Skeleton “Light” Wonder

Bonded Aluminium Platform?

Let’s not talk about the new car for now. Because I want to go back to February 15th and talk about something else.

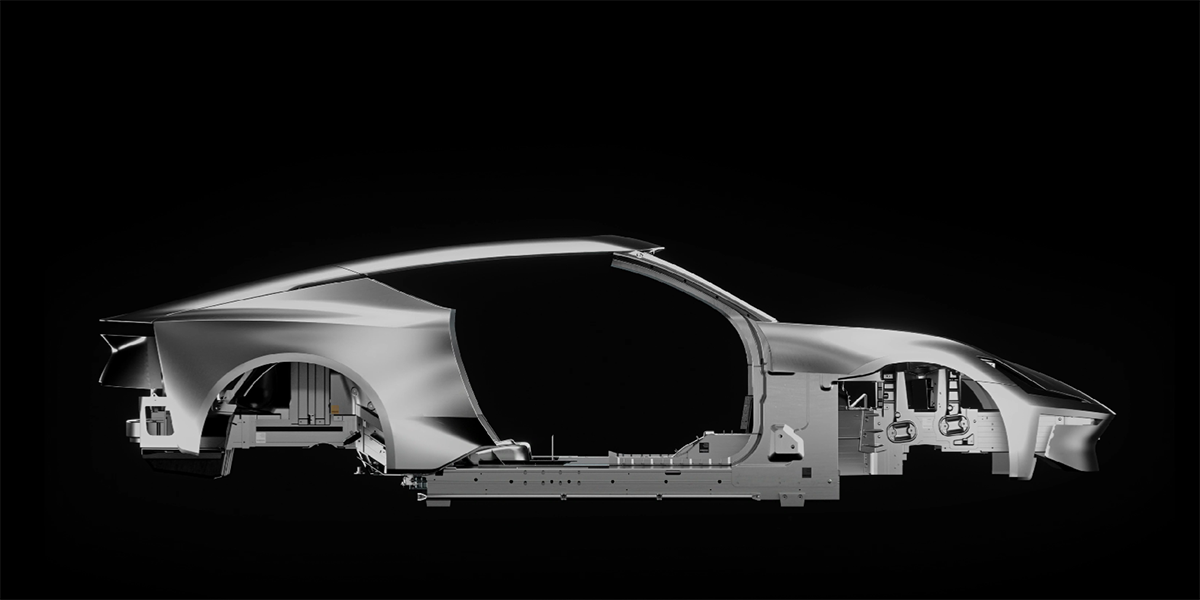

I was a little tired on the day after Valentine’s Day while Polestar, on the other side of the Eurasian continent, unveiled some details of its upcoming model Polestar 5 that is still under development. After seeing these images, I was once again thrilled. This car instantly made me feel that it could replace the Polestar 1, which missed the boat to become the true halo car of the brand.

