In October of last year, Fleva Automotive began independent operations, and the ES33 concept car was transformed into Fleva’s flagship model R7, quickly taking center stage.

During a media exchange meeting on February 24th of this year, the new CEO of Fleva Automotive, Wu Bing, stated that the new R7 would sell 10,000 vehicles by 2022. If sales started from the Beijing Auto Show, achieving this target would require a monthly sales of 1,300 units in the remaining eight months.

This number may seem practical, but we need to consider that the R7 is a pure electric SUV with a price point of less than RMB 400,000. The difficulty of this accomplishment is immediately apparent: every competitor in this price range on the domestic market is a strong contender, with high performance, intelligent features, design, luxury, cost-effectiveness, service, and energy supplementation all becoming required features for pure electric SUVs in 2022.

In addition to fierce competition regarding the product itself, brand labels have also gradually become increasingly important in this market during the car selection process.

So the question remains, what makes the Fleva R7 stand out?

PP-CEM™ Perception “Grand Slam”

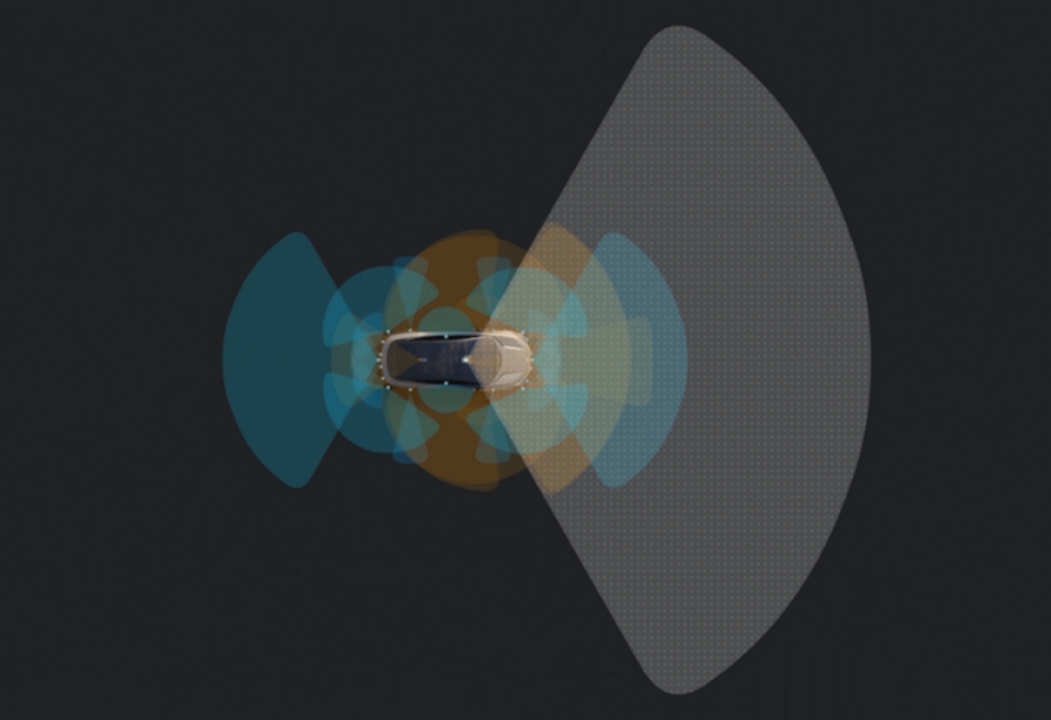

PP-CEM™ is a high-level advanced driving solution for pixel-level point cloud fusion developed by Fleva Automotive which stands for Pixel Point Cloud (multi-source perception system) and Comprehensive Environment Model (multi-dimensional environment model). This solution is equipped with 33 perception sensors of various types, enabling a 6-fold perception fusion plan with full-time, full-scenario, ultra-long distance, and multi-dimensional capabilities.

As the first model to apply this system, the Fleva R7 features the newest combination of laser radar and 4D imaging radar. This is probably the world’s earliest model to mass-produce with a laser radar, 4D imaging radar, 8 million cameras, and Orin X chips, achieving a “Grand Slam” in perception hardware. It is also probably the most precise, expensive, redundant, and most demanding advanced driving solution for fusion algorithms.

