Introduction

Author: Xingxing

On March 21st, FEIFAN released a video presenting the R7 intelligent hardware, with a rich configuration, which has sparked our interest in this product again.

When an intelligent electric vehicle company presents its products by listing the number of hardware components, you should know that this will be the beginning of a competition for hardware.

For the practice of integrating various advanced hardware components into cars, there is a common term in the industry: “heap material.”

Looking at the core information of R7, do you think it is redundant? However, the development of autonomous driving capability is too fast, and hardware needs to support software OTA throughout the entire lifespan of the car, which may be the reason.

Therefore, let’s take a look at the core technology of R7, and see if it can stand firm in the mid-to-high-end market.

FEIFAN did not come for “matching”

FEIFAN is an independent electric vehicle brand under SAIC Group, positioned in the mid-to-high-end market and emphasizing technology and fashion as its main features.

R7 is also the mass-produced version of ES33, the concept car of the R brand in that year. According to FEIFAN, R7 will be the flagship product in the current product line, which indicates the amount of effort that will be poured into this car.

Many people think that FEIFAN is a transformation of the R brand, established by SAIC Group for its multi-brand strategy, mainly aiming to form a high-low matching with high-end brand IM in the intelligent electric vehicle market.

This view is not comprehensive. FEIFAN CEO Wu Bing said:

The establishment of FEIFAN was based on the real needs in the market. There are still many potential customers in the mid-to-high-end market that can be exploited. We can fully utilize the advantageous resources within the SAIC family to rapidly bring our products to the market.

There is no such concept as “matching.” It’s just that we focus on different markets. In the future, there may be some overlap in product lines, but for now we hope to penetrate our current market thoroughly.

With such goals in mind, we can see that FEIFAN has indeed put in a lot of effort into the first flagship product R7, equipped with top-level hardware such as 4D imaging radar, laser radar, 8 million cameras, 8155 chip, and NVIDIA Orin.

After introducing FEIFAN, let’s take a look at the product strength of R7, from the following three aspects:

- Product design;

- Intelligent technology;

- Three-electric technology.

“Multiple” Perception Hardware

Note:

Please be aware that “heap material” is a neutral term, and its meaning even more so when used in smart electric vehicles. Throughout the entire lifespan of an intelligent vehicle, software can be upgraded through OTA, but often hardware upgrades are not that simple, which is not only true for cars, but also for wearable devices, mobile phones, and digital devices.Therefore, designing a hardware system that can meet the software iteration throughout the entire lifespan of a car is desirable, and the pre-embedding strategy of such hardware meets the demand of users for advanced intelligent capabilities during the mid-to-late stages of a car’s lifespan.

In the key words of the R7 product introduction, “intelligent” may be the most important because the official slogan of R7 is “the ultimate intelligent pure electric SUV”.

For the intelligence of the whole vehicle, we mainly focus on two aspects: “intelligent cockpit” and “intelligent driving”.

Let’s first look at intelligent driving.

According to the official statement:

RisingAuto has developed a set of “advanced intelligent driving system based on pixel-level point cloud fusion”: PP-CEM.

