The secrets of Lucid Air’s battery technology

Author: PotatoFish c

As expected, the period between March and April is a good time for recruiting. Soon after we posted the job ad (click here to submit a resume), we welcomed our new colleague in operation.

This very health-conscious new colleague made “so cute” her catchphrase after finding out that none of us had the habit of taking a nap at noon.

Come on, we start work at 10 am, and who can take a nap at noon?

If we talk about “cuteness,” it must be our bosses.

Nowadays, it’s not uncommon for bosses of major tech companies to show up to promote their own products.

However, Lucid Motors CEO Peter Rawlinson has taken this to a new level recently.

As the former chief engineer of Tesla Model S, Rawlinson is undoubtedly a tech-savvy manager.

Through a battery technology exchange meeting, he fully demonstrated what it means to be an “outstanding CEO who understands technology.”

As the current longest-range production car in the world according to the EPA, what are the secrets behind the battery pack of the Lucid Air?

High Voltage = High Efficiency

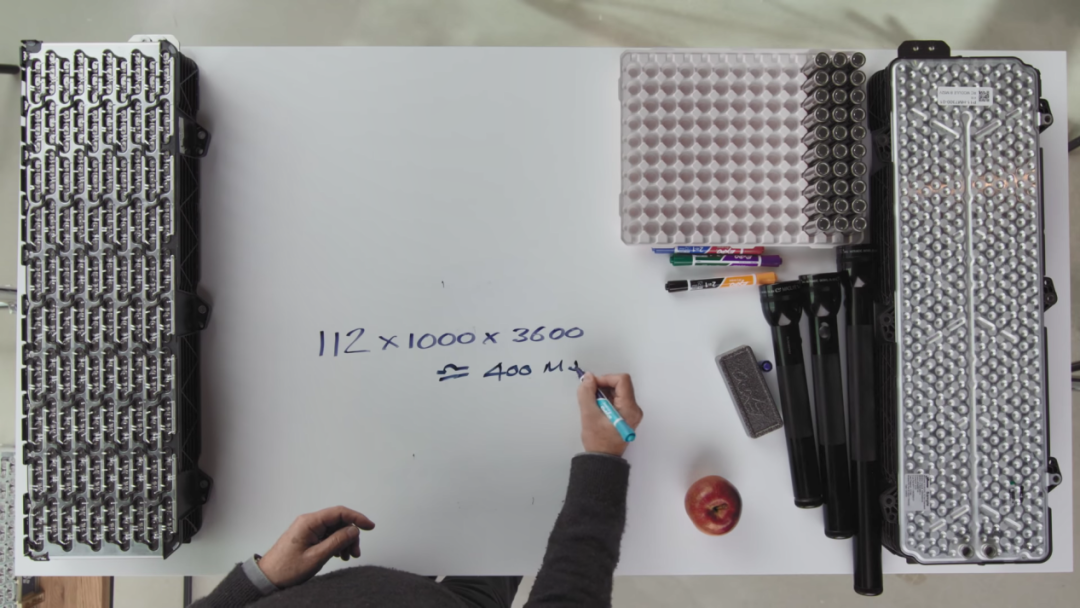

The Lucid Air Grand Touring is equipped with a 112 kWh battery pack. What does 112 kWh mean in terms of energy?

Rawlinson gave us a very vivid example.

“We picked up a 100-gram apple from the ground and placed it on a table one meter above the ground, consuming one joule of energy in the process. The 112-kWh battery pack is equivalent to about 400 million joules, which can allow us to repeat the apple picking action 400 million times.”

How was the 112 kWh determined?

Rawlinson first explained the relationship between energy and power, and introduced a very clear and easy-to-understand calculation process for us.