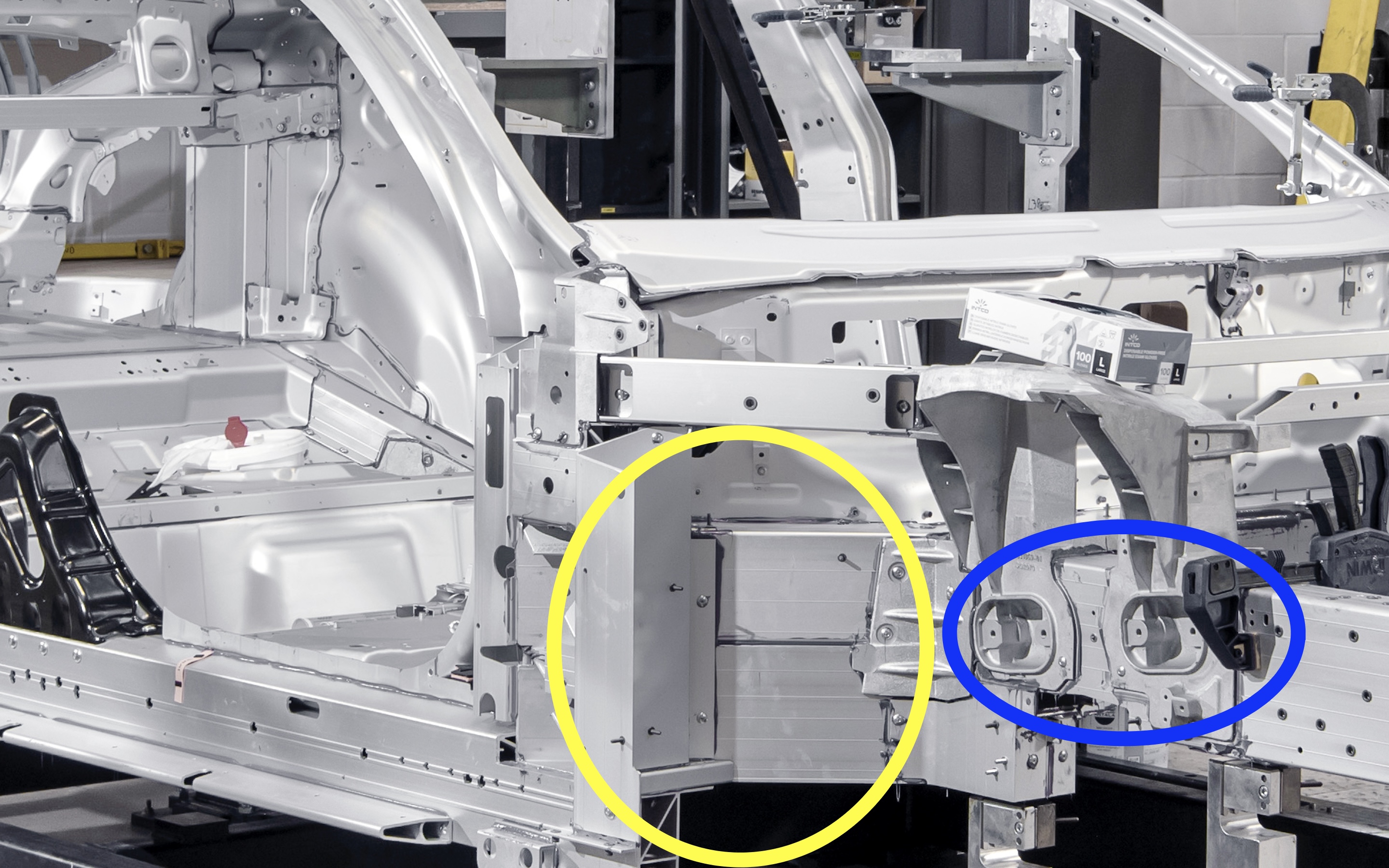

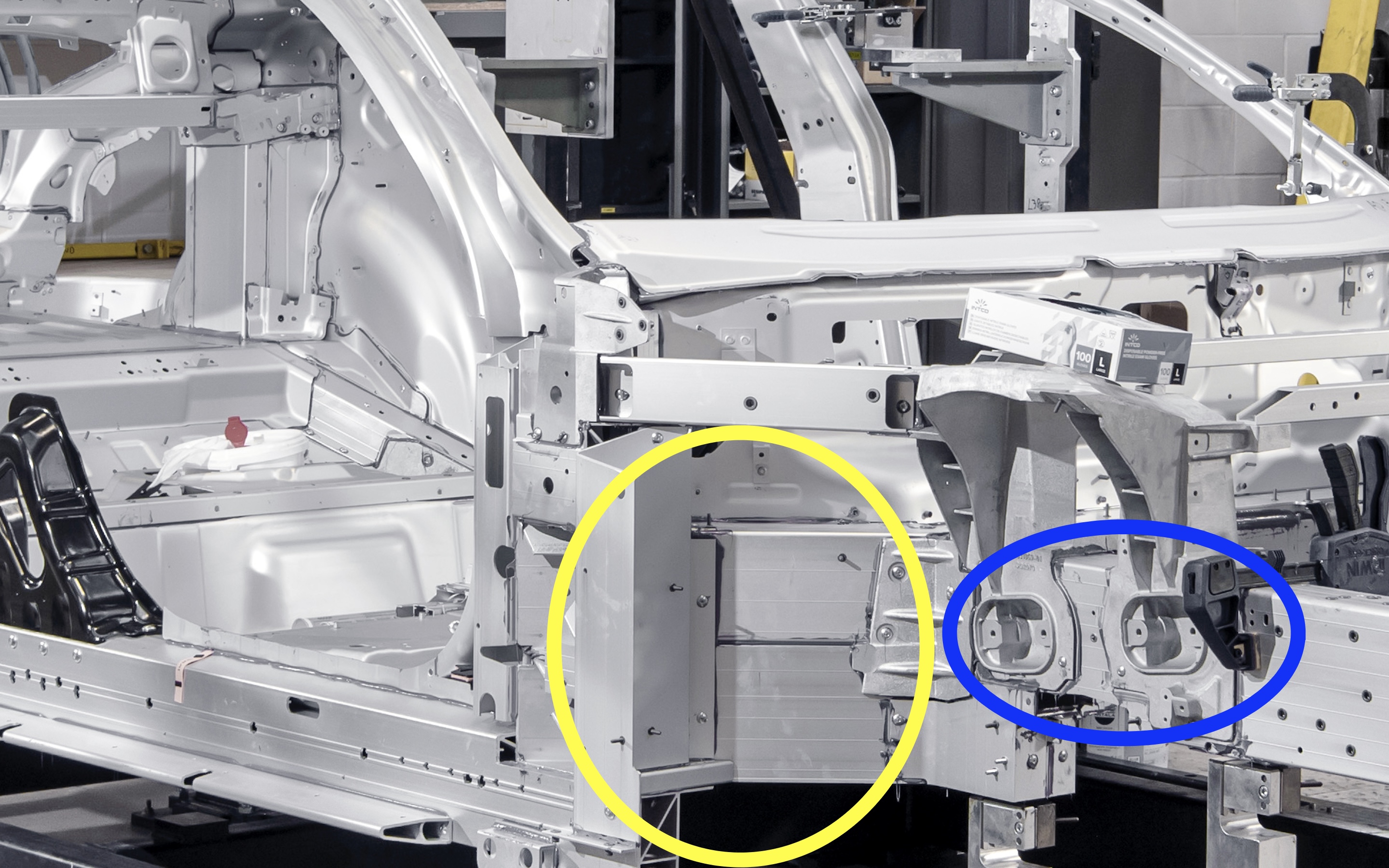

Why does a mere car frame excite me so much? Let me enlarge the pictures first.

If you spotted the paint bucket on the back seat and the Inke Medical (300677, a stock that many people are trapped in) brand gloves on the tower top, then congratulations, you’re completely off-topic.

The picture was taken at Polestar’s development center in Coventry, England’s “Racing Valley”. It’s normal for a development site to be a little messy.

Now, let’s refocus on the yellow circles. Can you see that these Brits don’t even know how to glue properly? No wonder the British automotive industry is declining… Sorry, the British automotive industry is indeed declining, but it is still the center of racing and sports car manufacturing in the universe.