The core reason for Fleva R7’s use of high-level hardware and multiple redundant safety features is to achieve complete perception of corner cases. At present, when choosing and configuring hardware for automatic driving perception, OEMs generally consider cameras to be the primary perception hardware. However, when faced with some corner cases, due to the “lack of experience” for cameras, they cannot accurately identify all the information on the road, leading to recognition errors and hence potential dangers. For example, we often see cases where auxiliary driving systems incorrectly perceive white trucks as the sky, leading to accidents.

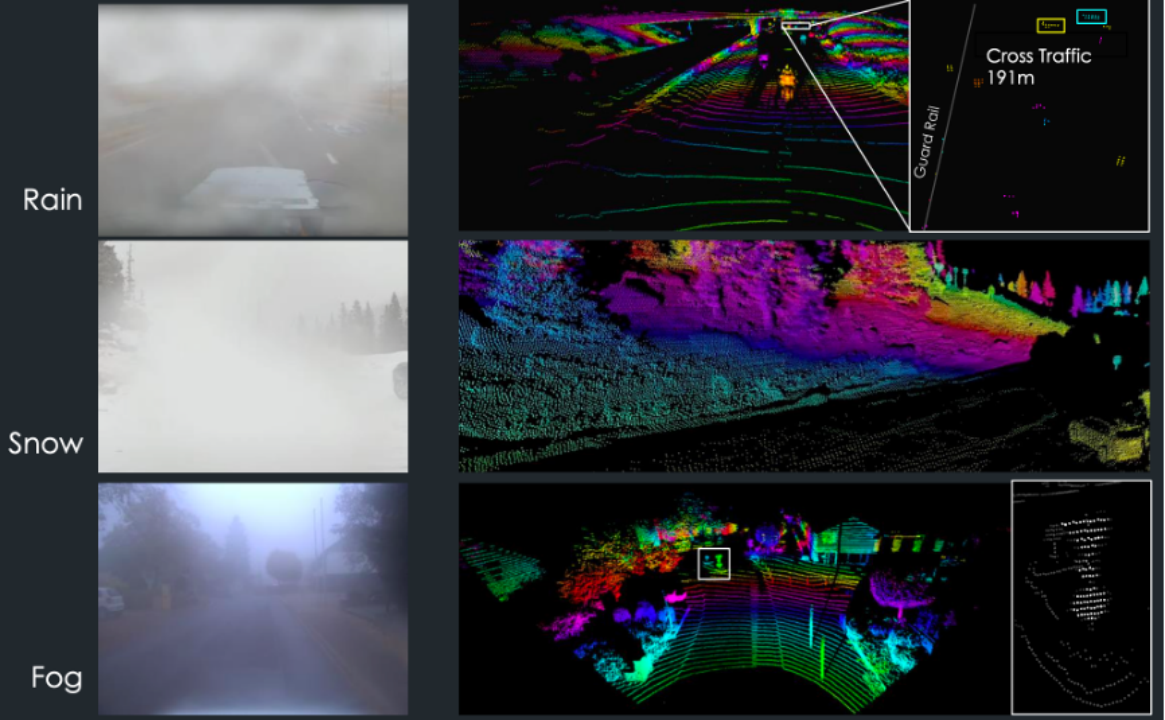

In extreme weather conditions, cameras can hardly function. For example, in heavy fog or sandstorms where even human eyes struggle to see, current ADAS systems are generally ineffective.

To address these issues, we need to increase safety redundancy. One way is to train cameras on infinite corner cases, as Tesla is doing with its “pure vision” approach. But in terms of perception, Tesla uses complex algorithms and feeds its neural networks with millions of images to achieve 3D signals which can be directly obtained by lidar or 4D radar.

Another mainstream solution to overcome camera perception limits is to expand hardware capabilities by adding various types of sensors. Lidar and 4D imaging radar are the common choices for multi-sensor fusion.

