Author: Chang Yan

To get the latest and freshest Tesla financial reports, you need to wake up at 5 o’clock Beijing time and read the news while enjoying the morning dew.

However, as an early bird, I failed to get up this time. Apart from the fact that my recent insomnia, which has almost exceeded the human disease’s cognitive energy, has caused me to be in low spirits, the more important reason is that the opening of two factories in this quarter has already advanced too much of our excitement quota, and the closure of the Shanghai factory due to the epidemic has also reduced our happiness dose.

Before the financial report was released, I thought that Tesla was going to tell us that “Plaine-Jane is true”.

Unexpectedly, the previously scattered cards were arranged and integrated to produce such strong weight.

Tesla never sleeps.

Sales Volume Unreduced, Gross Margin Higher

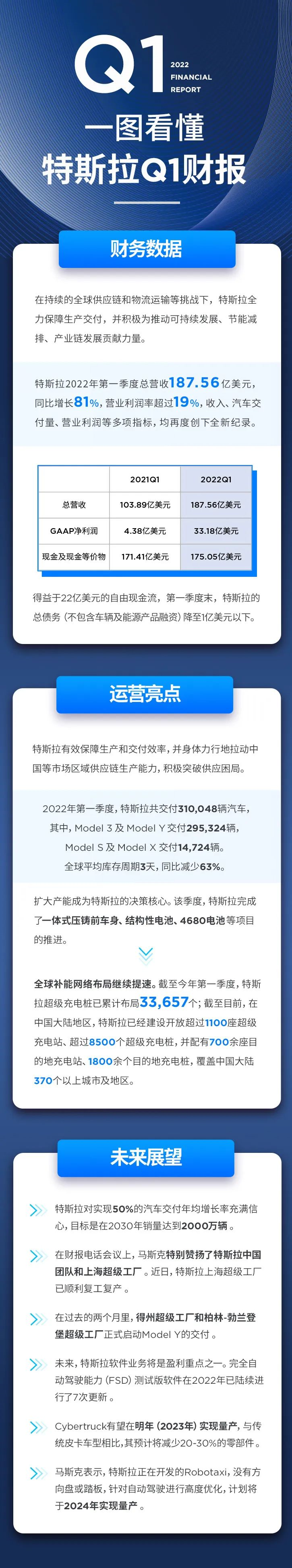

Everything is as usual. Tesla’s financial and delivery data showed significant growth every quarter, which is “normal”. For this part, I won’t repeat it. Please pay attention to the long chart at the end of the article.

What we care more about is whether the abnormal epidemic will change these trends and directions.

At the financial report conference, Musk joked that “the Shanghai factory has angrily come back,” although the Shanghai factory is still in the state of just resumed work and under considerable supply chain pressure. Musk still said, “We may have a rabbit in our hands”:

” This quarter, we will see the new highest production capacity of the Shanghai factory. The quantity of vehicles in the second quarter will be higher than that in the first quarter.”

Since 2019, Tesla has added a large number of pictures that can reflect this quarter’s most critical highlights to its financial report files. The content of this quarter’s report file can be said to be the most warm-hearted in history. The smiles and fireworks of the opening ceremonies of the two factories can still make us feel the beauty of that time. This sense of stability is also reflected in Tesla’s full confidence in the capacity of the two factories.

Musk said that Tesla is still confident in achieving a 50% increase in delivery volume compared to last year in 2022 (about 1.5 million vehicles delivered annually), and even thinks that Tesla has a high chance of reaching the level of 1.6 million vehicles delivered annually.The financial data shows that even if the production volume does not increase, Tesla will still make more money. In this quarter, Tesla’s per-car gross margin reached a staggering 32%. In late March, a survey by Autoline showed that Tesla was about to surpass Mercedes to become the automaker with the highest profit per car. Note that this is the profit value, not the profit margin. Considering that Mercedes has a much higher unit price than Tesla’s car series, Tesla’s gross margin can be regarded as the highest in the industry, and even the net profit margin has reached the gross margin of many peer companies.

What is even more frightening is that there is no sign of any slowdown in this profit margin. When discussing Tesla’s increase in gross margin, the media previously tended to attribute it to Tesla’s technological innovation and capacity climb. However, from this quarter’s earnings conference call, Tesla’s strong position in the market and pricing strategy appear to have played a more obvious role in the short term.

