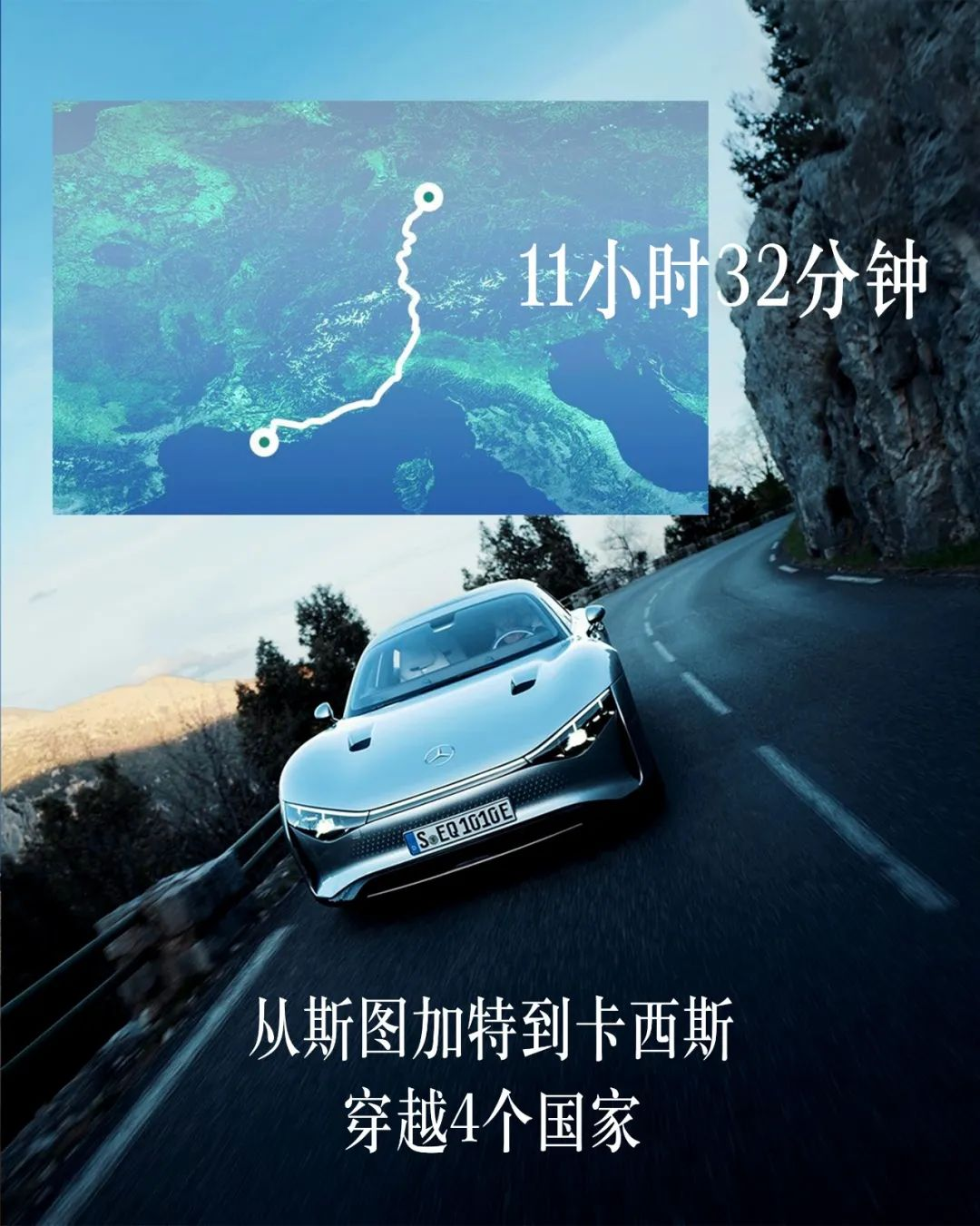

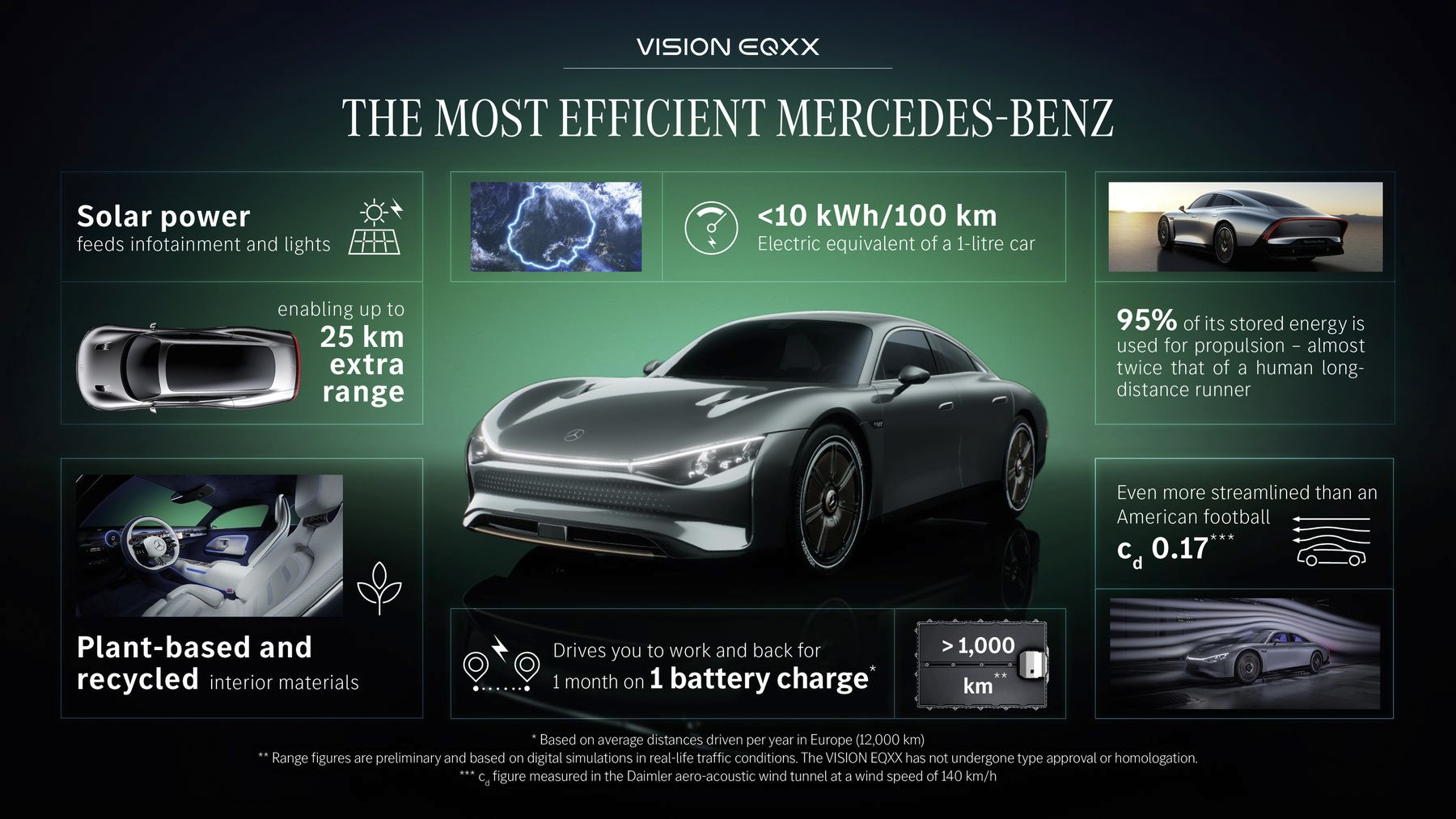

On April 14th, Mercedes-Benz VISION EQXX concept car completed its first real-world energy efficiency test on European roads. With only one charge, the car traveled over 1,000 kilometers and created Mercedes-Benz’s lowest energy consumption record, averaging 8.7 kilowatt-hours per hundred kilometers.

Starting from Sindelfingen, Germany, VISION EQXX drove in various road conditions, including high-speed highways, mountain roads, and tunnels, and endured harsh weather conditions such as rain and extreme temperatures before arriving in Cassis, France. When it reached the final destination, the remaining battery level was around 15%, equivalent to a range of approximately 140 kilometers. The car cruised at an average speed of 140 kilometers per hour, and the overall average speed was 87.4 kilometers per hour.

It is worth mentioning that Mercedes-Benz has successfully showcased its strength in electrification by achieving an energy consumption performance of 8.7 kWh/100 km under such comprehensive road conditions. Let’s delve into the reasons why VISION EQXX can achieve such low energy consumption.

