Author: Lingfang Wang

Editor: Kaijun Qiu

Battery technology has undergone a significant differentiation and has become more distinct.

From March 25th to 27th, the 2022 Electric Vehicle One Hundred Forum was held online. Every year, the forum invites the most representative battery companies in the market to speak, and this year is no exception.

The biggest highlight of this year is the exciting reversal of the route once thought to be weakening:

- The 4680 large cylindrical battery cell has risen strongly and is highly sought after by companies such as Panasonic, EVE Energy, and BYD. Contemporary Amperex Technology (CATL) launched the Kirin battery, which boasts a system density that is 13% higher in performance, and has made a strong comeback.

When it was believed that the next generation would undoubtedly be solid-state electrolyte, SES proposed the concept of mixed liquid lithium-metal batteries, bringing the electrolyte that was going to take a “hard” route back to liquid state. Meanwhile, Weilan New Energy will supply NIO’s 360wh / kg semi-solid-state batteries, which will be mass-produced at the end of this year or next year.

Of course, whether these routes can be successful remains to be seen, as the market will have the final say. However, the 46 series of large cylindrical battery cells, semi-solid-state batteries, and mixed liquid lithium-metal batteries have not yet entered the commercialization stage.

Therefore, “Electric Vehicle Observer” only takes stock of the statements and public data of the heads of various companies.

Kirin Battles with the Three Cylinders

The 4680 once again boosted the cylindrical battery cells.

In 2020, cylindrical battery cells accounted for less than 10% of China’s power battery market, and globally, they only accounted for 23%, significantly lower than square and soft packs. With Tesla’s global sales skyrocketing, cylindrical battery cells have gradually regained some market share. After Tesla launched 4680, the large cylindrical battery cell has become even more popular.

At the 2022 One Hundred Forum annual meeting, the camp of large cylindrical battery cells represented by 4680 has significantly expanded. Panasonic, EVE Energy, and BYD are all optimistic about the prospects of large cylindrical battery cells.

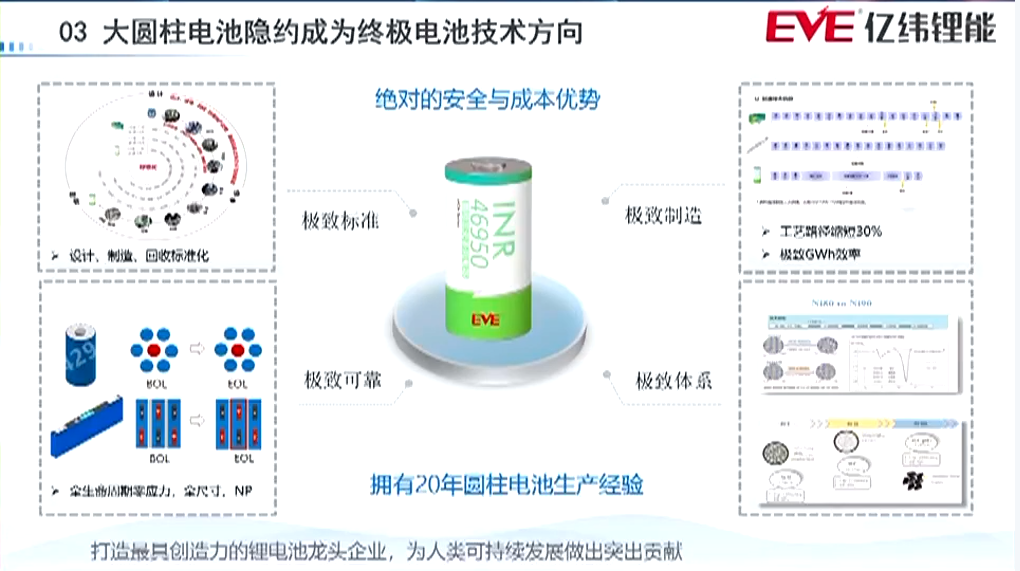

Liu Jincheng, Chairman of EVE Energy, used phrases such as “the king of the industry is just beginning to rise,” “absolute safety, economy,” and “ultimate technology direction” to support the large cylindrical battery cells and the 46 series.

Of course, talk is cheap; investments count.

EVE Energy has announced the production capacity of 200GWh for large cylindrical and square battery cells and will be built by the end of 2022.

EVE Energy can relatively balance the three packaging routes, and its heavy investment bet on cylindrical battery cells must have seen their advantages.