On one hand, Tesla stated that the current waiting time for vehicle orders is already quite long, which reflects strong market demand. A confirming data is that the average inventory cycle of Tesla globally is only 3 days, indicating that the produced vehicles can be quickly delivered. On the other hand, Musk stated that the multiple price increases currently are “actually expected the increase in supplier and logistics costs”. Although he also said that if costs do not rise, prices may be slightly reduced, but in fact Tesla has used the strong demand side to earn a price differential that should not have existed.

Producing more, selling more, and making more money – this is something that would be enough to make another brand ecstatic for a year, but Tesla has achieved it and even unlocked hidden bonuses. With abundant funds, Tesla has prepared a solid foundation for its follow-up actions.

In this part, a supernatural event also occurred. After the Super Bowl, known as the American Spring Festival Gala, Tesla’s orders surged, but the most counterintuitive thing was that Tesla did not advertise. That is, after other brands had done a lot of advertising, people who wanted to buy electric cars ultimately chose Tesla.

As Musk said, “0 advertising expenses, in exchange for a trillion-dollar effect” – this sentence actually violates China’s advertising law.

Tower of Technical ExcellenceEvery step of the evolution of automotive technology is undoubtedly a long process. It may be due to Tesla’s long-standing spotlight that many originally boring terms have become familiar, such as integrally cast.

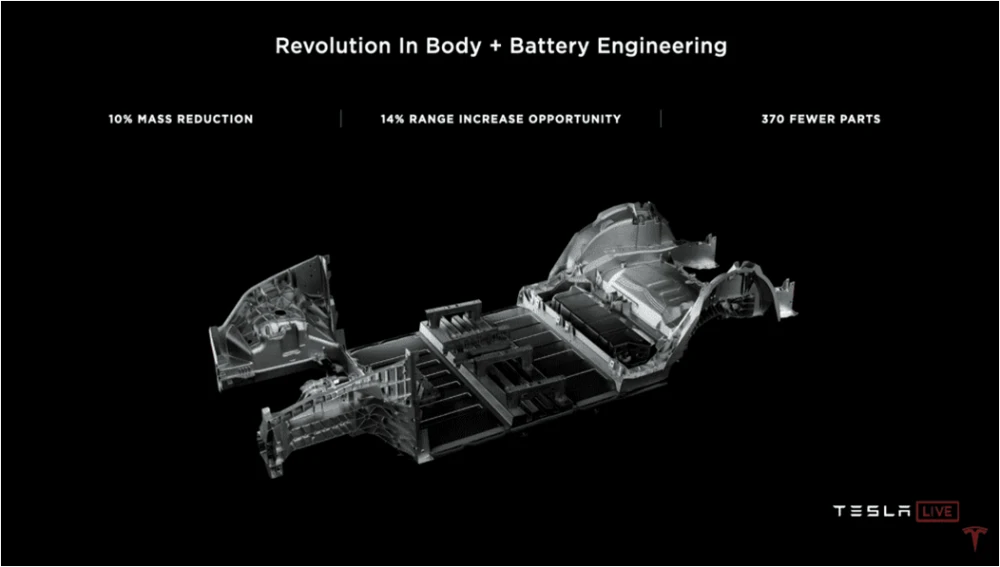

After multiple popularizations, we once again saw a detailed explanation of integrally cast in the financial report materials. In order to avoid the “I hit myself” situation, Tesla chose to use a comparison between the Model 3’s white body and the latest structural body of the Model Y. In the front and rear parts of the body, the Model 3 uses a total of 171 body parts, while the Model Y only needs 2. The difference is amazing, and the reduced welding joints have reached more than 1,600. Tesla stated that this can greatly reduce production time and even effectively reduce factory area after the process has matured.

The mid-section sandwiched between the front and rear body should be the 4680 battery pack according to plan.