Ultra-Low Drag Coefficient

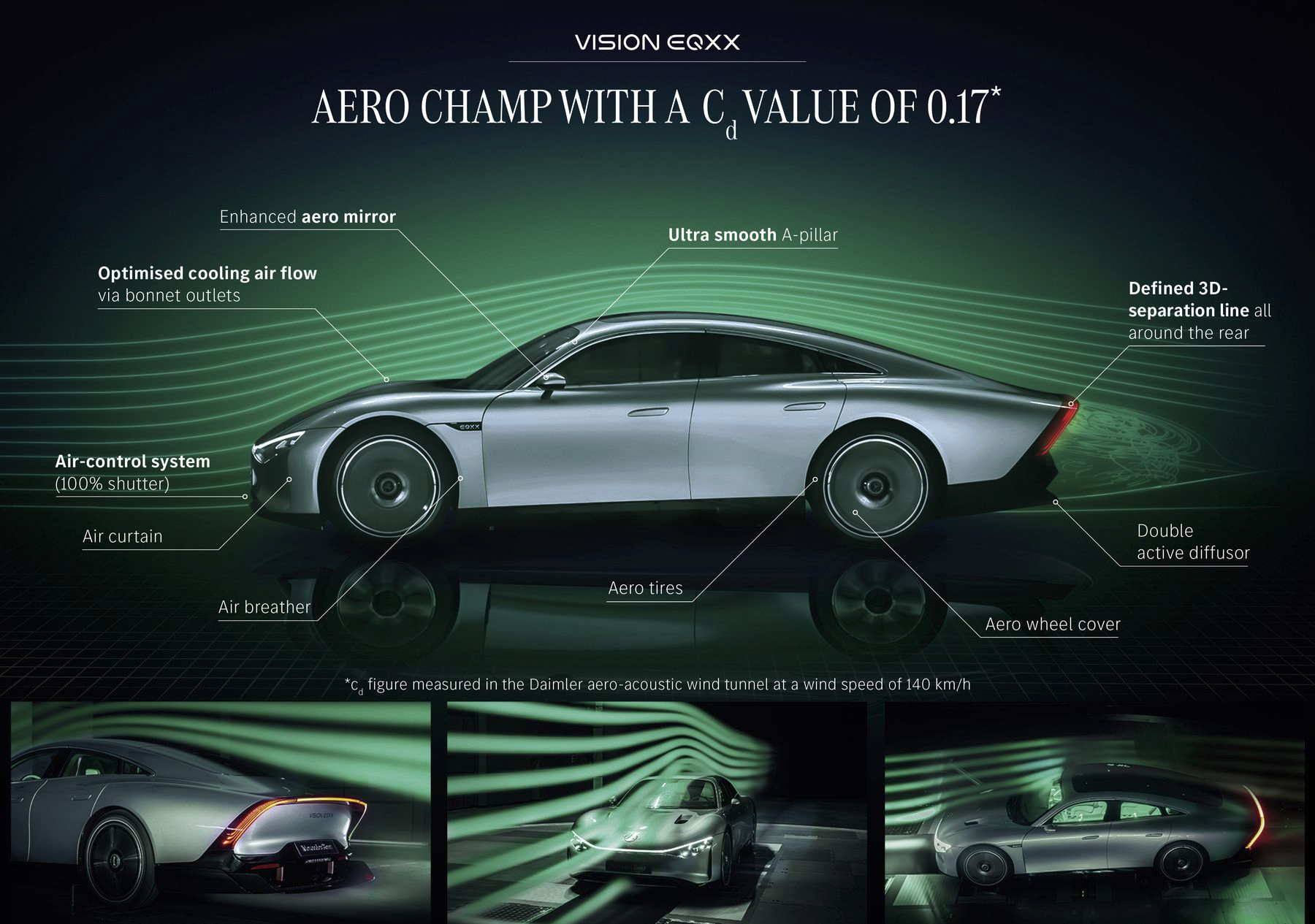

First and foremost is the air resistance. In the era of gasoline vehicles, wind resistance coefficient might have been just a marketing gimmick used by manufacturers. However, in the electric vehicle era, every manufacturer must seriously consider wind resistance coefficient. From the door handle to the entire car’s design, everything must be carefully designed.

The VISION EQXX concept car’s design features an extremely streamlined exterior, resembling a flowing drop of water. The car’s wind resistance coefficient has been optimized to 0.17 through various design details, including aerodynamically reinforced and optimized wing mirrors, super-smooth A-pillars, a front face air control system, and tire coverings. This coefficient is even lower than the 0.20 coefficient that the Mercedes-Benz EQS achieved to set the world record for the lowest wind resistance only recently.The extremely low 2.12 square meters of frontal area and the compact rear track of the vehicle made a significant contribution to the improvement of aerodynamic performance. In addition, when the speed reaches 60 km/h, the active rear diffuser can automatically open to optimize the airflow, significantly reducing the drag coefficient.

Next is the tire. Mercedes-Benz cooperated with Bridgestone to use Turanza Eco tires, and combined with lightweight and environmentally friendly ENLITEN and Ologic technology, the rolling resistance coefficient was reduced to 4.7, even the tire sidewall has been aerodynamically optimized.

