Markdown Translation

Author: Shiyun Zhu

Editor: Kaijun Qiu

“I just want to go to Tesla and ‘screw screws’ now.”

On April 14th, Heige said in the “Tesla postponed employment group.”

Heige has received an offer from Tesla Shanghai Lingang factory for more than half a month. However, Heige is still at home waiting because Tesla is still in shutdown.

“Screwing screws” refers to the work of general workers with the lowest professional skill requirements in the factory, and frontline workers often self-deprecate themselves as such.

When the author tried to verify when Tesla Shanghai plant resumed work, he inadvertently met this group of “screw-bolting guys” and thus saw the huge impact of Shanghai’s epidemic on frontline industrial workers who could not work from home.

“Eating noodles, lying down”, guarding the door, and running away…At this moment, everyone is separated from the routine assembly line, making their own choices and persistence.

Below are their stories.

Mr. A currently employed: Expecting “hanging noodles” with two slices of salted pork.

Egg paste, crispy onion slices, and a hanging noodle.

Mr. A posted his today’s “closure meal” in the group. Someone immediately said that this is “hanging noodles”, a kind of meal only used for sustenance. But Mr. A doesn’t think so: “Just add two slices of salted pork, and it will be perfect. I don’t have high requirements for food, only two meals a day. Just let me go to work early.”

On March 28th, Shanghai began to screen and block, and the Pudong, Pupan, and adjacent areas where many car factories are located were in the first batch of blockaded areas. Tesla announced the suspension of production activities at the Shanghai Super Factory on the same day, and only a small number of workers are currently performing equipment maintenance in the factory.

Mr. A “took a vacation” like this.

Including Tesla, many Shanghai car companies have issued basic salaries for employees who are currently unable to work due to blockades, and a basic salary of several thousand yuan can still support their lives.

The problem is that the window period before the blockade was very short, and the initial notice only blocked for four days. Many people did not stockpile many supplies. At the beginning of the blockade, Mr. A ate white rice and Lao Gan Ma for several days in the rental house. After the community had a low-priced group purchase, he finally ate vegetables and meat, and “life was greatly improved.”

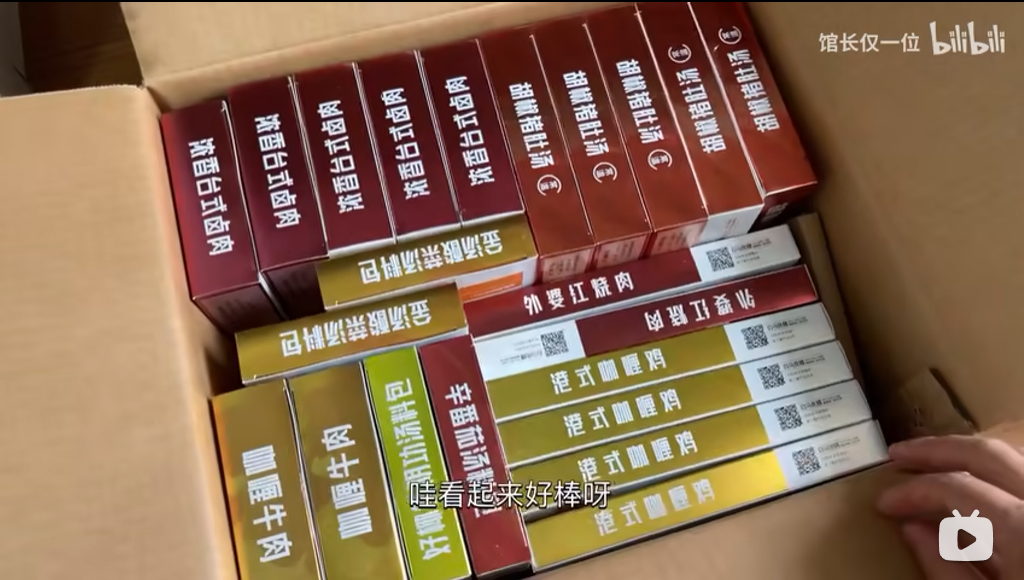

Around April 10th, Tesla provided staff with anti-epidemic packages consisting of pre-made meal ingredients including braised pork, curry chicken, and braised pork over rice, at an average price of approximately 15 yuan with a minimum order of 35 boxes.

Around April 10th, Tesla provided staff with anti-epidemic packages consisting of pre-made meal ingredients including braised pork, curry chicken, and braised pork over rice, at an average price of approximately 15 yuan with a minimum order of 35 boxes.

“The price is about the same as Taobao, equivalent to the company delivering without making a profit; it’s considered a benefit,” an older brother in the group said. However, the price is such that “even bolt workers can’t afford it”; “if the price (6 yuan/box) could be like that, it would be cheaper.”

Mr. Liang, who is about to start working for Tesla, said: “I have to hold on even if I can’t hold on.”

There are also many “prospective Tesla employees” who cannot purchase the anti-epidemic package. “The whole batch that went on the 15th ‘fell,’ “Black Brother said. “Go, not to work; stay, unable to leave Shanghai. And every day, they lie flat in their rented house.”

Mr. Liang is part of “that batch.”

Mr. Liang passed Tesla’s interview at the end of February and was scheduled to start on March 15th. In early March, Mr. Liang arrived in Shanghai, rented a room in a village near the factory, and received a notification that the start date was postponed (March 13). Since then, Tesla has arranged for Mr. Liang to obtain three consecutive nucleic acid tests before starting work on the 29th.

Unexpectedly, Shanghai was suddenly locked down on the 28th, and Mr. Liang entered a “standby” state.