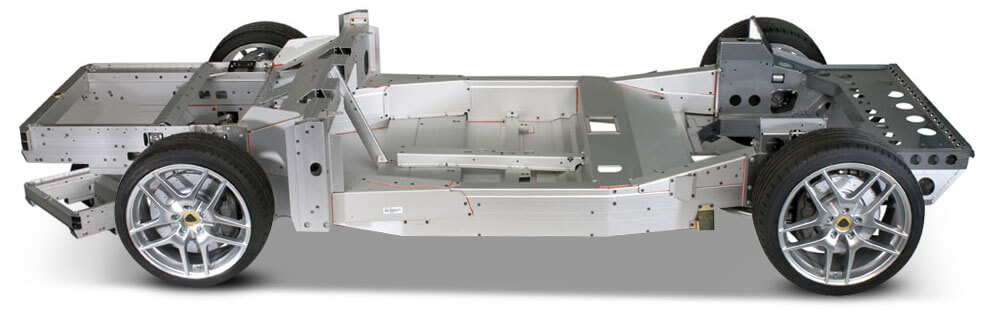

So, what’s the point of gluing here? And why are there many rivet-like things? Because this car uses a fully-bonded aluminium platform. As the name suggests, the production process of this type of chassis is to combine various shapes of aluminum alloys with special epoxy resins and rivets to achieve a stronger and lighter body.

So what’s so impressive?First of all, using aluminum alloy on the car body is more advanced than steel. Aluminum alloy has a lower density, so more materials can be used to optimize the structure and increase the body strength.

Connecting car body parts with glue has a decisive advantage over simple riveting or welding: bonding on a surface unit basis. Rivets can only connect two parts in a point-by-point way, and welding can achieve only a line-by-line connection.

Compared with these two methods, bonding the car frame with glue or epoxy resin can use thinner materials, while avoiding problems such as material deformation and changes in strength characteristics under welding heat.

Well, this is very British. Because most of these cars in the world come from the UK. For example, Lotus’ Elise, Exige and Evora, Aston Martin’s DB11, DBS Superleggera, and more niche Morgans.

However, the seemingly high-strength, lightweight, and obviously cheaper aluminum alloy adhesive platform also has its drawbacks.

The drawback is production efficiency. Each part needs to be glued and then wait for solidification, which obviously requires a lot of labor and is not a very suitable frame for mass production. However, Polestar claims that the 280 engineers from the UK R&D department of F1, small-batch sports cars and other professional backgrounds have found a way to mass-produce this type of frame.

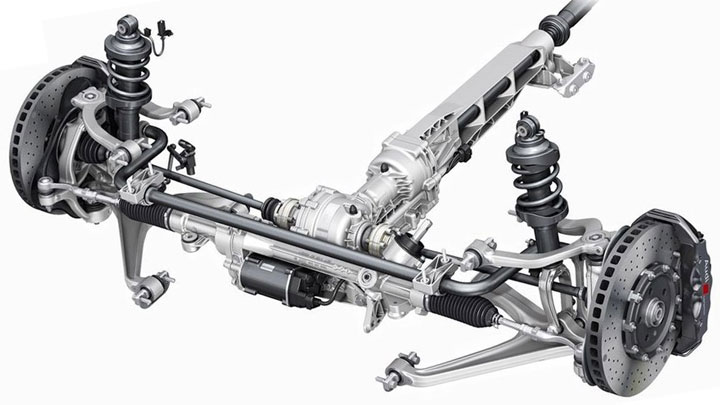

Is there also a bright spot in the suspension?In fact, Polestar emphasizes that the white body of the Polestar 5 will be lighter than vehicles one level lower while providing stronger torsional stiffness than 2-seater sports cars or supercars. Looking back at the pictures, it can be seen that the upper arm mounting position of the front double-wishbone suspension in the blue circle is significantly lower than that of normal models, usually referred to as low-position double-wishbone.

Double-wishbone is common in luxury models, but low-position double-wishbone is usually only found in supercars. The advantages of lowering the upper arm mounting position are many, the most obvious of which is that the horn part can be shortened, which is beneficial to lightweight, and it reduces the non-sprung weight, which is more important for handling.

Secondly, low-position double-wishbone has a smaller width restriction on the wheel hub and can also obtain a lower front-end line. However, due to the relationship between the mounting position and the lever principle, the strength requirements for the upper arm and its mounting position and bushing are increased, and it is obviously only suitable for higher performance chassis.