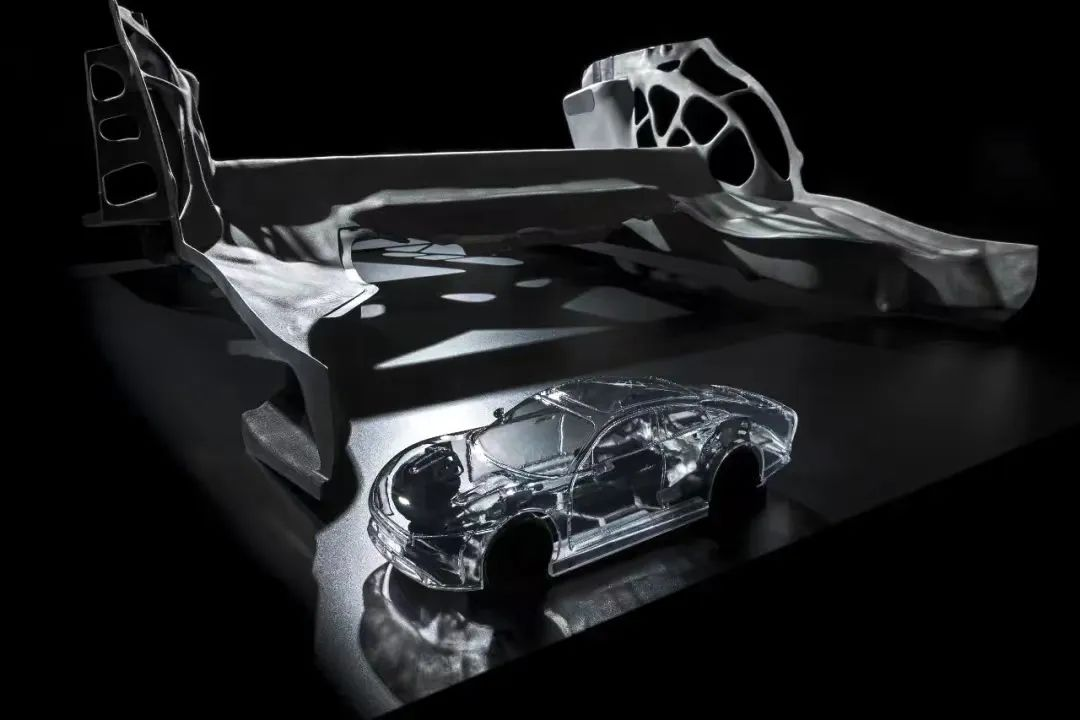

Ultimate Lightweight Design

The curb weight of the VISION EQXX vehicle is 1,755 kilograms, which is extremely lightweight for an electric vehicle that is over 4.6 meters long, has a wheelbase of 2.8 meters, and is equipped with a battery pack of almost 100 kWh.

Various lightweight techniques were used in the vehicle design, such as the battery cover using sustainable carbon fiber-sugarcane composite material originated from F1 racing technology; the BIONEQXX™ rear underbody casting used an aluminum monolithic casting process, and the lightweight unitary structure casting replaced heavy components consisting of multiple parts, saving material for non-load-bearing structures. Compared to traditional components, weight is reduced by up to 20%.

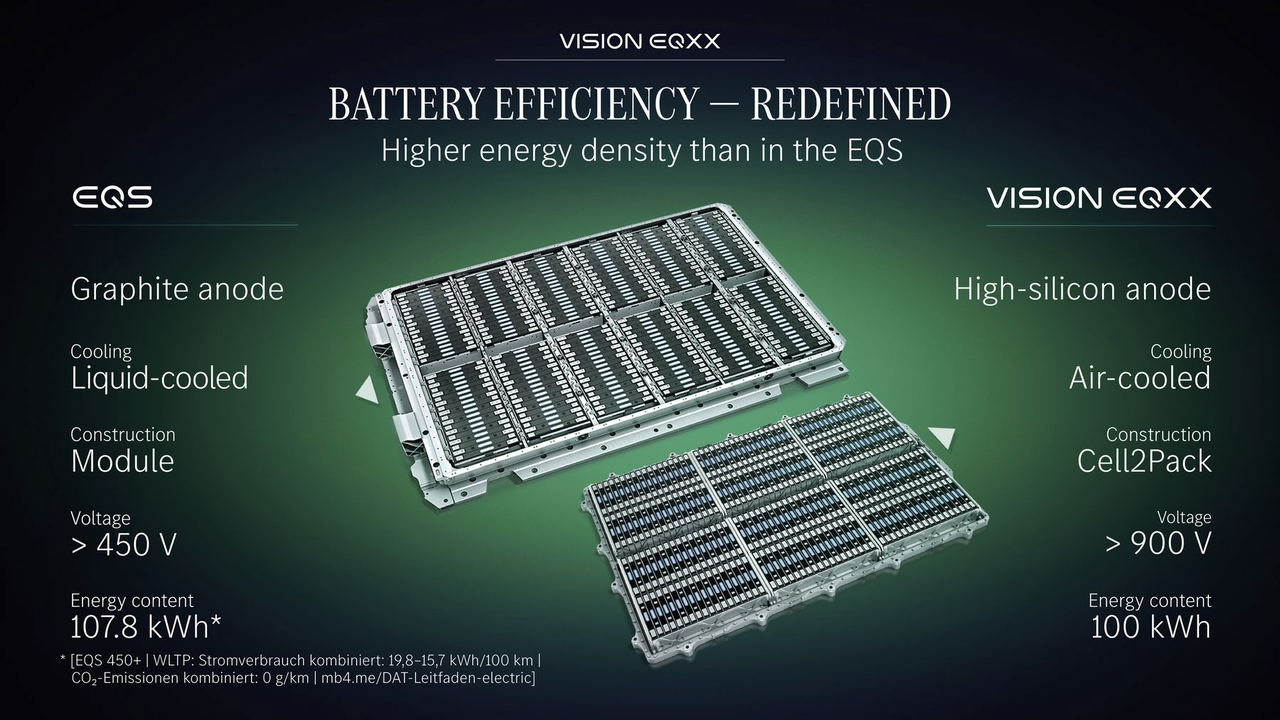

The EQXX dedicated battery pack has an energy of nearly 100 kWh, which is almost the same as the battery capacity of the all-new EQS, but the size is reduced by 50%, with a 3D size of only 200 x 126 x 11 cm, and the weight is reduced by 30%, weighing only 495 kilograms.

