Author: Chang Yan

For our General Manager who has had the honor of owning the first Mercedes-Benz EQS in Asia for some time now, there is a “bad news” and a good news.

The “bad news” is that the EQS, which cost him a seven-digit RMB price tag, will soon no longer be the most expensive electric car series of Mercedes-Benz.

The good news is that he will soon have the opportunity to enjoy the honor of being the first to own the latest one again.

- As long as he is willing to spend another seven-digit RMB price tag.

Recently, Mercedes-Benz announced its next key move in electrification: Mercedes-Benz will combine its latest EQ technology with the most popular SUV models in major markets such as China and the United States, and launch two new high-end models, the EQS SUV and EQE SUV.

The flagship EQS SUV will be unveiled globally on April 19, 2022, and another EQE SUV will have its global premiere later this year after the completion of engineering tests.

The production plans for both cars are also underway, with the EQS SUV officially starting production in June 2023 and the EQE SUV entering the market in October.

Like previous luxury SUVs, the two new cars will be produced at Mercedes-Benz’s Tuscaloosa, Alabama factory, and Mercedes-Benz also announced that it will build a new battery assembly plant in Bibb County, Alabama, about 10 kilometers from the factory, to provide battery packs for these two heavy-duty models with representative new technologies.

At this point, a familiar and somewhat unexpected name emerged.

Mercedes-Benz announced that this battery plant will be powered by Farasis Energy, a battery technology company under the Farasis Technology Group, and Farasis’ expertise in new energy and zero-carbon solutions will also help the entire plant achieve its carbon neutrality goals.

Familiarity comes from the fact that we have had many encounters with various products from Vision Group on various occasions.

For example, the Mochi automatic charging robot launched by Vision Group earlier makes charging no longer “finding a station” but “finding a person”, which is an exploration by Vision Group in promoting the low-carbonization of the entire automobile lifecycle. Interested friends can click on the video below to review our previous programs.

The unfamiliarity is because this is the first time that Vision Group has appeared on the EQ model’s battery supply chain list.

I asked CEO An, what do Mercedes-Benz EV owners value the most?

Safety is my first answer received, of course, regardless of the vehicle’s value, positioning, or size, safety is always the primary need of electric vehicle users. But the result of safety often requires a large amount of past experience and data as supporting evidence.

As a top-player in the automotive industry, Mercedes-Benz’s pursuit of safety is beyond doubt. For example, the module project has about more than two thousand product-related requirements. When facing the core components of a pure electric vehicle like the power battery pack, Mercedes-Benz has more strict indicators and audit processes.

Specifically, for the battery pack project, it becomes more than four thousand review clauses.

Vision Group has always been recognized for its expertise in chemical and engineering research and development of battery safety, as well as its emphasis on safety reputation in the industry.

Similarly, we still cite facts as examples to speak.

As a supplier to Nissan, Vision Group has been providing power batteries for the Nissan Leaf. So far, hundreds of thousands of Nissan Leafs have had no serious battery accidents in the past twelve years, and the number of Nissan Leafs owned and operated mileage continues to increase every day.

“Hundreds of thousands of vehicles,” “12 years,” “daily increase” – these keywords are the best proof of Vision Group’s safety strength.In this cooperation, Farasis Power has undergone a comprehensive and thorough review and testing by the headquarters of Mercedes-Benz in product design, software and hardware production, risk control, change management, and product verification.

What I care about more is performance.

Unexpectedly, the EQ series of Mercedes-Benz may not be a brand that pursues extreme performance in traditional automotive sports, but its pursuit of the ultimate balance of broad performance is above other brands, such as the EQS, which is currently registered with the MIIT, having the longest endurance capacity under the NEDC standard in China. Similarly, the EQS AMG model also has the ability to enter the 3-second club in zero-to-one-hundred acceleration. For both of these, there are extremely high demands on the peak discharge performance and long-term stability of the battery.

For example, the EQXX concept car unveiled at CES 2022 has extremely high settings in terms of wind resistance coefficient and thermal management system, and can even achieve 1000km of WLTP standard endurance capacity with a 100kWh battery pack capacity, which also set a new standard for the energy density and high temperature stability of the power battery.

I believe that for EQS SUV and EQE SUV, which represent the luxury, high-end, and high-performance product series in the Mercedes-Benz family, Mercedes-Benz will definitely demand even higher battery performance standards from them. This indirectly serves as an evaluation and certification of the battery performance provided by Farasis Power.

