The content of this article is sourced from 42how and has been translated by ChatGPT

Battery Stability

On October 29th of last year, Volvo Cars successfully went public in Sweden. Its current market value is equivalent to more than RMB 300 billion, or 30 times the USD 1.8 billion it was acquired for by Geely 12 years ago. Of course, in addition to providing Li Shufu and option-holding old employees with decent returns, Volvo itself has also gained a healthier cash flow.

So, what do you do with the money when you get rich after going public?

Invest, of course, in a fully electric transformation.

Volvo Cars recently announced that it will invest approximately RMB 21 billion in battery manufacturing. This funding will also be injected into a battery manufacturing plant built by Volvo and the Swedish domestic battery manufacturer Northvolt in Göteborg, Volvo’s headquarters in southern Sweden. This plant has a planned annual output capacity of 50 GWh and there will be a research and development center as well.

The new plant is scheduled to start construction in 2023 and begin production in 2025, supplying batteries for 500,000 Volvo pure electric models and high-end sub-brand Polestar pure electric models per year.

Cars?

New bottleneck

Together with the Swedish version of CATL, Volvo has secured future battery supplies. However, according to data, the annual production capacity of the Torslanda plant is only 300,000 units, which seems to fall short of the future 50 GWh battery capacity.

In other words, the production of car bodies must keep up with the production of battery packs. So, after getting rich from the IPO, Volvo continues to spend money, and recently announced that it will invest about RMB 7 billion in the Torslanda Manufacturing Plant in Göteborg over the next few years to prepare for the production of the next-generation pure electric cars.

Casting

I saw an official press release from Volvo these days, which stated:

As part of the planned investment, the company will introduce some new, more sustainable technologies and manufacturing processes in the factory. These include introducing large-scale aluminum casting technology for body parts, new battery assembly plants, and a fully refurbished paint and final assembly workshop.

Wait a minute, “large-scale aluminum casting technology for body parts” is just integral casting, right?“`markdown