High-Efficiency Powertrain System

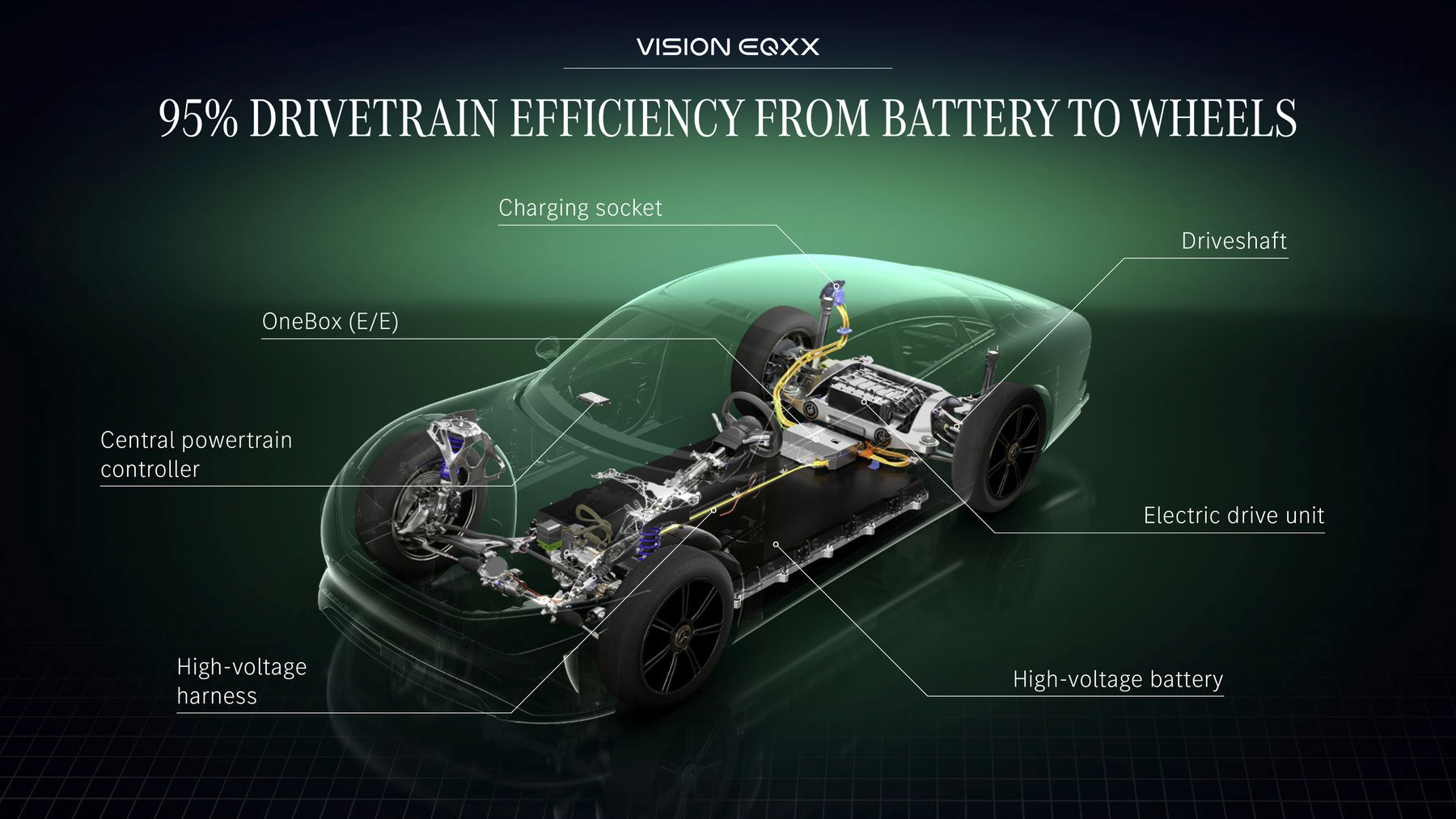

Under the joint creation of the engineering team in Stuttgart and the Mercedes-AMG High-Performance Powertrains team (HPP), the EQXX has a peak output power of 180 kW and a drive efficiency of 95%, and note that this is the system efficiency from the battery to the wheels. In comparison, the current system efficiency of most electric vehicles is around 75%.

The energy density of the battery pack has reached 400 Wh/L, with a working voltage of over 900 V, which marks the first successful application of 900 V voltage technology. During the journey, the high voltage system exhibited the expected stability and reliability.

The energy density of the battery pack has reached 400 Wh/L, with a working voltage of over 900 V, which marks the first successful application of 900 V voltage technology. During the journey, the high voltage system exhibited the expected stability and reliability.

Energy Recovery and Solar Power Generation

As long as there is a slope or braking, the VISION EQXX concept car can recover energy from it. During this process, electric braking can meet most of the braking needs without the involvement of mechanical brakes, enabling lighter aluminum brake discs to replace steel ones and further saving kinetic energy loss.

