Wanbo from the copilot temple

Reference for intelligent cars | Public account AI4Auto

The recall incident has exposed the enormous domestic supply network behind Chinese-made Teslas.

From the core three-electric system to the body sheet metal, to the charging gun, and even to some of the hardware of the automatic driving system, they are all contracted by domestic suppliers.

So, in addition to the FSD chip, Chinese-made Teslas have achieved complete “domestication.”

Recalls brought up the “supply chain”

Recently, Tesla recalled some Chinese-made Teslas in China. This in itself is not surprising, as recalling vehicles is a routine operation for Tesla.

But unexpectedly, this recall incident brought to the surface a local stakeholder behind a Tesla–Sanhua Zhikong.

The reason for the recall is that the positioning of the electronic expansion valve of some Chinese-made Teslas will have a slight movement, and because the software (version 2021.44 to 2021.44.30.6) lacks a correction function, it may cause the valve to open, the heat pump compressor to stop working, and the vehicle’s heating function to fail.

And Sanhua Zhikong is the supplier of the electronic expansion valve for Chinese-made Teslas, and the core business of this company is mainly control components for refrigeration, air conditioning, home appliances, and automotive parts.

After the recall incident occurred, rumors circulated in the market that the recall was caused by hidden dangers in the electronic expansion valve that Sanhua Zhikong provided to Chinese-made Teslas.

In response to this, Sanhua Zhikong issued a notice in the first time, saying that it is not their responsibility.

In the announcement, it was stated that the Tesla recall event was mainly due to communication interruptions in the vehicle controller and had nothing to do with the electronic expansion valve itself.

Although Sanhua Zhikong is not involved in this matter, as a supplier of the world’s largest electric car company, they are already a “community of common interests.”

Digging deeper, such a community of interests in Chinese-made Teslas has become a huge circle of friends.

Who are the Tesla domestic suppliers?

