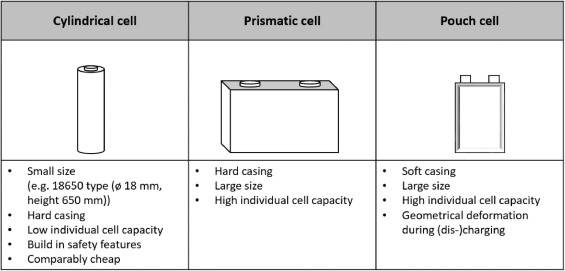

Today’s most conventional electric vehicle battery system looks like this: the smallest indivisible unit is called a cell, which can be divided into cylindrical, soft pack, square shell and other categories depending on its shape. We are familiar with specs such as 18650/2170/4680, which are describing the specification of the cylindrical cell.

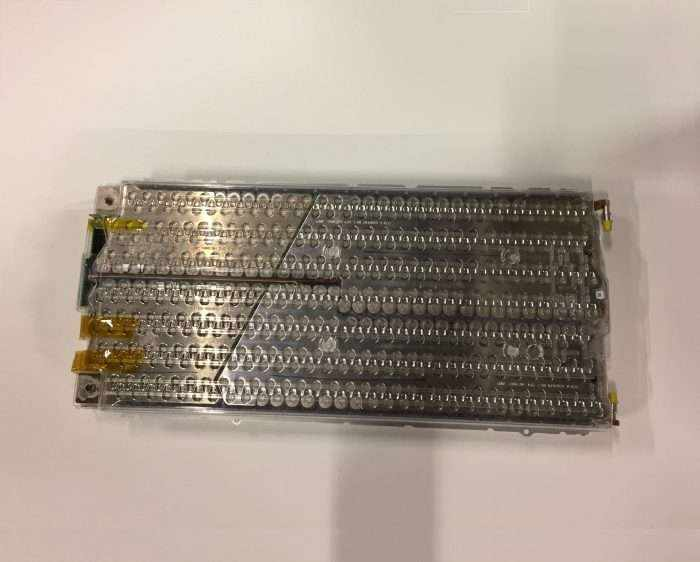

Several cells are densely arranged to form a module. The battery demand for pure electric vehicles is large, so we often need several modules. These cell modules are placed inside a metal casing, and combined with cooling, circuitry, battery control and other components, they constitute a complete battery pack.

The battery pack is the final product of the battery system. So the last step of the whole process is to install this “pack” into the car.

Assuming that the cell specs are the same, if more cells are used to form a larger module, the number of modules that can be placed in the same size battery pack decreases, but the total volume of space between the modules also decreases. Hence, the battery pack can accommodate more cells, and provide greater capacity, which is known as the “big module” battery pack.Translate the Chinese Markdown text below into English Markdown text while preserving HTML tags inside it