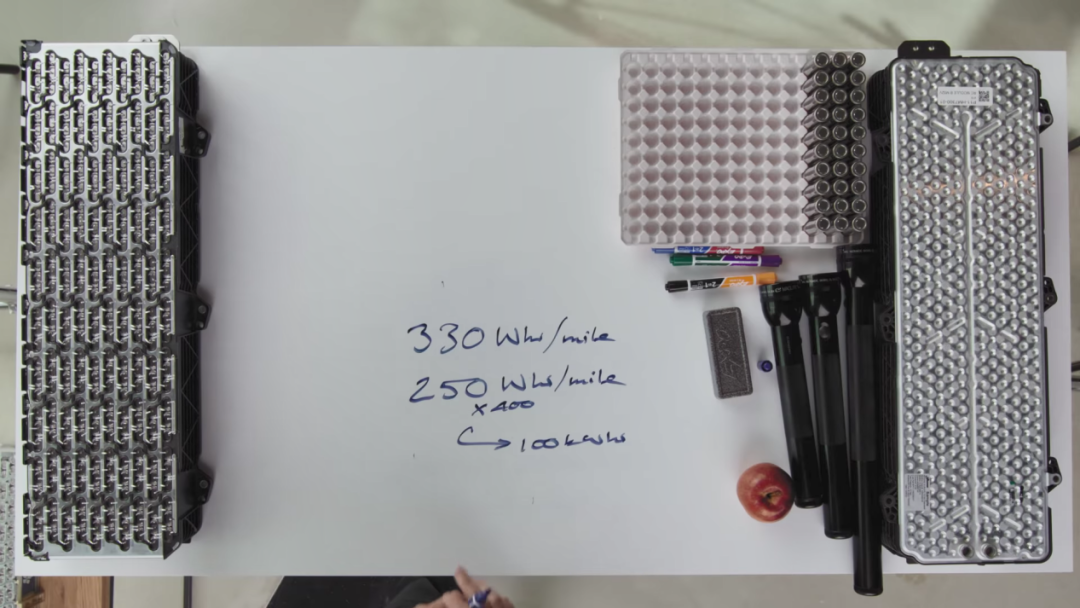

About 10 years ago, each mile driven by an electric car would consume about 330 Wh of electricity. With the advancement of technology, today’s electric cars consume only 250 Wh per mile driven.To enable an electric vehicle to have a range of 400 miles, a 100 kWh battery pack is required.

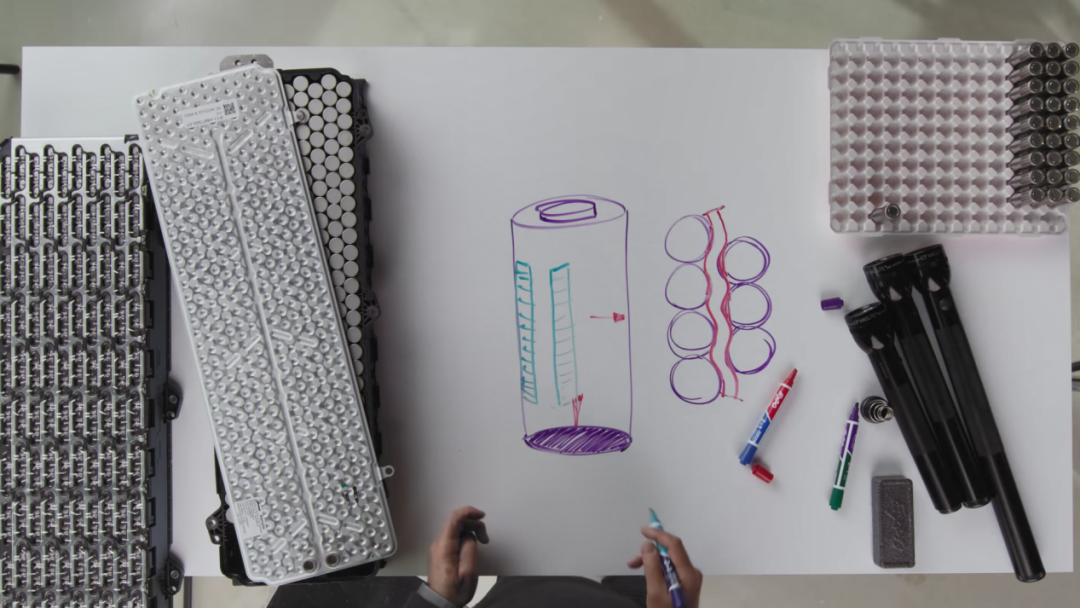

Continuing the calculation, the 2170 battery used in Lucid Air has an energy capacity of about 17-18 Wh per cell, so around 6,000 2170 cells are required to form a 100 kWh battery pack.

This is the design base of the Lucid Air battery pack, consisting of 6,600 2170 cells.

However, everyone knows about stacking batteries, and for an electric vehicle with the longest global EPA range, there are, of course, some different tricks.

For example, the battery pack voltage of current electric vehicles is generally around 400V, but Lucid uses a high voltage of 924V.