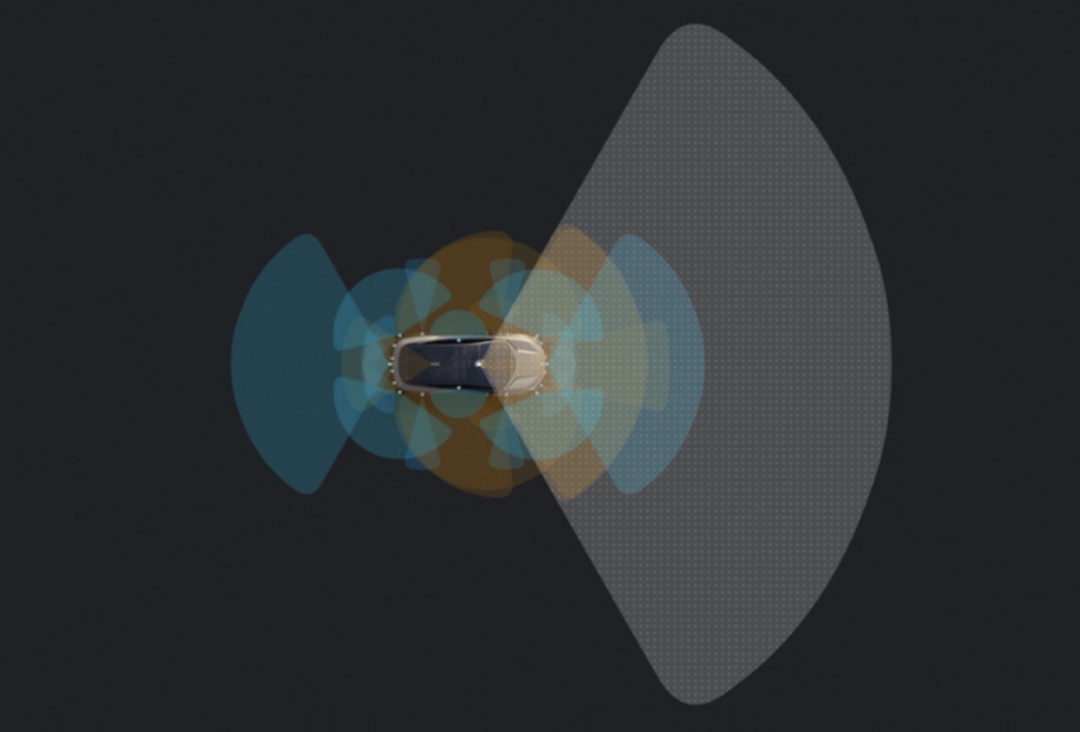

This system integrates 33 perception hardware configurations and can achieve six-dimensional perception fusion capability in all-weather, all-scenarios, super vision distance, and multiple dimensions.

The perception and calculation hardware for the entire intelligent driving system includes:

- Luminar Lidar;

- NVIDIA Orin™ chip;

- Premium 4D Imaging Radar;

- 5G-V2X technology.

From the perspective of the mainstream automatic driving perception hardware architecture in the current market, perception hardware is transitioning to “high-performance cameras + mmWave radar + Lidar”, among which cameras are mainly upgraded to 8 million pixels; mmWave radar is seeking the application of 4D imaging radar.

Because the upgrade of the camera pixels increases the requirements for computing power, the mainstream practice is to upgrade the front camera to an 8 million pixel solution, while the side cameras are generally still 1-1.3 million standard-definition cameras.

For example, Tesla Model 3/Y has 8 cameras with 1.3 million pixels each, and ES6 has 8 cameras with 1.3 million pixels each.

The R7 is equipped with 12 cameras, including one front-facing 8 million pixel camera and 11 2 million pixel cameras. This is where I am surprised. Upgrading camera pixels can indeed improve detection distance and accuracy, but it also places higher requirements on costs and algorithms.

The reason why we still need to do this is mainly because machine vision still occupies a very important position in the entire perception of autonomous driving. The information flow of high-pixel cameras is still the most direct data for feeding algorithms, and high-pixel cameras have natural physical advantages in depth perception and accuracy, contributing to the development of advanced intelligent driving.# Tesla’s Choice: 4D Imaging Radar and LiDAR for Safer Autonomous Driving

Tesla’s “pure vision” solution is limited by the physical constraints of hardware when dealing with extreme weather and scenes. While it can achieve distance and height measurements, developing a specially-designed supercomputing platform and utilizing massive quantities of driving data to feed the algorithms can be a costly and time-consuming endeavor. Even then, Tesla has yet to achieve perfect semantic segmentation accuracy with its cameras under extreme weather conditions.

Faced with this problem, Tesla chose to persist with “pure vision,” while companies like Google, Huawei, and domestic OEMs opted for a fusion solution, which includes integrating LiDAR and 4D imaging radar.

Mass Production of 4D Imaging Radar

For a long time, millimeter wave radars have been the assistants to cameras, at least in the current L2 solutions.

But since Tesla suggested the removal of millimeter wave radars, the relationship between the golden partners has subtly changed. Against the backdrop of chip shortages leading to difficulties in parts production, Tesla’s decision to cancel millimeter wave radars is naturally understood as a cost reduction move. However, reality may not be that simple.

The principle of millimeter wave radars is to emit electromagnetic wave signals and receive target signals to obtain relative velocity, distance, angle, and direction of obstacles around the vehicle. This method, along with heterogeneous sensors consisting of cameras, makes algorithm fusion difficult.

As Dr. Andrej Karpathy discovered in the development of Tesla’s autonomous driving algorithm, millimeter wave radars always tend to misreport information, resulting in noise in the perceptual information for objects such as high ground water access points, bridges, crossing obstacles, and oncoming vehicles.

This noise greatly interferes with the data fusion of cameras and millimeter wave radars.