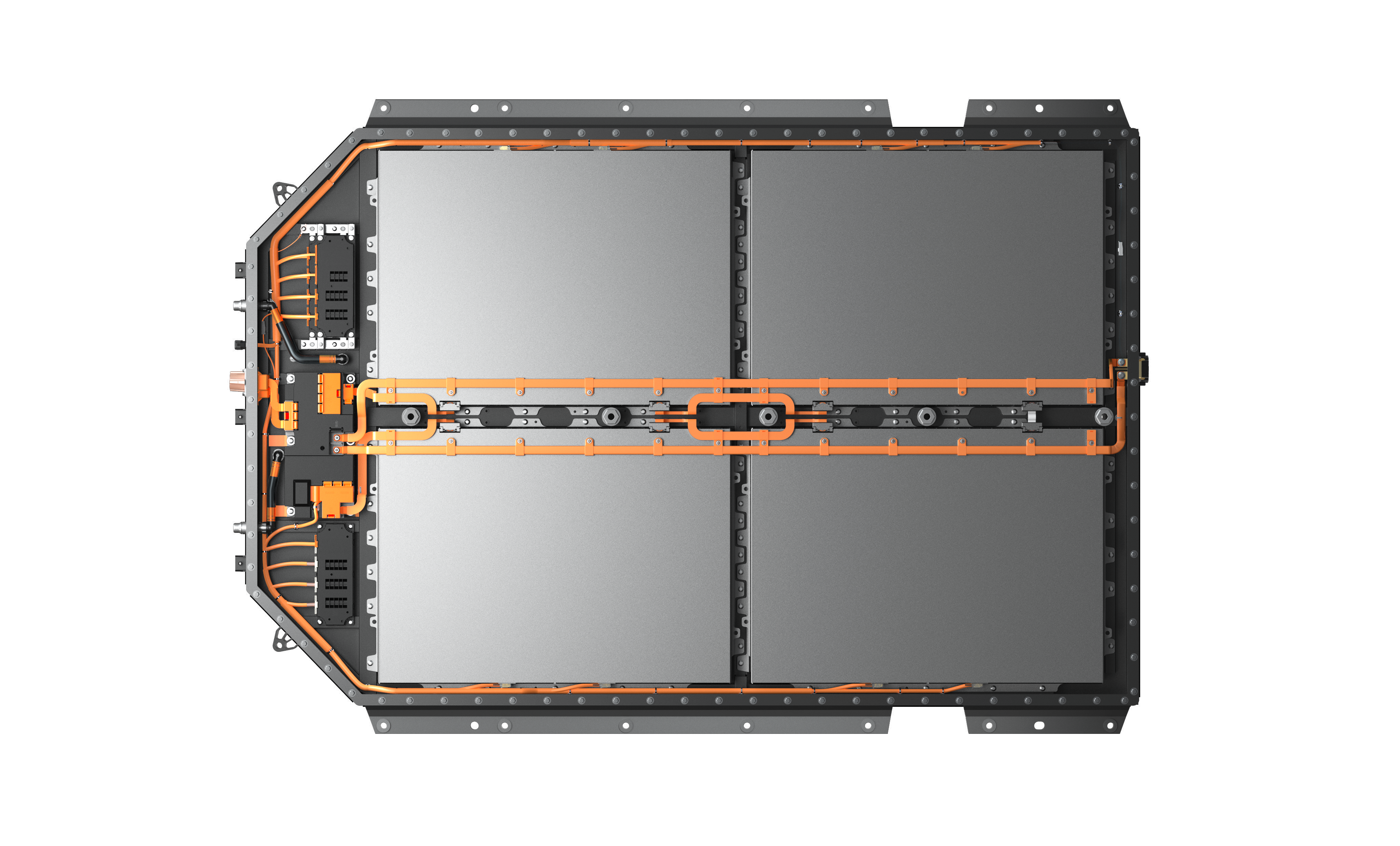

Facing the performance test, Farasis Power is also not intimidated. According to industry news, “stacked square shell” technology has been adopted by Farasis Power in this cooperation. Battery products using square shell technology have also exhibited better performance in key performance indicators such as endurance and safety compared to rival products.

And I believe that the international background of Farasis Power, as well as its systematic capability at the group level, are the key to completely pulling away from the competition in this competition.