Liu Jincheng summarized four advantages: extreme standards, ultimate reliability, ultimate manufacturing, and ultimate system.Firstly, the design, manufacturing, and recycling of large cylindrical batteries can be standardized.

Secondly, large cylindrical batteries have stable structures and zero stress throughout their entire lifespan. Square and soft pack batteries experience internal stress and structural changes due to expansion during their lifespan. “From the beginning of battery usage to its end, square and soft pack batteries actually become different things, while cylindrical batteries remain the same.”

Cylindrical batteries can achieve ultimate manufacturing capabilities. “Its supply chain path is shortened by 30%, its production efficiency in GWh is higher, and our battery has achieved a chemistry with a nickel content of 90, using silicon-carbon. Its system should be the ultimate system in the current ternary battery system”

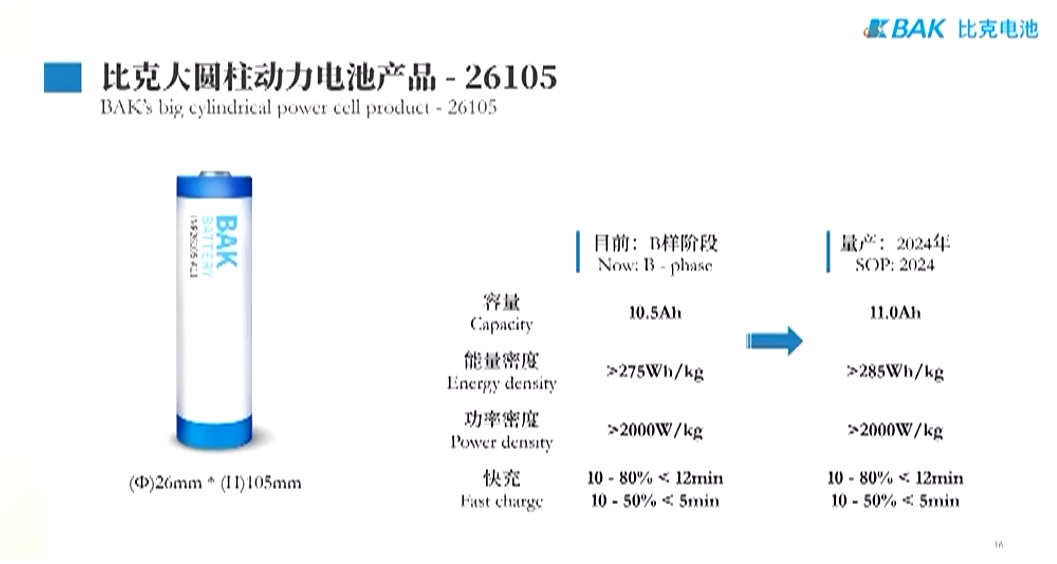

The deputy general manager of BYD Battery, Fan Wenguang, revealed data for large cylindrical batteries: The aluminum shell battery core of 26105, the energy density of B-sample stage product is 270Wh/kg, the power density is greater than 2000W/kg, and the supporting models have a range of more than 700 kilometers. It can charge more than 500 kilometers of range in 12 minutes, or more than 280 kilometers of range in 5 minutes. It can cycle more than 800 times in pure fast charge.

According to the plan, the energy density of this battery will reach 285Wh/kg when it enters mass production in 2024.