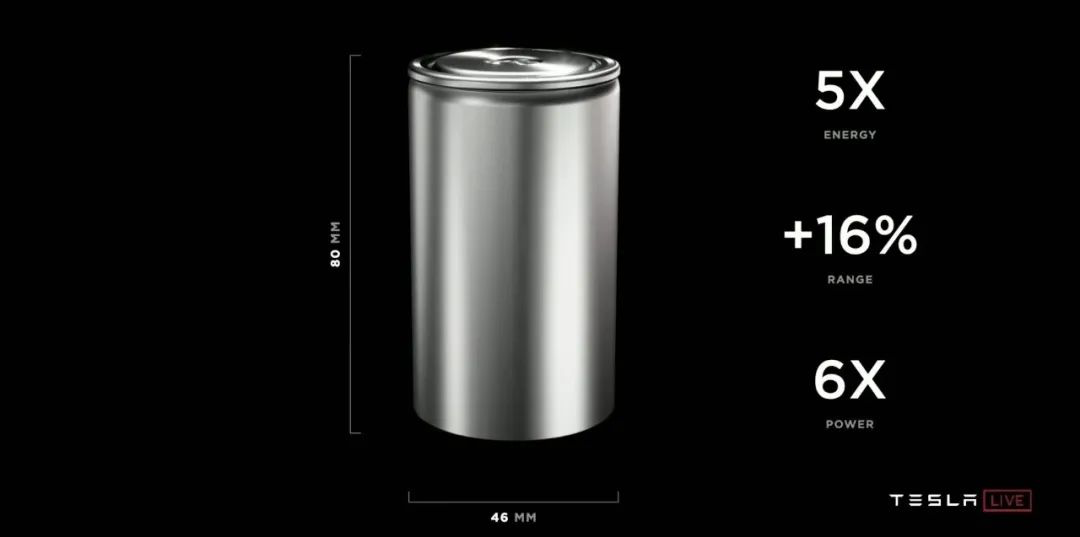

The information disclosed in this financial report is that the 4680 battery is powerful, but it is not yet fully mature.

In terms of performance, Musk said that Tesla’s current 4680 battery has reached the level of the best products on the market, and it will surpass all competitors in 2023.

However, although the 4680 battery has made continuous progress, it still cannot control all costs. This also means that large-scale use still needs to wait for a period of time. Tesla stated that the 4680 battery will be mass-produced in Q3 this year, but existing models, such as the Model 3, may still take a few years to transition to the same technical architecture.

At the same time, factories such as Giga Texas, which have already introduced 4680 vehicle models, will also introduce production lines for 2170 battery models this year, and parallel production of the two batteries will become the mainstream for the next period of time.On the conference call, Musk didn’t forget to tease: “We have some exciting battery news to share in the coming months.”

From the statement, Tesla is developing an anode production process with flexible adjustment formula to dynamically adjust production based on raw material prices and content.

During the conference call, Tesla revealed its views on the 800V high-voltage architecture.

Apparently, Tesla is already working on related technology testing because “800V voltage has both advantages and disadvantages on Model 3/Y.”

The obvious benefit is that “the cost per vehicle could be reduced by $100 by switching from 400V to 800V,” but this requires a certain vehicle volume.

Therefore, Tesla is considering using the 800V voltage for Cybertruck and Semi.

Oh, speaking of Cybertruck, there is another thing that continues to test patience: the large-scale production of Cybertruck will continue to wait until 2023.

Other things

It’s hard to imagine how big Tesla’s business map is, or rather, it’s hard to accurately define Tesla’s current business scope.

Many things that are brushed over could become the most important parts of the company in the next few years.

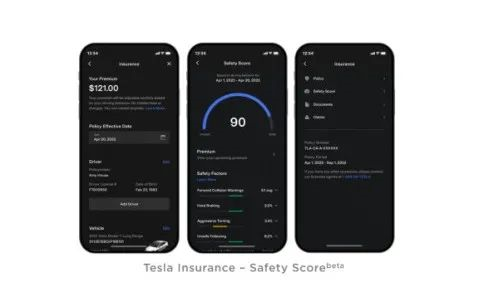

Tesla’s insurance business has become the second largest insurance company by business volume in Texas, and is developing new business in multiple locations. Its value lies in dynamically reflecting the current driving safety value of car owners, which is more referenceable and cost-effective.