The Lidar is pretty powerful

Lidar has attracted the most attention among all sensors in recent years. Almost all high-end intelligent vehicles are equipped with Lidar. However, embedded Lidar technology needs to be redefined and constructed rather than just using industrial obstacle avoidance or mapping Lidar. Therefore, there are few mass-produced models available. It is not only the cost of Lidar that is at issue but also much controversy surrounding its performance, durability, and safety. After all, everyone wants to be the first to taste the crab, and the taste should be good.

Luminar’s flagship Lidar, called Lris, is a high-performance Lidar that fully meets automotive regulations. Lris is a rotating Lidar with a 120° x 26° field-of-view. At 10% reflectivity, it can detect objects up to 250 meters away.

Currently, mainstream Lidar manufacturers’ products, such as China’s DJI, VLD, and Valeo abroad, mostly use 905nm wavelength. But Lris has a wavelength of 1,550nm, which has stronger penetrating ability. It also performs better in spot quality and repetition frequency than 905nm, and this wavelength is also more friendly to the human eye.

Moreover, Luminar’s Lidar is flatter in shape and much smaller in size, making it easier to integrate into the vehicle body without affecting the overall design. In the event of a minor collision or scratch, the smaller size of Lris is also safer in probability.

This is the performance of Luminar lris in extreme weather conditions, as shown on the left camera which is almost unusable, but the laser radar has scanned 3D information hundreds of meters away without being greatly affected by rainy and snowy weather.

This is the performance of Luminar lris in extreme weather conditions, as shown on the left camera which is almost unusable, but the laser radar has scanned 3D information hundreds of meters away without being greatly affected by rainy and snowy weather.

