Author: Mu Min

With the rise of autonomous driving, visual cameras, millimeter-wave radar, and LiDAR are all rapidly evolving.

As for LiDAR, there are gradually three main mainstream routes, namely: mechanical rotating LiDAR, hybrid solid-state LiDAR and solid-state LiDAR.

Mechanical rotating LiDAR was the earliest to appear and is commonly found in early autonomous driving test vehicles such as Waymo, Baidu Apollo, and Pony.ai.

Solid-state LiDAR has just entered the early stage of mass production in front-loading and has begun to be betted on by major OEMs such as SAIC.

Hybrid solid-state LiDAR is the most worthy of mention, and is more competitive in terms of performance, meeting regulations, safety and mass production. Therefore, the world’s first mass-produced LiDAR car, XPeng P5, and later GeometryAuto Alpha S HI version, Fevan R7, NIO ET7, Ideal L9, and Salon Mechadragon, etc. have appeared in this technology route.

Although these models have different positioning and prices, and the LiDAR products they carry have their own considerations, it does not prevent us from roughly comparing the LiDAR technology strength of each company from the performance dimension.

- From the two indicators of ranging and angular resolution, both NIO ET7 and Fevan R7 LiDARs are tied for first place.

- In terms of mass production time, XPeng P5 is the earliest, NIO ET7 is in second place, and most other LiDAR mass-produced cars such as Fevan R7 will be delivered in the next two years.

With the official delivery of NIO ET7 in 2022, the year of mass-produced LiDAR pre-installed in cars has officially begun.

Next, let’s start with NIO ET7 to glimpse how LiDAR is internalized in the market.

What is image-level LiDAR?

Before understanding the LiDAR of NIO ET7, let’s take a look at the technical principle.

The technical principle of LiDAR is that a ultra-short laser pulse is emitted by a laser emitter, which is projected onto the target object. The laser is diffusely reflected, and the diffuse reflection light is received by the laser receiver. By measuring the flight time of the laser beam in the air, the distance from the target object to the sensor can be calculated.

In the process of the automotive industry’s evolution towards advanced autonomous driving, accurate perception of the surrounding complex road environment is constantly needed. Visual cameras and millimeter-wave radars have their hardware limitations, such as difficulty in reliable recognition for high light ratio, dark light, static obstacles, etc. LiDAR, on the other hand, is less affected by these factors and has become the “darling” of autonomous driving perception hardware.By collecting reflected light pulses and reconstructing three-dimensional spatial data, lidars can not only identify vehicles ahead, but also effectively identify target objects such as road surface protrusions, missing manhole covers, debris, and large stationary obstacles, which are difficult for current cameras to achieve.

Currently, there are various routes for lidars, but there are three main types: mechanically rotating, hybrid solid-state, and solid-state lidars.

Objectively speaking, each route has its own advantages and disadvantages. However, when it comes to mass production of autonomous driving, hybrid solid-state lidars are the most suitable.

Because the architecture of mechanically rotating lidars is difficult to apply to mass-produced cars with strict cost requirements, hybrid solid-state lidars are the best choice for autonomous driving. Solid-state lidars have a lot of room for improvement due to their inability to achieve the required performance of AD, i.e. long distance and high resolution.

The hybrid solid-state lidar has a fixed emitter receiver and a fixed light source and detector, which scans the space through a rotating or vibrating mirror. Its advantages are that the aperture of the collected light path is larger and it is easier to achieve further detection distance, and also has high resolution. Moreover, the upstream industrial chain is relatively mature, such as motors, reflectors, lenses, etc., making it suitable for large-scale production in the current stage.

Therefore, considering comprehensive performance, safety, and mass production factors, the development of hybrid solid-state lidars is the fastest, and it has become a product carried by many new cars.

The lidar carried by NIO ET7 is a hybrid solid-state lidar provided by Innovusion.