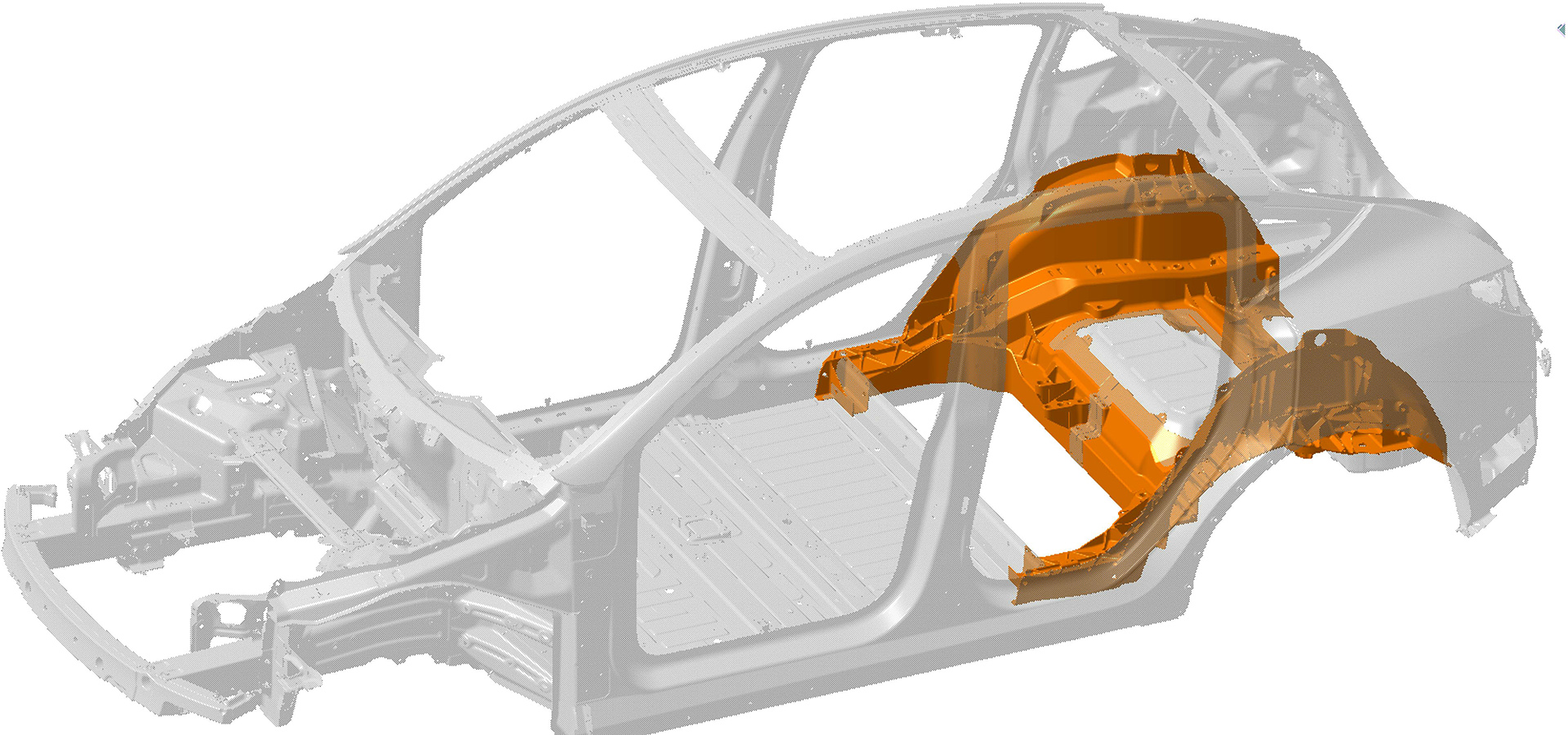

After watching the video, I found that it is true. Volvo also wants to produce cast-body cars. The accessories are almost the same as those of Tesla Model Y, and both have chosen the position of the rear floor.

In addition to Nio’s announcement last year that it has successfully developed heat-treated aluminum alloys for die-casting, and XPeng’s Wuhan factory will import large-scale die-casting equipment, Mercedes-Benz’s EQXX concept car displayed at CES also showed an organically shaped aluminum cast rear floor.

In addition, there are reports that Ford and BMW will also use integrated casting technology in some new-generation models. However, Volvo’s one-piece casting solution called “Megacasting” is one of the players with the most specific timeline, in addition to Tesla, where it has already been implemented.

What is Megacasting?

What are the benefits of die casting?