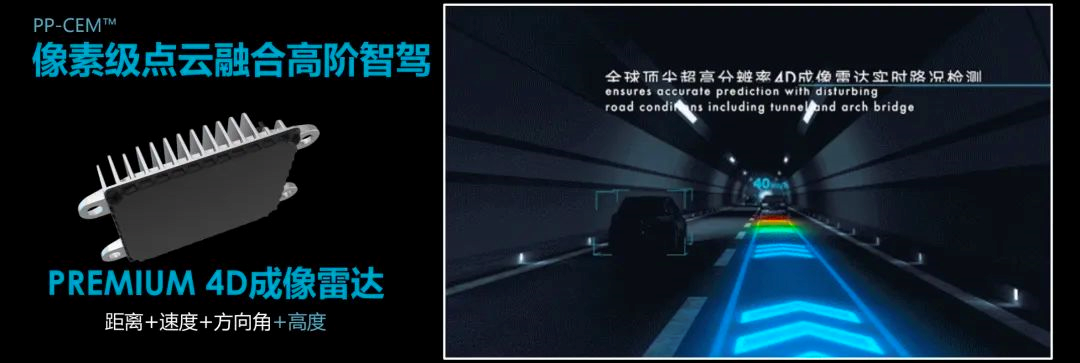

4D imaging radar seems to be designed to solve these problems. The Fei Fan R7 is equipped with the ZF Premium 4D Imaging Radar, which has a maximum detection distance of 350 meters.

The premium 4D imaging radar can accurately detect distance, velocity, angle, direction, and height, with a four-fold increase in long-range point cloud density. The R7 is equipped with two such radars.

In short, the premium 4D imaging radar has the potential to effectively improve the detection accuracy of extreme weather-driving conditions for objects such as ice cream cones, access points to underground water, bridges, and crossing obstacles, improving driving safety. As for how it performs after mass production, concrete experiences with the product will be necessary to determine.

LiDAR### Translation

In December 2020, Luminar went public on NASDAQ and became the highest-valued lidar company in the world. At its peak, Luminar’s market value surpassed $12 billion.

However, facing industrial production difficulties and the decline of US tech companies, Luminar’s stock price is now only $5.4 billion.

Iris is Luminar’s flagship product, mainly targeting mass production at the vehicle-level:

- It uses a 1550-nanometer laser source;

- The maximum detection range is 500 meters;

- Objects with a reflectivity of less than 10% can be detected within a range of 250 meters.

This kind of performance provides powerful hardware support for advanced autonomous driving systems. In order to achieve this performance, Luminar took a unique approach in the technical route of lidar:

- Firstly, it adopted a receiver with a 1550-nanometer wavelength. The material used for this receiver is more expensive than traditional silicon: the rare InGaAs.

- In addition, Iris uses MEMS technology in conjunction with ASIC chips to achieve solid-state and miniaturization of lidar, making it easy to install and produce.

As a result, Luminar’s lidar power is 40 times higher than that of its competitors, and even in extremely low-light environments, it can “see” objects on the road, providing vehicles with richer environmental perception information.

This technology is due to the acquisition of optoelectronics company Open Photonics and InGaAs optoelectronic detector design company Black Forest Engineering by Luminar in 2016-2017.

In other words, the mass production of R7 represents the application of high-end lidar, before which drones like DJI and Huawei used only mid-to-low-end lidar. Iris, the lidar used in R7, provides the foundation to upgrade R7’s advanced driver assistance system.

To sum up, it’s hard to believe that this is a product that is about to be mass-produced based on its hardware level. According to Fayan Auto News, the first batch of PPV pre-fabricated mass-produced cars from Fayan R7 has officially been assembled, meaning that the R7 production line is fully operational and production tests have been completed.

The production line’s maturity, the software and hardware tuning of intelligent driving and intelligent cabin are close to mass production. However, since the vehicle hasn’t been delivered yet, all the above expectations for R7’s intelligent driving capability are based on the hardware performance. Although hardware is the foundation, algorithms are the specific manifestation of whether the system is usable and good to use.### Revisiting the Intelligent Cockpit

When it comes to the intelligent cockpit, we usually evaluate it from three aspects: hardware foundation, interaction methods, and audio-visual entertainment.