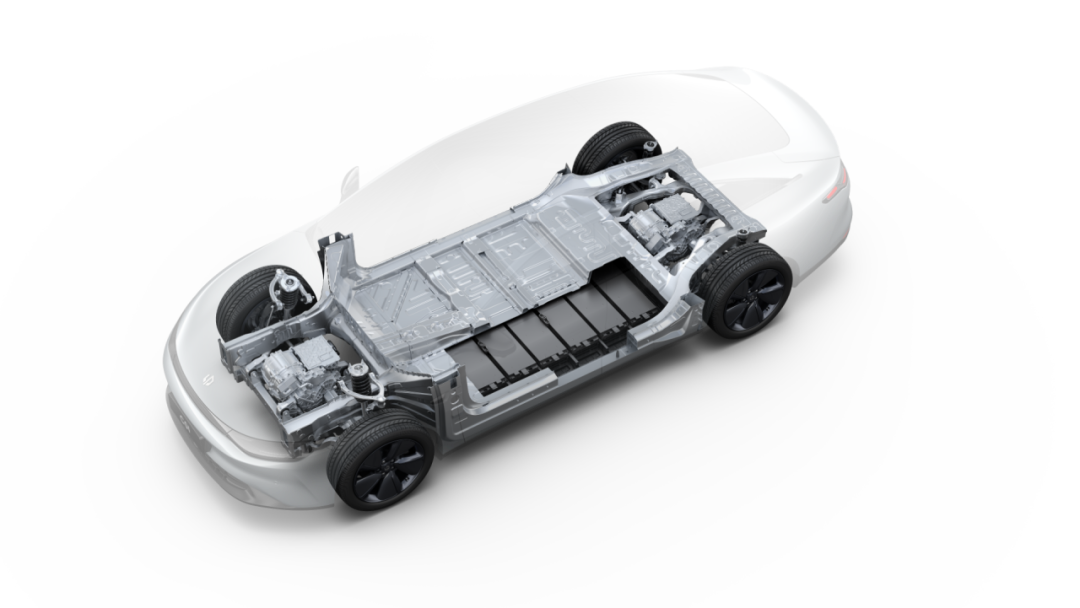

Furthermore, by eliminating the gap between modules, all battery cells are densely arranged into a huge module within the battery pack, which now consists solely of a multitude of battery cells and has eliminated individual modules. The so-called CTP, Cell-to-Pack technology, is achieved.

Please note that with the implementation of CTP technology, the decentralization of battery packs has reached its limit. Cells are the smallest and indivisible units, while the pack is the final, complete product. The next step is CTC technology, which essentially goes beyond the pack level of the battery system, and is an integration between the battery system and the vehicle’s body (outside the battery system).

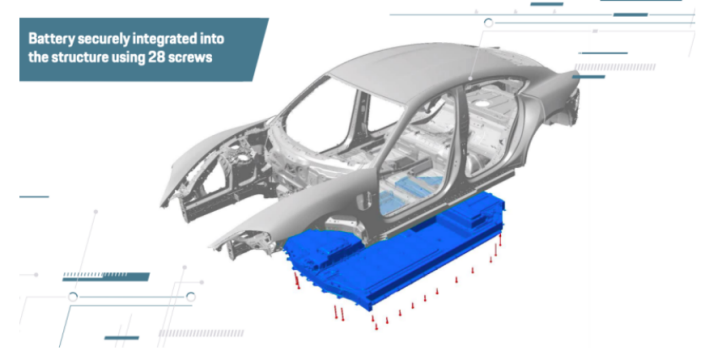

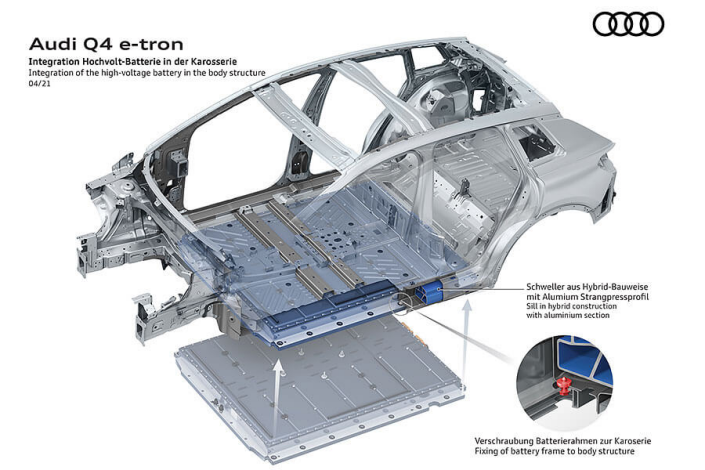

Conventional battery packs, whether they are for hybrid cars or all-electric vehicles, can be considered as “suspended” or “embedded”in the vehicle’s chassis. Usually, the battery pack is connected to the chassis using bolts or other similar methods. You must have heard of electric cars that had to have their battery packs replaced due to malfunction or degradation, therefore requiring connectors that are removable without damage.

This conventional method has been used for many years and is naturally an initial stage of an electric car’s development. In the past, when cars ran on gasoline, people bolted the engine oil tank shut; switching to electricity, it’s natural to bolt the battery (pack) to the car instead. Especially in the early stages of the development of electric cars, it was common to have issues in the battery system that required maintenance, and even just to repair a broken battery cell, the entire battery pack had to be disassembled, repackaged, and then bolted back together, which may seem normal to most people.