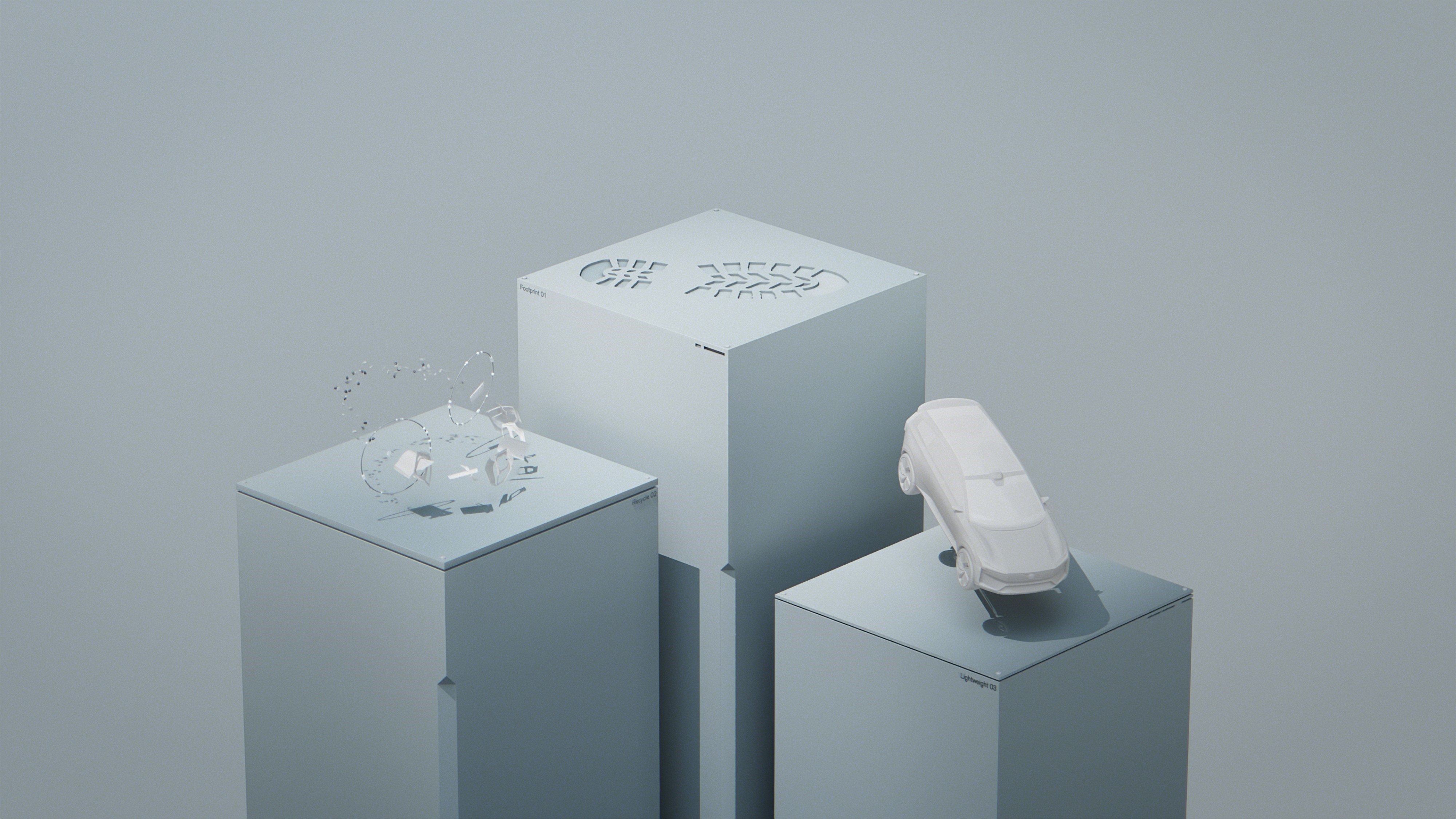

From this official promotional video screenshot with a strong Nordic design style and a bit of a restrained style, Volvo believes that one-piece die-casting has three main advantages.

“`1. Reduce the number of parts;

- Reduce carbon footprint;

- Reduce vehicle weight.

These are interrelated and mutually supportive factors, far from being contradictory.

A single aluminum rear floor can reduce weight and increase the driving range of vehicles. Integrating this component eliminates some heat treatment and welding processes, simplifying production complexity. The removal of excess waste on site can also be reused by melting it down, saving costs in terms of materials and logistics, and reducing the overall impact of the manufacturing process and supply chain on the environment.

If you’re looking for more information on this technology, you can check out my previous article on the topic, Don’t Talk About Production Volume, Talk About Casting Volume!.

If you’ve made it this far in just 2 seconds, you may still have concerns about the inability to repair integrally cast components.

Well, you can rest easy. Even if the process uses punching and welding techniques, if your car is rear-ended to this extent, it’s still a major accident and a write-off. Anyway, we still believe that future AI autonomous driving technology will improve the active safety performance of every car.

Expert Q&A

On the first day of the Year of the Tiger, I had the opportunity to hold a video conference with Dr. Mikael Fermér, head of the Volvo Cars platform architecture team, and get more information about the project.

Q1: Which vehicle models use integrated casting technology? When will they be launched?

We will introduce the integrated casting process on our new all-electric platform, possibly in 2025. The first product will be announced later.

Q2: Has the supplier of the casting machine been determined, and what specifications will it have?