Therefore, the Polestar 5 will be the best-framed model in four-door sedans after the Logonda Taraf produced by Aston Martin.

In the era of electrification, performance indicators of power unit alone without emotional value are clearly insufficient to form sufficient differentiated competition. However, the material and form of the chassis and suspension can still distinguish the premium level of a vehicle. And the reason why the Polestar 5 makes me climax is that it can experience design and manufacturing processes comparable to sports cars on a four-door sedan.

Ah? Is such a good chassis only used for sedans?

Polestar O2

> Here it comes! This is the real Halo Car.

> Here it comes! This is the real Halo Car.

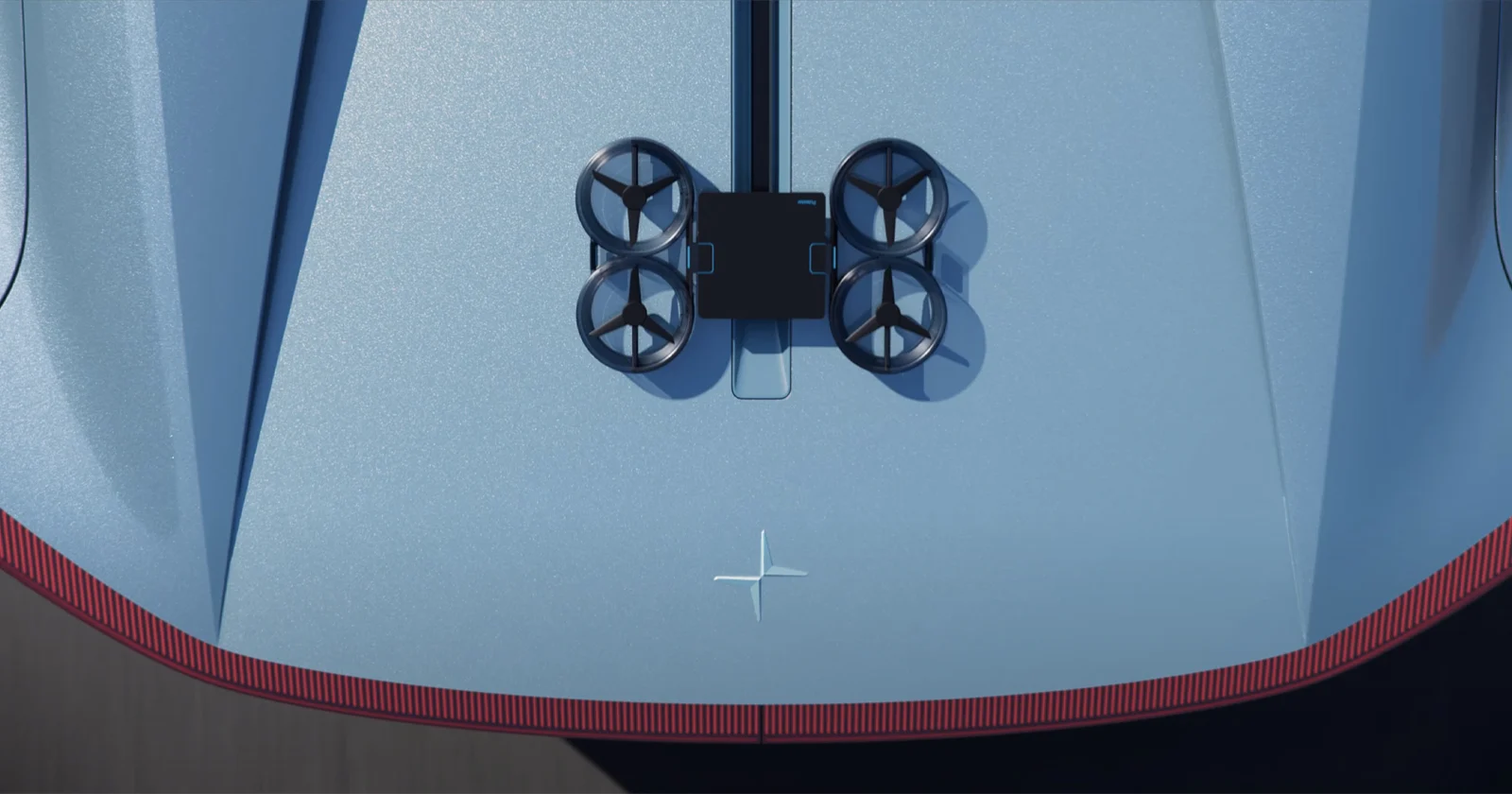

Hard Top Convertible 2+2, equipped with a drone

This is a production-model 2+2 electric hard top convertible that comes with an aerial photography drone that can automatically take off and land in the negative pressure zone at the rear of the car. The drone is made by AeroFugia, which is also an investment of Geely. The car features classic design elements of Polestar, but as a concept car, specific configurations and data are not the main focus. Therefore, I will introduce some innovative concepts that better represent its creativity.

Oh, by the way, it’s normal for a concept car to be a little bit vague. Success can be achieved if a concept car can move people’s hearts.

Take environmental protection to the extreme

Regarding the interior, the soft materials of the seat belt and seat, as well as other interior parts, are all made of the same material. Volvo calls this the “Mono-materials” concept. Because many materials are usually fixed together by bonding, it can be difficult to recycle these interior materials and it may lead to the production of useless waste. By unifying the materials, Volvo makes it possible to recycle more interior materials and reduce the burden on the environment.

Volvo has labelled every part of the aluminum alloy material in the vehicle body. The advantage of doing this is that the aluminum alloy can be classified and recycled when disassembling the car body, ensuring that the material retains the same mechanical characteristics after remelting.

Conversation with Design Director Maximillian Missoni

To learn more information, 42 Garage connected with Max in California.

Finally, the highlights of the interview are presented:

Is convertible easy to make?

