Facing the continuous rise of the new energy market, customers are demanding higher mileage range and faster charging rates for electric vehicles. Mainstream electric vehicles in China have reached a range of around 600 kilometers, equivalent to the range of a single tank of fuel for regular gasoline-powered cars, based on the New European Driving Cycle (NEDC). The next step in improving charging rates will be a key solution to the “range anxiety” of new energy electric vehicles.

Typically, charging rate depends on charging power, where charging power is equal to charging voltage times charging current. Higher charging current means increased circuit losses, and if the current exceeds 350A, the charging gun circuit needs to be water-cooled, further increasing the difficulty of operating the charging circuit and decreasing the charging efficiency. Increasing charging voltage can improve the charging rate of electric vehicles while keeping the charging current constant, thereby reducing charging losses. To meet these demands, more and more automakers are launching 800V or even higher-voltage electrical systems.

Electrical architecture design for high-voltage fast charging of vehicles

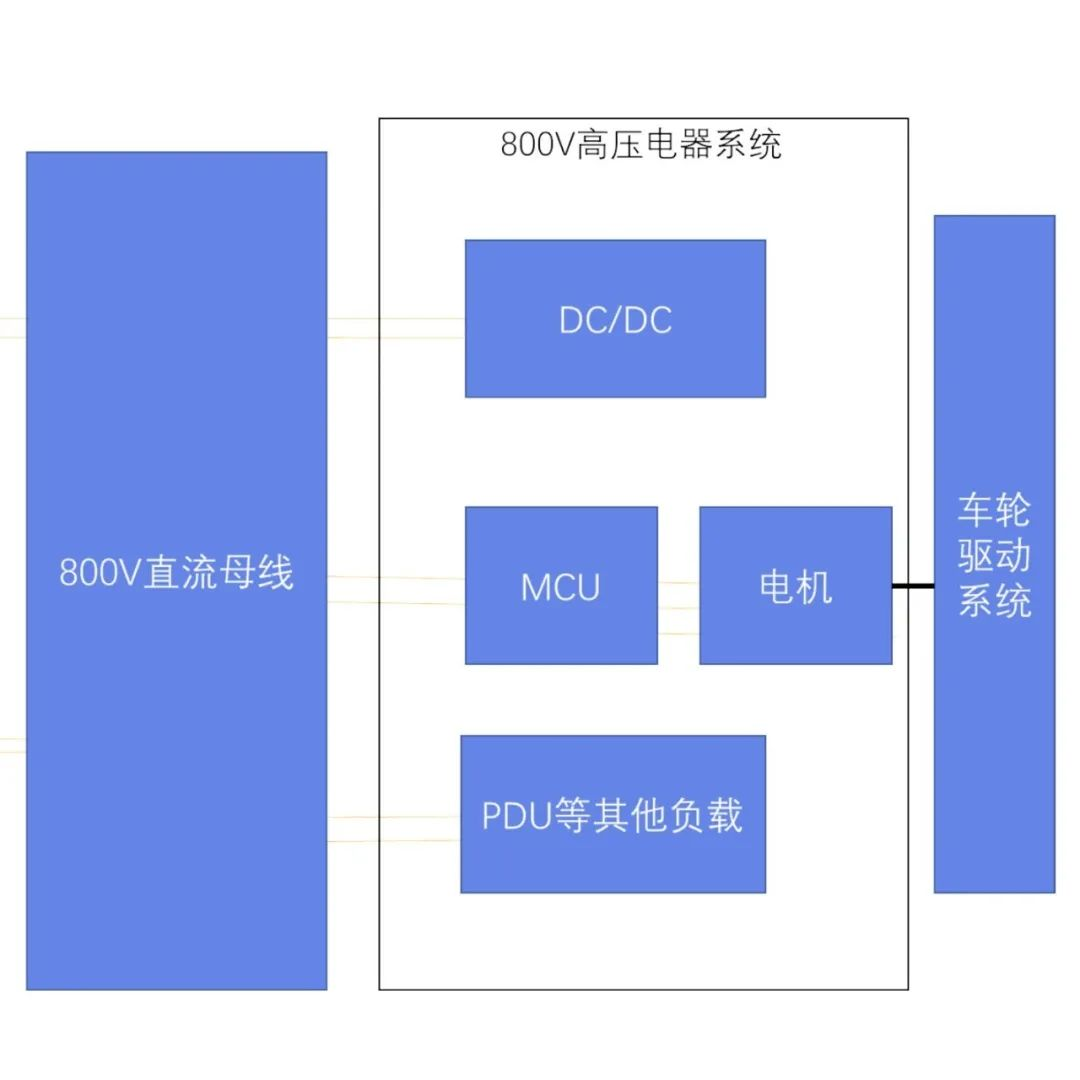

●800V Power Battery and 800V High-voltage System

Currently, the charging level of power battery systems for mainstream electric vehicles in the passenger car market is 400V. Due to physical limitations of charging piles and high-voltage components in vehicles, the direct way to increase charging power is to increase battery voltage. As shown in figure 1, raising the power battery and high-voltage components to an 800V system would be a solution.

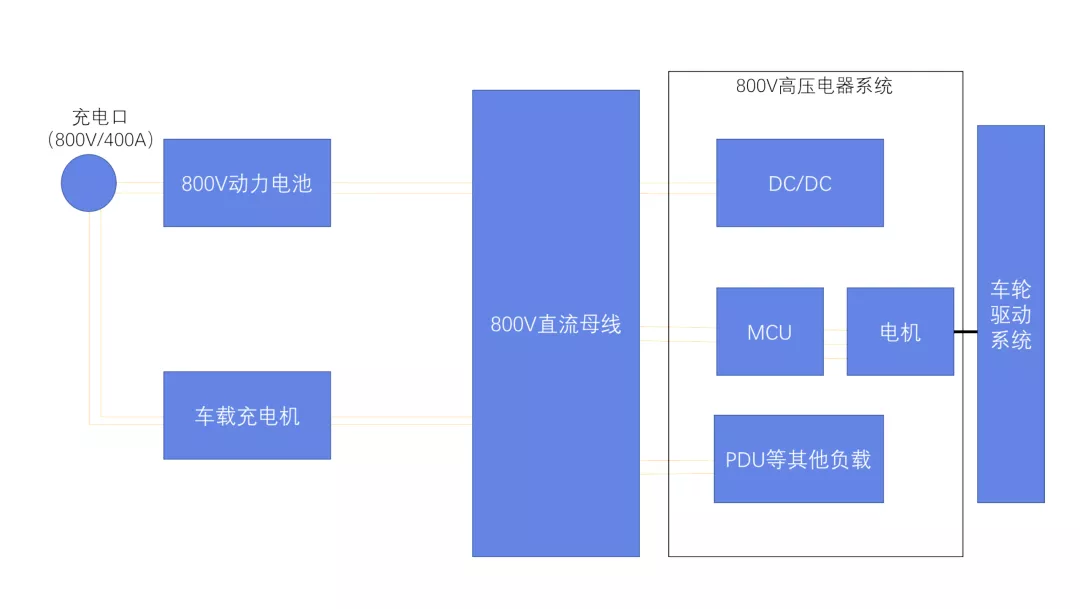

●800V Power Battery and 400V High-voltage System

Considering cost and other factors, utilizing the existing 400V voltage level component platform and charging infrastructure, it could be feasible to add a DCDC device between the vehicle charging interface and the power battery and high-voltage components, as shown in figure 2.