This lidar is combined with 32 high-performance sensing hardware, including:

- 7 8-megapixel high-definition cameras;

- 4 3-megapixel high-sensitivity panoramic cameras;

- 5 millimeter-wave radars;

- 12 ultrasonic radars;

- 2 high-precision positioning units;

- 1 V2X and 1 enhanced driver monitoring.

They together form NIO’s super sensing system, Aquila.

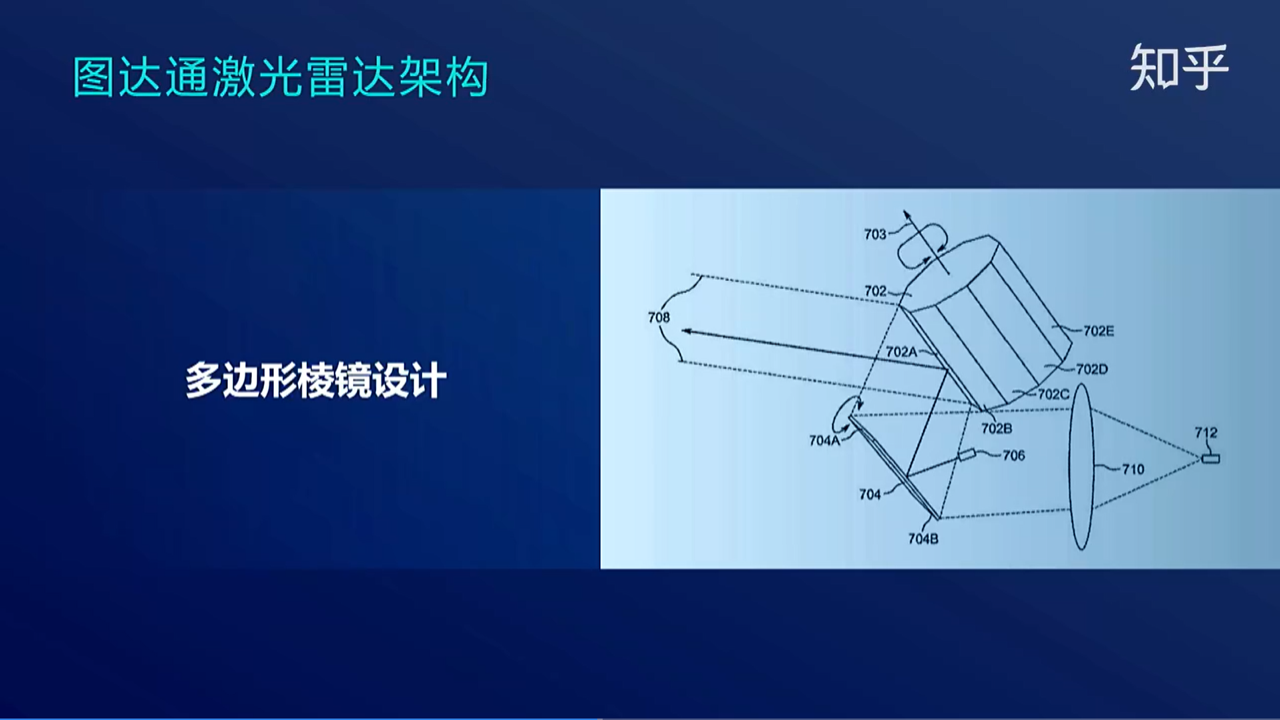

Furthermore, NIO ET7’s lidar adopts a polygon prism design, and its patent diagram is shown below:

Let’s take a look at some of the characteristics of this LIDAR without getting into complex explanations. NIO refers to the ET7’s LIDAR as an “image-level LIDAR,” which means that this LIDAR generates high-definition “point cloud” images.

Let’s take a look at some of the characteristics of this LIDAR without getting into complex explanations. NIO refers to the ET7’s LIDAR as an “image-level LIDAR,” which means that this LIDAR generates high-definition “point cloud” images.

