Author: Zhu Yulong

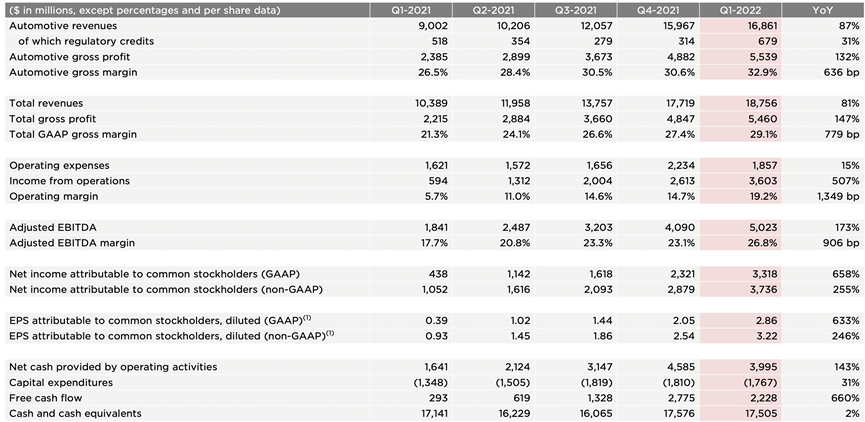

Financial Aspect

Q1 total revenue was $18.76 billion, with automotive revenue at $16.86 billion, an 87% YoY growth. Gross profit margin was 32.9%, up 24% YoY. During a time of global supply shortage, Tesla began to increase car prices, and delivery quantities continued to rise. Tesla’s Q1 net profit was $3.28 billion, compared to $0.464 billion in the same period last year.

Vehicle Aspect

Q1 total sales volume was 310,000 vehicles, up 68% YoY. Model 3&Y sales were 295,300 vehicles, up 62% YoY, accounting for 95%; Model S/X sales were 14,700 vehicles, up 625% YoY. Elon Musk stated that Tesla is confident in achieving at least a 50% growth on the basis of 2021 (producing 1.5 million vehicles). Due to the impact of the pandemic, Shanghai factory lost one month of production (estimated 60-70 thousand vehicles) and is now trying to recover full production. Currently, the waiting time for customers who place orders is very long, and some orders cannot be delivered until next year. There are currently 3,724 charging stations, with 33,657 charging piles. There is a significant difference between the growth rate of Tesla’s supercharging pile speed and vehicle growth rate.