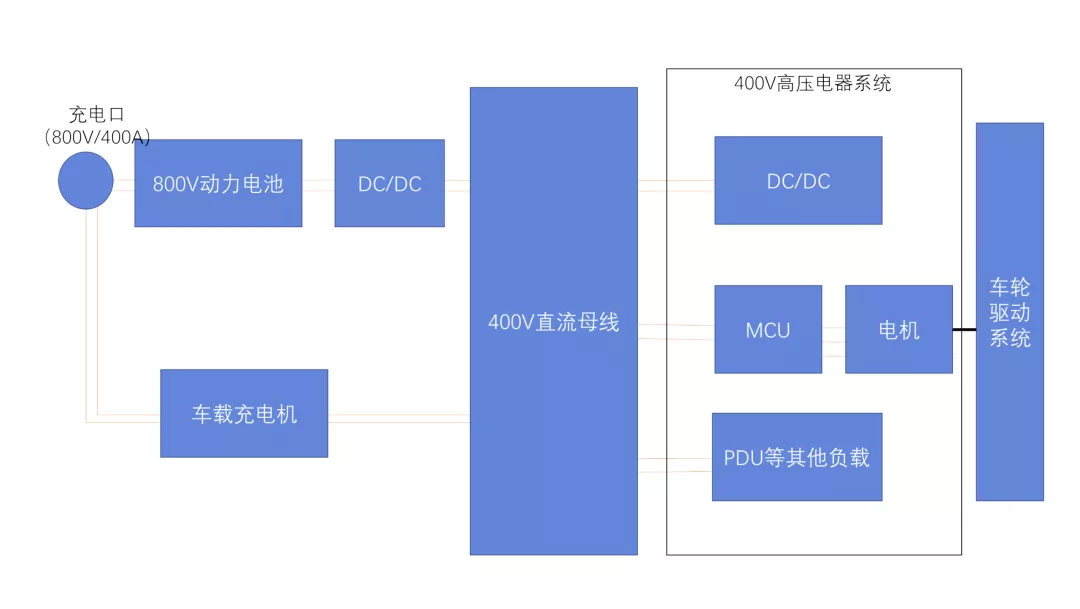

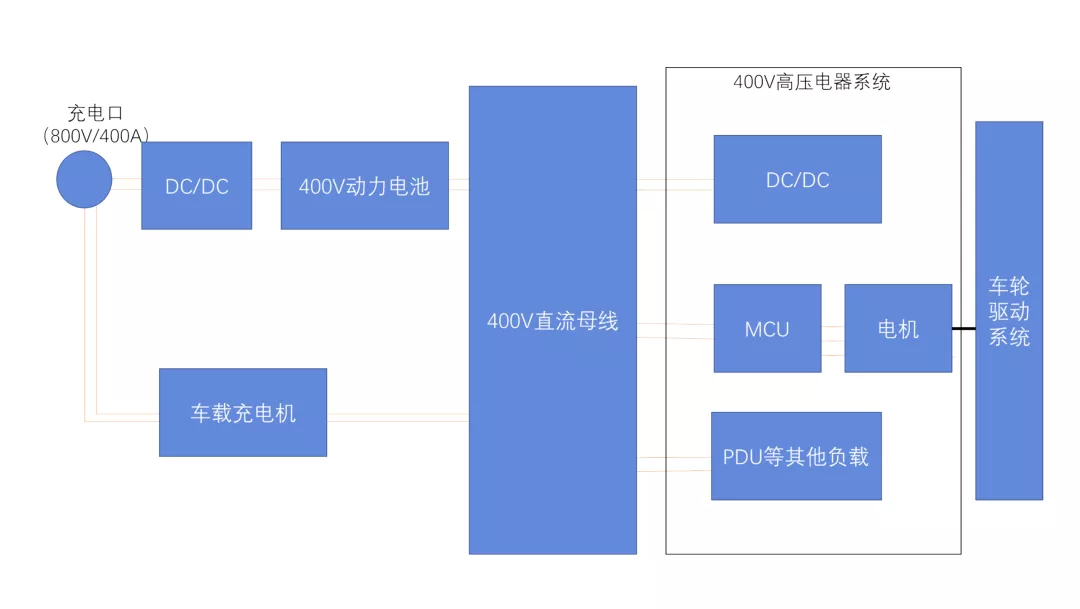

●400V Power Battery and 400V High-voltage System

By distributing the battery in a series-parallel configuration, a configurable power battery system can be designed. By connecting the batteries in series, an 800V charging voltage can be provided, while connecting in parallel can provide 400V driving voltage. This scheme requires a higher degree of complexity in battery management system design and additional control circuits.