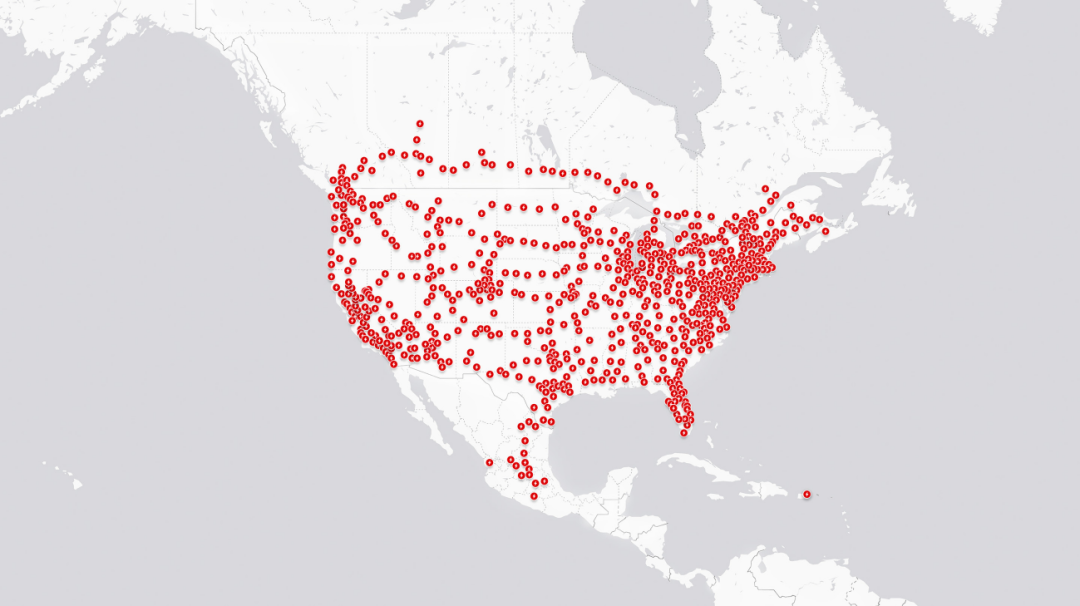

Previously, Musk promised to help North American car owners build more supercharging stations to ease the pressure of charging queues in some areas. Therefore, a new round of expansion is imminent on the basis of the existing charging network.

Tesla also found a way to improve economies of scale while taking a jab at gasoline cars at the same time. They discovered they could recycle aluminum cast wheels from traditional cars, melt them down, and cast them into the body of the Model Y. This is actually a traditional metal recycling business, which comes with a natural history view of the survival of the fittest.

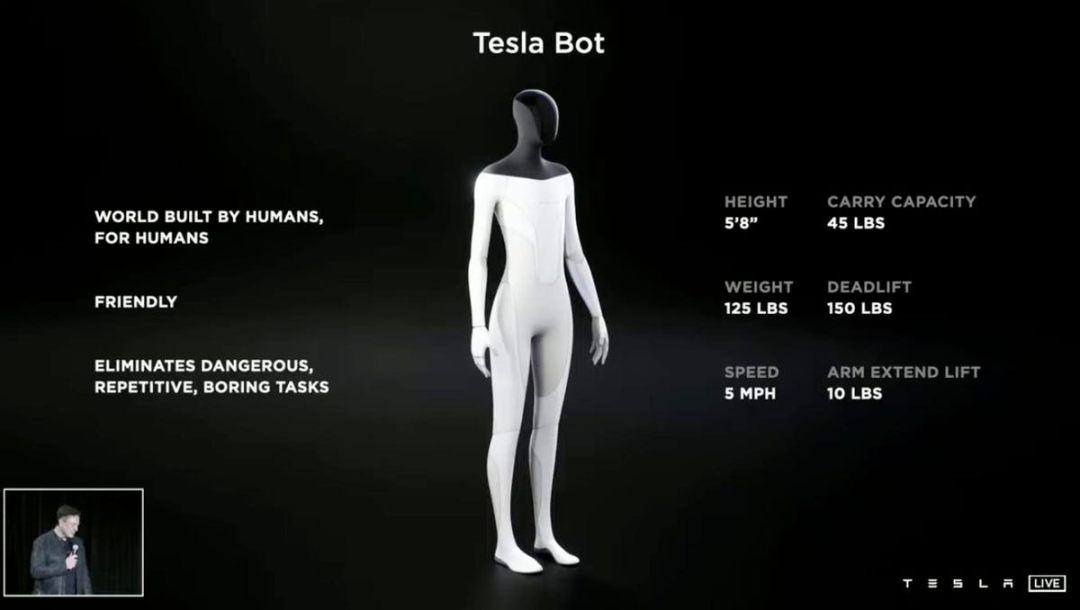

Although robots haven’t made any concrete appearances, “their importance will become apparent in the next few years.”

Musk firmly believes that “robots will eventually be more valuable than the car business and more valuable than FSD.”

Unified destination of loose technology

Why do we feel calm when Cybertruck is not going into production until 2023?

Why would we say that FSD and the car business seem to be equally valuable?

Because…Tesla has explicitly stated that it will hold a Robotaxi event in 2023 and mass-produce “highly optimized Robotaxi specialized vehicles” in 2024.

Although Musk said, “We don’t want to disclose anything in advance on an exciting product announcement,” it is clear that this car will not have a steering wheel or pedals.

“There are other innovations surrounding it that are quite exciting.”

The ultimate goal is for “riding a Robotaxi to cost less than a subsidized bus or subway ticket.”