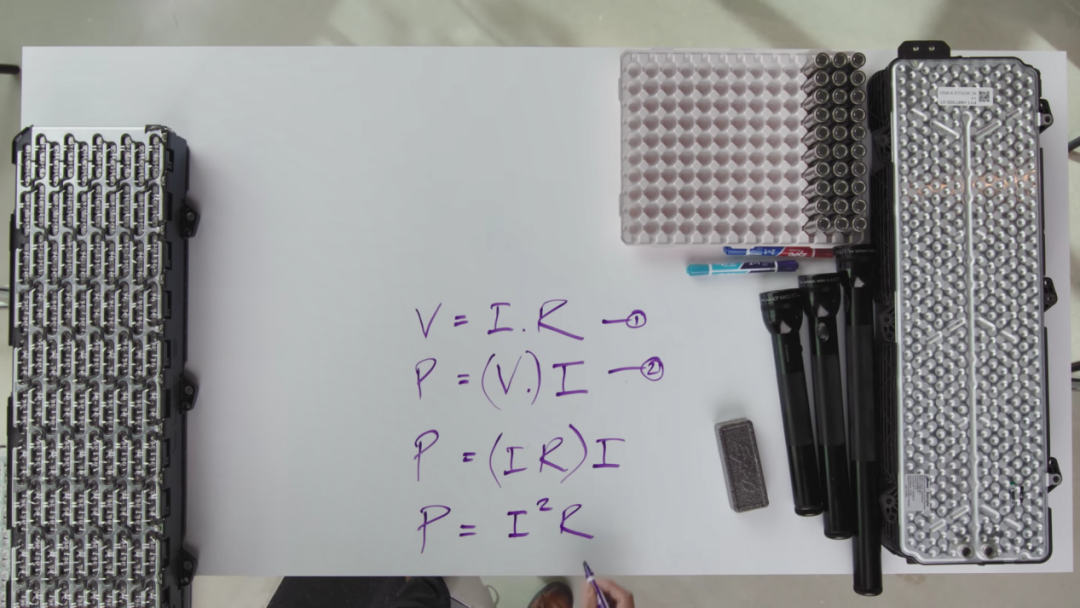

As for why this is done, Rawlinson used some basic physical formulas to explain the theoretical support behind the choice of high-voltage battery.

Ohm’s law

Voltage U = Current I × Resistance R ———— Equation ①

Power calculation formula

Power P = Voltage U × Current I ———— Equation ②

Substituting Equation ① into Equation ② gives

P = I^2 × R

This is also the formula for calculating the system resistance heating power.

And this heating power is of no use to us, we want it to be as small as possible.

According to P = I^2 × R, it can be seen that the smaller the current I, the smaller the heating power of P.

The problem is, how do we reduce the current while keeping the total system power constant?

As P = U × I shows, when the power P is kept constant, increasing the voltage U will cause the current I to decrease.

Taking Lucid Air as an example, Lucid increases the battery pack voltage by double, so the current becomes half of the original, and the heating power decreases to one-fourth of the original.

Therefore, high voltage means higher driving efficiency, which is one of the reasons why Lucid chooses a high-voltage battery pack.

How to Build 924V Voltage

The full charged voltage of a single 2170 battery cell is 4.2V. So, how can we boost this voltage to 924V?

First, let’s introduce the concept of battery series and parallel connection. Series connection can increase output voltage, while parallel connection can increase output current.

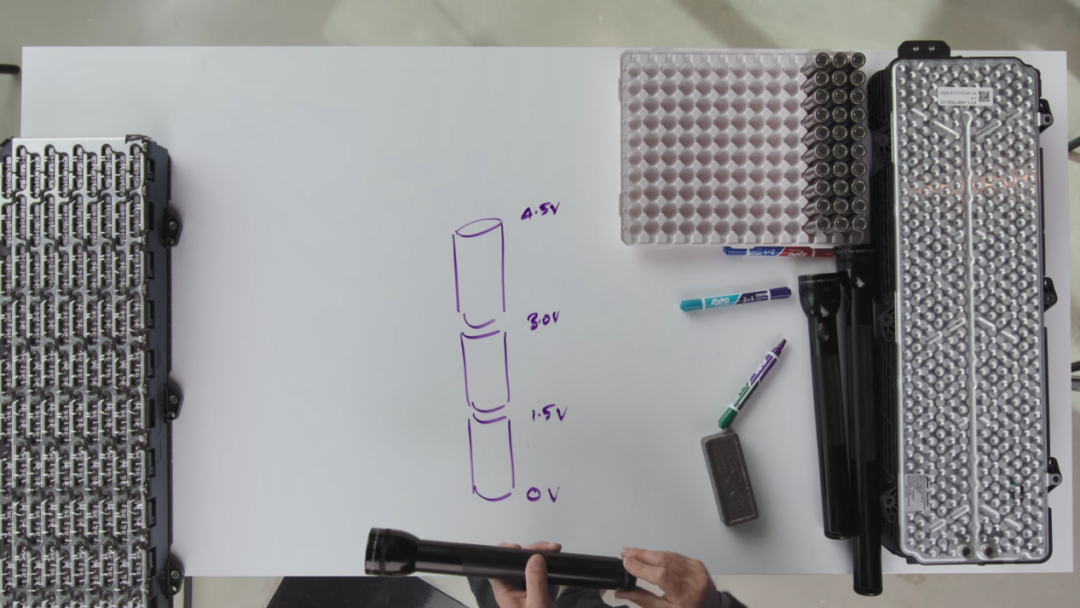

Rawlinson used three different lengths of flashlights with different voltage levels to illustrate.