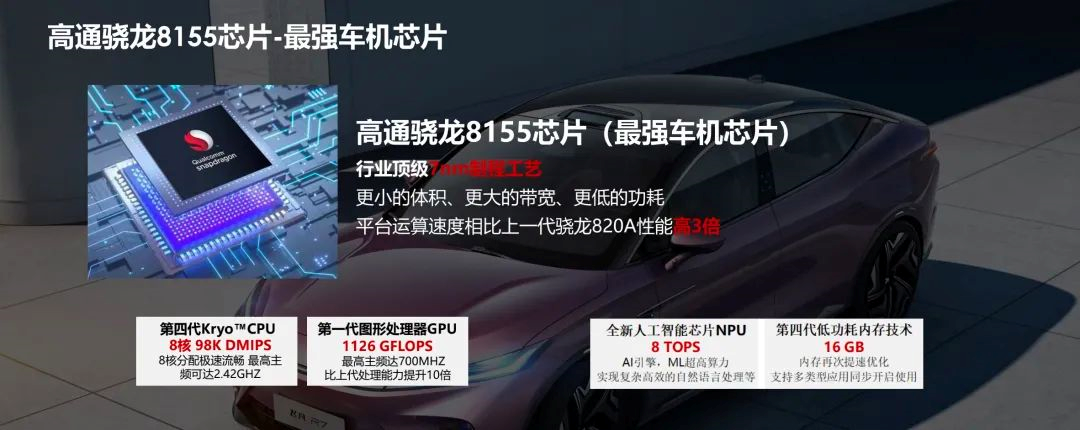

The R7’s main computing chip for the cockpit is none other than the famous Qualcomm 8155, which is possibly the most powerful car machine chip available before mass production.

This chip should be familiar to many people and has several characteristics:

- 7nm process technology;

- Fourth-generation CPU with 8 cores, 98k DMIPS, and a frequency of 2.24 GHZ;

- GPU with 1126 GFLOPS and 700 MHZ frequency;

- NPU with 8 TOPS;

- 16 GB of memory.

In summary, it is three times more powerful than the mainstream 820A.

Based on this computing chip, the R7 offers the Trinity multi-dimensional sensory interactive system.

What is this system?

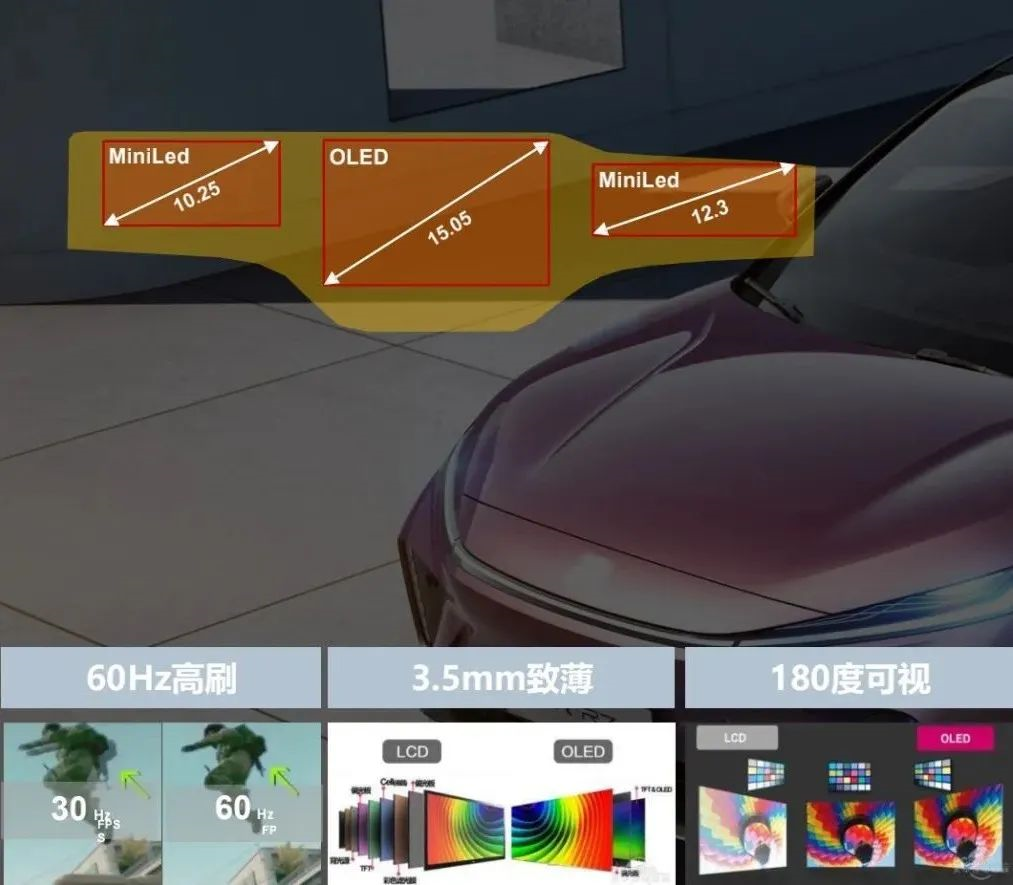

It is a set of 43-inch triple screens that create an interactive entrance. The hardware for this entertainment system includes:

- A 10.25-inch instrument screen, a 15.05-inch central control screen, and a 12.3-inch copilot screen;

- An OLED central control screen with a resolution of up to 2.5K for delicate display, PPI 201;

- 60 HZ high refresh rate.

Combined with voice capabilities, the entire cockpit’s entertainment capabilities can bring a very stunning experience, and the triple screen has been verified by models such as the Ideal ONE and the LanTu FREE.

If the triple screens and voice are standard abilities for an intelligent cockpit, then the R7 has a new interactive product: “Giant Screen AR HUD Front View System.”

It looks familiar, right? That’s right. This is the giant screen AR HUD that is going to be mass-produced on the future ET5, but the R7 has produced it first. What is the purpose of this system?

- AR: Augmented Reality

- HUD: Head-Up Display

AR HUD realizes five technological breakthroughs(the instrument information and navigation information are displayed on the windshield):

- Cinema-level projection screen;

- High-definition and better picture quality;

- Shadow-free technology;

- 10-12000 nit brightness, unaffected by any sunlight;

- Broader and richer display area.The AR technology can project vehicle information and entertainment content directly onto the windshield of the car, forming a screen similar to a “big TV”, with a projection distance of 7.5 meters according to the official statement. This means that watching TV in the car is no longer limited to the car screen, but also has a “big TV” available.

The entire intelligent hardware of R7 is already at the top level, with 4D imaging radar, LiDAR, 8 million cameras, 8155 chips, and Nvidia Orin. These are all high-end configurations for luxury cars, but we know that “hardware stacking” is no longer a rare thing for the entire market. The key is whether Feeyo can match excellent algorithms. This point is currently unclear.

The importance of algorithms is almost the core of whether this car’s assisted driving and cabin entertainment can be used and how well it can be used. The final ability can only be seen after the delivery of the actual car.

Is SAIC’s Self-developed “Three Electrics” R7’s Secret Weapon?

Before looking at the technical details, let’s take a look at the R7’s powertrain:

- The maximum motor power is 400 kW, and the maximum torque is 700 N·m.

- Acceleration of about 4 seconds per 100 km

- Multiple power battery solutions, endurance of more than 600 km.

Such power data is also definitely outstanding on the current market. Two self-developed technologies by SAIC achieve this capability: first, Hair-Pin motor; second, double-layer structure battery pack design.

Let’s take a look at what an 8-layer Hair-Pin motor is?

Before introducing Hair-Pin motors, let’s first introduce motors:

In the new energy industry, the most commonly used motors are permanent magnet synchronous motors and asynchronous motors. The difference is whether the rotor speed is consistent with the rotating magnetic field speed of the stator. If the rotor speed is the same as the stator, it is called a synchronous motor; if it is not the same, it is called an asynchronous motor.

Since the structure of permanent magnet motors is relatively simple, and the energy conversion rate of asynchronous motors is low, permanent magnet synchronous motors have been widely used.

The rotor of the permanent magnet synchronous motor is a permanent magnet, and the stator generates a magnetic field by energizing the winding. The driving force for rotation is achieved under the interaction of the two magnetic fields. To some extent, the larger the current passing through the winding, the stronger the power, the smaller the resistance of the winding, and the higher the energy efficiency.

Therefore, in order to improve power density and energy consumption level, all motor manufacturers are trying to stuff as much copper wire as possible into a limited space, which is what we often call “slot filling rate.”

