Tesla Berlin Factory Officially Opens After 8-Month Delay

On March 22 at 3 PM local time, Elon Musk delivered 30 Model Y cars made in Germany to the first batch of owners at the Tesla Berlin factory. German Chancellor Olaf Scholz and Economy Minister Robert Habeck also attended the delivery ceremony to support Musk. On that day, Tesla’s stock price increased by 7.6%.

Everything seems to be thriving, and many people believe that the Tesla Berlin factory has penetrated into the heart of Europe, leaving no chance for Volkswagen, BMW, and Mercedes-Benz to compete. They predict that the streets of Europe will be full of Tesla cars.

However, I have to throw a little cold water on the Tesla Berlin factory. Despite being mythically hyped as “Made in Germany”, the production capacity of the Tesla Berlin factory and Tesla’s future competitiveness in Europe are significantly overvalued.

Labor Shortages, Water Shortages, Supply Chain Shortages Lead to Grim Production Capacity

For a factory, its lifeline is naturally effective production capacity. The Tesla Berlin factory’s general publicized production capacity is 500,000 vehicles per year, but experts are aware that this is the production capacity under full load. There will be a “production capacity climb” phase in the middle.

Currently, the production capacity climb rate of the Tesla Berlin factory is not fast, as predicted by Morgan Stanley: it can produce 54,000 new cars in 2022 and 280,000 in 2023. It will take until 2025 to climb to annual production capacity of 500,000 vehicles.

There are many reasons behind this, the first being labor shortages.

_20220324171452.png)

Currently, according to IG Metall, Germany’s largest labor union, the Tesla Berlin factory has only over 3,000 official employees, while the Berlin factory and battery factory plan to hire 12,000 people. Due to the low unemployment rate in Germany, the labor force in the factory’s region is severely lacking. Tesla has even included relevant train routes to attract people to apply for jobs, but the effect is not significant.

Moreover, Germany has a robust employee protection policy, and the labor union’s strength is very powerful. Although German workers are rigorous, when it is time to get off work or take a vacation, “007” or “996” schedules are impossible. Even if Musk sleeps in the factory, it’s not helpful. (Note: In 2018, when Tesla encountered a production capacity crisis, Musk slept in the Fremont factory in California several times).

In addition to labor shortages, the haze of environmental problems has not dissipated.“`

At the opening ceremony of the Tesla Berlin factory, there were also some uninvited guests- environmentalists, who have “never left” since Tesla decided to build the factory.

Earlier, local environmental organizations complained to the environmental department, accusing Tesla of “stealing” local drinking water. Eventually, Tesla agreed to reduce the amount of water used by the factory by more than one-third. Finally, on March 4th, the local government approved the production of Tesla.

This is just the tip of the iceberg of the environmental organization’s actions. Originally, the two sides “pulled” for three months on the issue of “tree felling” in the factory site area. In the end, Tesla had to plant three times the number of trees cut before passing. Later, various problems such as noise pollution, light pollution, the impact on ant movements in soil, and the hibernation of bats and snakes in the forest kept emerging, and no one knows what else will happen in the future.

The water problem in front of Tesla has not been resolved yet. Next year, Tesla plans to build a 50GWh battery factory here, so the water issue needs to be re-negotiated, and local water resources have become very scarce.

In addition to labor shortage and environmental pressure, the supply chain of the Berlin factory is also a major problem.