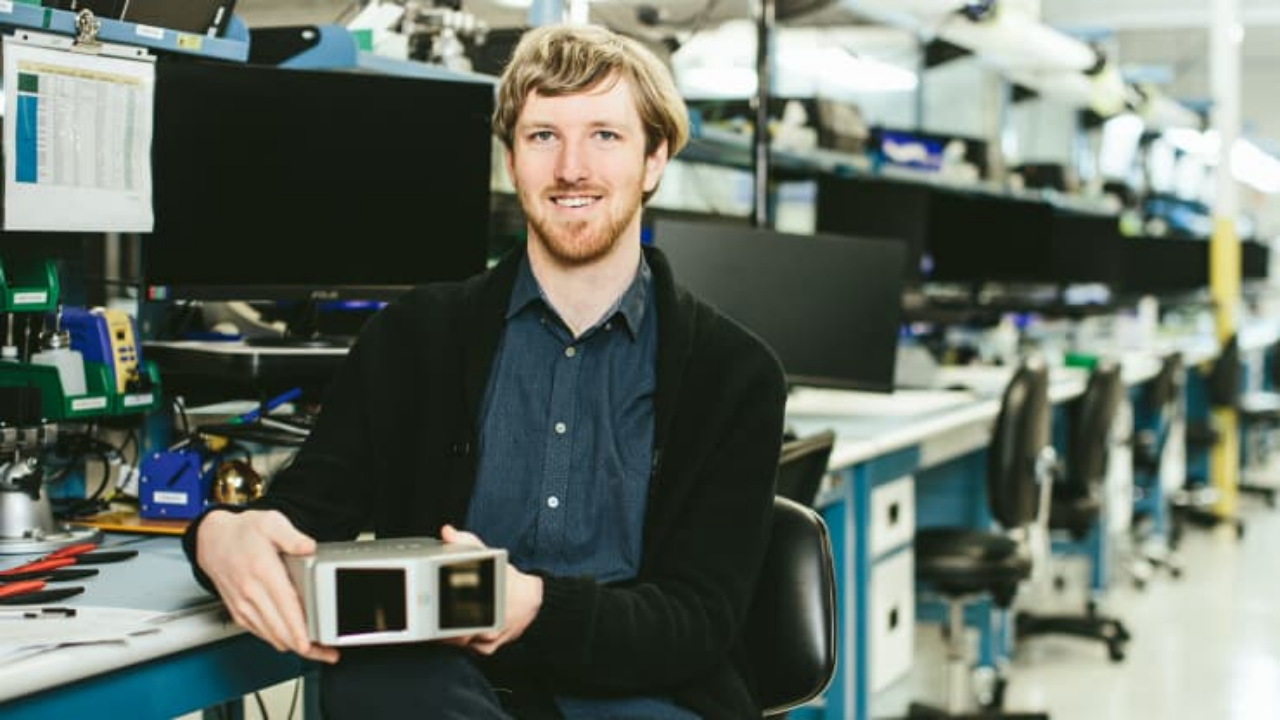

Driven by Austin Russell, a post-95s genius, Luminar not only went public at the end of 2020, but also successfully solved the cost problem of indium-gallium-arsenide materials for receiving sensors and the supply chain bottleneck issue by acquiring Black Forest Engineering, a company specialized in this field, and developing its own ASIC chips. By mastering the initiative in production, Luminar can better ensure the manufacturing needs of car manufacturers and customers.

As a technology rising star, Luminar has always been very cautious in choosing partners. Its clients include giants in various fields such as Mercedes-Benz and Airbus. But as expected, the FAW R7 will be the first mass-produced car equipped with the Luminar lris laser radar, which I am looking forward to.

FAW and Luminar are “bireciprocal selection”, as FAW sees the superior performance of Luminar lris, while Luminar believes that the laser radar can maximize its performance in the FAW R7 PPCEM™ solution, and can be quickly put into production with the support of the global supply chain established by SAIC.

Be patient, there is 4D imaging radar

In June last year, Tesla cut off the millimeter wave radar for the North American Model 3/Y and turned to a pure visual perception solution.

This is inseparable from the inherent disadvantages of millimeter wave radar, because it cannot detect height information and has low longitudinal resolution, making it difficult to be used as an effective reference. Therefore, when facing some stationary objects, millimeter wave radar is easily “nervous”, such as when crossing gantries and bridge piers, there is a probability that vehicles using mixed perception of camera and millimeter wave radar may experience “ghost braking”. Another reason is that under batch sales, Tesla can save a lot of costs by removing millimeter wave radar.

The 4D imaging radar not only provides vertical height recognition, but also has a much higher overall resolution than millimeter wave radar. In theory, the 4D imaging radar can not only achieve more precise identification in scenarios such as passing through gantries and bridge piers, but also directly identify objects such as cones, road signs, and stationary vehicles due to the improvement in resolution. Moreover, because the radar emits electromagnetic wave signals, the work performance of 4D imaging radar is still excellent in rainy, snowy, and dusty weather, which can compensate for the problem of reduced recognition ability of cameras and lidars in harsh weather conditions.

The 4D imaging radar not only provides vertical height recognition, but also has a much higher overall resolution than millimeter wave radar. In theory, the 4D imaging radar can not only achieve more precise identification in scenarios such as passing through gantries and bridge piers, but also directly identify objects such as cones, road signs, and stationary vehicles due to the improvement in resolution. Moreover, because the radar emits electromagnetic wave signals, the work performance of 4D imaging radar is still excellent in rainy, snowy, and dusty weather, which can compensate for the problem of reduced recognition ability of cameras and lidars in harsh weather conditions.