We are in the final stage of negotiations and are in talks with some leading manufacturers to make a decision as soon as possible. One-piece cast rear floorpan will be a starting point. These machines can also be used for front or middle structures, and casting the entire bottom may be at least twice or three times the capacity of the current machine, but these machines are not yet on the market, so the largest machine available today is about 12,000 tons. Our goal is to use a machine with a locking force of 8,000 tons and a cycle time of 140 seconds for the production of the rear floorpan. The Torslanda plant has a capacity of 60 units per hour, and the number of die-casting machines we purchase will also be determined based on this target.

Q3: What engineering challenges are there for one-piece die-casting? Is the aluminum alloy used also like Tesla and does not require heat treatment?

You must respect the physical principles of molds and castings. Typically, when using a steel structure, you would use a specific closed beam structure. However, one-piece die-casting has an open cross-section, and if you choose to close these structures, it will increase costs and weight. Obtaining the best stiffness in the required locations is a new R&D challenge. We have developed an aluminum alloy material that does not require heat treatment. Otherwise, the alloy would be as brittle as potato chips. We are currently studying different alloys, and the difficulty we face is that from a sustainable perspective, we need a large amount of recycled aluminum in the alloy. We are studying alloys with 50% recycled aluminum. We are also studying alloys with 100% recycled aluminum, but these alloys have not yet met our target standards.

Q4: Volvo has set a zero-climate burden vision for 2040. What environmental considerations are there?

The furnaces in the factory will be heated with biogas. But overall, if you want to reduce carbon dioxide emissions, you must track it all the way back to mining because the biggest energy consumption is aluminum smelting, and of course, this is also the main source of carbon dioxide emissions. So we must sign contracts with aluminum suppliers that provide low-carbon dioxide emissions, with less than 4 kg of carbon dioxide emissions per 1 kg of aluminum, which is our standard. The aluminum alloy waste generated on-site can be directly returned to the furnace, reducing transportation costs and material waste. This is also a major advantage of one-piece die-casting of aluminum alloys. By comparison, stamping processes will produce about half of the waste that needs to be transported.

Q5: The mold cost of one-piece die-casting is high. What are its advantages?

I think the advantage of one-piece casting technology is that you can truly optimize the product for each product or segment market. This avoids the limitations of traditional platforms, where scaling ratios are already predetermined. I think this is very important as we prepare for the transition to better electric vehicles. Will there be new energy storage methods, new motors, or hub motors in the future? What I mean is that there may be many new things, so you must master flexible technology, which is much more flexible than traditional preset settings.## Guessing and Thinking