The two core features of this LIDAR are:

- Long detection range;

- High resolution.

According to information released by NIO, the ET7’s LIDAR can detect up to 500 meters, and can achieve a detection distance of 250 meters with 10% reflectivity. It has a 120° ultra-wide viewing angle and a super-high resolution of 0.06°x0.06°. This LIDAR is the world’s first 1550 nm LIDAR to achieve large-scale mass production and the first ultra-long distance, high-precision LIDAR delivered to end users.

The ability to detect up to 500 meters is a hardware capability.

According to industry insiders, “this LIDAR does not sacrifice other performance in order to detect up to 500 meters. Moreover, it can achieve centimeter-level accuracy when detecting different target objects at 5 meters, 10 meters, and 250 meters. This is the hardware’s own feature.”

You may wonder how the NIO ET7’s LIDAR compares to other cars’ LIDARs.

Who has the strongest LIDAR?

The core technologies of an LIDAR are detection range and resolution.

When a car enters a state of autonomous driving, the LIDAR will constantly perceive the vehicles in front in real-time. When encountering danger (vehicles), the car will choose to automatically change lanes or decelerate or even automatically brake.

Ba Junwei, the CEO of Tuda Technology, once said, “In order for a car to brake safely, it needs 100-150 meters of warning distance. When the LIDAR collects data, it can collect 10 to 15 frames per second. In order to reduce false alarm and missed alarm rates, multiple frames of data need to be collected, which requires 0.5 to 1 second of data accumulation.”

During this process:

- Perception, planning, and decision-making take 0.5 seconds to 1 second;

- Executing instructions and braking takes 2.5 to 4 seconds;

- After these times have elapsed, when the vehicle is traveling at 120 km/h, the braking distance required is 50 to 60 meters.

Therefore, the entire distance requires about 100-150 meters. To ensure a warning distance of 100 meters, a standard detection distance of 250 meters is needed.

Now, let’s take a look at the comparison chart below.

Only two mass-produced vehicles, the NIO ET7 and the WeRide R7, currently have lidar sensors that can cover a detection distance of 250 meters, while the other lidars’ detection distance is mainly 150 meters, with the exception of the Ideal L9 lidar, which reaches 200 meters.

Only two mass-produced vehicles, the NIO ET7 and the WeRide R7, currently have lidar sensors that can cover a detection distance of 250 meters, while the other lidars’ detection distance is mainly 150 meters, with the exception of the Ideal L9 lidar, which reaches 200 meters.

Hardware-provided detection distance is a quantifiable foundation for meeting safety requirements, and theoretically, the longer the detection distance, the more redundant time available for vehicle decision-making.

Another indicator is angular resolution. Angular resolution is mainly determined by the scanning mode, as shown in the above figure. Currently, the lidars on the market have an angular resolution of mainly 0.2°×0.2°.

For example, for a 20 cm x 20 cm box, the angular size at 100 meters is approximately 0.1°. If the resolution is only 0.2°, the box is likely to be missed at this distance. Because a resolution of 0.2° means that the box can only be seen at 40 meters, and after accumulating multiple frames of data, the car may already be in front of the box just as the decision-making phase begins, which could lead to accidents.

In contrast to the lidars on the market, the NIO ET7 has a maximum angular resolution of 0.06°. When encountering the same box, the lidar can ensure that at least 4 points are detected on the box, and after accumulating 5 to 10 frames of data, it takes about 1 second and is 70 meters away from the box to start decision-making and braking, with sufficient time for braking.

As for the wavelength of the lidar, each has its advantages and disadvantages. The wavelengths of lidars on cars are usually 905 nm and 1550 nm.

According to research by the book Nine Chapters of Intelligent Driving:

Currently, the lasers for TOF lidars are mainly 905 nm, while Luminar, Velodyne, and Ouster use 1550 nm, and all FMCW lidars use 1550 nm.