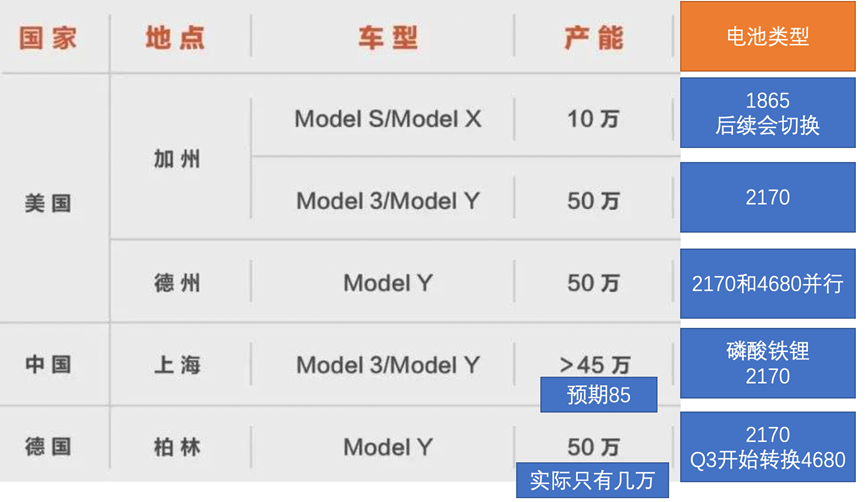

Current Annual Production Capacity of Each Factory

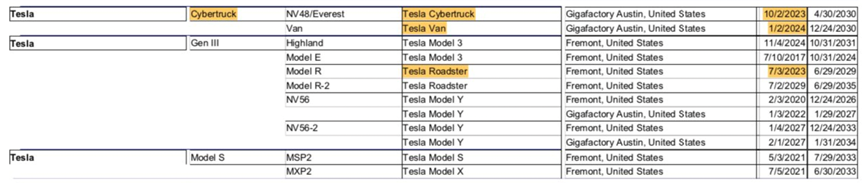

California: Model S&X 100,000 vehicles, Model 3&Y 500,000 vehicles Shanghai: Model 3&Y over 450,000 vehicles (estimated actual capacity this year can exceed 850,000 vehicles) Berlin factory (the same size as Shanghai) and Texas factory (the largest in the world) are in the ramp-up phase, with an average annual delivery growth of 50% in the next few years.

Supply chain constraints have caused the factories to operate below capacity for several quarters, and some component prices have been rising by 20%.

Information in the Report

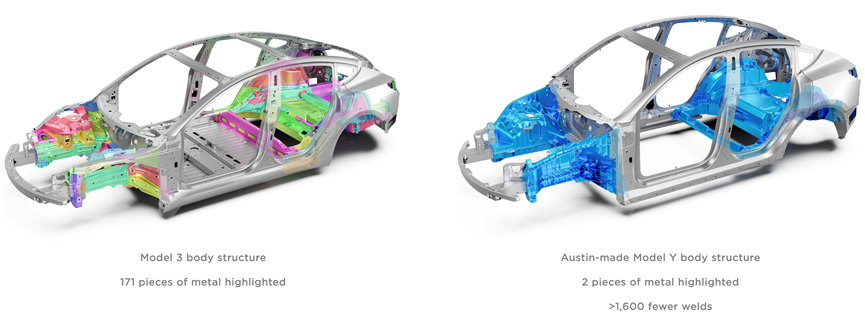

At the manufacturing level, the Model Y front and rear frames are both produced using an integrated die-casting process (casting almost two-thirds of the vehicle body), reducing 1600 welding points compared to the 171 parts in Model 3. Cybertrcuk has 25-30% fewer components than traditional pickups. Since waste aluminum is recycled for casting, the impact on the yield rate is not significant. In the Texas factory, waste aluminum goes directly from the stamping workshop to the casting workshop.

The Texas factory will produce Model Y with 4680 structural batteries and currently normal 2170 battery pack in 2022. Due to the fact that the Shanghai factory is currently 70% lithium iron phosphate and 30% ternary batteries, Tesla’s first quarter was equipped with more than 40% lithium iron phosphate batteries. The ramp-up in Berlin factory is also relatively slow. At present, the factory produces 350 Model Y per week, and the current goal is to achieve a target of 1,000 vehicles per week by the end of April 2022.

Tesla hopes to expand the Berlin factory to produce approximately 5,000-10,000 vehicles per week (corresponding to 20,000-40,000 vehicles per month)before the end of 2022. According to current predictions, about 30,000-50,000 cars will be produced in the Berlin factory this year, and it will be able to ramp effectively in 2023. The German-made Model Y currently uses 2170 batteries (some of which are supplied by LG). It stopped production for three weeks in Q3 for modifications, and it is said that this 2170 is a new version, similar to the module transitioning to the 4680 structure.

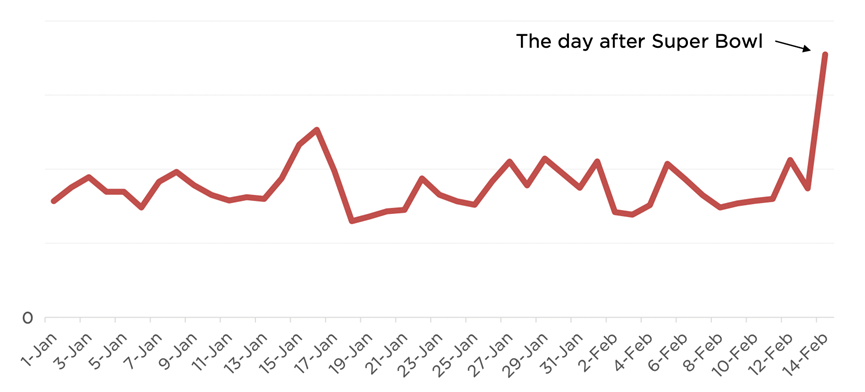

As all American automakers started advertising during the Super Bowl, Tesla, which did not advertise, still benefited afterwards. The benefits of this leader are still very obvious.

