Author: Zhu Yulong

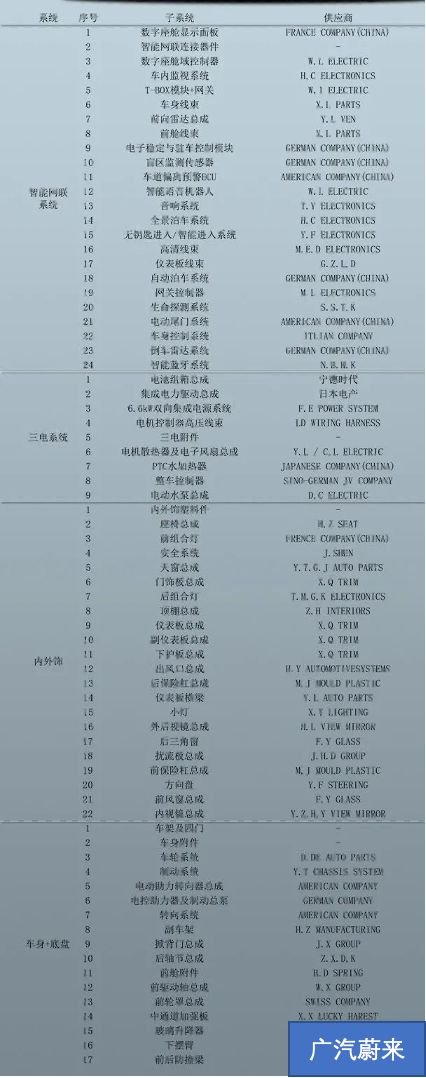

I don’t know how many people still remember the very bizarre BOM cost list published by GAC NIO before. Please take a careful look at the types of segmentation at that time, including intelligent network connection, three-electric system, interior and exterior decoration, and chassis. The biggest work for a complete vehicle enterprise in manufacturing and procurement is to ensure that these parts can be smoothly taken back to the warehouse and then scheduled according to the production plan.

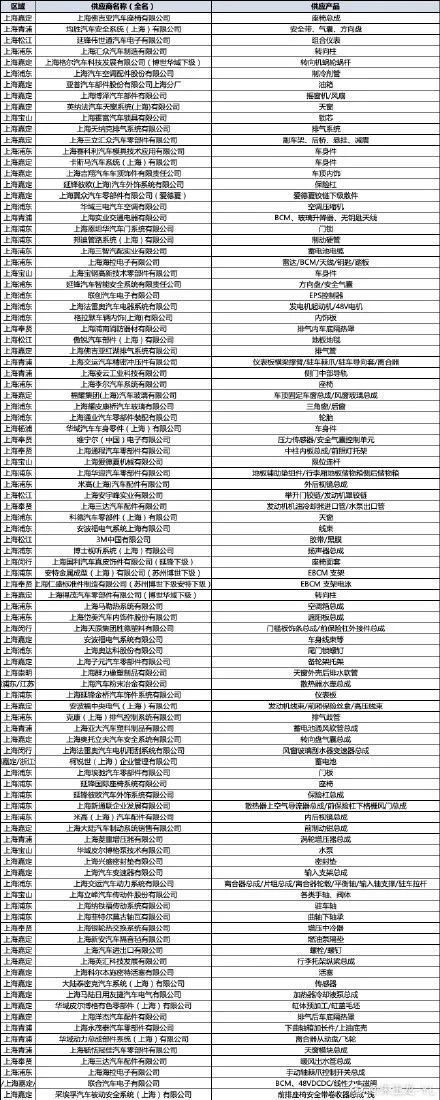

As Shanghai has a very complete automobile parts industry chain and together with the Yangtze River Delta automobile parts manufacturing base, is providing cost-effective parts for China’s automobile industry. The following is a review of the product supply chain based on the SAIC Group system.

Most of the suppliers we see above are first-tier suppliers in the automobile industry. Due to the fact that Yangshan Deepwater Port is located on one side of Shanghai’s Donghai Bridge, its cargo throughput is 22 million TEUs. In the automobile industry chain of Shanghai, a large number of containers belong to first- and second-tier component companies every day. After unloading at the port, they are transported to factories in the Yangtze River Delta through the developed expressway network of the Yangtze River Delta. In the automobile industry, various raw materials (plastics, metals, nylon, chips, and even screws) are assembled and processed by the factories in the Yangtze River Delta and are supplied to the entire automobile industry chain in China.

As mentioned in the above list, Shanghai’s industry chain has a large number of foreign-funded, joint venture, and private automobile parts companies, including more than 100 companies such as Bosch, ZF, Tenneco, and SAIC’s component companies. They are all busy producing various automobile parts. First-tier suppliers need to wait for materials from second-tier suppliers, and second-tier suppliers obtain basic raw materials from the entire industrial chain. All links are interdependent. If the pace of the entire transportation process is not right, the entire automobile industry in China will be out of stock.

Therefore, XPeng Motors and Huawei’s CEOs will jump out because the real urgency is traditional automobile giants. Their daily losses are huge, and it is not solved by relying on a very limited closed-loop production, which is not at all a solution to the problem.

I think many things come at a cost. We encounter difficulties and need a relatively long time to recover. During the recovery process, we feel powerless and sentimental staying at home. The automobile industry is very fragile, and it cannot be saved just by wanting to save it at a certain stage. The losses caused by the previous chip shortage have added to the damage to the entire vehicle operation, and in my personal judgment, it has reached a very weak stage.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.