Today’s Summary of Korean Battery Exhibition

I spent some time today looking at the Korean Battery Exhibition, which was held on March 17th this year. The main focus was on the technology released by major battery companies (SK On, LG Energy Solution, and Samsung SDI) and their positive electrode enterprises.

I plan to introduce it in two parts over the weekend, with a focus today on the three major companies: SK On, which has taken on a more aggressive strategy than LG Energy Solution worldwide, focusing on safety and saying “I won’t burn.” SDI specializes in high-end batteries, focusing on its own PRiMX battery brand. LG Energy Solution mainly talked about solid-state batteries this time, and mainly talked about the Hummer BEV they developed with General Motors on-site.

Figure 1. Minister of Industry and Commerce Resources of Korea attends.

The main battery technology of the Korean Battery Exhibition in Seoul, South Korea, worth KRW 200 billion R&D innovation fund for power batteries.

(1) SK On

The entire exhibition area is mainly divided into the “Start On” area, which introduces the corporate image of SK On, the “Always On” area, which introduces innovative technology, partners, and battery services, the “Beyond Expectations” area to showcase the company’s future goals, and the “Around You” area, which introduces the full lifecycle of batteries and environmental protection content. Of course, SK On was also very impressive this time, as they directly brought a plug-in hybrid Ferrari SF90 Stradale to the exhibition. SK On plans to increase annual production capacity from 40 GWh at the end of 2021 to 500 GWh by 2030, and from the current backlog of orders, it appears that they have a backlog of 1600 GWh.

Figure 2. The plug-in hybrid and P260 battery.

In the Start On area, the NCM9 battery is placed at the forefront. This is SK On’s high-performance battery with the highest energy density, which won two innovation awards at CES2022 in the United States. Through a proprietary coating process, it can be fast-charged to 80% in about 18 minutes (the fastest charging speed currently available). NCM9, which integrates this technology, will begin production in 2023 and will be supplied to Ford.

Figure 3. SK On’s material development process.The Z-shaped stack of SK On is shown in Figure 4.

The PHEV battery and MEB battery of SK On are shown in Figure 5.

In the Always On Zone, safety technology is mainly demonstrated through the manufacturing process. Currently, SK On has used about 300 million battery cells in electric vehicles without any fire incidents. SK On also launched a battery diagnosis service to detect and notify drivers of battery life and abnormal conditions, and developed “BaaS AI (Battery and Service Artificial Intelligence)” to monitor the battery status, as shown in Figure 6.

When a specific battery cell unit catches fire, SK On also considers introducing S-Pack technology, which can block heat to prevent the fire from spreading to the entire battery pack, as shown in Figure 7.

SK On is developing solid-state batteries through external cooperation. It is collaborating with Dr. Goodenough from the University of Texas at Austin and Professor Seungwoo Lee from the Georgia Institute of Technology in academia, with the goal of developing solid-state batteries by 2030, as shown in Figure 8.