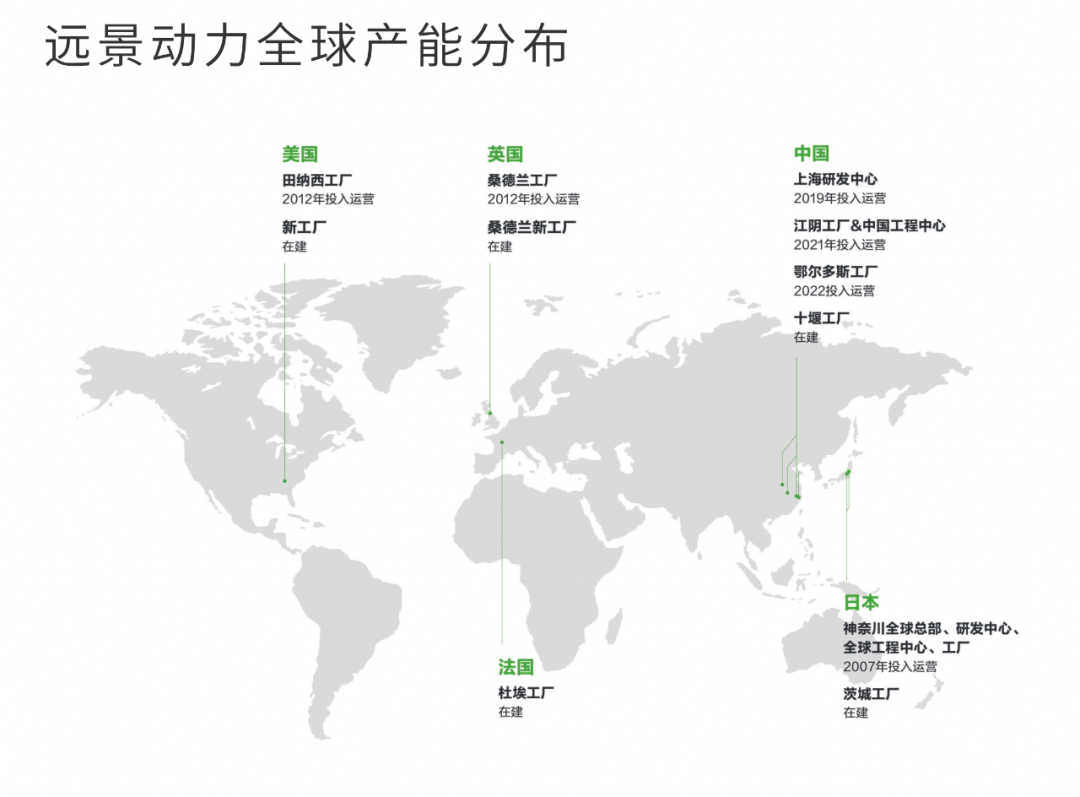

Thanks to the original vehicle layout, YF-CDV (Yuanfeng Clean Energy) has been an enterprise with distinctive internationalization and production capacity layout from the very beginning. As YF-CDV has already cooperated with Renault in France, Nissan in the UK, and four major mainstream car companies including Honda in Japan, YF-CDV has completed the global production capacity layout across Asia, Europe, and America, and has also possessed the capability reserve of directly building and producing in the United States and carrying out mass production.

Thanks to the original vehicle layout, YF-CDV (Yuanfeng Clean Energy) has been an enterprise with distinctive internationalization and production capacity layout from the very beginning. As YF-CDV has already cooperated with Renault in France, Nissan in the UK, and four major mainstream car companies including Honda in Japan, YF-CDV has completed the global production capacity layout across Asia, Europe, and America, and has also possessed the capability reserve of directly building and producing in the United States and carrying out mass production.

It is understood that in the course of this project, Mercedes-Benz’s headquarters in Germany has conducted an all-round risk assessment of YF-CDV’s global operations, involving business operations and other aspects, and even introduced third-party independent assessments. One little story is that the cooperation between YF-CDV and Mercedes-Benz is a project of overseas production base supply, so the assessment is conducted simultaneously in China and the United States. Due to the time difference, YF-CDV’s core team usually meets the audit in China during the day and continues the audit in the United States in the middle of the night.

This includes the assessment of corporate social responsibility, carbon emissions, and other aspects. Based on Mercedes-Benz’s carbon-neutral vision, the entire battery factory and even the electric vehicle production factory need to make changes in energy layout and supply chain energy consumption management. YF-CDV’s management and overall solution in the entire renewable energy industry chain are also sufficient to be Mercedes-Benz’s “zero-carbon technology partner”. Markus Schäfer, Member of the Board of Management of Mercedes-Benz AG & Group Research and Mercedes-Benz Cars Development, said, “YF-CDV will be our main battery supplier, ensuring the production capacity of Mercedes-Benz EQ series in the United States for the next few years. YF-CDV’s leading zero-carbon solution and power battery technology not only ensure the sustainability and safety of our battery supply chain, but also allow us to provide our customers with the most outstanding power battery technology.”

Conversely, this thinking also has great significance for the development of YF-CDV. In terms of scale, Mercedes-Benz has proposed a production plan of at least 6,000 vehicles per year, and will further increase production capacity with the change of sales, as the battery pack capacity and specifications of EQS SUV and EQE SUV are large and high, which is of great help for YF-CDV to expand its scale and enhance its competitive advantage in this segment market.To achieve the goal of full electrification by the end of this century, Mercedes-Benz and its partners plan to establish eight battery factories worldwide, with a production capacity of 200 GWh by 2030.

Zhang Lei, CEO of Farasis Energy and executive chairman of Farasis Group, commented: “We are delighted that Mercedes-Benz has chosen Farasis as a strategic partner. As a global zero-carbon technology partner, we will accelerate green technology innovation to address the climate crisis challenges facing humanity.”

As of the announcement of the new factory in the United States, Farasis Energy has already established 10 production bases in China, Japan, the United States, the United Kingdom, and France, and its total production capacity of zero-carbon batteries will exceed 300 GWh by 2025.

Undoubtedly, this cooperation will bring tremendous benefits to both parties’ economies of scale, and Farasis Energy is expected to leverage more brand collaborations in the foreseeable future.

Finally, let’s remind An Zong (CEO of the company) that the new battery is coming, and are we preparing to buy a new car again?

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.