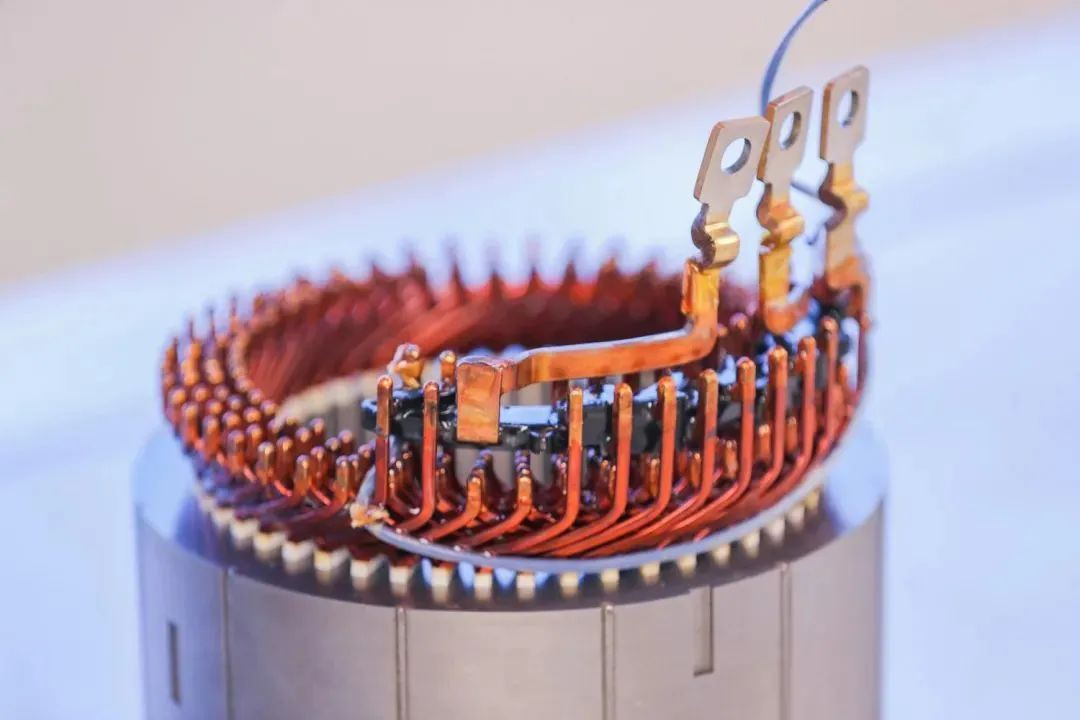

The Hair-Pin motor is a form of stator winding, which simply means the winding form of copper wire inside the motor. SAIC uses a shape similar to a hair clip for winding, so it’s called a “hair clip-style.”

The Hair-pin wire adopts a flat design, which has the advantage in shape over the traditional cylindrical enameled wire winding method, allowing more copper wire to be placed in the original space of the stator.

And that’s not all, SAIC has designed this winding to be 8 layers which increases the surface area of the copper wire, and as AC current passes through the wire, there is an obvious skin effect. A larger wire surface area would result in less resistance, thereby improving efficiency.

The result is that this set of motor components has higher efficiency and stronger power. According to SAIC’s official introduction, “The highest efficiency of the Hair-Pin motor can reach 97%, and it uses oil cooling for heat dissipation to extend the running time of the motor at high speeds“. Another innovation in the electric drive system is the coaxial structure design, which means that the rotor shaft of the motor passes through two sets of reduction gears to the output shaft. The output shaft rotates coaxially with the hollowed-out rotor shaft, making this structure more compact than the parallel axle structure electric drive system.