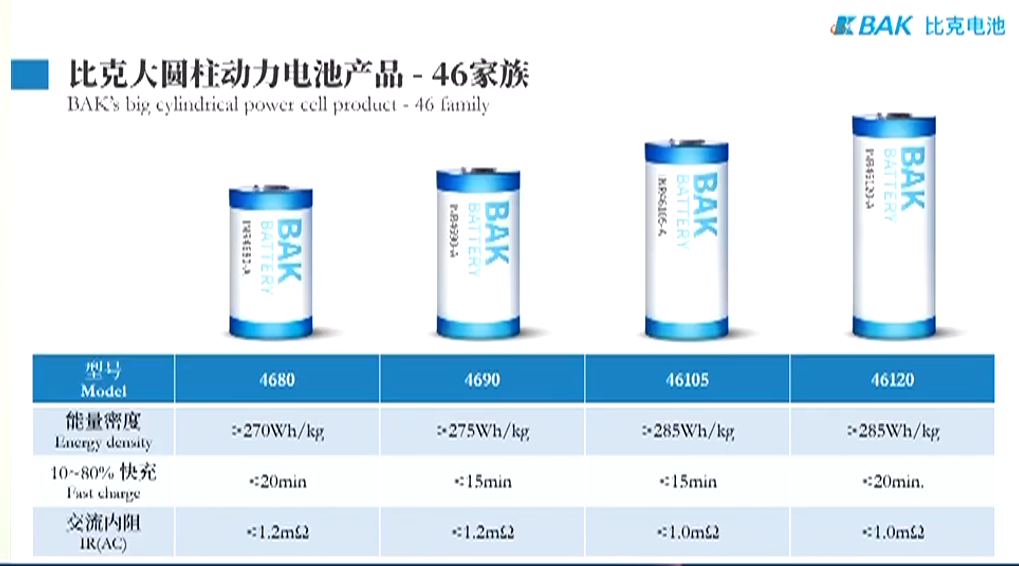

The height of the 46 series battery ranges from 80-120mm, and the energy density can reach 275-300 Wh/kg. Its 10-80% fast charging can be as fast as 15 minutes and as slow as 20 minutes. It also includes some customized products that meet special needs, such as fast charging performance that can be achieved in less than 9 minutes.

Fan Wenguang also provided demand predictions, combining received customer demand with industry information judgments. “By 2025, large cylindrical batteries will account for at least 30% of market share, or about 480 GWh, which has exceeded the total demand for the global (power battery) in 21.”

Panasonic, as a major supplier of Tesla, also predicts that the 4680 battery will become the main product for cylindrical batteries in the future.Facing the fierce attack of cylindrical batteries, CATL has also launched a new product, the Kirin battery as a counterattack.

According to Wu Kai, the chief scientist of CATL, this is a system-level battery technology, with an energy density 13% higher than the 4680 system.

According to the data released by CATL, when using phosphate iron lithium, the energy density of the Kirin battery system exceeds 160Wh/kg and 290Wh/L; when using ternary system, the energy density of the system can reach 250Wh/kg and 450Wh/L. Under the same battery chemistry system and the same battery pack size, the Kirin battery can carry 13% more power than the 4680 system.

Specific parameters may be revealed by CATL at the upcoming conference next month.

It can be seen that the battle between square and cylindrical batteries has already begun.

Blue Point Half-solid-state PK SES Lithium Metal

In terms of improving energy density and safety, the industry hopes to rely on solid-state electrolytes and position them as the next generation of batteries. However, a new startup company, SES, has introduced the concept of a hybrid liquid lithium-metal battery, announcing that it can achieve lithium metal as negative pole without requiring solid-state electrolyte, improving energy density and achieving safety.

In the view of Hu Qichao, founder and CEO of SES, in addition to energy density, manufacturability is also very important, which directly determines the feasibility of industrialization. Mature production and manufacturing processes are also an important factor affecting battery safety. If everything from materials to equipment to processes is new, it means that uncontrollable factors throughout the life cycle of battery production are greatly increased, greatly increasing the risk.

In his view, the manufacturability of solid-state batteries is seriously inadequate.

Therefore, in terms of technical direction, they chose a liquid electrolyte with high concentration solvent in salt, combined with an intelligent control software system to monitor the health of lithium metal batteries.

SES lithium metal battery technology includes three parts. The first is Hermes, a new material research and development platform. The second is Apollo, large-scale engineering and manufacturing of lithium-metal batteries for vehicles. The third is Avatar, an AI-based security monitoring software.

The small cells they produce can maintain a high energy density in a very wide temperature range (-30°C to 40°C) and a very wide discharge rate range (from 10 hours discharge to 10 minutes discharge).

In terms of fast charging, it can reach around 12 minutes to charge from 10% to 90%.