All these flashlights use 1.5V No. 1 dry cells as energy source. Putting three dry cells in series to the flashlight will get a voltage of 4.5V, and four dry cells in series will get 6V. Six dry cells in series will give 9V.

Similarly, to boost 4.2V of a 2170 battery cell to 924V voltage, we need to connect 220 2170 battery cells in series.

However, if we use the way of connecting batteries like flashlights, connecting 220 2170 battery cells end to end will have a length of about 15 meters. Such length is obviously not suitable for cars.

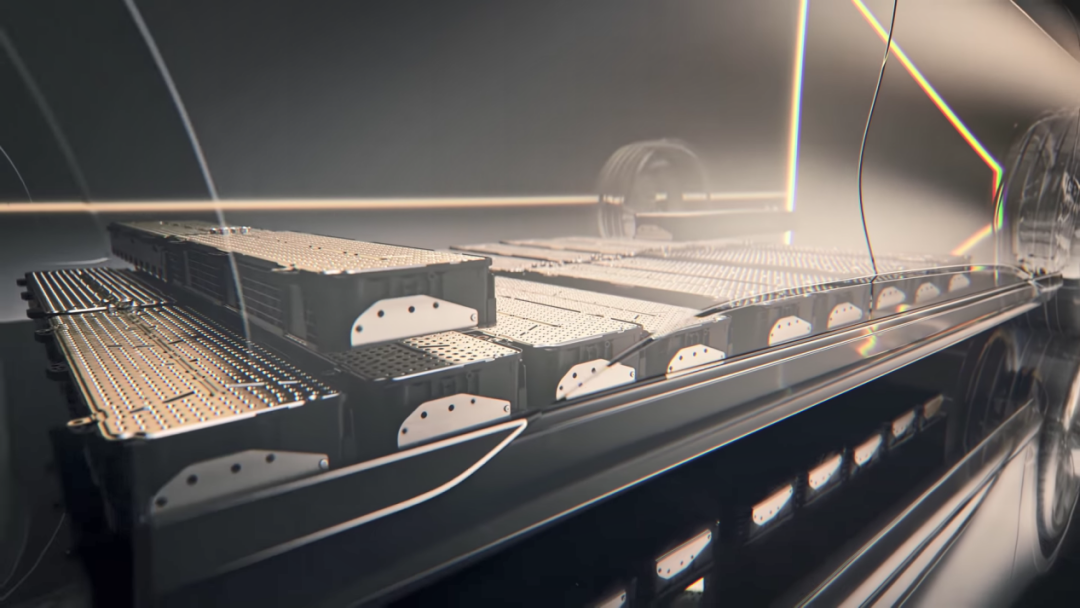

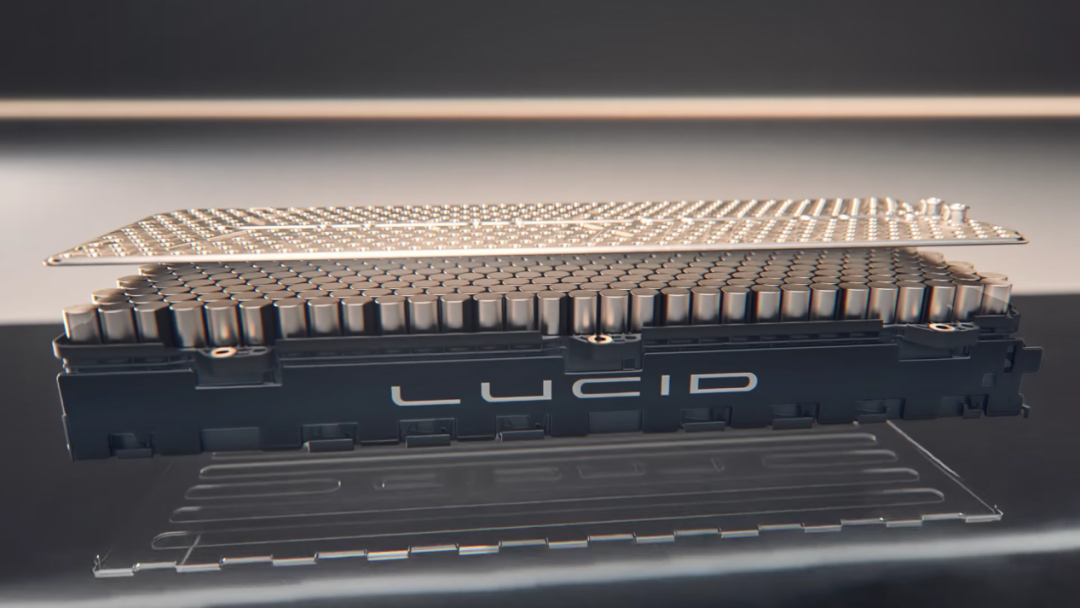

In fact, in order to balance the voltage level and current output capacity, Lucid divided 6,600 2170 battery cells into 22 groups, with each group consisting of 300 battery cells that form a battery module.