“Even though I already have an offer, not starting work means no basic salary, and I have to pay for being locked down in Shanghai myself,” said Mr. Liang.

(Rooms for rent around the Tesla Lingang factory cost at least around 600 yuan for a single apartment, water is 7 to 8 yuan per ton, and electricity is 1 yuan per kilowatt-hour. Mr. Liang has spent one or two thousand yuan on supplies since March 27.)

When asked if he could continue to endure well or not, Mr. Liang said: “I have to endure it, even if I can’t hold on, I have no choice because I cannot cause trouble for others in other places due to the situation in Shanghai.”

Many people who have come to Shanghai from outside to work at auto factories are like Mr. Liang. There are already nearly 200 people in the “Tesla deferred start” group, some waiting and some have turned to other electronics factories.

In group chats, it was also mentioned that other brands also have many pending employees who are in a dilemma of whether to stay or leave and have to pay for lockdown expenses.

Mr. G, who is also about to start working, said: “I volunteer every day and argue with people.”Originally, Mr. G’s plan was to go to Shanghai on March 13th, have a physical examination on the 14th, and start work on the 15th. “But as soon as I arrived in Shanghai by plane, HR called to tell me that the start date had been postponed. I had no choice but to wait, and now I’m volunteering in the community.”

Mr. G’s logic is simple: “If the epidemic doesn’t end, the company can’t operate, so I want to contribute a little to the epidemic prevention effort.“

The community where Mr. G is located has more than 500 people, and the volunteers are responsible for maintaining order, blocking the corridors and the community, and controlling close contacts and second close contacts to stay at home and receive and send parcels. In addition to a large amount of work, stopping the corresponding residents from going out also brings about a lot of quarrels.

Since starting volunteering on March 15th, the 26-year-old Mr. G has spent his days guarding the tent, sleeping in the corridor at night, eating box meals, quarreling, washing up in the security room, and living day to day.

“It’s good” to resign: I won’t work 12-hour shifts again

Twenty-year-old “It’s good” is a “rebel”. On April 14th, “It’s good” happily announced that he had resigned from Tesla, checked the transportation and home policies, and was going back to rest for a while.

Why did he give up the paid time off in Shanghai and even the possible bonus in April? “It’s good” said that it was because Tesla is going to increase its production next month. “Now, 880 vehicles per day are already overtime, and it will be increased to 1000 per day, and finally to 1300 per day. But the monthly salary will only increase by a few tens of yuan, and we have to work in two shifts.” “Brother, (you can do it) you go ahead.”

“It’s good” decided to enter the factory shortly after last year’s National Day due to seeing a post on “Tieba” that Tesla implemented an 8-hour three-shift system, with high income.

However, upon entering the factory, the three-shift system turned into a 12-hour two-shift system. “Except for the long white shift, the other shifts are not good.”

“It’s good” started working at Tesla just as sales took off. According to data from the China Association of Automobile Manufacturers, Tesla’s monthly sales in China exceeded 50,000 units for seven consecutive months from September last year to March this year, with an average monthly sales volume of more than 60,000 units in January to March.

But for “It’s good,” this only means “bad luck.” Due to the tight production schedule, “It’s good” had no time to go to the delicious cafeteria 10 minutes away, and could only eat poor-quality box meals in the workshop. Smoking is not allowed inside or outside the factory and it is not allowed to take off masks or play with mobile phones while walking inside the factory.

“They also regulate it like this abroad, but abroad it’s 8 hours, and here it’s 12 hours.” “Fine,” with a crying cat emoji, “I won’t work 12-hour shifts anymore (in the future).“

“Fine” has run away, and it came at a high cost. They had been working for six months and were required to provide 30 days’ notice before quitting. In order to quit as soon as possible, they voluntarily forfeited their corresponding salary for early April. For “Fine,” who earns a monthly salary of around 6,000 yuan and has to spend 5,000 yuan on gaming, this is not a small amount of money.

But “Fine” was very calm about it.

“What are you going to do with no money?” I asked.

“You don’t have to worry about that.” “Fine” suggested that if I were to work at Tesla, I should live in Sotuan (Shanghai Sotuan town, 11 kilometers from the Tesla factory), “It’s convenient to go out during Sotuan’s break.”

Some Companies in Shanghai Are Showing Signs of Resuming Production

According to incomplete statistics, several Shanghai automakers and parts suppliers, including Tesla, SAIC Volkswagen, SAIC General Motors, and SAIC Motor, are either fully or partially closed, or producing in small batches.

However, whether to adopt a closed production model is not determined by the government, but depends on the production unit’s guarantee of raw materials, components, and living materials and conditions.

On the evening of April 14th, He XPeng, founder of Xpeng Motors, posted on WeChat Moments that if Shanghai and its surrounding supply chain companies are unable to find a dynamic way to resume production, all vehicle factories in China may have to close in May; On April 15th, Yu Chengdong, CEO of Huawei’s Consumer Business and Intelligent Automotive Solutions Business Unit, posted on WeChat Moments that if production cannot resume in Shanghai, all technology/industrial industries related to Shanghai’s supply chain will completely shut down after May, especially the automobile industry.

The good news is that as of April 11th, Shanghai has implemented differentiated prevention and control measures at three levels: sealed areas, controlled areas, and prevention areas. Several production companies are in the controlled areas, which means that orderly resumption of production in strict compliance with epidemic prevention policies has taken another step forward.

On April 15th, there were rumors that Tesla will start limited production from April 19th. During the same period, SAIC Group issued guidelines for resuming production and epidemic prevention measures, requiring “production companies to initiate a stress test for resuming production on April 18th based on their situation.”

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.