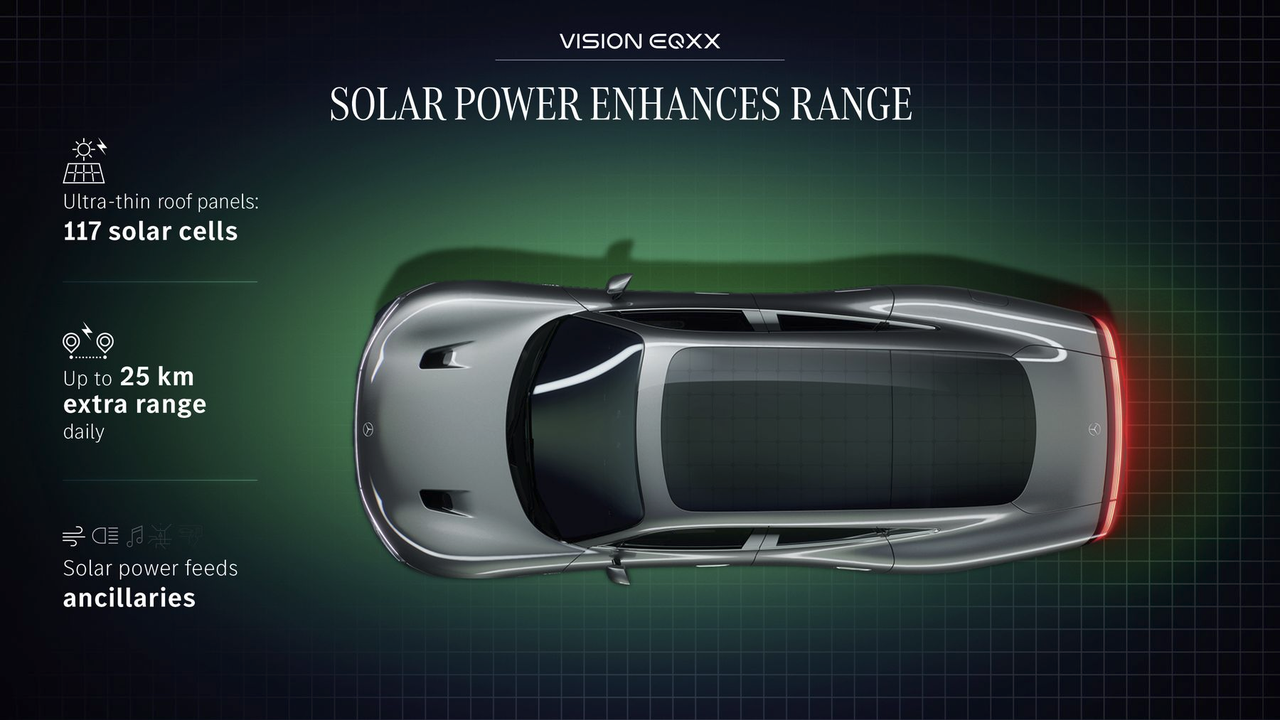

At the same time, the 117 solar cell modules on the roof of VISION EQXX can power the 12 V battery system and thereby power navigation and other systems.

Solar charging has increased the vehicle’s range by over 2%, providing an additional range of about 25 kilometers during this journey of over 1000 kilometers.