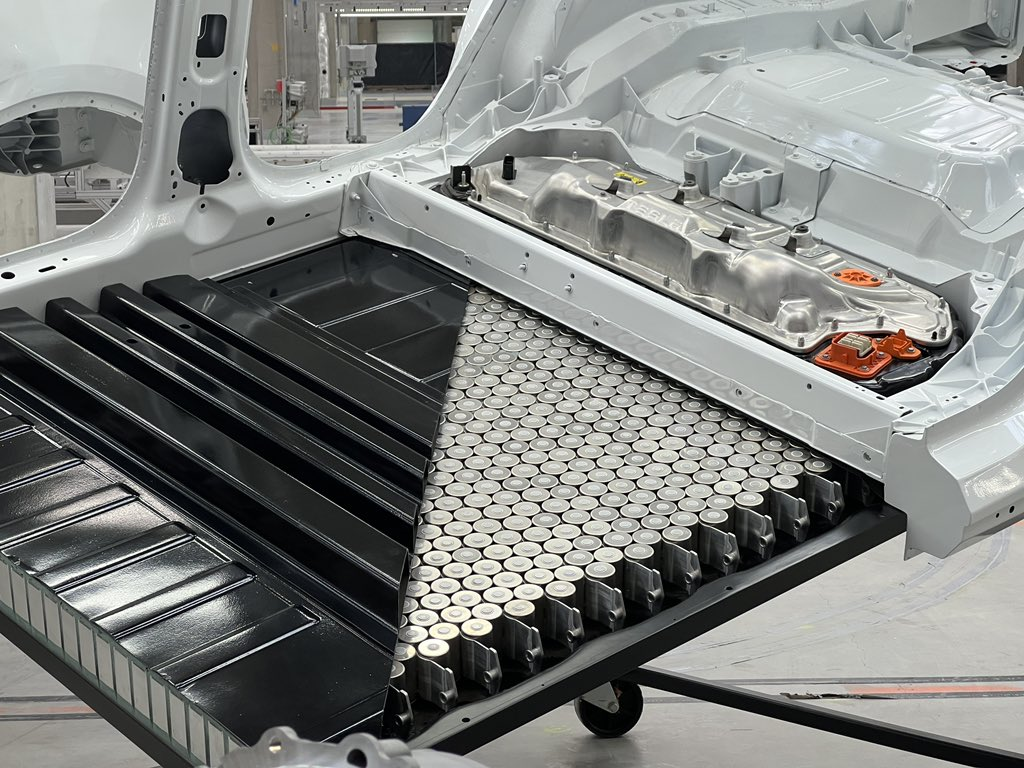

Currently, the Model Y produced by the Berlin factory is equipped with 2170 lithium-ion batteries imported from China, and some other key components also rely on exports from China. For the time being, the Berlin factory can be regarded as a CKD assembly plant of the Shanghai factory.

In the future, for Tesla Berlin factory to achieve mass production, it is necessary to seek cooperation with European local supply chains. Although the European automobile industry is very strong and has many “hidden champions”, in the new energy industry chain, China is more comprehensive, flexible, and even has lower costs. Currently, the domestic production rate of Tesla’s Shanghai factory supply chain has exceeded 90\%, and it will reach 100\% in the future.

Does Tesla really not worry about selling German-made cars?

“`# Tesla Shines in Europe in 2021

JATO Dynamics data shows that Tesla sold 168,000 new cars in Europe in 2021, with its main model, the Model 3, selling 141,400 units, becoming the best-selling electric car in Europe in 2021.

However, European competitors are not sitting idly by, but accelerating their counterattacks. In 2019, there were only 33 different pure electric vehicles in the European market, a year later, this number increased to 57, and in 2021, the number increased to 74. There will also be a surge in 2022.

Volkswagen plans to achieve a sales ratio of pure electric vehicle models of over 70% in the European market by 2030; Stellantis, which was formed by the merger of Fiat-Chrysler and PSA Group, is even more aggressive, planning to achieve annual sales of 5 million pure electric vehicles by 2030, all of which will be passenger cars sold in the European market; BMW plans to expand its lineup of pure electric vehicles to 15 by 2022 and achieve annual sales of 1.5 million electric vehicles by 2030.

Moreover, the counterattack from Europe is no longer just those backward “oil-to-electricity” products. Electric cars born on pure electric platforms, represented by the Volkswagen ID series, are gradually becoming the main characters. For example, the Volkswagen ID.4, which was launched in Germany in 2021, is not inferior to Tesla in terms of popularity. The waiting time is currently 10 to 12 months due to chip shortage.

After the production capacity of Tesla’s Berlin factory reaches 500,000 vehicles, in order to maintain the current “no worries about sales” status, the cost performance of the product still needs to be highlighted. In the past few years, Tesla’s dominance in the Chinese market has relied on “price reductions”. The price of the domestic Model 3 standard range version was 328,000 yuan in 2019, and the lowest price dropped to 235,900 yuan on July 30, 2021. Every time the price is reduced, a large number of orders can be obtained. In addition, nearly half of the production capacity is shipped to Europe, so Tesla can basically maintain a supply shortage in China.

After the production capacity of Tesla’s Berlin factory reaches 500,000 vehicles, in order to maintain the current “no worries about sales” status, the cost performance of the product still needs to be highlighted. In the past few years, Tesla’s dominance in the Chinese market has relied on “price reductions”. The price of the domestic Model 3 standard range version was 328,000 yuan in 2019, and the lowest price dropped to 235,900 yuan on July 30, 2021. Every time the price is reduced, a large number of orders can be obtained. In addition, nearly half of the production capacity is shipped to Europe, so Tesla can basically maintain a supply shortage in China.

As mentioned above, Tesla’s Berlin factory does not have any cost advantages. The costs of labor, energy, and supply chain in Germany are significantly higher than those in China. The investment of 5.5 billion euros in the Berlin factory is twice that of Shanghai, China, even if 10\% of the tariffs and transportation costs are waived, the German-produced Tesla does not have much room for price cuts.

At the same time, the development of electric vehicles in Europe is extremely dependent on subsidies. Taking Germany as an example, pure electric vehicles that cost no more than 40,000 euros can enjoy a subsidy of 9,000 euros, accounting for more than one-quarter of the car price, similar to the Chinese market 3-4 years ago.

Similar to the development path of China’s new energy, government subsidies will gradually decline. The subsidy amount for high-priced electric vehicles like Tesla will only decrease. For example, in 2021, the British government decided to reduce the subsidy threshold from 50,000 pounds to 35,000 pounds. Tesla’s starting price in the UK is 43,500 pounds, and it cannot continue to enjoy subsidies, while its old rival Volkswagen ID.3 has a starting price of 31,700 pounds and can still enjoy a subsidy of 2,000 pounds.

