Author: Zhu Yulong

The Tesla Texas factory opening event, called Gigafactory Cyber Rodeo, showcased a lot of things. Overall, the themes of this event were the opening of the factory, the new version of Model Y (integrated aluminum casting, CTC), the 4680 battery factory, and the upcoming CyberTruck in a year. Of course, in the era of CTC, it not only means using wing-like structures as fuel tanks like airplanes, but also producing cars in a more efficient way across the entire factory, and the battery factory is part of it.

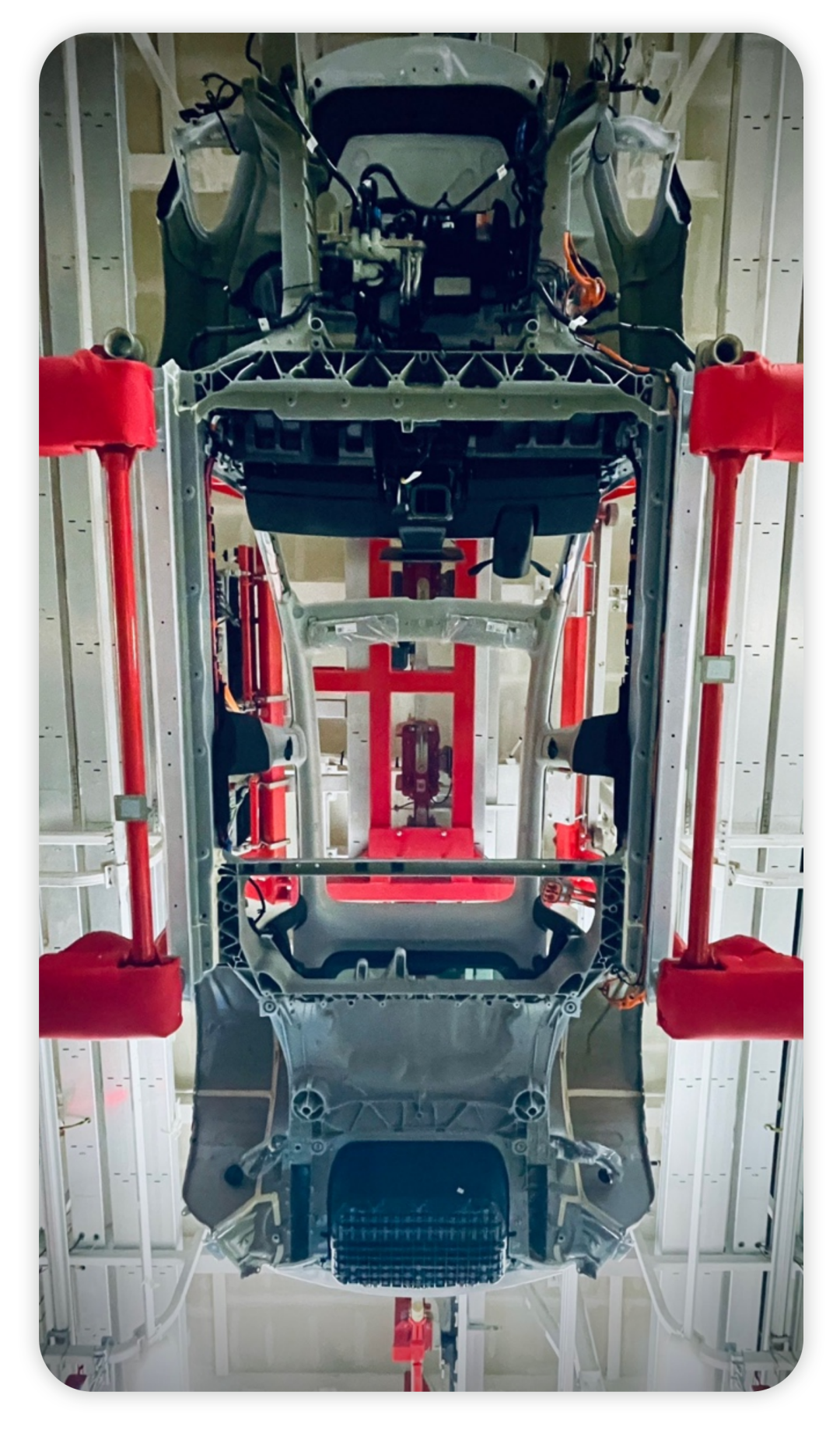

Please also pay attention to the layout changes of the Texas factory, which may be more important than CTC. In terms of layout logic, Tesla has completely reconstructed the process of traditional car manufacturing. Traditional cars go through a series of processes, including stamping, welding, painting, and assembly. However, the new Texas factory, based on front and rear casting + CTC battery system, has turned the entire