Advanced Heat Management System

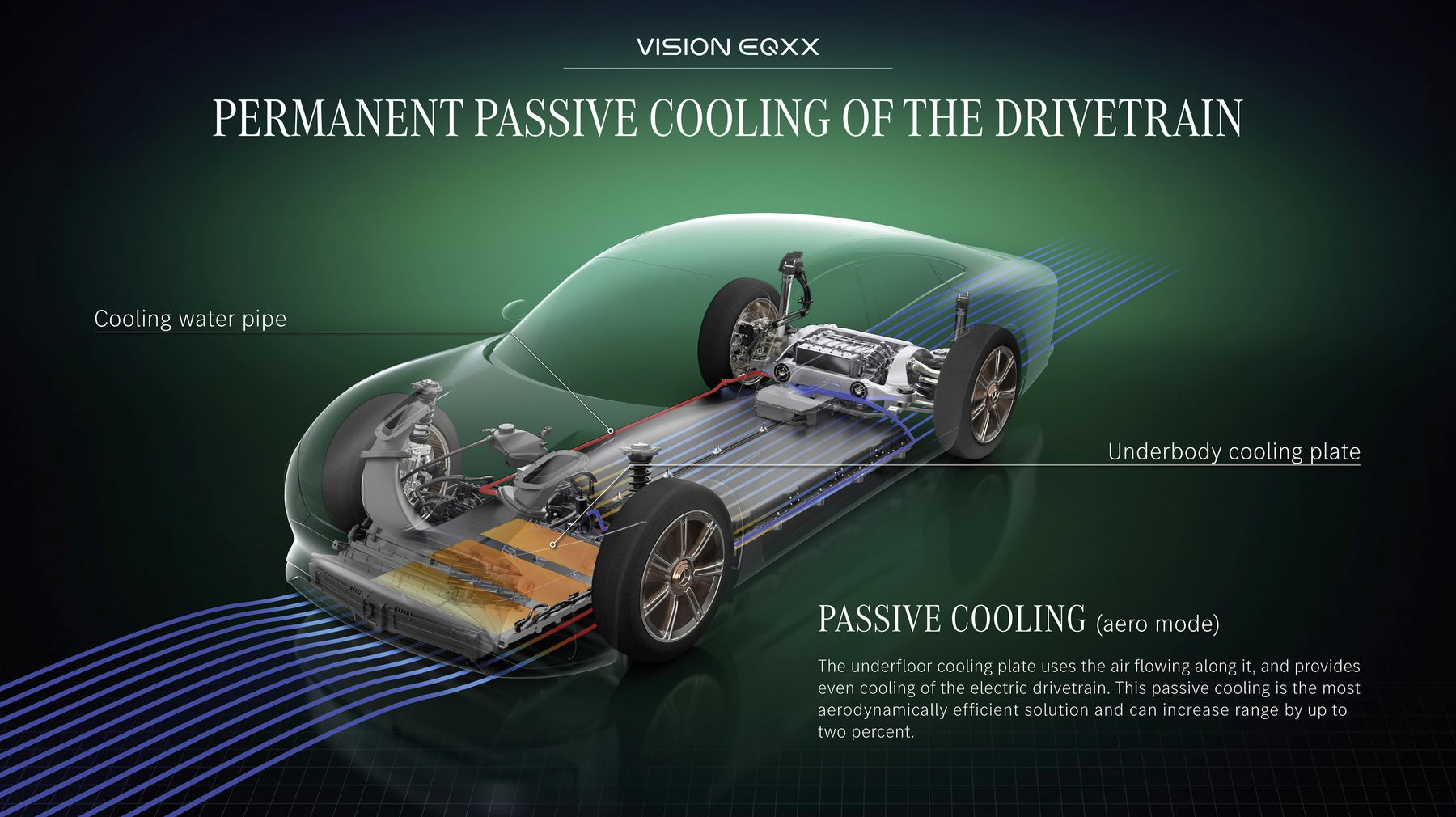

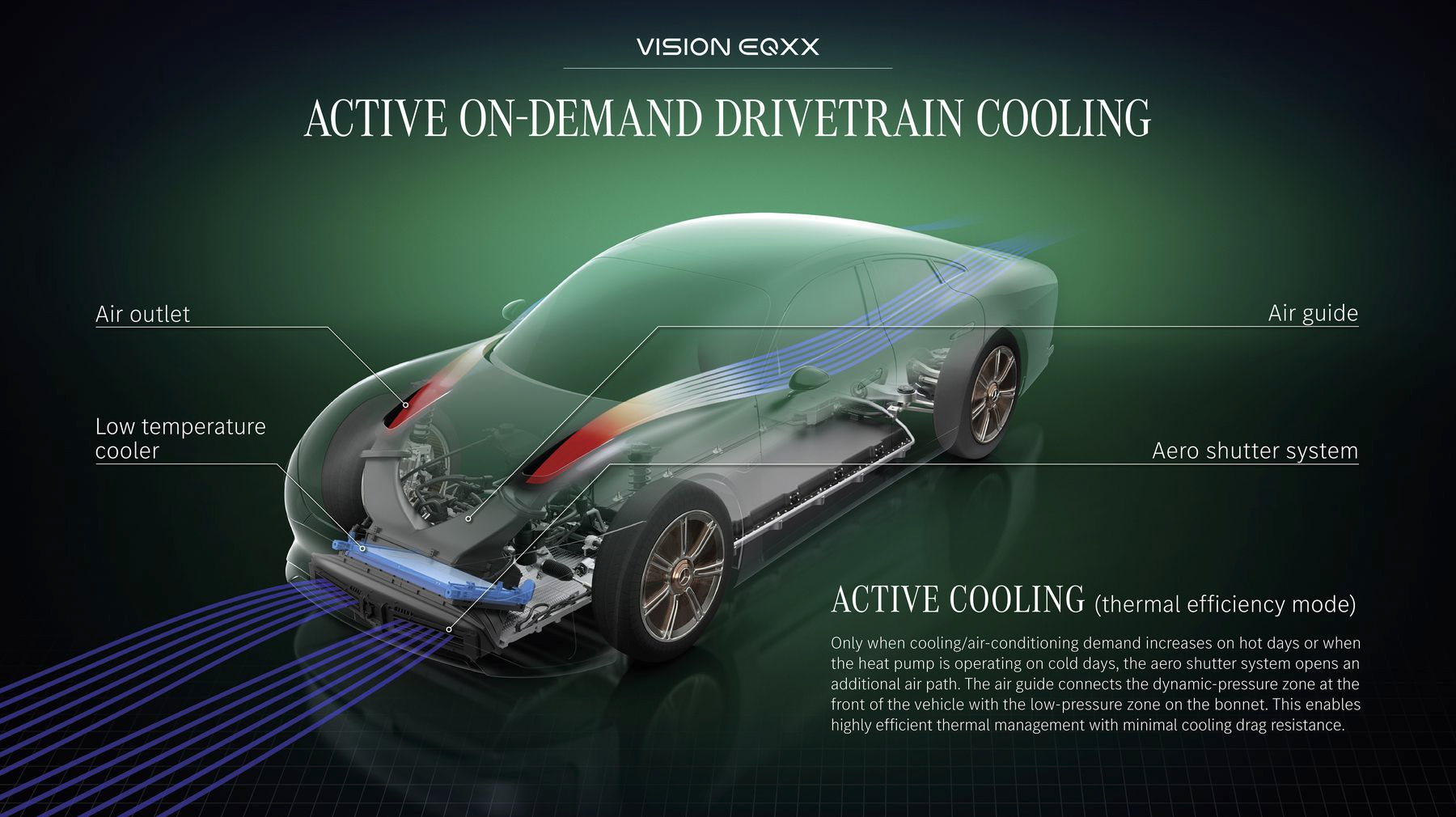

EQXX has a unique design for the transmission system heat dissipation and air conditioning heat pump. The use of a heat sink plate installed on the bottom of the vehicle can achieve passive cooling of the transmission system by air flow, increasing the vehicle’s range by about 20 kilometers.