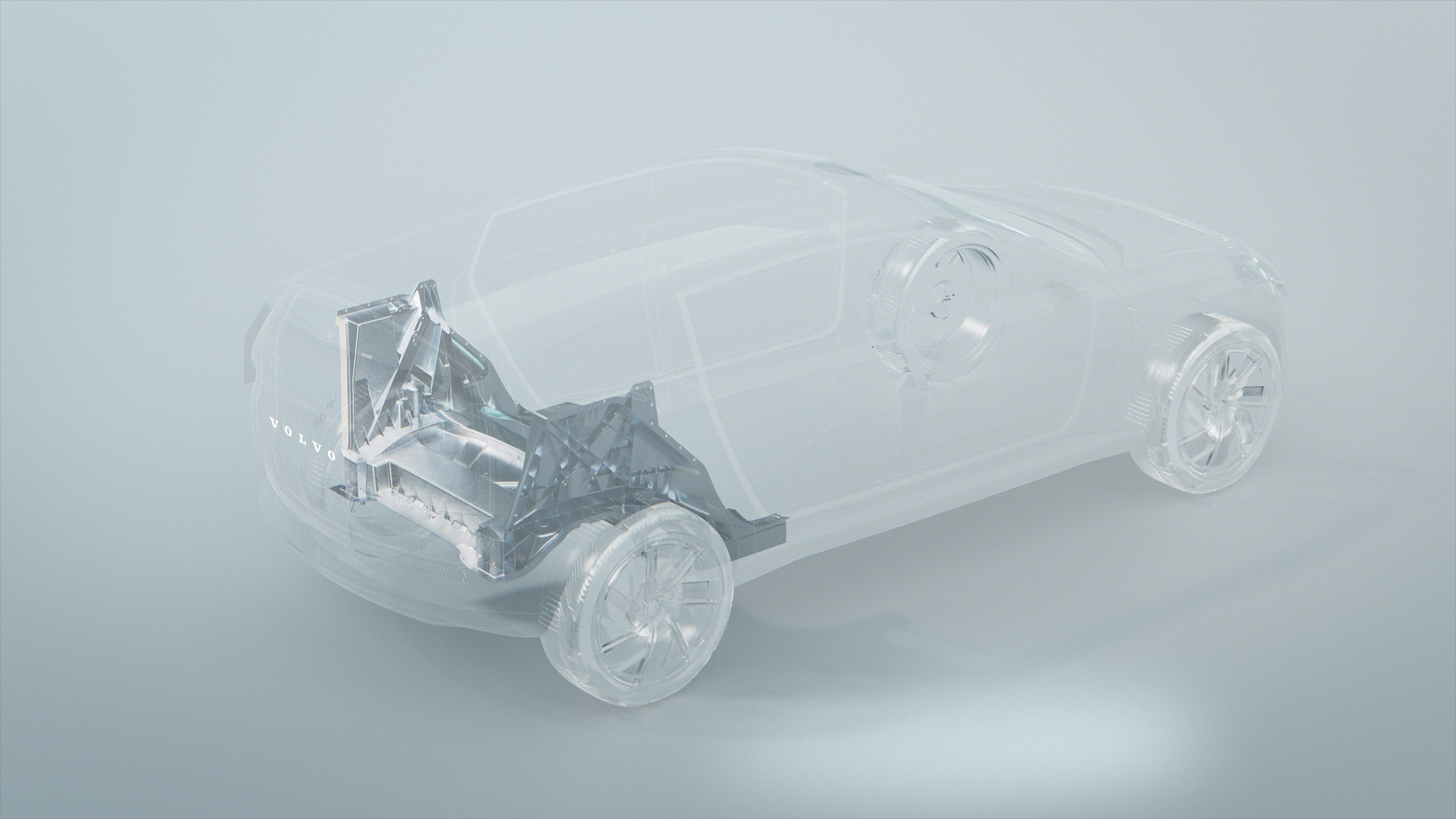

The one-piece casting technology is only used in the rear floor, while the wheelbase of the vehicle and the shape of the upper body still have degrees of freedom. Therefore, what is reduced is not necessarily the vehicle model, but the type of platform. This is also why the SPA2 architecture will be the main force of future Volvo.