In a battery module, the 300 2170 battery cells are also evenly divided into 10 groups. Each group consists of 30 battery cells connected in parallel to form a “Group”.

The 10 Groups in a module are connected in series to get an output voltage of 42V.

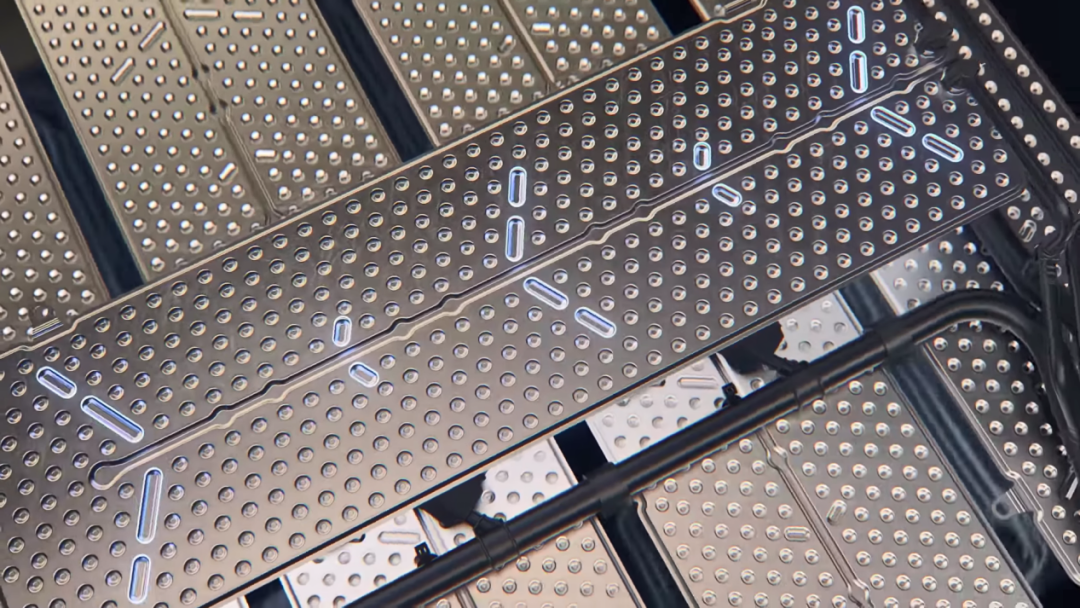

In order to allow the 300 battery cells to be arranged vertically and parallelly to form a battery module, Lucid made two efforts.

