Author: Zhu Yulong

Yesterday, my friend Frey Liu commented on the content of the cylindrical battery strategic release event (13th factory put into operation) of EVE Energy. I think it can be combined with the material mentioned at the Bai Ren Hui. EVE Energy is an interesting domestic battery company that has been walking along three routes: cylindrical (previously non-power market), soft pack (SK cooperation), and square shell. In the last Bai Ren Hui, the company determined the technical route of large cylindrical and square shell laminations. This time, let’s analyze the cylindrical approach.

EVE Energy’s cylindrical production capacity is located in Guangdong, Hubei (including two), and Zhejiang. The expansion project of this small cylindrical battery product line has a total investment of 3 billion yuan and produces 18650 and 21700 cylindrical batteries. The annual production capacity can reach 750 million (6 lines with a global production efficiency of 300ppm high-speed production) with stable and efficient full-process automation operation. According to the Lighthouse factory requirements, digital operation is adopted to achieve lower carbon emissions. Currently, the cylindrical battery production capacity scale will reach 1.5 billion.

Small cylindrical battery planning

Looking at the target market, let’s calculate the overall capacity based on 3Ah for 1850 and 5Ah for 2170. Based on this, if we make ternary based on 3.7V, 1.5 billion will be between 16.65 GWh and 27.75 GWh, and the target is to see that the future market may reach 5 billion.

From the market perspective of the global cylindrical battery space, the market value increased from $872 million in 2021 to $1.65 billion, and the quantity for the first five years increased from 820 million to 1.45 billion.

Looking at the product line, because there are more categories in the industrial and consumer categories, they can be divided into:

-

V series: High-energy series for small power cells, involving the needs of endurance for electric power-assisted bicycles.

-

P series: High-power series for small batteries, including power tools and cleaning tools.

-

C series: Ultra-high cycle series for energy storage. This logic may be more suitable for small energy storage directions.

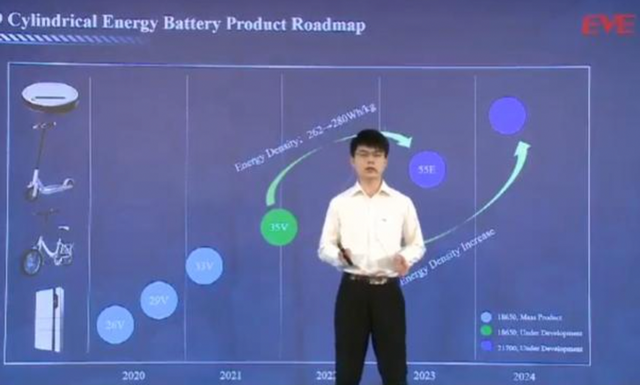

For small power batteries, due to the demand for endurance mileage, energy density needs to be improved. From the product line, it will be raised from 35V to 55E, and energy density will be raised from 262 Wh/kg to 280Wh/kg. 50E will be launched in 2022, and 55E will be launched in 2023.

The demand for different types of products varies greatly in terms of battery requirements, which is quite interesting:

- Electric bicycles and balance cars: The cycle life of the battery is 1000 times, and the continuous use time is 1-5 hours. The products include 18650 (26V, 33V, 35V) and 21700 (50E).

- AGV/forklift: The cycle life of the battery is 2000 times, and the continuous use time is 1-5 hours. The products include 18650 (26V, 33V, 35V) and 21700 (50E).

- Power tools: Due to the high current required by the drive motor, the current range is 10A-30A, and the working temperature range is – 20~80 degrees. The products include 18650 (15P, 20P, 25P) and 21700 (40P).

- Gardening tools: The current range is 5A-30A, and it needs to discharge continuously for 10~60 minutes. The working temperature range is – 20-80℃. The products include 18650 (20P, 25P), 21700 (40P) and 32130 (C32).

- Vacuum cleaners and sweepers: They last for 10-40 minutes, and the current range is from 2A to 25A. The products include 18650 (20P, 25P), 18650 (26V, 29V, 33V), and 21700 (40P, 50E).

- The working time required for robots: 1~5 hours. The products include 21700 (40P, 50E).

- Energy storage mainly requires a cycle life greater than 4000 times, 10 years, and a relatively low upper temperature range from – 20 to 60 degrees. The products include 32130 (C32), 33140 (C33), and 40135 (C40).

Developing lithium iron phosphate cylindrical batteries is actually an interesting idea. In fact, Ningde era started to do this in this field. From the cylindrical shape of lithium iron phosphate, the design of non-polar ears can be used to shorten the electronic path and reduce heat generation. The lithium iron phosphate cylindrical products made by Eve Energy Co., Ltd. pass the needle piercing test from the perspective of reliability. Relatively speaking, they have good anti-expansion properties and a safe design that supports rapid gas release. In terms of production efficiency, the winding structure supports high-speed production. The standardization of battery cells can support flexible group structure, and 48V, 60V, and 72V standardized modules and systems can be adopted according to different applications.The cylindrical products of lithium iron phosphate cover C32, C33, and C40 in 2021-2022, iterated to C46 with a range of 150-195Wh/kg in 2022-2023, and C46A, C40B, and C33A in 2023-2024.

Development Direction of Large Cylindrical Battery

As this product mainly covers small cylindrical batteries, the feature of large cylindrical batteries is to form a new generation of standard power batteries, with relative lower end cost as the product quantity develops.

Cylindrical batteries may become the ultimate technology direction of power batteries. The large cylindrical battery mentioned in the Hundred People’s Club has absolute safety and cost advantages, mainly reflected in the following four aspects:

(1)Ultimate Standard: Design, manufacture, and recycling can be standardized;

(2)Ultimate Reliability: In the whole life cycle, it has a stable structure and zero stress between batteries, with no changes from the beginning to the end of battery usage;

(3)Ultimate Manufacturing: It can achieve ultimate manufacturing, shorten the process path by 30%, and have higher production efficiency per GWh;

(4)Ultimate System: It has achieved a chemical system containing 90% nickel and used silicon-carbon materials.

Conclusion: The issue of cylindrical batteries in China has been lingering for a long time. With the development towards higher quality in China and reliable customer demands, there is still a strong impetus for its progress.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.