The reason is:

According to Luminar CTO Andy Sun: We need to consider the maturity of the supply chain for any product we make because we can’t make all the components ourselves. Specifically, for FMCW lidars, in principle, the lasers don’t have to use 1550 nm, 905 nm can also be used, and there is no essential difference in technology between using 1550 nm or 905 nm. Only in the field of optical communication are devices that are compatible with FMCW based on the 1550 nm band; these devices’ supply chains are relatively mature, and their costs are controllable. In comparison, the cost of using 905 nm for FMCW is too high.In addition, considering the safety requirement of human eyes for continuous light, the power upper limit of 1550 nm is 40 times larger than that of 905 nm. According to the coherent amplification principle of FMCW, theoretically, 1550 nm can test a distance 40 times farther than 905 nm.

According to the article written by the industry veteran Zhou Yanwu, “high-power laser sources need to consider human eye safety, so only 1550-nm lasers can be chosen. The 1550-nm lidar is 100,000 times safer than traditional 905-nm lidar.”

Moreover, even in time-of-flight, the ability of 1550 nm wavelength lidar to overcome sunlight noise is stronger than that of 905 nm. However, the disadvantage of 1550 nm wavelength lidar is the high cost.

In the entire perception system, the direct impact of sunlight on lidar is lower than that on visual cameras, so lidar naturally has an advantage in supplementing visual defects in certain special scenarios.

Finally, the number of lidars, whether one or two or even three or four, is the last factor that affects the actual effect of lidar.

NIO ET7 is equipped with one lidar, XPeng G9 is equipped with two, Avita 11 is equipped with three, and Salon Mecha Dragon is equipped with four lidars.

Theoretically, more lidars will bring more accurate perception ability, and multiple lidars can be redundant to each other, but it also brings an objective increase in cost. If cost is not considered, more lidars will definitely help improve perception. But mass-produced cars are ultimately for the civilian market and need to consider factors such as maintenance and calibration.

According to the head of an overseas self-driving company: “The number of lidars still depends on the definition of the entire vehicle when the OEM needs to solve which problems with the lidar. As long as this lidar can meet the lifecycle of this vehicle and continue to support software OTA capabilities, one or two depends on the situation. Personally, I think the lidar potential of ET7 and RisingAuto R7 is great.”

Based on the above analysis, in terms of performance parameters, NIO ET7 and RisingAuto R7’s lidars are the strongest, followed by Ideal L9 and XPeng G9 equipped with two lidars, and the performance of other models with single lidar will be relatively poor. As for the performance improvement brought by using multiple lidars, it needs to be further compared after the mass-produced car is truly on the road.

On the road, how does the best lidar perform with the NIO ET7, which is equipped with a lidar?

At the end of this month, the NIO ET7 will be officially delivered to customers, and the Laser Radar on board will be synchronously enabled, and we believe that you will soon be able to feel its performance during test drives.

At the end of this month, the NIO ET7 will be officially delivered to customers, and the Laser Radar on board will be synchronously enabled, and we believe that you will soon be able to feel its performance during test drives.

Before being officially delivered to customers, let’s first analyze the concept theoretically and compare it with traditional visual perception solutions. Compared with the mainstream perception solutions of traditional models based on visual cameras and millimeter wave radar, the presence of a laser radar in NIO ET7 itself highlights some distinctive features.

Currently, visual cameras face the industry difficulty of “high light ratio.” When a vehicle enters a tunnel in the daytime, or suddenly enters a tunnel on a road without streetlights at night, the light in the tunnel will suddenly become bright, causing several frames to expose in the camera and resulting in invalid data to be perceived by the camera. This affects driving safety to a certain extent.

Due to the inherent characteristics of the laser radar, the Laser Radar of the NIO ET7 is basically not affected by lighting conditions. This is a feature that production laser radar vehicles can achieve.