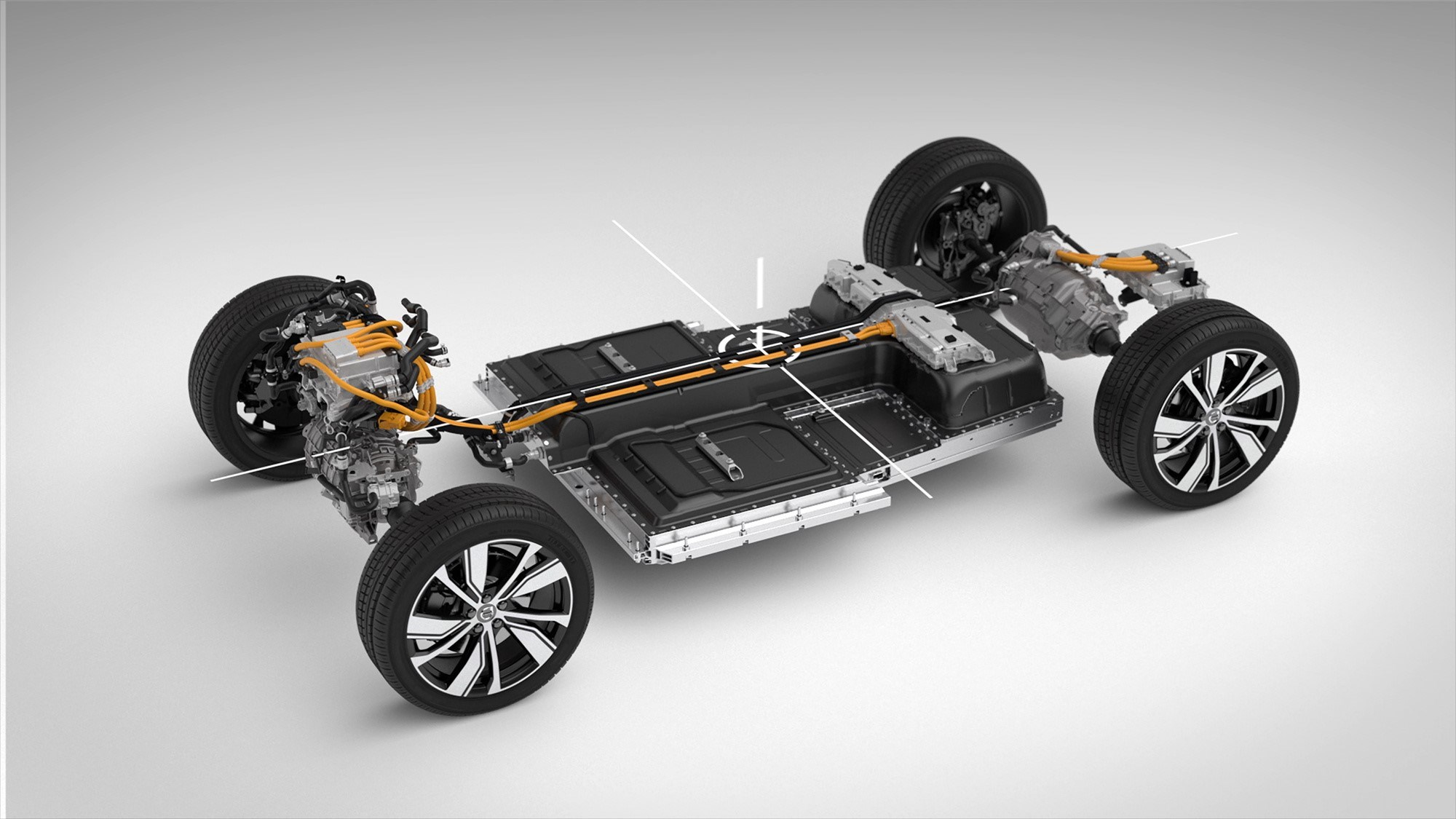

Volvo CTO Henrik Green once said in a media interview that the pure electric version of SPA2 will have a flat battery chassis, instead of the current Volvo pure electric models that use a horse saddle-shaped battery pack on the hybrid platform. Therefore, I boldly speculate that mega casting will probably be used in the SPA2 pure electric models.

Traditional brands have been fighting on the battlefield for many years. In order to win more subdivided markets, it is inevitable that a complex product line has gradually formed. In order to survive in this increasingly complex pure electric smart car race track, the pressure on host factories in terms of pricing and gross profit margins will inevitably make more companies adopt the single-product explosive logic of new forces such as Tesla.

High-cost molds mean that their life span must be squeezed to the limit to make good business. This also means that the longer the cycle of the body itself, the more reasonable it is. In this way, with further reduction of vehicle models, larger areas of integrated casting, and even the entire vehicle body, will become a reality driven by the market. The premise is the ability of automakers to grasp market demand and the rationality of initial product planning.

In addition to the hardware itself, intelligent product experience, sustainable software iteration capabilities, and effective user operations are also crucial. Whether this crossover SUV, which looks like the old V70, can create ripples in this red sea after mass production depends on whether Volvo can quickly light up these new car-making skills.