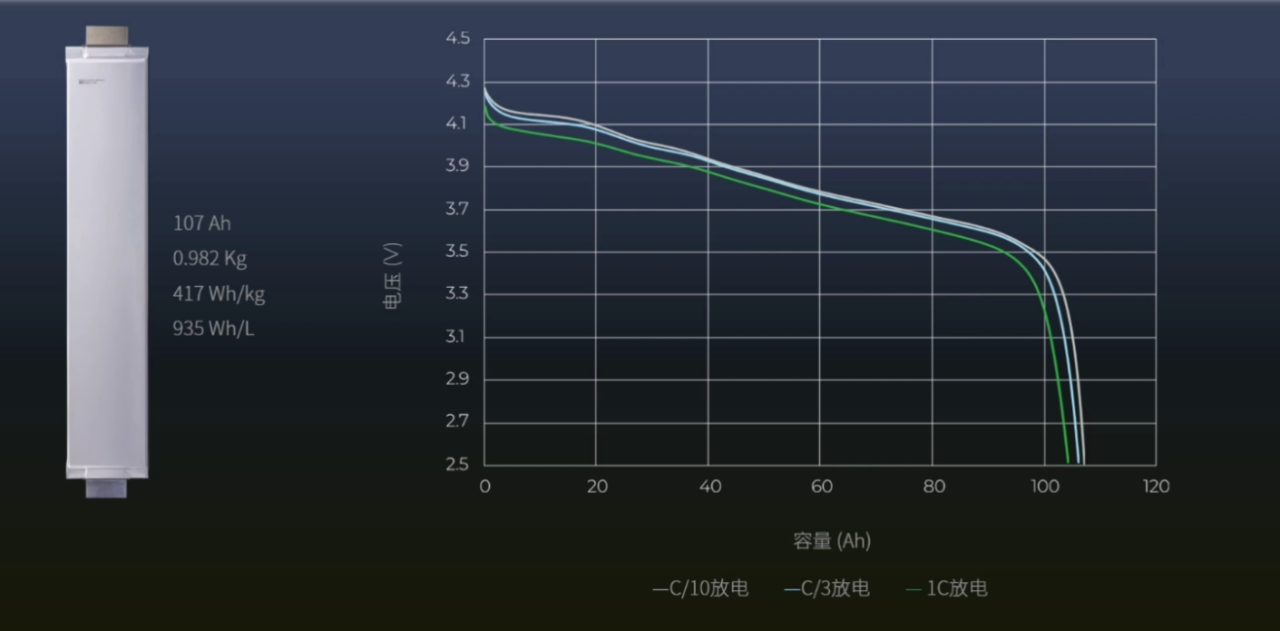

They have currently manufactured the first car-grade lithium metal battery with a capacity of 107 Ah, an energy density of 417 Wh/kg and 935 Wh/L, and a weight of less than 1 KG. This is the world’s first lithium metal battery with a capacity of over 100 Ah and the world’s largest lithium metal battery.

Currently, SES is collaborating with three automakers, General Motors, Hyundai, and Honda, to develop the A sample of lithium metal batteries for vehicles. According to the current plan, they will go into the B sample next year, the C sample the following year, start mass production in 2025, and are now steadily pushing forward.

At present, the semi-solid state is leading the mixed liquid lithium metal battery.