(2) SDI

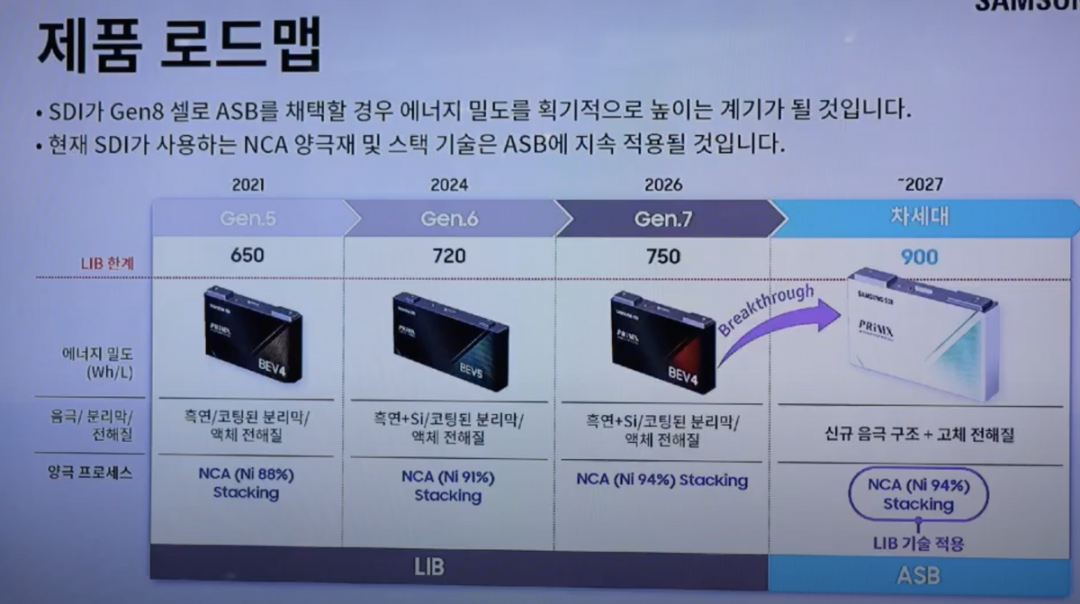

At the end of 2021, Samsung SDI released the independently developed brand “PRiMX”, hoping to provide the best experience with the highest quality batteries. From a technical perspective, the roadmap is clear:

●In 2021, the NCA Gen1 of GEN5 is already in mass production, with an energy density of 650Wh/L (88% nickel content).

●GEN6 NCA Gen2 is planned to be in mass production in 2024, with an energy density of 720Wh/L (91% nickel content).

●GEN7, upgraded by 2026, sets a target of 750Wh/L (94% nickel content).● Full solid-state batteries will be mass-produced starting from 2027, with the goal of achieving 900Wh/L.

▲ Figure 9. Samsung SDI’s relatively stable technical roadmap

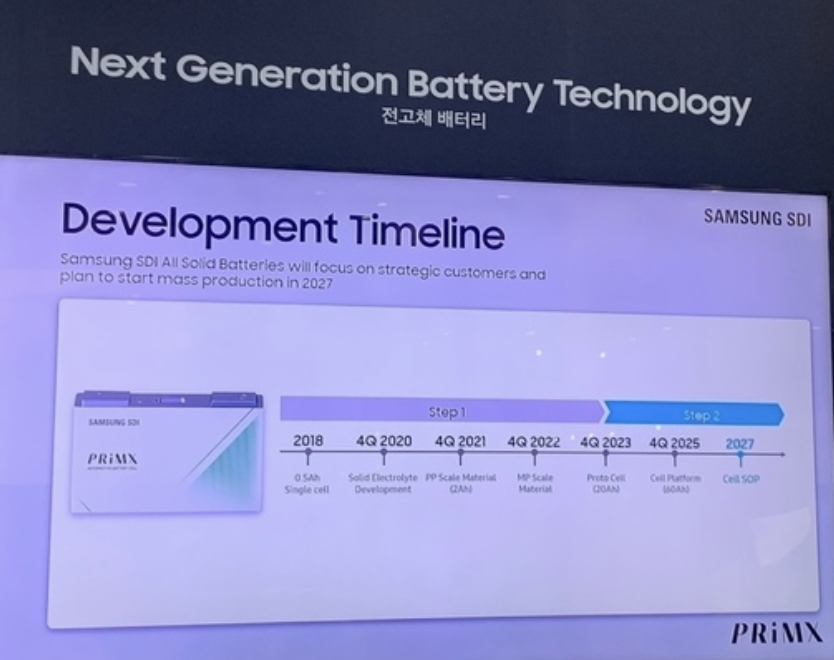

Below is Samsung PriMX’s development roadmap for full solid-state batteries, with most of the PP Scale Material work completed in the fourth quarter of 2021, MP Scale Material testing scheduled for the fourth quarter of 2022, and a 20Ah trial production battery cell scheduled for the fourth quarter of 2023.