If making electric cars as affordable as possible was Tesla’s previous corporate ambition, then this is undoubtedly a more disruptive and challenging step than the previous version.The feasibility of the technology needs to be verified, and the cost of implementing the overall technology deployment in engineering needs to be reduced to a profitable level.

In a previous interview with TED 2022, Musk stated that now there are 100,000 Tesla owners in North America who have received the beta test version of FSD, while in January, this number was only 60,000. Considering the total purchase volume of FSD and the current speed of beta version updates and iterations, it is highly probable that FSD will achieve full-scale testing in North America this year.

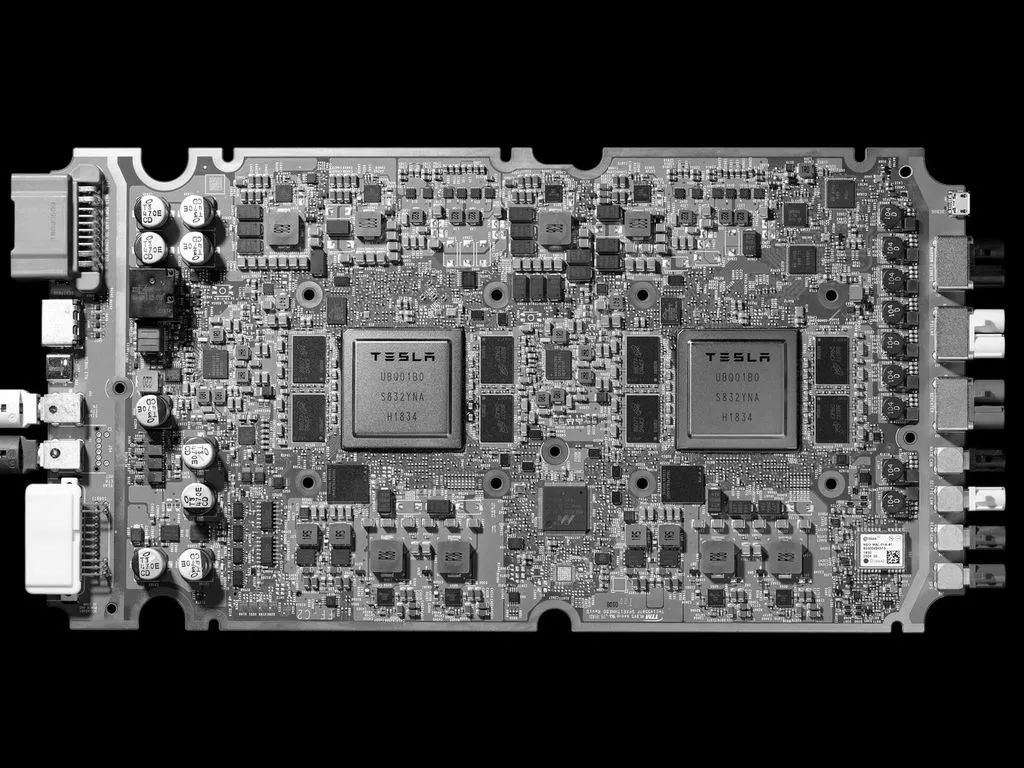

Although there is still a long way to go before the completely safe and accident-free operation level required by Robotaxi, at least in 2022, Tesla can fully unify the current FSD-related code and technical route, and shift more development efforts towards a brand new hardware platform, including the rumored HW4.0 and key scenarios.

In previous information before Robotaxi, Tesla only mentioned it on Battery Day, stating that Robotaxi could be better supported when the battery can withstand an accumulated lifespan of 1.6 million kilometers. Currently, Tesla’s production of LFP batteries and BMS have undergone sufficient verification, and the aforementioned production technology has also prepared for Robotaxi’s hardware costs to be more durable and cheaper.

For a long time, Tesla’s financial reports have not made product enthusiasts as excited as they did in the past few years.

One reason is that a large portion of the report is describing scale production.

The second reason is that it feels like a lot of technology is scattered, without a single integrating node.

But just like a sand painting, in the vast canvas, several lines appear without being understood, suddenly being connected with details added, making people suddenly realize and cheer.

Recently, Musk announced that Tesla is developing its Master Plan 3.0, and Robotaxi is undoubtedly the prelude to this new chapter.

Recently, Musk announced that Tesla is developing its Master Plan 3.0, and Robotaxi is undoubtedly the prelude to this new chapter.

However, as Internet dwellers, we have recently experienced the pain of geographical isolation due to the pandemic. In such a situation, the potential technological divide brought about by the Robotaxi era, as demonstrated by FSD, might be more painful than we could imagine.

A new season begins.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.