vehicle production into parallel + modular assembly. This change not only reduces production pace and costs but also brings a revolution to the logic of manufacturing new energy vehicles, making it more suitable for the future rapid iteration of new energy vehicle architecture, which may include modular iteration and cross-platform integration. The skateboard chassis concept began to attract attention last year. Will Tesla’s new factory provide a better solution?

The emergence of new energy vehicles is not only a revolution in automobile powertrain but also a reconstruction of the entire automobile industry. All links in the industry chain will be rethought due to the emergence of new energy vehicles. This is also the embodiment of Tesla’s first principle.

Details of the 4680 battery

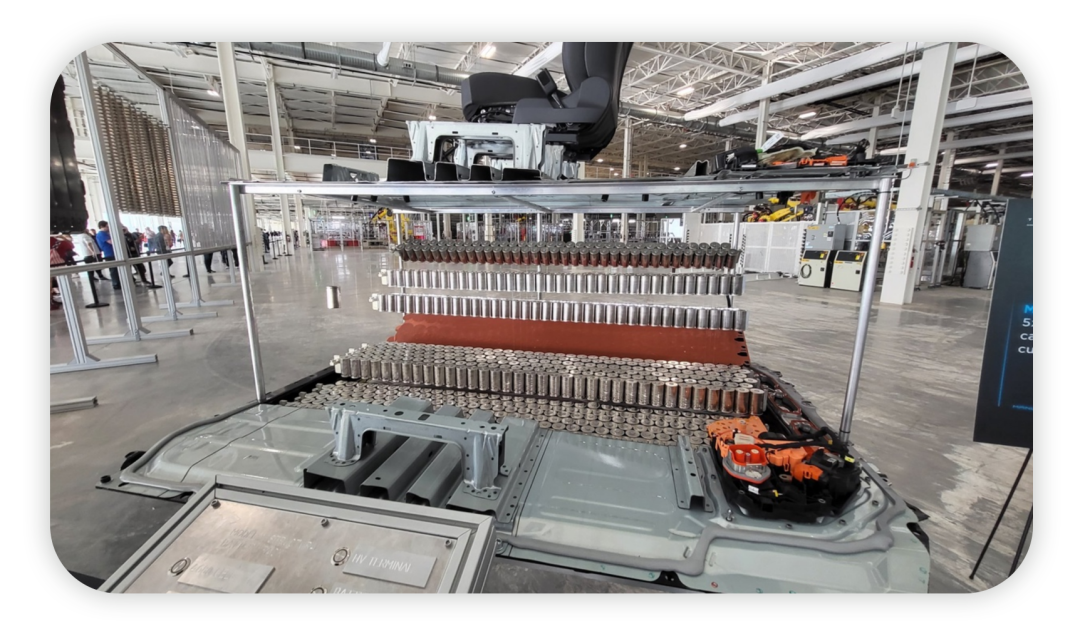

In the figure below, we can see the overall structure of the 4680 battery very clearly, and the top-level water-cooled plate can also be seen in the figure below.