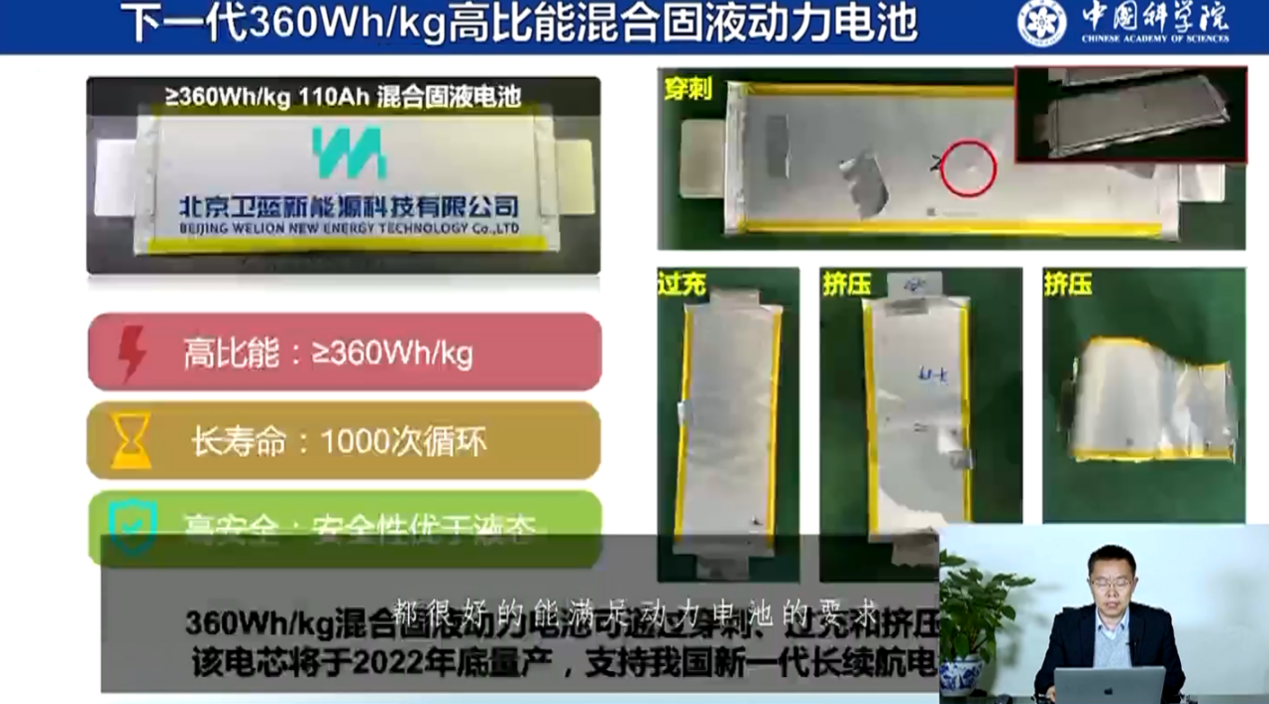

Li Hong, a researcher at the Institute of Physics of the Chinese Academy of Sciences, said that Wiboolun’s semi-solid state battery will enter mass production for NIO ET7 at the end of this year or early next year, with a single charge of 1000 kilometers, a battery pack capacity of 150 degrees, and a single cell energy density of 360 Wh/kg.

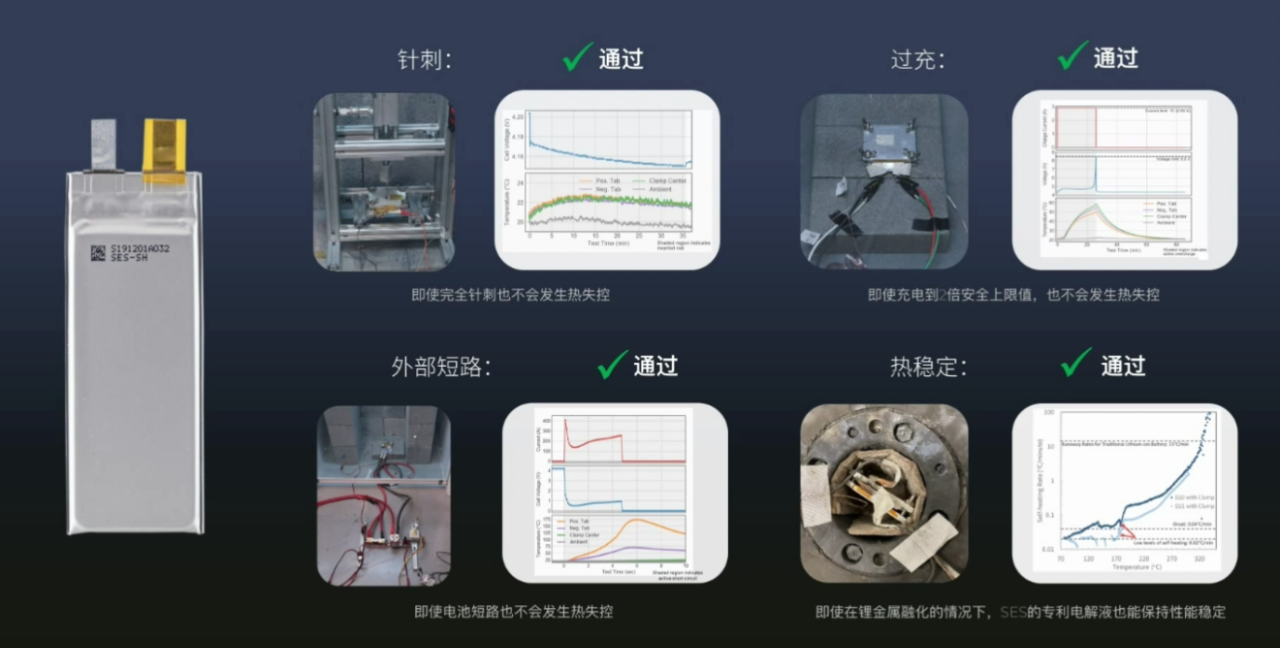

This battery can also pass safety tests such as puncture, overcharge, and crush, meeting the requirements of electric vehicles.

When tackling the problem of solid electrolytes, Wiboolun new energy chose the technology of in-situ solidification, which converts part or all of the liquid electrolyte into solid electrolyte through chemical and electrochemical reactions. If all of it is converted into a solid electrolyte, it is a fully solid-state battery, which is a new research path for making fully solid-state batteries.