When the weather is hot and air conditioning is needed, or when the weather is cold and the heat pump is running, the air conditioning system will activate the “intelligent air curtain” of the active air intake grille, opening additional air flow channels. The air flow channel connects the high pressure area at the front of the vehicle with the low pressure area at the top of the engine hood, achieving efficient heat management with minimal air resistance.

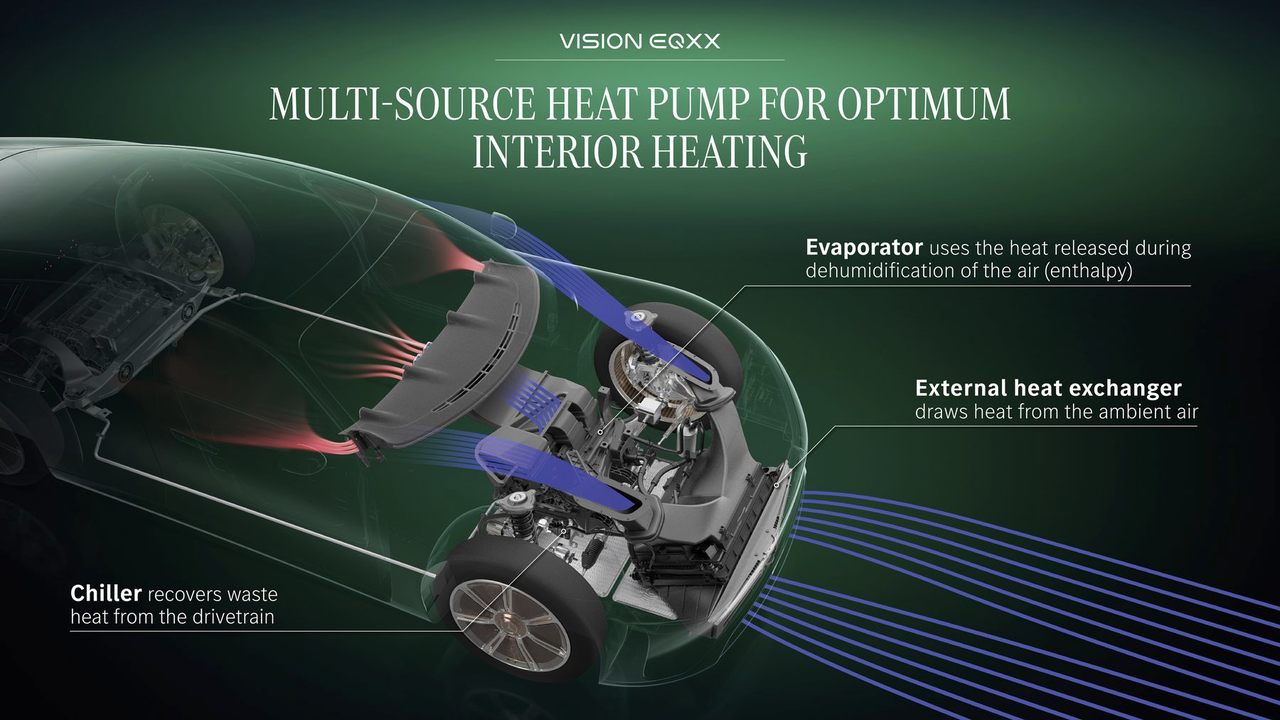

The vehicle is equipped with a multi-source heat pump that can even absorb heat from the outside air, collect heat emitted during the air dehumidification process, and collect waste heat from the transmission system, thereby maintaining cabin temperature with lower energy consumption and reducing active power consumption.

### Final Words

### Final Words

Mercedes-Benz has applied advanced electrification technology to EQXX and demonstrated its unparalleled strength in the automotive industry. Although it may take some time for these technologies to be fully applied to production vehicles, the impressive energy performance undoubtedly shows the ultimate performance that electric vehicles should have in the future.

At the end of the article, it is necessary to clarify the issue of the altitude difference in the test journey. Many friends think that this test used the altitude difference and drove from the mountain top to the seaside.

In fact, it can be easily found through a simple search that the starting point of the journey, Sindelfingen, is about 400 meters above sea level, and the endpoint, Cassis, is at the seaside. There is a total drop of more than 400 meters between the starting and ending points, and the Alps have to be crossed in the middle.

Such altitude difference and road conditions cannot be said to have no effect on the final result of 1,008 kilometers and an average speed of 87.4 kilometers per hour, but can only be said to have a slight helping hand.

What really makes EQXX complete the challenge is its strong technical strength.

🔗Source: mercedes-benz

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.