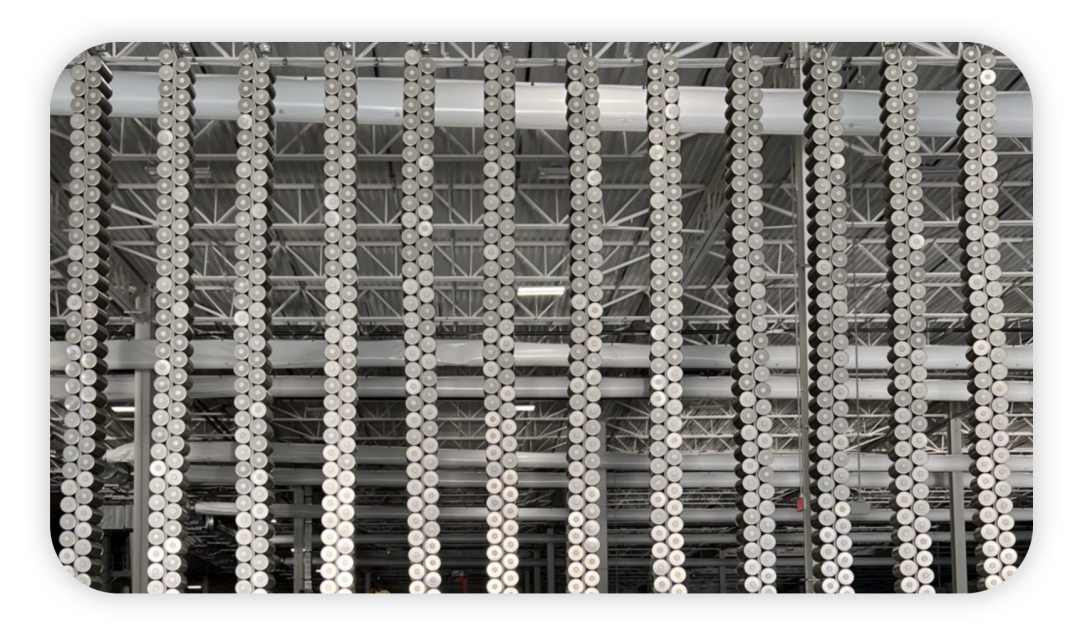

Tesla has the 4680 battery pack suspended like sausages, allowing us to see the overall structure. There are 34-35 cells per group, and they are suspended in 24 columns with classic water-cooled plates for heat dissipation in the middle.

In the overall display, it’s similar to the opening of the Berlin factory before, with a similar cross-sectional diagram.

With the combination of the following two figures, it is clear that the structure of the 4680 cell body is directly involved in the mechanical bearing of the entire vehicle. However, the protection of the entire pack structure still relies on the stronger cast aluminum structured car body load-bearing, allowing the high-pressure cast aluminum lower shell to be integrated together.

On the factory side, some coated pole pieces are also displayed, which can have a better effect on battery cell manufacturing.

Progress of 4680 Battery CellFrom Berlin to Texas, Tesla has emphasized the progress of 4680 cells and structural batteries. In terms of global layout, the development and trial production line of 4680 cells are located in Fremont, while production is in Austin. The yield rate of cells for large-scale production has reached 90% and in some good cases, even 93%, which means that it has already met the requirements for large-scale production. Starting from April, Tesla just began the large-scale production of 4680 cells, which relies heavily on the trial production of over a million cells produced in small quantities in Fremont in the previous quarter. Tesla’s Q1 earnings conference call referred to the trial production of Model Y, which amounted to about 1000 cars and most of the vehicles were used for various experiments, with only a few cars available for special customers to try. Overall 4680 capacity will gradually increase from April and will come out in Q2 2022. It can also be seen that at the Texas plant, the battery factory is a part of overall production.

Conclusion: With a deeper understanding of 4680, we can see that its structure is simpler than we expected. In fact, the pack design of the entire battery is making subtraction, further simplifying the process and increasing the overall yield rate.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.