However, this conventional method also causes obvious structural redundancy, as both the vehicle’s bottom floor and the battery pack’s casing are whole pieces of metal sheets. Their functions overlap extensively; the vehicle chassis protects the battery pack, and if designed correctly, it can also protect the passenger from explosions caused by the battery (or just because there is an extra layer of protection, it does not guarantee that there will be no danger).

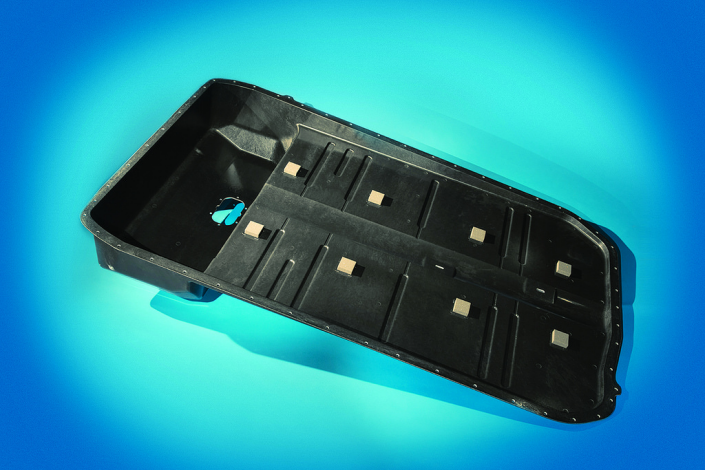

Actually, for some battery packs from certain manufacturers, the upper shell is made of lightweight non-metallic materials like fiberglass. These are protected by the body structure of the vehicle and do not need to bear the main impact resistance, but only seal the battery pack and suppress the threat of the battery pack to the passenger compartment.

Actually, for some battery packs from certain manufacturers, the upper shell is made of lightweight non-metallic materials like fiberglass. These are protected by the body structure of the vehicle and do not need to bear the main impact resistance, but only seal the battery pack and suppress the threat of the battery pack to the passenger compartment.

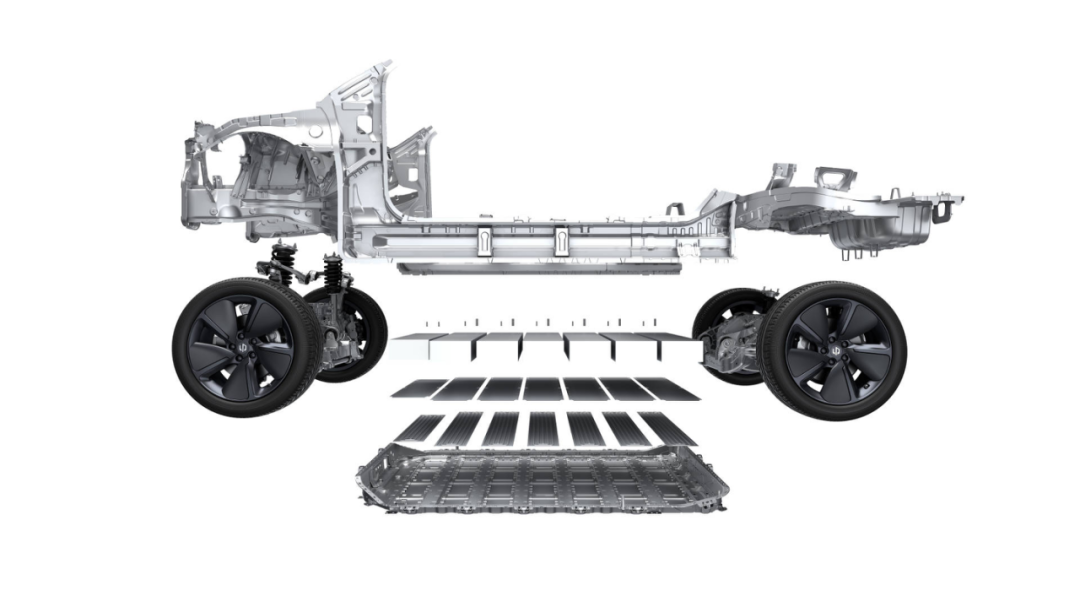

Under the passenger’s feet, there is a metallic body floor, followed by a hard plate of the battery pack’s upper shell, and then the real thing that provides power – the battery cell. CTC, in short, is to merge these two plates into one – yes, a lot of technical explanations may seem complex, but the truth is just that simple.