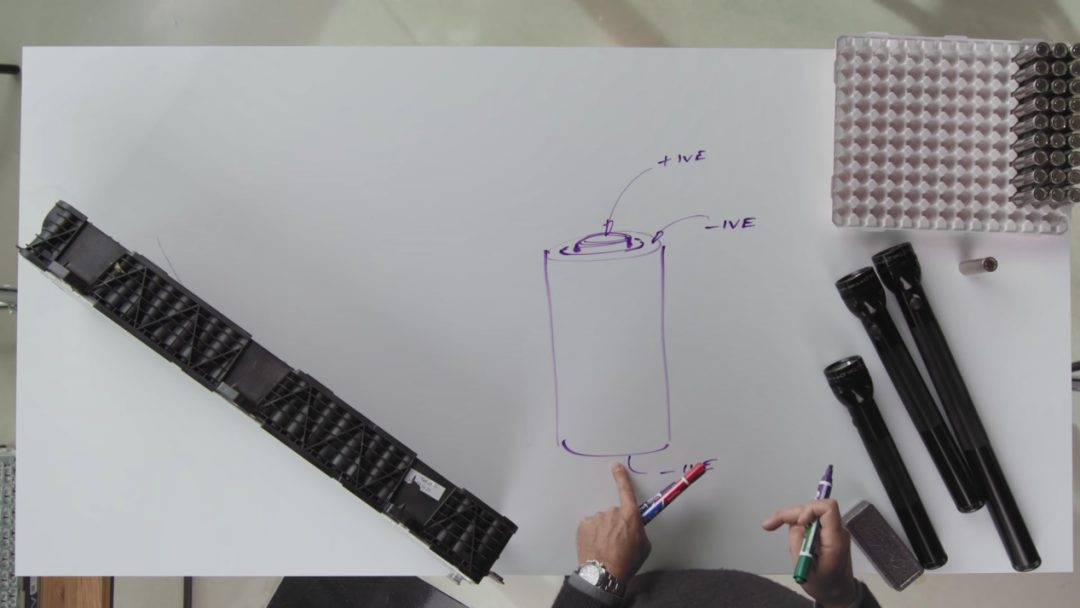

First, the positive and negative poles of the 2170 battery cell are both located at the same end of the cell.

This design, as we mentioned in our previous article about interpreting Tesla’s patents, has clear benefits. Interested readers can click here to view the article. With this design, all battery cells only need to be arranged vertically, and the series and parallel connections between the cells can be completed through positive and negative terminal connectors.

This design, as we mentioned in our previous article about interpreting Tesla’s patents, has clear benefits. Interested readers can click here to view the article. With this design, all battery cells only need to be arranged vertically, and the series and parallel connections between the cells can be completed through positive and negative terminal connectors.

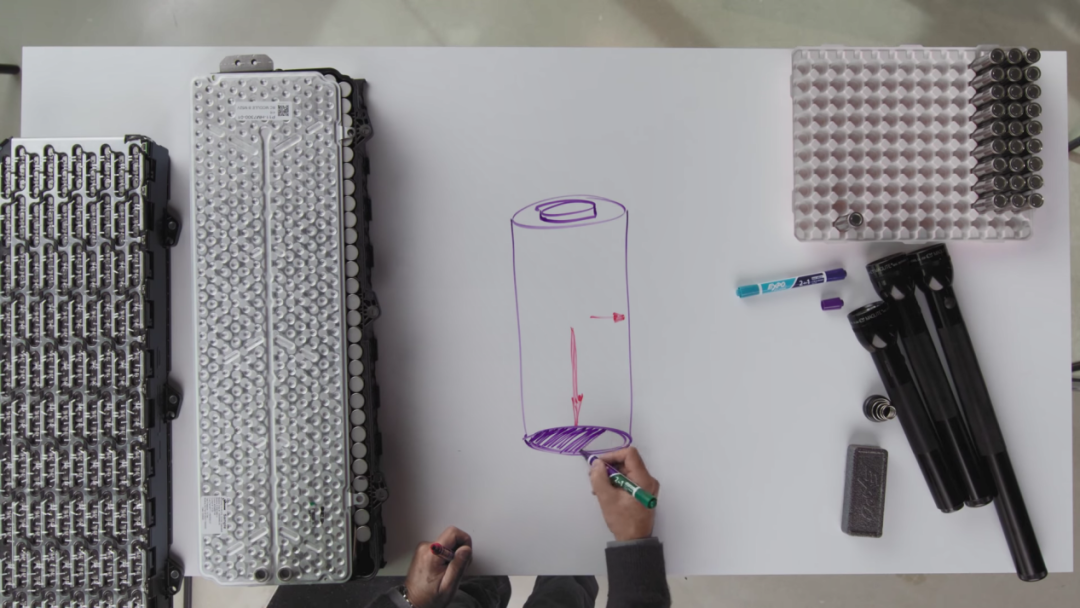

Secondly, battery connection technology.

When referring to these connectors, Peter mentioned a very trendy term, “one-piece die-casting.” Yes, these connectors are precisely manufactured using one-piece die-casting technology.

At the same time, Rawlinson also detailed why aluminum was chosen as the connector material. The primary function of the connector is conduction. The smaller the connector’s resistance, the lower the heat generation, and the higher the efficiency. From this point of view, we should choose the metal with the lowest resistance, silver. However, silver is too expensive. Combining the factors of cost and conductivity, copper became the first choice. But copper is relatively heavy.

In terms of comprehensive conductivity, cost, and weight, aluminum is the best choice as the connector material.

When welding the battery cells to the terminal connectors, Lucid also had its own idea.

To ensure safety, the usual practice in the industry is to weld fuses to the positive and negative terminals of each battery cell respectively. If a single battery cell short circuits, the fuse will instantly blow, disconnecting the battery cell from the battery module, thereby ensuring the safety of the battery module.

However, Lucid found that for a single battery cell, using two fuses was completely unnecessary. Firstly, as long as one end of the positive and negative electrodes of the battery cell is disconnected, the connection between the cell and the battery module is broken. Secondly, compared to ordinary connecting materials, the resistance of fuses is higher, resulting in lower efficiency.