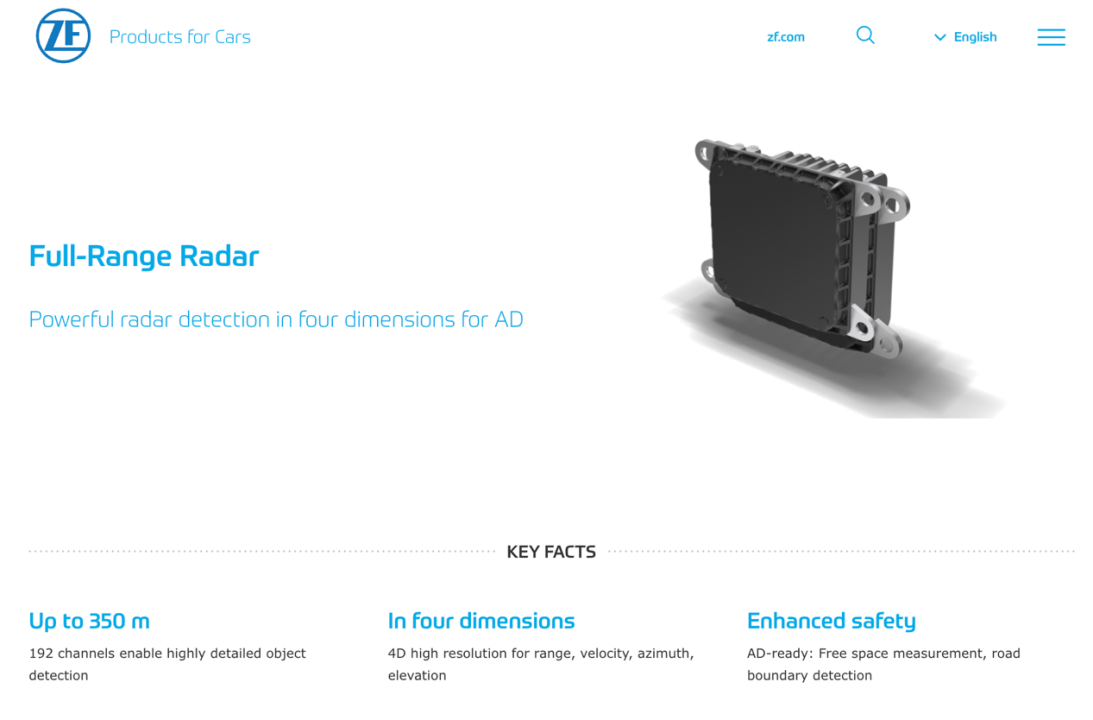

The first-ever mass-produced Nvidia Orin X chip is adopted by Feiteng R7, which provides powerful computing capability for this complex perception hardware. The premium 4D imaging radar from ZF mounted on Feiteng R7 can achieve a detection range of up to 350 meters, while the detection range of traditional millimeter wave radar is generally less than 250 meters. Although lidars have already provided strong perception redundancy for the entire set of perception hardware, the addition of 4D imaging radar further deepens the safety redundancy.

For the entire intelligent electric vehicle industry, the comprehensive supplement of 4D imaging radar and lidar for perception hardware has brought Feiteng R7’s perception hardware to the pinnacle of imagination. However, this sophisticated perception hardware generates a huge amount of data in real-time. Therefore, Feiteng R7 needs to be equipped with a powerful computing platform.

Feiteng R7 adopts the Nvidia Orin X chip, the most powerful autonomous driving chip, which has single-chip computing power of 254 TOPS and 7 times the computing performance improvement over the previous generation Xavier chip, while controlling power consumption below 55 W. On Feiteng R7, we will see up to two of these chips, providing computing power of 508 TOPS.

As the flagship product of Feiteng brand this year, Feiteng R7 not only has top-notch perception hardware, but also other configurations that are inclined towards resources of SAIC Group’s latest three-electricity technology platform, such as high-density batteries, oil-cooled electric drive, and flat wire motor.

In terms of intelligent driving systems, having strong hardware alone without matching excellent algorithm software as support still cannot achieve a good user experience. This is like a physically strong person without a smart brain, who cannot become a master. Therefore, let’s look forward to the actual experience that Feiteng R7’s “grand slam” perception hardware can bring us.

Three-Electricity# RISING POWER Energy Solution: Flyaway R7

Flyaway officially refers to their three-electric system as the “RISING POWER” energy solution. As for the battery, the Flyaway R7 uses NCM 523 cells with a chemical formula that is safer and more stable than 811, and increases its energy density to 195 Wh/kg, supporting a range capacity of more than 600 km.

By utilizing a double-layer horizontal cell layout, Flyaway also reduced the thickness of the battery pack vertically which not only improves energy density but also the cabin space design. Additionally, the contact area between cells is reduced, further reducing heat dissipation, and combining with a five-core battery thermal management system using aviation-grade insulation material aerogel, the battery reached a safety level of L0 with no heat spread.

Moreover, the Flyaway R7 incorporates the QUICK CLICK patented battery swapping system, which allows for battery replacement and upgrades. Flyaway claims the entire swapping process can be completed in as little as 2.5 minutes and can meet quick swapping needs 5,000 times, three times more than the national standard requirements. It also supports the replacement of batteries with different energy densities after further advances in battery technology.