CTC, the road that Li Auto took instead of Tesla

“Turning two plates into one” may seem simple to understand, but that doesn’t mean CTC is easy to achieve. Using the body floor as the battery pack cover, whether it should be counted as part of the body or the battery, the connection method between the battery system and the body structure can no longer be just a few bolts.

The reason is simple – bolts are not enough to ensure high-standard sealing performance, and other connection methods with better sealing performance are needed. The result is that nearly lossless disassembly and replacement cannot be realized.

Previously, bolts were used to connect two separately sealed parts – the bottom of the body was welded together, and water would not seep into the floor seams when driving through water. The battery pack was rigorously sealed, with an IP68 rating for any movement. There was not as high a requirement between these two, and bolts were easy to assemble and disassemble, and the battery pack could even be replaced directly if there was a problem.

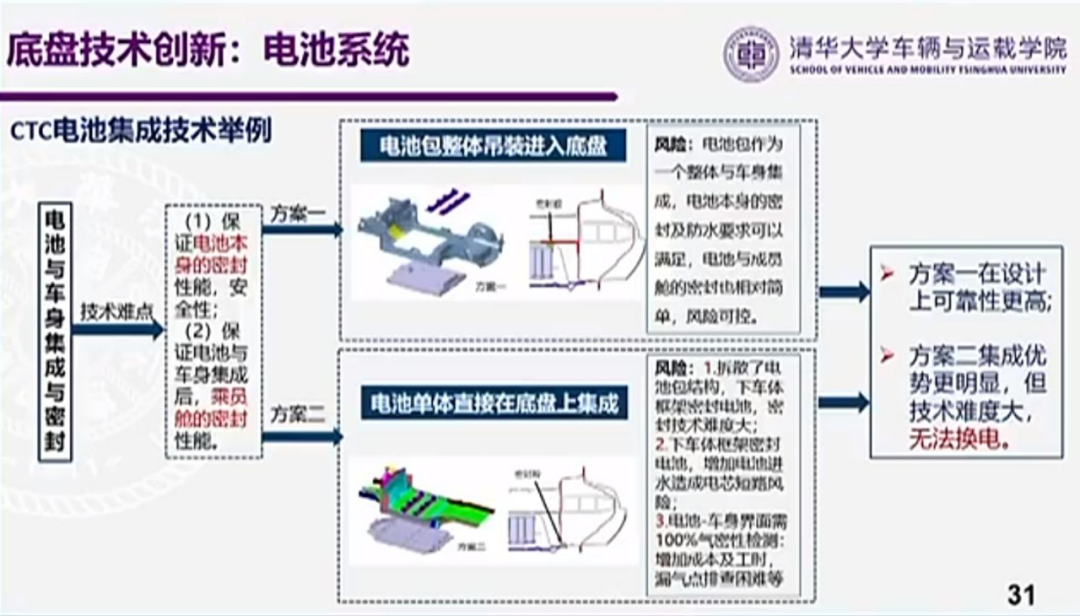

CTC currently has two main implementation methods: one is to “seal the battery pack first and leave the body leaking,” and the other is to “lay the body floor first and leave the battery pack exposed on top.” Academician Minghao Ouyang refers to the former as CTC, and believes that the latter should be called “CTV (vehicle)”, but we will not distinguish between them here.