Li Hong said that with this solution, they can be compatible with various positive and negative electrode materials that are currently available, as well as the battery materials of most lithium-ion batteries. They can solve the problem of maintaining good contact between the solid electrolyte and the positive and negative electrode materials during the cycling process, and can comprehensively balance the requirements of high-voltage charging, safety, lithium dendrite precipitation, and volume expansion control.

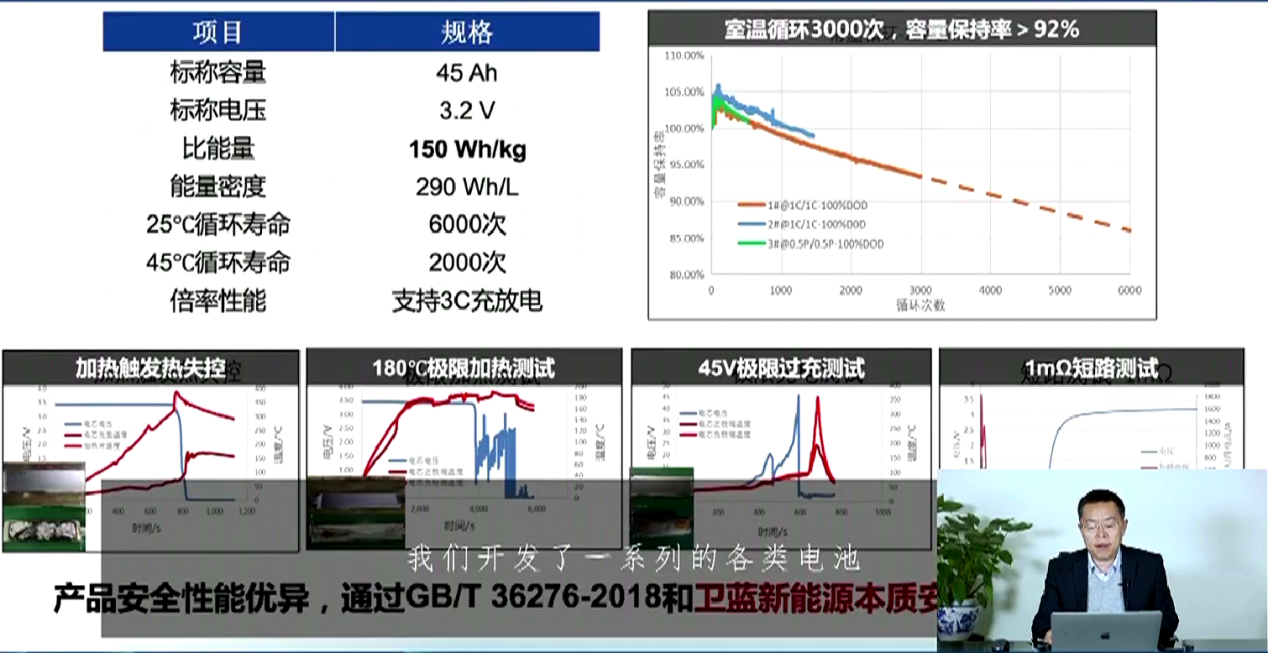

Based on these solutions, they have developed a series of batteries, including a 150 Wh/kg inherently safe solid-liquid mixed energy storage battery for large-scale energy storage. These battery cells can all pass national safety tests and perform significantly better than national standards, including higher thermal runaway temperature limits, higher maximum overcharge limits, and passing short-circuit and puncture tests.