Max indicated that currently, the focus of this car as a halo car is to showcase the potential of this adhesive platform, which is particularly difficult to achieve in terms of line design, while the mechanical details are assured by professional engineers.

Max indicated that currently, the focus of this car as a halo car is to showcase the potential of this adhesive platform, which is particularly difficult to achieve in terms of line design, while the mechanical details are assured by professional engineers.

Based on his response and the small-batch production of this platform, it is not difficult to speculate that this car seems to have the possibility of mass production. He also emphasized that the bottom battery of this all-aluminum adhesive platform is not flat, which will provide better rear foot space, similar to the ideas of Porsche Taycan and Lucid Air.

What does O2 mean?

To summarize Max’s response: literally, it means oxygen. The implication is that the convertible model can bring the pleasure of breathing in fresh air from nature, while also promoting the concepts of pure electric and environmental protection, providing clean air.

Are there any other color options available?

Max thinks this is a very good question. Regarding color choices, he used the word “astringent” to describe Polestar. If a brand offers all colors at the beginning, the impression presented by the brand’s design is actually not clear and lacks strength. Therefore, Polestar requires a more distinct visual tone to have a clearer visual message. To cater to more tastes, there will be more color options available in the upcoming models, of course, provided that they are carefully selected to fit the brand image.

What about the drone?

Max stated that this was a joint decision made by Polestar CEO Thomas and Geely Group President Li Shufu. The pleasure of driving should also include the joy of sharing.

However, taking pictures alone is not very meaningful. Regarding this, Polestar has made preliminary plans, which is to provide different shooting modes to choose from.

Of course, due to various regulations and engineering feasibility issues, such devices will have various conditions even if they are mass-produced. But this undoubtedly opens up more specific ways to play with drones. Whether Polestar will realize the drone concept proposed by the Porsche Taycan’s predecessor, the Mission E, remains to be seen. It’s better if it comes out, but it doesn’t matter if it doesn’t. Anyway, the really cool thing is still the Polestar 5. Anyway, let’s wait and see.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.