Option one is the method used by Tesla. It first satisfies the sealing requirements of the battery system. Looking only at the battery, the production and manufacturing, including sealing, are not much different from those of non-CTC battery packs, so it is considered to have relatively controllable risks. However, because a complete battery pack needs to be manufactured first, the shape of the battery pack, especially the upper shell, will be somewhat limited. Therefore, the potential for efficiency improvement of the vehicle/ body structure may be less than that of option two (of course, it may be too early to discuss this now).

Option one is the method used by Tesla. It first satisfies the sealing requirements of the battery system. Looking only at the battery, the production and manufacturing, including sealing, are not much different from those of non-CTC battery packs, so it is considered to have relatively controllable risks. However, because a complete battery pack needs to be manufactured first, the shape of the battery pack, especially the upper shell, will be somewhat limited. Therefore, the potential for efficiency improvement of the vehicle/ body structure may be less than that of option two (of course, it may be too early to discuss this now).

Option two is the choice of today’s ZERO RUN. The body is a complete body that is sent over, and the battery pack is in an “open” state without an upper cover. When installing the battery part onto the body, the lower shell of the battery pack and the body floor and upper shell are sealed together. This approach prioritizes the sealing of the passenger compartment, but it is clear that the sealing of the battery is far more important at this time. When installing and sealing the battery part, the body structure has basically been completed, so it is necessary to consider the fact that the body is such a large “burden,” so the installation process is relatively more complex and cumbersome.

Therefore, compared with option one used by Tesla, ZERO RUN’s CTC carries more unknown risks.

Of course, option two also has its own advantages. Because the floor part is welded to the body as a whole, various horizontal and vertical beam structures can be easily designed, and there is no need to consider avoiding the surrounding structure when the battery pack is connected to the body like in option one. Compared to option one where the body “borrows” the battery cover, there will be advantages in structural efficiency. In other words, in terms of weight, material technology (cost), stiffness targets, etc., better overall body performance can be achieved (same cost but lighter, same weight but stiffer, etc.).

High-tech, but not that “black”

CTC can indeed significantly improve the overall performance of electric vehicles.

First of all, for the battery system, by removing a redundant layer of structure, the battery system can have more space. Additionally, this can allow for the vertical space to be conceded to the passenger compartment and/or reduce the vehicle height and increase the ground clearance. In short, the space is more compact, and how it is used will depend on the boss’s mood.Secondly, the reduction of weight is real by removing a layer of board, although the reduction of redundancy in vertical space is not obvious. The lightweight advantage of CTC “removing a layer of board” is quite attractive for pure electric vehicles. The reinforcement effect of CTC on the vehicle structure also increases, which reduces the amount of body materials needed for the same rigidity target, indirectly promoting lightweighting.

Finally, CTC makes (or forces) the battery pack casing to be connected to the body in a more stable way – after all, the casing itself will become a part of the body, which increases the contribution of the battery pack to the body rigidity. In fact, the conventional battery pack can already provide a stiffness improvement of 50%, improve vehicle NVH and other related performances. After the application of CTC, the contribution of the battery pack to the body rigidity may be even greater.

Since CTC technology is so attractive, why have only a few automakers started to apply it until today?

We have explained the difference in sealing methods. Leap Motor’s CTC is a riskier way. Even though Tesla’s CTC battery pack has a lower sealing difficulty, there is still some risk of passenger cabin sealing, especially in terms of durability after long-term use. Of course, these risks may have been solved, but before enough time has passed, no one can say for sure that they do not exist.

The problem of after-sales maintenance is also easy to understand. If there is a problem with the battery in the conventional battery pack, replacing the battery pack is simply a matter of unscrewing bolts, and there are even companies like NIO that rely on battery swap to supplement energy. Once there is an abnormality in the battery pack after CTC, replacing or opening the battery pack will inevitably mean dismantling the body. This will also come with the risk of secondary sealing. Whether the replacement of the CTC battery pack will affect the body structure, no one can give a definitive answer now. Before the problem arises, no one knows if there is a problem.

Of course, you can say that you will only drive an electric car for two years and then buy a new one, but the entire value chain is linked. As long as the electric car keeps running, it will inevitably encounter battery failures sooner or later. If the difficulty of the tail-end maintenance is high and the cost is high, the entire life cycle will be shortened or the cost will increase within the cycle, which will inevitably affect the new car’s residual value rate at the front end. There is no such thing as a completely unaffected way of purchasing and using a car.