The demand from Powerwall drove the Q1 installation to 846MWh, an increase of 90% year-on-year. The Megapack factory is expanding production capacity, and the Tesla giant Megapack energy storage project “Townsite Solar and StorageFacility” will become the infrastructure of the future new grid, with a capacity of 360MWh. Each Megapack can store 3MWh of energy at a time. The project is located in Boulder City, Nevada, which can provide power for 60,000 households and reduce 400,000 tons of carbon dioxide emissions per year.

The demand from Powerwall drove the Q1 installation to 846MWh, an increase of 90% year-on-year. The Megapack factory is expanding production capacity, and the Tesla giant Megapack energy storage project “Townsite Solar and StorageFacility” will become the infrastructure of the future new grid, with a capacity of 360MWh. Each Megapack can store 3MWh of energy at a time. The project is located in Boulder City, Nevada, which can provide power for 60,000 households and reduce 400,000 tons of carbon dioxide emissions per year.

Other Technical Information

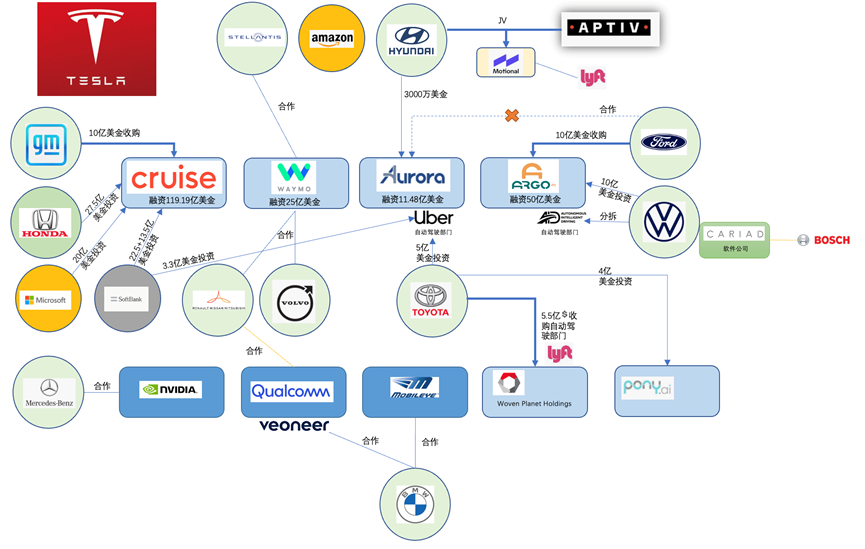

The problem of autonomous driving has been shouted out since 2016, and this year Tesla plans to release the FSD beta to all US car owners by the end of the year. The whole difficulty exceeds Elon Musk’s expectations. From the perspective of the business model, Tesla is also developing Robot Taxi. Tesla optimizes autonomous driving based on its own models, and there is no steering wheel/pedal in the design, which optimizes the cost issue on the basis of the original one. The prototype car will be released in 2023, and it is expected to be realized in 2024. This has a great impact on companies that do Robot taxi globally.

From the perspective of upgrading from 400V to 800V, Elon Musk believes that the advantages of 800V are limited for Tesla (400V SiC has been deployed), but the cost increase is very obvious (on the vehicle and charging facilities), and it needs to be mass-produced and delivered to flatten the cost. That is to say, Tesla has not done the 800V research before, but from the perspective of cost assessment, it has not yet reached that point.

Conclusion: After demonstrating strong profitability, Tesla’s combat effectiveness poses a huge challenge to all car companies worldwide. The model of traditional lean production saves money, but the growth rate and ceiling are completely different from developing and innovating.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.