Therefore, Lucid chose to weld a fuse to the positive electrode of the battery cell and a thicker ordinary conductor to the negative electrode.

After discussing a single battery module, connecting 22 battery modules in series yields an output voltage of 924V.

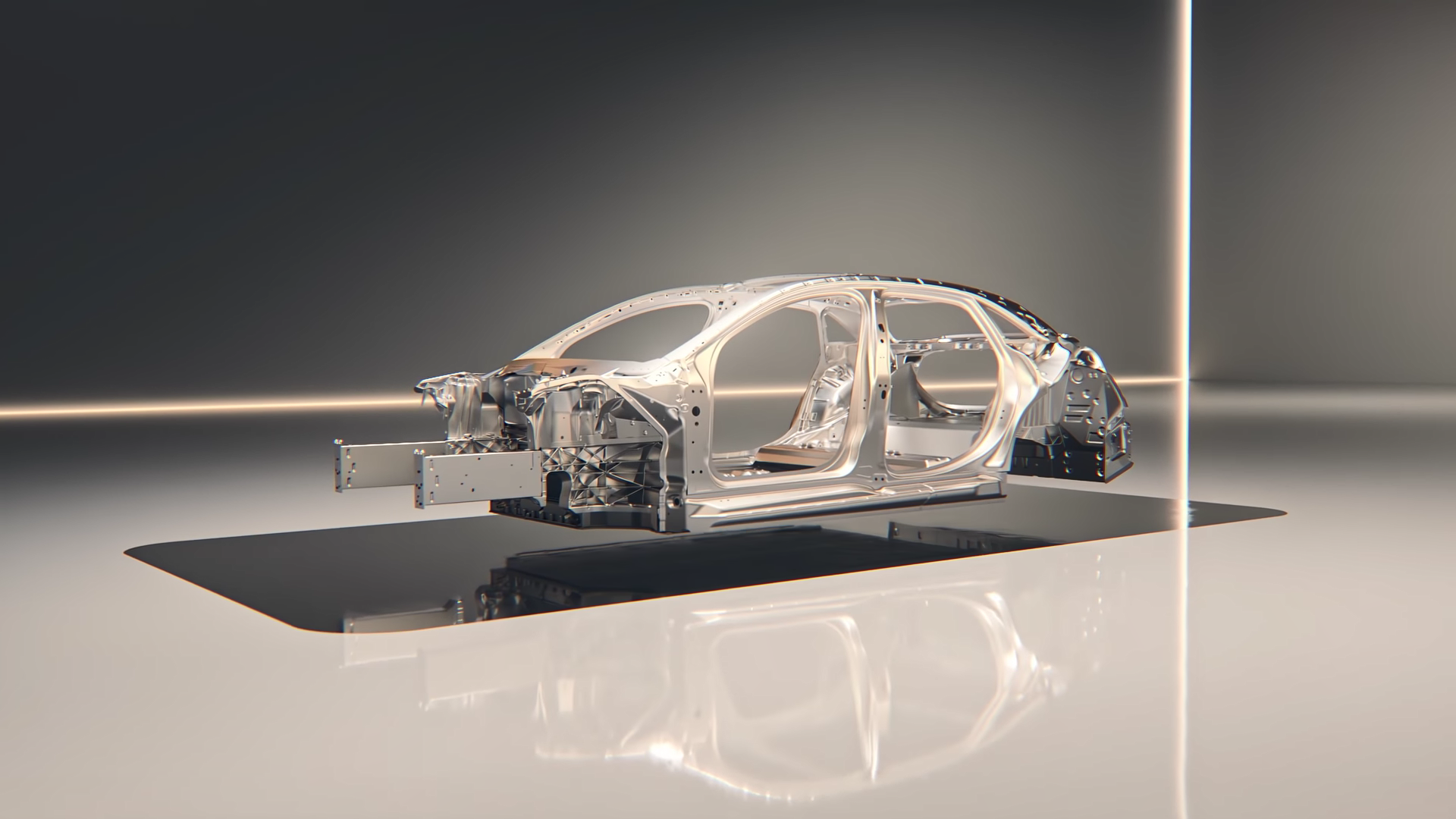

In summary, Lucid used a 220-series, 30-parallel connection method to assemble 6,600 pieces of 2170 battery cells into a 112 kWh, 924V battery pack.## A Unique Cooling Solution

