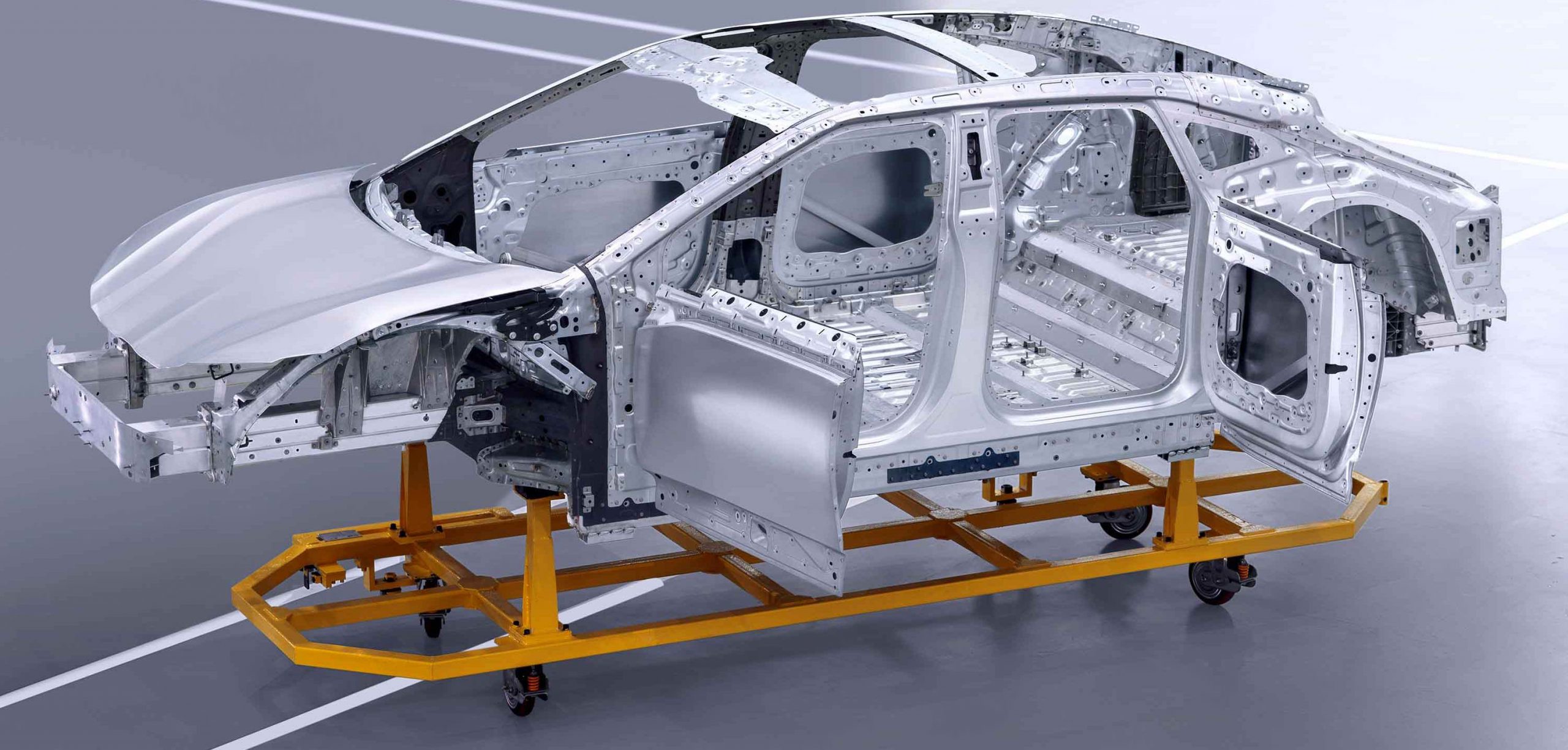

On April 15, the first production line of HiPhi Z, the second flagship product of GAC Group, was officially launched in the high-quality factory of GAC City. In order to achieve the unique design of the star-ring ISD screen on the HiPhi Z body, two irregular and smooth long troughs need to be outlined on both sides of the body. GAC engineers have applied a mixture of riveting and welding techniques to the white body, replacing traditional wrapping techniques, and realizing innovative structures for hidden external water cutting sheet metal that can meet the installation of ISD screens without weakening structural strength. They also added 1.5mm thick structural steel to the waistline to further ensure the rigidity and structural safety of the ISD screen on the side.

At the same time, GAC’s iconic butterfly door design has been fully retained. In order to better balance safety and body durability, engineers have optimized the body structure design, support and hinge structure of butterfly doors, making the service life of butterfly doors reach more than 100,000 times. In addition, all four doors and door anti-collision bars are made of 7-series aerospace aluminum alloy, with a bending resistance of up to 16,000 N, effectively improving the passive safety coefficient of the body.

Meanwhile, the body has ingeniously combined high-pressure die-casting aluminum with low-pressure die-casting aluminum technology to improve the local rigidity and stability of the entire vehicle while achieving lightweighting of the body, providing protection for the safety and sports performance of the whole vehicle.

Source: GAC Group

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.