Author: Dazhao

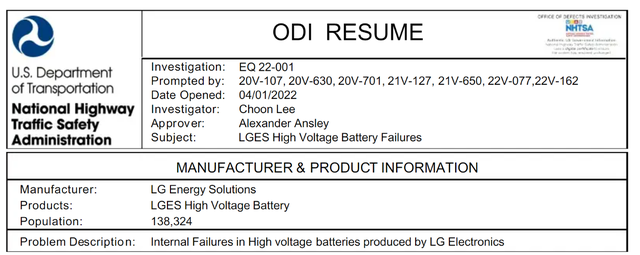

On April 6 local time, the National Highway Traffic Safety Administration (NHTSA) of the United States announced that it is investigating LG Energy Solution (LGES) for its battery safety issues, which have caused fires in electric vehicles and plug-in hybrid electric vehicles.

In a statement, LGES said, “We understand that the latest request from NHTSA is a follow-up process to determine whether the same or similar batteries involved in the recall have been supplied to other OEMs.”

LG Energy Solution also said, “LG Energy Solution will fully cooperate with the investigation.”

In the global new energy market, LGES’s battery can be regarded as the most unreliable with the most fires, the largest recall, and the widest range of brands involved in the history of new energy vehicle development. However, by compensating affected companies such as General Motors and Hyundai Motor, LGES’s development is still moving forward rapidly.

NHTSA’s third-party investigation this time, no matter what the purpose is, will have a huge impact on LGES.

NHTSA said it would write to LGES and other carmakers that may have purchased the same or similar cells from LGES, notifying other car manufacturers that defective batteries from LGES may be present in their vehicles.

NHTSA stressed that all defective batteries must be recalled by car manufacturers.

Currently, the investigation involves 138,324 new energy vehicles. NHTSA’s move indicates that more electric vehicles may face recalls.

In fact, NHTSA has previously cooperated with major manufacturers such as General Motors and Volkswagen to participate in the investigation of LGES batteries, but this time it launched a direct investigation, with a wider impact.

What may have caused NHTSA to make a change is LGES deliberately avoiding the issue.

NHTSA said that LGES has a battery factory in the city of Holland, Michigan, which told the DetroitNews in September last year that it was contacting LGES to determine other vehicles that may have been affected, but the investigation has not yet begun.

The investigation into LGES cited six recalls or filings.

First, in February 2020, Mercedes-Benz recalled a 2019 Smart Fortwo electric vehicle.## Second, in October 2020, Hyundai actively recalled certain KONA electric vehicles produced between September 2017 and March 2020, totaling 25,564 vehicles.

After this recall, Hyundai expanded its recall scope and added 52,000 electric vehicles sold in the European market.

As of this recall, there have been 13 fire incidents in KONA electric vehicles, mainly in South Korea, as well as one each in Canada and Austria.

Third, in November 2020, General Motors announced the recall of Chevrolet Bolt EVs manufactured between 2017 and 2019, totaling approximately 69,000 vehicles.

Prior to this recall, there were a total of 5 Bolt EVs on fire, which resulted in two people inhaling smoke and being injured. With subsequent combustion incidents, the total number of Bolt EV fires has exceeded 10.

Fourth, in March 2021, Hyundai announced a global recall of approximately 82,000 electric vehicles, including KONA and IONIQ.

Currently, the cumulative number of KONA EV fires has exceeded 15.

Fifth, in February 2022, Stellantis, the parent company of Chrysler, announced the recall of 19,808 units of Pacifica plug-in hybrid mini-vans produced in 2017 and 2018.

As of the recall, there have been 12 incidents of Pacifica PHEVs catching fire.

Sixth, in March 2022, Volkswagen decided to recall 351 units of ID.4 produced between December 16, 2020 and December 8, 2021.

Although NHTSA only listed six recalls, the actual number is far more than that.

For example, in August 2021, General Motors recalled another 73,000 Chevrolet Bolt EVs (many media outlets incorrectly added the recall numbers, resulting in more than 140,000 recalls. In fact, the second recall of 73,000 already included the first recall of 69,000), as the first solution of locking the battery was ineffective, and the second solution was to replace the battery pack.

The causes of electric vehicle fires are generally multifaceted, including battery quality issues and immature designs from automakers.

However, the reality is complex, which sometimes leads to disputes, with the battery factory blaming the automaker for inadequate design and the automaker complaining about the substandard batteries from the battery factory.

Considering the large amount of data involved in the above recall, it is inevitable that LGES battery’s safety is being questioned.

It is worth noting that due to the two recalls of Bolt EV and other electric vehicles, General Motors has cumulatively spent approximately $2 billion, and has therefore chosen to seek compensation from LGES.

LGES subsequently announced that it agreed to compensate General Motors $2 billion (some sources say 95%) of the recall cost, with the condition of establishing a joint venture enterprise to manufacture batteries for General Motors’ next generation of electric vehicles.