The swappable and upgradeable battery does guarantee the range, and the efficiency and performance of the motor are also noteworthy for the Flyaway R7.

The Flyaway R7 uses the brand new 8-layer Hair-pin motor. With more current flowing through the winding, the more significant its power output; the lower the resistance, the higher the efficiency. Therefore, all motor manufacturers try to fit as much copper wire as possible into the limited space to improve power density and energy consumption levels.

Hair-pin, commonly known as a “hairpin” stator, uses flat-wire design to fit more copper wire, and the Flyaway 8 layers Hair-pin further increase the surface area of the winding, effectively improving efficiency and performance.

Currently, the Flyaway R7 is available in single and dual motor four-wheel-drive models, with the latter having a peak power of 400 kW, peak torque of 700 N.m, and a zero-to-60 time in the 4-second range. To maintain peak performance for an extended period, the motor uses a direct pour cooling system with higher heat dissipation efficiency. Everyday driving scenarios such as continuous acceleration and high-speed cruising would no longer compromise the motor’s performance which makes me excited to see how the car performs on the race track.

The Third SpaceCompared to the intelligent driving process, recently the focus has been on the internal intelligence of the cabin. Guided by the concept of the “third space”, the RisingAuto R7’s intelligent cockpit is no less advanced than its intelligent driving capabilities:

- A 43-inch true color triple screen crosses the cabin

OLED display panels are now a major trend in automotive entertainment systems, and the RisingAuto R7’s center console uses an OLED panel with a size of 15.05 inches that has a resolution of 2.5K (2560*1600, 201 PPI), covers 100% of the NTSC color gamut, has a contrast ratio of 1,000,000: 1, and a refresh rate of 60 Hz. This screen brings desktop-level display quality to the cabin of the car.

- A large screen AR-HUD head-up display system

The AR-HUD system in the RisingAuto R7 is provided by Huawei’s optical products, which offer a wide viewing angle of 13°x5°. Thus, at a distance of 7.5 meters, it can display a huge area of information while only taking up 10L of space. This increase in area and display quality enables the AR-HUD to perform many functions, such as projecting movies, in addition to simply projecting vehicle information and navigation. I am also curious what else the RisingAuto team can do with this AR-HUD.

- Qualcomm Snapdragon 8155 chip

This is currently the most mainstream flagship chip, manufactured on 7nm process technology. The NPU can achieve 8 TOPS of computing power, and has 16GB of memory, which makes the overall performance three times that of the 820A.

In the “third space” of automotive technology, hardware configuration and basic infrastructure are the biggest stumbling blocks in technological breakthrough. In the RisingAuto R7, these base problems have been resolved based on the hardware and architecture. The next challenge for RisingAuto is how to build a service truly oriented towards SOA on this hardware to surpass the new players in the industry.

Conclusion

To exaggerate a bit, the RisingAuto R7 is loaded with all kinds of “trendy” hardware that we often read about in the news. Regardless of the type and performance of the perception hardware, or the configuration of the three-electrical systems, and the cabin, we can perceive RisingAuto’s sincerity in the hardware selection in the R7.

Recently, RisingAuto Automotive and SAIC Motor Corporation’s Innovation Research and Development Institute announced the establishment of the RisingAuto Design Co-Creation Center and the RisingAuto Intelligent Driving Co-Creation Center. This indicates that both RisingAuto and the SAIC Group take the RisingAuto R7 very seriously.

This makes me very curious about the price of the RisingAuto R7 and the performance of the mass-produced version of the software. I believe that at this point, everyone shares my expectations as well.

And what I may expect from FAW-Volkswagen could be exactly what FAW-Volkswagen has been craving for. It is not until the launch of FAW-Volkswagen R7 that the consumers’ unfamiliarity with FAW-Volkswagen is slowly fading away.

To keep investing in the right thing is a necessary condition for the success of FAW-Volkswagen R7 and even the entire SAIC in the second half of the competition. However, what could be the sufficient condition for success? I think we’ll find out the answer after the release of FAW-Volkswagen R7.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.