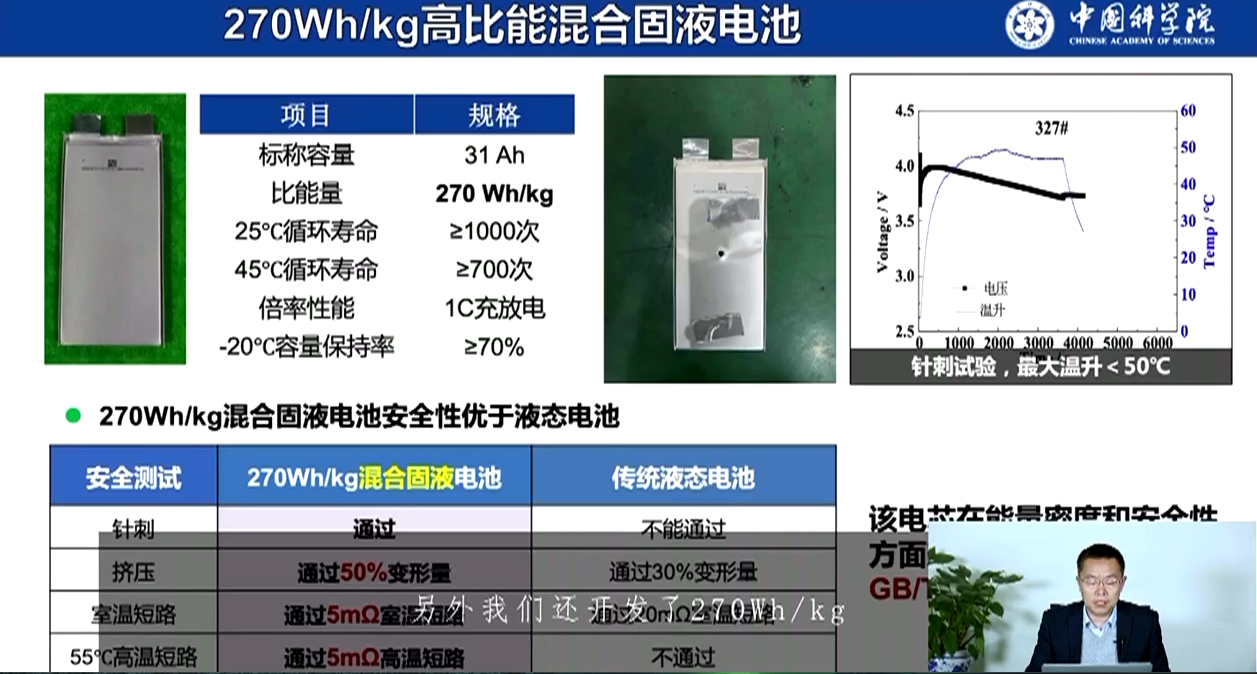

They also developed a high specific energy mixed solid-liquid battery for drones, with a specific energy of 270 Wh/kg, which currently has significant advantages in balancing energy density and safety, and has passed safety test national standards.