At the same time, “Made in Germany” does not mean that it can travel unimpeded in Europe. If we look at the overall volume of the European automobile market, we will conclude that “Europeans like to buy European cars”. However, if we only look at specific countries, we will find that Germans drive Volkswagen, French people buy Peugeot Citroen, Italians buy Fiat, and British people buy Ford (most of the local British brands have been sold, and Ford has factories in the UK). People generally only buy their own country’s cars.

This involves the support for the local industry, but more importantly, the guidance and support from the government. For example, buying a Ford car in the UK may entitle the government to provide an additional subsidy of one or two thousand pounds. This is not difficult to understand. For instance, in 2021, if you buy a BYD Han EV in Shenzhen, you can get an additional discount of RMB 20,000. BYD’s new energy vehicles can be seen everywhere in Shenzhen.

This involves the support for the local industry, but more importantly, the guidance and support from the government. For example, buying a Ford car in the UK may entitle the government to provide an additional subsidy of one or two thousand pounds. This is not difficult to understand. For instance, in 2021, if you buy a BYD Han EV in Shenzhen, you can get an additional discount of RMB 20,000. BYD’s new energy vehicles can be seen everywhere in Shenzhen.

Therefore, German-made Tesla does not necessarily mean “European Tesla”. As various countries’ domestic automobile brands power up new energy, each country will have a certain degree of “local protection”.

This is why Volkswagen and PSA have acquired so many brands. The Volkswagen brand can sell in Germany, but in other areas such as the Czech Republic and Slovakia, the “Skoda” face is more marketable. In Spain, it is better to hang the “Seat” logo, even if most of the time these cars are “rebadged cars”, but “national conditions are here” anyway.

Therefore, building a factory in Germany does not mean that Tesla can sell completely in Europe. It still needs to win through more advanced battery technology, production processes, and intelligent experiences such as 4680 batteries, CTC, and integrated casting. However, all of these have some uncertainty. According to the progress of Tesla’s German battery factory, the 4680 battery will take at least until after 2024 to be installed.

In any case, if Tesla wants to maintain its dominant position in Europe, building a factory in Berlin is far from enough. The competition in the European market will still be very exciting.

The “Shanghai Model” cannot be replicated

Although Musk stated that Tesla’s Berlin factory has “important strategic significance”, compared with the achievement of Tesla’s helping hand at the Shanghai factory, the Berlin factory can only be considered as a bonus.

2018 was one of the most dangerous moments for Tesla, despite the release of their groundbreaking Model 3 product, they were stuck in “production hell”, leading to CEO Elon Musk sleeping in the factory in California several times.

2018 was one of the most dangerous moments for Tesla, despite the release of their groundbreaking Model 3 product, they were stuck in “production hell”, leading to CEO Elon Musk sleeping in the factory in California several times.

Not being able to deliver cars meant there was no positive cash flow, resulting in continuous “bleeding” for Tesla. Their financial reports showed that they lost 785 million US dollars in the first quarter of 2018. If this burning rate continued, Tesla’s cash flow would have been depleted by the end of that year.

The capital markets also gave Tesla a “knife” as credit rating agency Moody’s rated them as “junk” levels, and JPMorgan Chase gave a “reduce” recommendation for their stocks. With no hope of further financing from the capital market, Tesla had no choice but to improve their production capacity quickly to survive, which was a race against time for them. Perhaps every new carmaker has gone through this stage. Luckily, Tesla found the answer in China.

On October 17, 2018, Tesla signed a land transfer contract with the Shanghai government, granting them a low-interest loan of 18.5 billion and land that was only one-tenth of the market price! In January 2019, the Tesla Shanghai Super Factory (Gigafactory) began construction, and on October 15 of that same year, the factory entered the commissioning phase. As a result, the first batch of Tesla-made Model 3 cars was delivered on December 30th of that year.

From groundbreaking to delivery, it took less than a year. In just two years, it has become Tesla’s most important production base. In 2021, Tesla delivered 482,000 new vehicles globally, with 536,000 deliveries for the entire year. Over half were produced in the Shanghai factory, and there are reports that suggest the Shanghai factory’s production capacity could expand to 700,000 units per year this year.

However, Tesla’s Berlin factory is lagging behind in terms of “Shanghai speed” and “Shanghai efficiency”. Tesla announced its plans to build a Berlin plant in November 2019, but it took them more than 30 months to begin delivery, which was more than eight months later than their initial estimate. This means that we should not judge Berlin based solely on our impression of the Shanghai factory, and our expectations of Tesla’s Berlin factory should not be compared to their Shanghai factory.

In fact, the “Shanghai model” cannot be copied. Tesla was considering whether to build a factory in India a while ago, trying to seize the market with the largest population in the world. As a result, Tesla sensibly gave up.

In the end, for Tesla’s grand goal of “selling 20 million cars per year by 2030”, I can only suggest “building more factories in China”.

Finally, welcome everyone to download the Garage App to learn about the latest new energy information. If you want to get more immediate communication, you can click here to join our community.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.