▲ Figure 10. Samsung SDI’s PriMX full solid-state battery

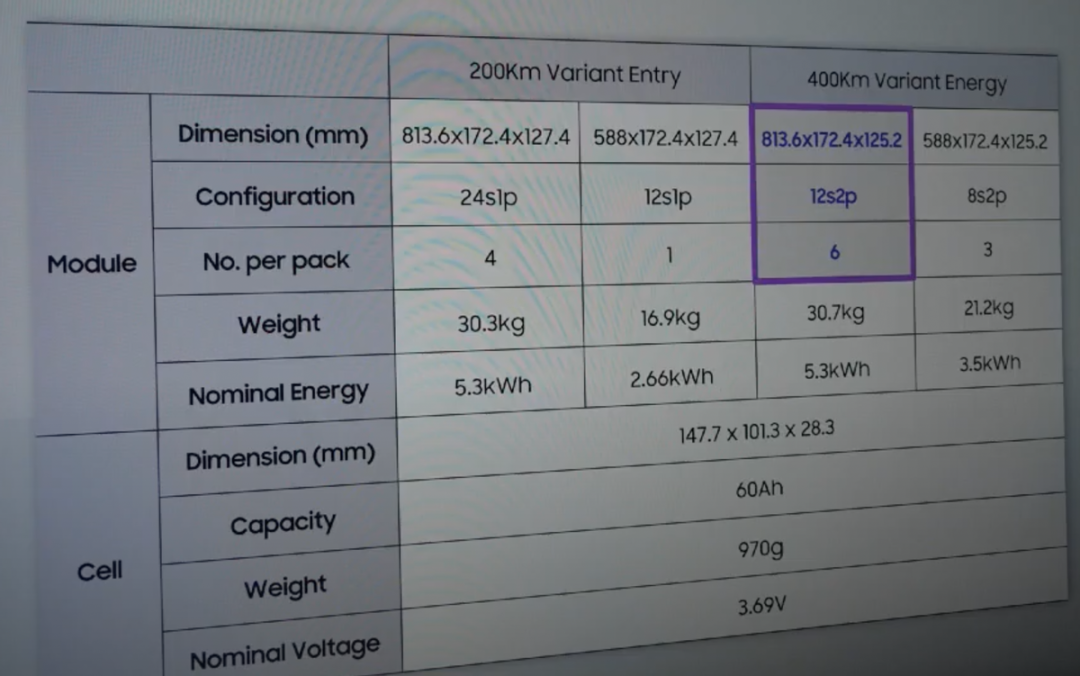

SDI may not have showcased anything else on site, but they did showcase the battery pack they made for Fiat earlier.

▲ Figure 11. SDI’s previously developed battery packs

(3) LG Energy Solutions

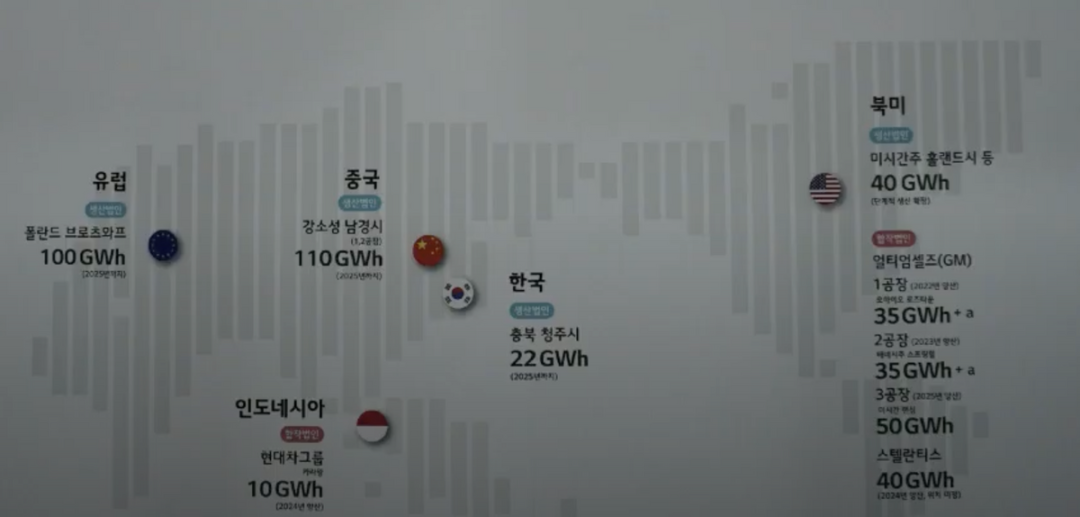

Everyone knows LG’s situation, with their current production capacity mainly focused on Europe, China, and the United States (with additional production capacity in South Korea and Indonesia). Their overall production capacity construction speed is relatively slow, and they also showcased GM Hummer and Tesla Model Y vehicles on site.

▲ Figure 12. LG’s latest global production capacity distribution

▲ Figure 13. The only battery on site

LG is simultaneously developing polymer-based and sulfide-based solid-state batteries, introducing differentiated materials and innovative production techniques such as NCMA (quaternary batteries with added aluminum) and Long Cell. Compared with existing technologies, energy density has increased by 16\%, and driving range has increased by over 20\%.

▲ Figure 14. LG’s battery mainly focuses on the next generation.Summary: From what I’ve seen, SK On seems to have a bit of a first-mover advantage in the Korean battery industry, building on the foundation of safety and proceeding more steadily.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.