Looking at the battery pack again

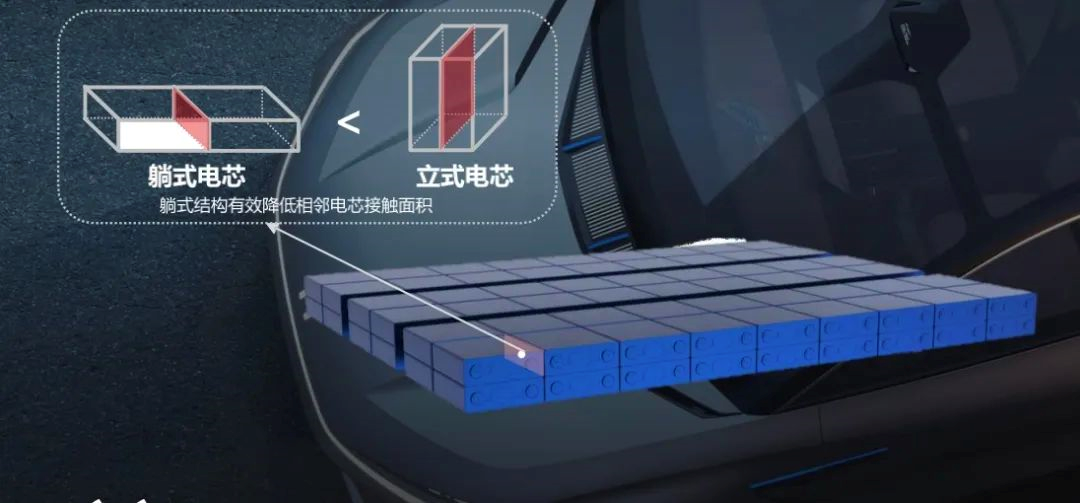

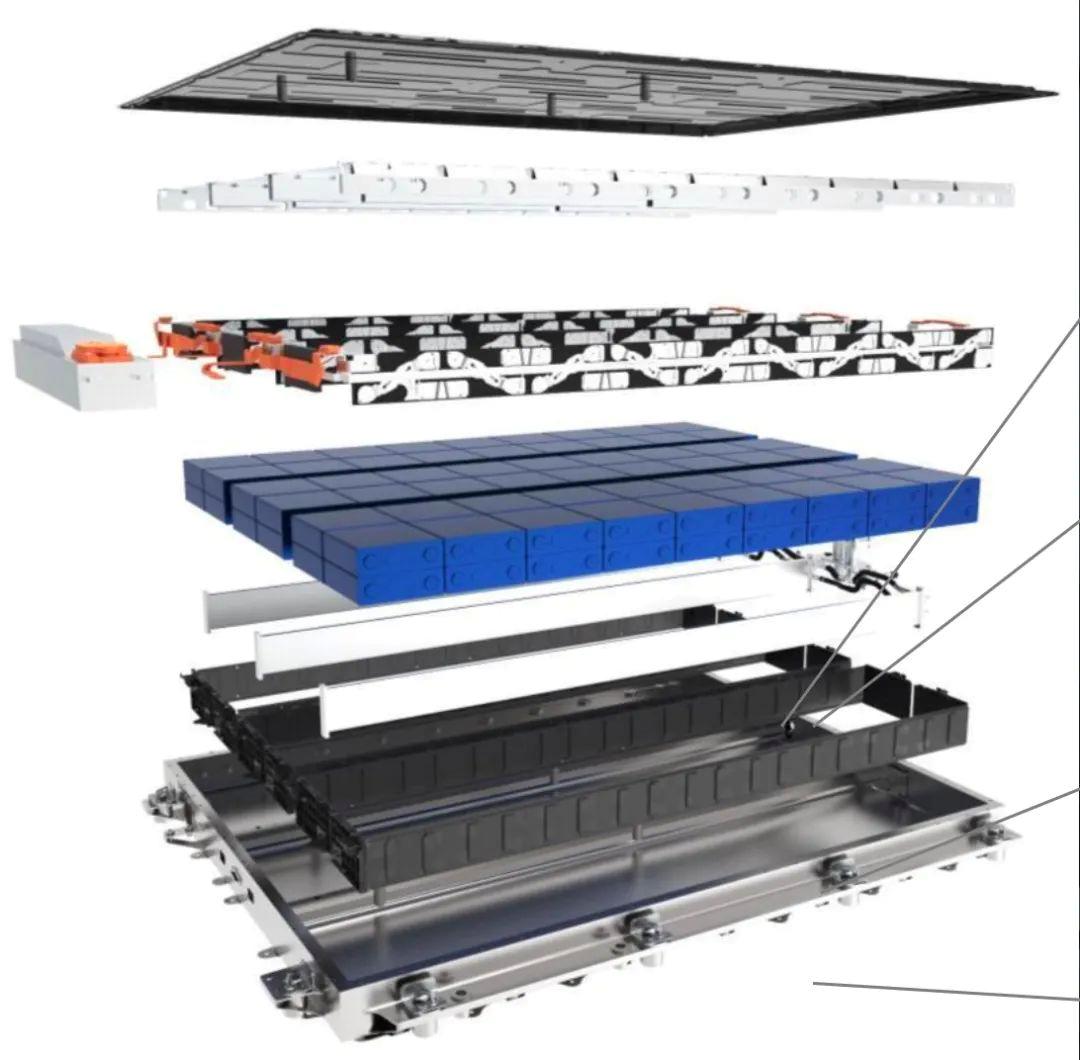

Unlike other large module schemes, SAIC’s self-developed battery pack uses a “double-layer horizontal orientation” design for the battery cells, which means the battery cells are laid horizontally.