However, as it is often the case with technological advancements, there are costs and risks involved with CTC technology, admitting and recognizing which does not deny the fact that it is the trend. Technological progress rarely comes without sacrifices or compromises. If safety and low cost had always been the main goals, we would still be driving cars with all-steel bodies, naturally aspirated engines, carburetors and manual transmissions everywhere, and the slow progress and social development would be frustrating.

However, as it is often the case with technological advancements, there are costs and risks involved with CTC technology, admitting and recognizing which does not deny the fact that it is the trend. Technological progress rarely comes without sacrifices or compromises. If safety and low cost had always been the main goals, we would still be driving cars with all-steel bodies, naturally aspirated engines, carburetors and manual transmissions everywhere, and the slow progress and social development would be frustrating.

Technological progress always entails trade-offs and hard choices, and only those who are willing to take risks for the sake of progress can create an opportunity for comprehensive and spiraling improvement. At the same time, it is also vital not to rush things and hide the imperfections and unknowns of new technology in order to quickly make it mature. There is no one correct way in this world, only a balance that needs to be found amidst conflicts, and the decision to move forward or backward.

CTC is a foundational and consequential “utility after the fact” technology, which is not easily visible or intuitive. The impact of CTC on the vehicle’s overall performance is often passed on through several hands. CTC reduces weight, increases space, improves range, and enhances stiffness, but you can never tell exactly how much each advantage is attributable to CTC. There is no parallel universe without CTC to compare with.

You can only say that CTC is amazing, but you cannot quantify the value that it brings. CTC can reduce weight, but you can also use the saved weight for more batteries, more sound insulation materials, or a larger electric motor. CTC can improve stiffness, but you can also save on materials by reducing the overall rigidity of the car body and then compensating with CTC. Automakers can use CTC’s contribution to weight reduction and stiffness enhancement to improve performance or reduce costs, or even achieve both, depending on their choices.

Ultimately, the actual performance and performance of a vehicle are what consumers pay for, while CTC is just a technical means to achieve them. Whether or not it can be implemented and successful is another matter entirely, as even with the most advanced technology, subjective effort, and financial investments, it is still possible to produce a pile of garbage. Therefore, it is difficult for CTC to become the protagonist in the spotlight unless it is forcefully rendered as some sort of rule-breaking black technology.

Volkswagen may only try CTP and CTC on the next-generation SSP platform, which may or may not be successful.CTC itself is not such a cutting-edge technology that even children can understand roughly in a few sentences. The vast majority of major car companies have the technical strength to develop CTC, but their respective driving forces, resources, and circumstances are different, and their pace and practices are also different.

Tesla uses CTC battery packs in the Model Y, and the background is that Model 3/Y has been selling well, so seizing the opportunity to further increase its advantages is not unreasonable. The new factories in Texas and Berlin do not have the sunk cost of old equipment, and they also provide a good opportunity for product iteration. As for the radical risks and maintenance costs, when has Tesla cared about these things? When does Tesla need to care about these things?

The situation for NIO is similar and different. The same is that there is no sunk cost because the sales of its previous models are not particularly high, and the subsequent revenue-generating ability of models other than the C11 is also relatively limited. At this time, choosing to take the lead is easier for NIO than for those leading automakers, as there are advantages to being a follower.

The difference is that NIO needs to take more risks and break more doubts, especially when it chooses the more risky CTC approach than Tesla, and NIO has not accumulated enough reputation and market trust (although Tesla’s reputation in manufacturing is not excellent, it has sufficient sales volume after all). If Tesla’s implementation of CTC lacks the “just try it” mentality of a decent competitive environment, the use of CTC by NIO is somewhat mixed with the mentality of taking risks to increase product competitiveness for a breakout.

There is neither good nor bad, and it is acknowledged that the front-runner is more likely to be unstable, and I wish that this time the front-runner’s rush is ultimately worth it.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.