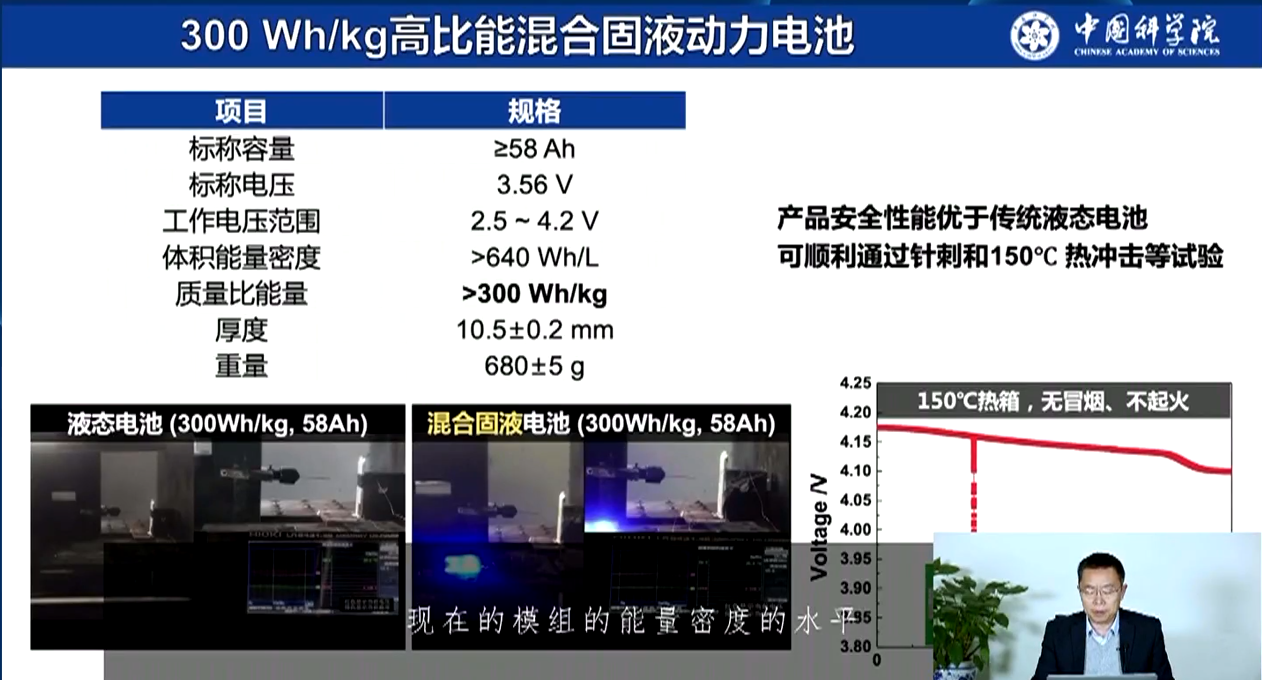

Moreover, WELANK New Energy has developed a mixed solid-liquid power battery with a specific energy of 300 Wh/kg. The battery can be fully puncture tested and can also pass the 150-degree heat box test at full charge. Its low-temperature performance and rate characteristics can fully meet the requirements of power batteries.

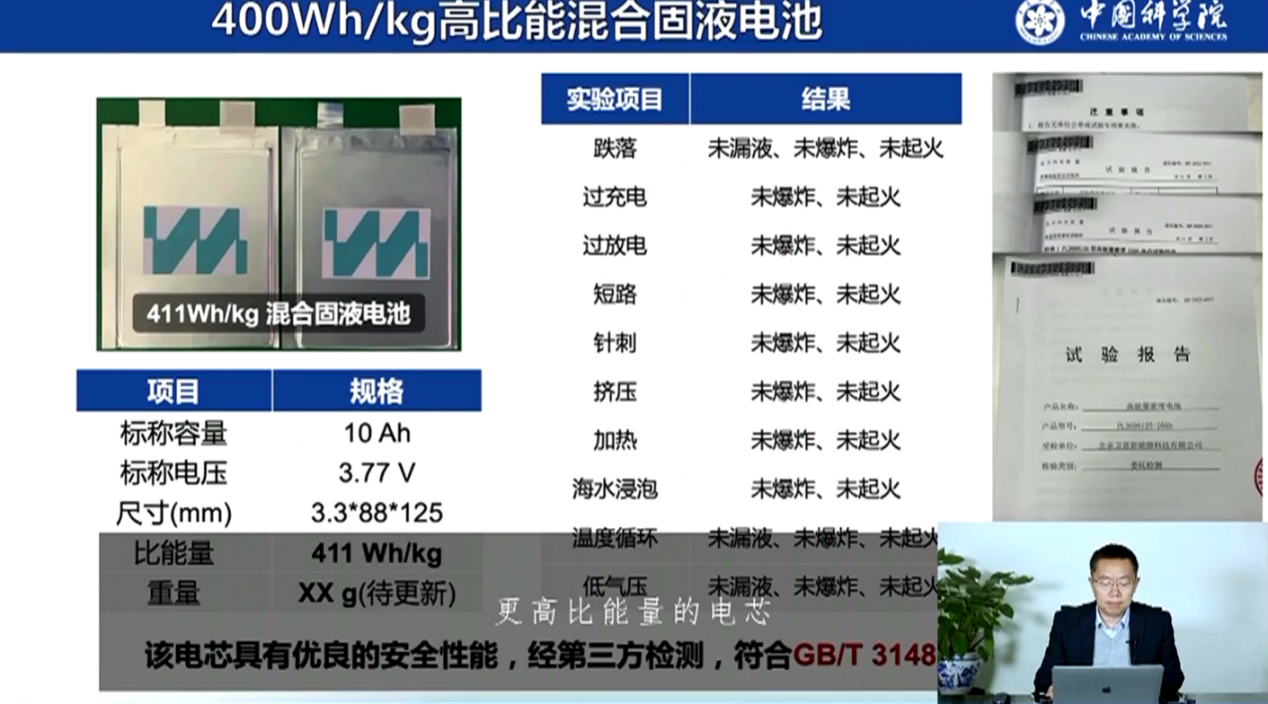

They have further developed a mixed solid-liquid battery with a specific energy of 400 Wh/kg and have developed an innovative comprehensive solution for battery cells and modules that can pass the shooting test, which is the first achievement at the module level.

Although these batteries are not yet in mass production, these data are still very encouraging. It is always amazing that these technologies can have new breakthroughs and regain vitality whenever we think that the existing technology has reached its theoretical or critical point.

Of course, there is still a long way to go from technological breakthroughs to commercial applications, and we look forward to more breakthrough technologies coming to the forefront.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.