As we all know, whether using cylindrical or prismatic battery cells, they are arranged vertically when making large module or CTP schemes. Of course, this increases the difficulty of heat dissipation, such as Tesla’s cylindrical scheme using a serpentine heat dissipation plate.

But the battery cells in R7 are arranged horizontally, making the cell tabs on the side. The greatest advantage of the horizontally arranged large module scheme is that it can reduce the complexity of the battery system, improve the utilization of battery cells, but the disadvantage is also clear. If the optimization of the thickness of the battery cells is not sufficient, the entire pack with two layers of horizontally arranged cells will become very thick, which is very unfavorable for chassis design. Another disadvantage is that the area of the battery cell’s flat surface increases after being laid horizontally, and the strength requirements of the battery pack become higher.

Because the torque of the car body is also transmitted to the battery pack, if the strength is not enough, the battery is prone to damage and becomes dangerous.

Let’s take a look at SAIC’s optimized results:

- The vertical height of the battery cell is 110mm, providing wider and more spacious seating space inside the car;

- With the design of no thermal spreading, by reducing the contact area between adjacent battery cells, if a single battery cell experiences thermal runaway, a domino effect can be prevented.The battery pack, which has already been used in the ER6, can achieve an energy density of 195 wh/kg with the safer 523 battery pack, and an NEDC range of over 600 km, which is quite impressive for a mid-size SUV. Therefore, as long as Fleva can manage the heat well enough, this car is likely to perform well in terms of actual range.

Young “Fleva”

R7 is a pure electric SUV aimed at younger consumers who place high demands on exterior design, which even influences their entire purchasing decision. In the context of the increasing emphasis on design in the overall new energy vehicle market, it is not easy for Fleva to produce a product that is both aesthetically pleasing and has a unique style.

Unique Exterior Design

The dimensions of R7’s body are 4900 mm / 1925 mm / 1655mm, with a wheelbase of 2950 mm. This is a large car close to 5 meters in size, which means that the R7 design team had to balance the issue of bulkiness caused by the larger size.

Front Face

R7’s front face adopts a closed grille design, which is similar to that of mainstream electric cars, with better overall unity. There is still a reserved air intake below the grille, which can effectively cool the braking system.

One of the highlights is that the headlamps on both sides of the front face are equipped with laser lighting systems, making it the world’s first production electric vehicle with laser headlights. The laser-assisted module provides high beam illumination above 40% when traveling at high speeds.

Side View

As an SUV, the overall height of the vehicle side is quite high. The design of the liftback gives the side view a smooth appearance; however, this design is loved by those who like it and hated by those who do not.

The two-tone body creates a sense of floating roof, and the aerodynamic drag of the entire vehicle can be reduced to 0.238, which is not outstanding but still somewhat above average.

Rear End

The rear end may be the part I personally don’t like, mainly due to the liftback design that makes the rear look neither highly imposing like an SUV nor elegant like a sedan.

Overall, R7’s design belongs to a conservative style. For example, the height of the body is obviously affected by the chassis battery pack, which does not mean that the ground clearance increases but that the visual thickness of the body increases.

However, the engineers and designers made the whole vehicle appear even more compact visually by using 21-inch wheels and optimizing the contour. In other words, the R7 still looks like a car with a good appearance.

In conclusion, the appearance of R7 has utilized a lot of designs with tangent lines and block-shaped surfaces, which can highlight the muscular and sporty feel of the entire car. Personally, I believe that the side view of R7 is the most attractive, with its sleek and smooth sloping roof. However, this type of design also has its disadvantages, as users who prefer traditional SUVs may be wary of it.

In conclusion, the appearance of R7 has utilized a lot of designs with tangent lines and block-shaped surfaces, which can highlight the muscular and sporty feel of the entire car. Personally, I believe that the side view of R7 is the most attractive, with its sleek and smooth sloping roof. However, this type of design also has its disadvantages, as users who prefer traditional SUVs may be wary of it.

Final Thoughts

From the perspective of R7’s positioning as a mid- to high-end SUV, this market itself is very large, but also highly competitive. Judging from the actual situation, R7 has produced the best hardware architecture, but testing it will be the “soft” part of its technical capabilities, to see whether the algorithms can drive these hardware components to unleash maximum value, which is still an unknown.

Within the SAIC family, CFMOTO has appeared more relaxed in terms of resource positioning than other competitors. Currently, SAIC Group has formed three main new energy brands: SAIC Passenger Cars (New Energy), CFMOTO, and IM Auto.

Although CFMOTO relies on SAIC, it still needs to pave its own way.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.