When dealing with shaped vehicles, the perception of the laser radar will be more accurate. According to NIO, “When it comes to some conventional-shaped shaped vehicles, such as flatbed trailers, the camera will have errors in judging distance, while NIO ET7 equipped with a laser radar will accurately detect the distance of these shaped vehicles.”

In urban automatic driving, large vehicles, such as buses and trucks, are often encountered when cutting in at close range. For visual cameras, incomplete recognition or distortion of data acquisition will cause significant errors in the position and attitude of the objective, thus leading to slower responses from the vehicle system. The NIO ET7 does not need to estimate distance through the camera but detects it directly through the laser radar, providing highly accurate measurement results.

In addition, due to the high imaging quality of the original point cloud of the HESAI laser radar, jump changes are unlikely to occur, and the predicted trajectory of the entry path of the objective will be more accurately determined.

It is reasonable to speculate that in the future, when pedestrians wait for the red light at the urban intersection, the Laser Radar of the NIO ET7 may perceive and predict the movement and posture changes of the pedestrians, enabling predictions of people to cross the crosswalk, and these functions will eventually be pushed to users through OTA.

In extreme scenarios, laser radar will also perform better. For example, in a city street with no streetlights, if it encounters an oncoming car with high beam lights and a pedestrian suddenly crosses, the visual camera is difficult to capture this target. The laser radar, due to its almost no influence on lighting conditions, can quickly capture the target and provide warnings to drivers. In the event of no response from the driver, the AEB automatic emergency braking function will be triggered.Compared with other LIDAR-equipped cars, the NIO ET7 is expected to perform better theoretically.

However, according to industry insiders, the NIO ET7’s LIDAR does not have a 100% guarantee to solve the “ghosting” problem from a hardware perspective, and if the LIDAR cannot be well processed, there will be certain challenges for the subsequent autonomous driving algorithm. However, in their tests, minimal ghosting will not have a significant impact on target detection.

Because the NIO ET7 has better detection distance and angular resolution performance, we speculate that this car will have a lower missed detection rate for target objects in actual autonomous driving status. Furthermore, due to the good hardware of this car’s LIDAR, there will be higher resolution, which will also help to reduce false reporting.

Junwei Bao once gave an example. If a pillow with a size of 20cm x 40cm is thrown from the car, the LIDAR of TuSimple can return 5 to 7 points when detected from 100 meters away. In other words, TuSimple’s LIDAR can detect a 20cm x 40cm object that is thrown 100 meters away, and the point cloud is clear. Under the same conditions, the standard detection distance of a 150m LIDAR is difficult to detect the same thrown object at the same distance.

This means that the NIO ET7, which has a stronger detection capability, will have more accurate perception of target objects when facing the same thrown object, thereby providing the basis for accurate instructions for automatic deceleration or lane change in autonomous driving operation and ultimately making autonomous driving more like human drivers.

In addition to Tesla’s insistence on relying on visual sensing solutions, more automakers are joining the LIDAR army.

The LIDAR of the NIO ET7 will be in a continuously activated state during vehicle operation, scanning and sensing the surrounding environment in real-time, and it will be complementary with the visual camera to make up for the lack of single-sensing hardware. When it is in mass production, we believe that the cost of LIDAR can be spread out.

Looking to the future, LIDAR hardware is developing rapidly.

According to industry insiders, if the LIDAR hardware capability is insufficient, the required information cannot be captured. Fortunately, the current-generation LIDAR hardware of the NIO ET7 will not be outdated in the next three to five, or even ten years. Next, we need to wait for the continuous iteration of the autonomous driving software of the NIO ET7. As for other LIDAR-equipped car models, it is necessary to consider the hardware replacement factors.As a car that competes with the BMW 7 series, the positioning of NIO ET7 determines that the capability ceiling of existing mass-produced cars is basically represented by its LIDAR. With this car running ahead, people will see the large-scale popularization of the era of autonomous driving earlier.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.