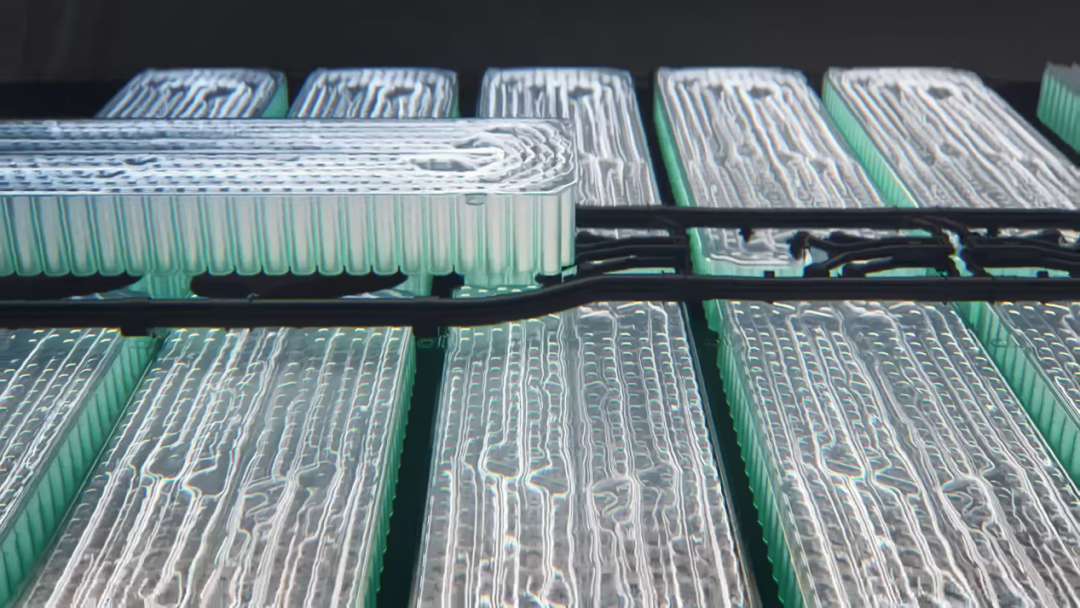

Rawlinson mentioned that the commonly used battery pack cooling solutions in the industry involve setting up cooling pipelines between individual battery cells. However, Lucid believes that this cooling method is highly inefficient for two main reasons.

- Battery Cell Heat Dissipation Problem

When battery cells are in operation, heat is emitted in all directions, but the heat conduction efficiency is not the same in different directions. Lucid found that the heat conduction efficiency in the longitudinal direction of the battery cell is much higher than in the horizontal direction.

As a result, the heat emitted during the operation of the battery cell congregates at the bottom of the cell.

- Efficiency Problem

The cooling pipelines arranged between battery cells have two problems. Firstly, the contact area between the cooling pipeline and the battery cell is not as large as expected, and in reality, the contact area is not continuous but intermittent.

Secondly, the cooling pipelines will occupy space in the battery pack, and the direct consequence is that the number of battery cells that can be accommodated in the same volume of the battery pack will decrease, thereby reducing the energy density of the battery pack.

Based on the above two points, Lucid adopts a cooling solution that is completely different from Tesla. Lucid cancels the cooling pipelines between battery cells and instead sets up a cooling plate at the bottom of the battery pack.

The advantages of this design include the following three points.

- Efficient Heat Dissipation

As mentioned earlier, the heat of the battery cells eventually accumulates at the bottom of the cells, and it is the most efficient to directly take away the heat from the bottom. Furthermore, the bottom of the battery cells is flat, and the contact surface of the heat dissipation plate is also flat. Therefore, the two flat surfaces can easily and tightly contact each other, further improving the efficiency of heat dissipation.

- Increased Energy Density

With the absence of cooling pipelines between battery cells, the cells can now be arranged closer together. This means that the energy density of the battery pack will be higher.

- Easy to Manufacture

The cooling plate is composed of two stamped aluminum sheets. Stamping is a production process that is very conducive to large-scale and mass production. Therefore, this cooling plate has lower costs, lower production difficulties, better consistency, and reliability.

Because Peter Rawlinson was once the chief engineer of Tesla Model S, and because Lucid Air and Tesla Model S have too many similarities in their technological structures, some people have told me that Lucid Air is just a Tesla Model S with a new shell.

However, in fact, we can feel that Lucid Air has its own soul from the technical details we have learned.

Just talking about the battery pack, we can feel that Lucid adheres to the energy-saving and efficient design concept from top to bottom.

This may also be one of the secrets why Lucid Air can win the first place in EPA range.

Lucid Air is a great car, but now its biggest challenge in competing with Tesla is the issue of insufficient production capacity.

According to Lucid’s 2021 financial report released earlier, affected by the supply chain issues such as chips, Lucid’s 2022 production forecast has been reduced by 40%, and the production capacity for the whole of 2022 is only enough to meet half of Lucid’s current pre-orders.

This also means that Mr. Chang, who has been thinking about Lucid Air, may not be able to buy it this year.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.