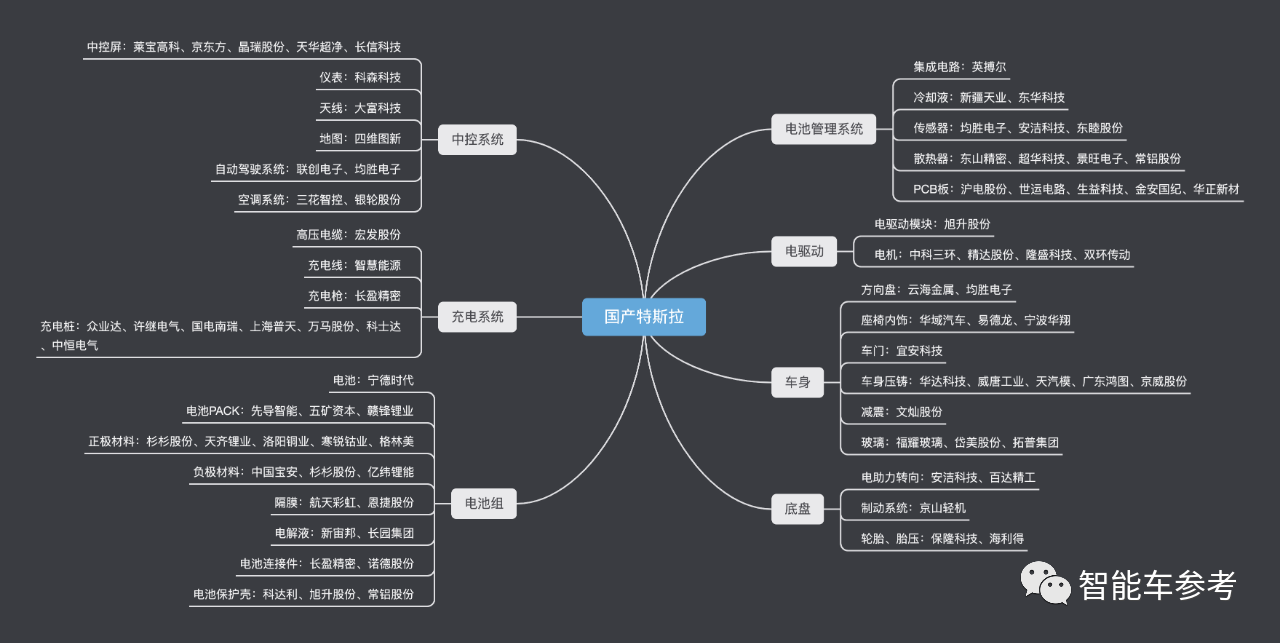

To disassemble a Tesla, the core components are nothing but the three core elements of an electric vehicle, the chassis, the center control of the cockpit, the body sheet metal interior, and the charging system.

So, how many domestic suppliers provide these core components?

The Intelligent Car Reference has sorted this out.

On the battery side, the largest power battery supplier for domestically produced Tesla’s battery pack is Contemporary Amperex Technology Co., Limited (CATL), supported by a huge Tier 2 industry chain, which includes various segmented links from battery packs to positive and negative electrode materials. There are also outstanding companies in this industry, such as Ganfeng Lithium, Tianqi Lithium, and Sanyuan Shares.

Xuray Technology provides the electric drive module, while the electric motor part is provided by companies such as Three-ring Systems Co., Ltd., and Jingda Shares.

In terms of the central control system, the central control screen is provided by companies such as BOE Technology Group, Crystal-Optech Co., and Tianhua Ultra-Clean Technology Co. Lcsoft is the supplier of visual sensors related to Tesla’s autopilot, and the high-precision map is supplied by Navinfo Co., Ltd.

In addition, there are also domestically produced Tesla’s charging system, vehicle body forging, battery management system (BMS), and chassis, which all have a vast network made up of numerous Tier 1 and Tier 2 stakeholders.

Overall, the domestic automotive component suppliers behind domestically produced Tesla cover almost all subsystems of new energy vehicles, including the three electric components, vehicle stamping tools, chassis, interior decoration, and central control, except for Tesla’s autopilot chip and algorithm.

In other words, for domestically produced Tesla, apart from the autopilot chip and algorithm, almost all components are “Made in China”.

For Tesla, domestication brings visible benefits to cost reduction and production capacity increase.

Digging deeper, looking outside, for the entire domestic electric vehicle industry, domestically produced Tesla is also an excellent demonstration effect.

How strong is the demonstration effect?

For domestic friendly competitors, especially new forces, domestically produced Tesla brings not only competition but also a stable and sound supply chain.

After all, compared with fewer than 10,000 monthly production volumes of auto manufacturing new forces, it is too costly for suppliers to establish dedicated production lines to meet their demand.

However, under the huge scale effect of domestically produced Tesla, the marginal cost of building production lines is reduced, and many commonly used automotive components can benefit from car manufacturers that have not yet achieved mass production.

As for NIO, XPENG, and Li Auto, nearly all of there models use CATL batteries.Below is the translated English Markdown text, preserving the HTML tags inside the Markdown:

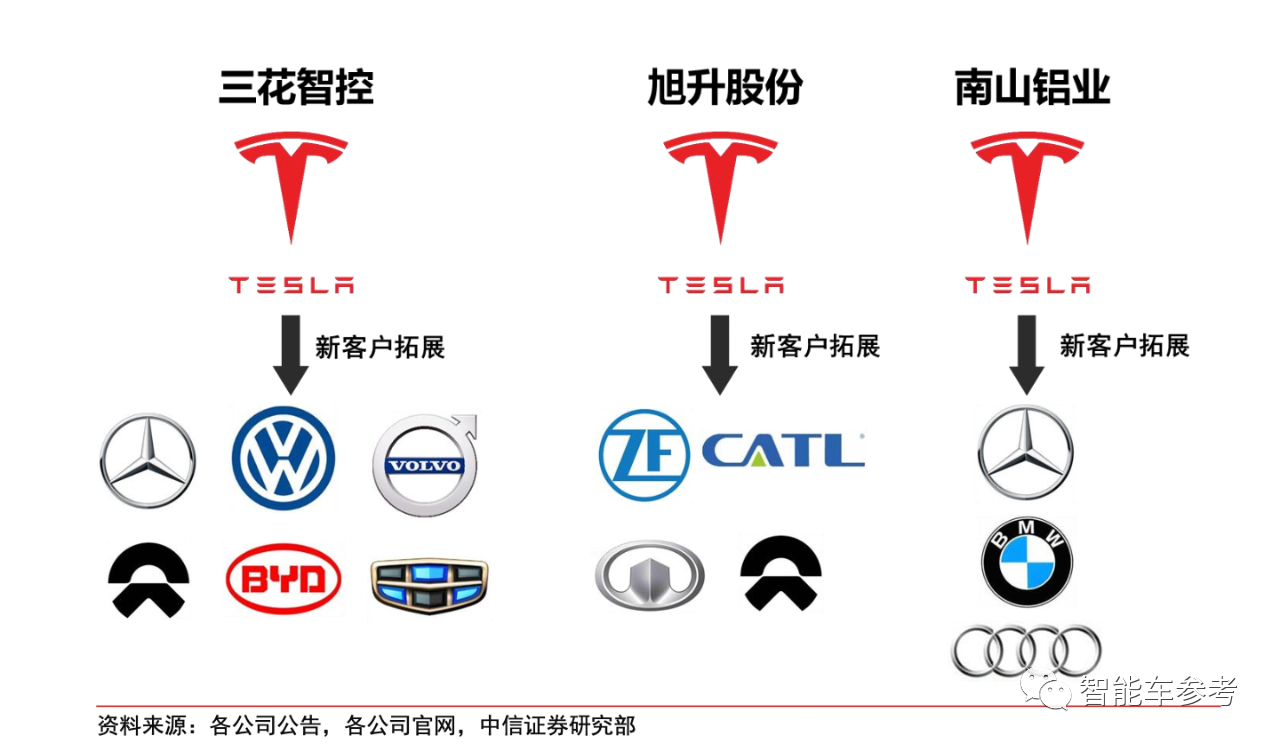

Affected by the recall event, Threes Intelligent Control–after becoming a supplier for Tesla–expanded to serve major customers like NIO, BYD, and Geely.

Analogously, Xusheng Stock, responsible for domestic Tesla electric drive modules, joined the supply chain of companies like NIO and Great Wall after Tesla.

For stakeholders, Tesla brings new business growth points.

Taking Threes Intelligent Control as an example, its 2020 financial report showed that due to the epidemic, the revenue growth of its core business–refrigeration and air conditioning electrical components–was sluggish, with a YoY increase of only 0.04%. However, under the trend of new energy vehicles, the revenue of its automotive parts business rose against the trend, with a growth of 49.57% over the previous year and an increase of 6 percentage points in revenue proportion, becoming its new growth engine.

In 2021, the growth of Threes Intelligent Control’s automotive parts business further accelerated. By the end of June last year, the relevant business grew by 122.14% YoY, with an increase of 7 percentage points in revenue proportion.

A single set of financial data is not only about how domestic Tesla is good for players on the local industrial chain. However, to some extent, the “shark effect” of introducing Tesla does not only affect friendly competitors in the same field.

Behind the scenes, the rapid development of the entire new energy vehicle industry has driven players in the entire industry chain and the direction of the traditional automotive industry chain.

one more thing

Localization manufacturing seems to have always been Musk’s production philosophy. This approach is not only in China; Musk has also said that the Teslas made in the US have the highest “made in America” ratio of any American automobile in history.

This production method of seeking maximum localization seems to run counter to the approach of mainstream OEMs to have a distribution network that spans the world.

However, the benefit of this localization strategy is the supply chain is stable enough, the physical distance from the vehicle production site is closer, which can reduce costs and avoid the risk of being choked by one aspect of the global supply chain.

So for those who believe that Musk could rely on domestic production…

They are mistaken.

— Complete —

“`

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.