Similarly to General Motors, Hyundai Motor also chose to seek compensation from LGES, for a sum of approximately $900 million.

Thus, it can be basically determined that the responsibility lies with LGES and their battery quality is extremely substandard.

So, what is the problem with LGES batteries? Let’s take a closer look at the above-mentioned recalls.

Regarding the Smart Fortwo with problems, Mercedes-Benz stated that the high-voltage battery produced by LGES had defects, which might ignite within the battery cells and increase the risk of fire.

Regarding the first recall, Hyundai Motor stated that the cause was the defect in the production process of the high-voltage battery, which might lead to a short circuit and result in a fire.

Regarding the second recall, Hyundai Motor stated that there was an internal electrical short circuit in the battery, which might increase the risk of fire when parked, charged, or driven.

Hyundai Motor claimed that the problem was due to the “folded anode tag” (probably a professional term but the translation is not exact, for those who understand can explain it in the comment section).

On July 21st, 2021, experts from LGES and General Motors determined that there were “two rare manufacturing defects in the same battery”, which were the root cause of the fires in Chevrolet Bolt EV batteries.

General Motors identified these two defects as anode tearing and separator folding, and stated that the defective batteries were produced in LGES’s factory in Ochang, South Korea.

In addition, after the 10th fire incident of the BOLT EV in Chandler, Arizona, General Motors claimed that there were also manufacturing defects in factories other than Ochang.

Among them, the commonality between the first five vehicles was that they caught fire when the batteries were fully charged or had just been used after being charged.

Stellantis stated that among the 12 fire incidents, all vehicles were parked with the engine off, and eight of them were connected to charging equipment when caught fire.# Volkswagen I.D4 recall

The Volkswagen I.D4 was recalled due to stalling occurrences in the United States. The National Highway Traffic Safety Administration (NHTSA) intervened in the investigation and stated that specific welding points on the Flexible Printed Circuit Assembly (FPCA) of the battery may not establish reliable connections, which could cause the vehicle to malfunction or unexpectedly shut down, resulting in collisions without warning.

The NHTSA concluded that the root cause of the Volkswagen I.D4 battery defect was that there were not enough welding points on the FPCA, and the thickness of the welding layer exceeded tolerance parameters.

In July 2021, Volkswagen became aware of this problem and the potential consequences. Since then, the use of the flux material in the production process at their supplier, LG Energy Solution (LGES), has been optimized. Three weeks later, LGES performed additional preventative measures by optimizing automated optical inspections.

It should be noted that the above summary of the accident mainly comes from Volkswagen’s statement, so bias cannot be avoided, and LGES rarely speaks of the matter. One exception was during the KONA EV fire incident, in which LGES claimed that Hyundai misplaced their recommendation for rapid charging logic in the battery management system. However, LGES ultimately paid compensation.

In fact, the poor reputation of LGES’ batteries is not limited to the electric vehicle market, but also extends to the energy storage market. According to South Korean media reports, in April 2021, a photovoltaic power plant energy storage system (ESS) caught fire. After a preliminary investigation, it was revealed that the origin of the fire was inside the energy storage unit, with LGES as the supplier of the battery cells.

The installation company’s project manager stated that “the fire occurred while complying with all safety standards required by the government and the manufacturer, and the charging rate (SOC) was limited to 90% because it was an outdoor facility.”

Furthermore, statistics show that of the 27 ESS fire incidents that occurred in South Korea from August 2017 to October 2019, 17 were equipped with lithium-ion batteries produced by LGES.

In the United States, on April 17, 2019, a fire broke out in the McMicken energy storage facility located in Surprise, Arizona. The accident injured four firefighters and was one of the most significant battery storage fires in US history.

According to an investigation report issued by the Arizona Public Service (APS), the lithium-ion battery rack provided by LGES and operated by storage company Fluence heated up and caught fire. The incident was classified as a “thermal runaway event” caused by internal battery defects, particularly abnormal lithium metal deposition and dendritic growth inside the battery.The conclusions drawn in the APS report were challenged by LGES, who used their own analysis report from Exponent to refute them.

In December 2020, LGES announced a recall of some Resu10H ESS household energy storage system products in the US market due to the risk of internal battery cell overheating and fire.

On the evening of February 13th this year, the Moss Landing energy storage station in California, the largest battery energy storage system in the world, caught fire again, with about 10 battery racks melted. This was the second accident at the project in the past five months.

Both accidents were determined to be caused by thermal runaway, and the battery supplier for this storage station was LGES.

Electric Momentum Speaks Out

The performance of LG batteries in the dynamic battery market and energy storage battery market can be described as disastrous.

Industry rumors suggest that Japanese and Korean batteries are more advanced than Chinese batteries. This is clearly biased. Good batteries should never sacrifice safety.

How far LG batteries can go remains a big question mark.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.