In charging mode, charging stations of different voltage levels connect to the corresponding charging ports in the high-voltage system through the charging gun. When connecting to an 800V DC charging station (hereinafter referred to as “high-voltage station”), the charging gun is directly connected to the battery management system (BMS) inside the battery, achieving a maximum instantaneous charging power of over 300kW with 800V charging voltage. When the charging station output is 400V DC, the charging gun is connected to the DC module interface. The module boosts the 400V DC voltage to 800V DC through a Boost circuit and then charges the battery.

In charging mode, charging stations of different voltage levels connect to the corresponding charging ports in the high-voltage system through the charging gun. When connecting to an 800V DC charging station (hereinafter referred to as “high-voltage station”), the charging gun is directly connected to the battery management system (BMS) inside the battery, achieving a maximum instantaneous charging power of over 300kW with 800V charging voltage. When the charging station output is 400V DC, the charging gun is connected to the DC module interface. The module boosts the 400V DC voltage to 800V DC through a Boost circuit and then charges the battery.

Taking Porsche as an example, the earlier Porsche Taycan adopted an 800V high-voltage system. In order to be compatible with 400V charging stations, Taycan added a Boost charging module that boosts from 400V to 800V in addition to the standard 800V DC charging system. This optional solution not only takes up space in the car body but also increases the development and hardware costs of the high-voltage system.

Influence of 800V fast charging technology on electrical system design

● EV charging standards

Currently, China’s EV charging standards are still based on the 2015 National Standard for Electric Vehicle Conductive Charging Systems, and the mainstream fast charging mode is mainly based on the 400V voltage platform. To achieve charging voltages of 800V or higher and achieve high-power charging, it is necessary to revise and improve the relevant regulations and standards for EVs.

● Power battery design

Higher battery packs are achieved by serially and parallelly connecting more individual battery cells. High-rate charging of the battery has a certain impact on both battery life and thermal management. In order to ensure safety during high-current charging, it is necessary to expand the power of the on-board thermal management system or improve the cooling system design to meet the cooling needs during high-current charging.

● Electrical safety design

Higher battery voltage will demand higher electrical isolation level for the electrical components, and the electrical clearance and creepage distance need to be considered in the design of high-voltage safety systems.

● Charging cable connection design

To achieve fast charging, liquid-cooled charging cables are usually required for charging powers exceeding 200kW. However, there is currently no established protocol on how to incorporate liquid-cooled cables into electrical specifications. In addition, the connection of liquid-cooled charging cables is cumbersome and will cause inconvenience for customers. To solve this problem, other options for fast charging connections may include the use of robots or wireless charging.

● Charging infrastructure

To achieve the above high-voltage charging technologies, matching charging infrastructure is required. In 2021, GAC Aion achieved the fastest EV charging record with a charging speed of “5 minutes to charge, 207 km to drive” through its dedicated A480 Supercharger. The Porsche Taycan, which released an 800V DC charging station in 2019, also requires its own charging station to achieve “4 minutes to charge, 100 km of range, and 80% charge in 15 minutes”.“`

However, there are very few charging stations that can meet the requirements of super fast charging. Even Tesla, which has the earliest layout on this track, has only built 920 super fast charging stations nationwide as of the end of August 2021, with only over 7,100 super fast charging piles, which is far from meeting the demand.

Summary: In 2021, with the continuously increasing demand in the new energy market, the 800V high-voltage charging has significant importance in solving the “range anxiety” of new energy vehicle owners. Manufacturers need to strike a balance between the feasibility of technical solutions and commercial impact to achieve the widespread promotion of high-voltage charging technology.

“`

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.