On January 8, 2022, I attended the launch event of the new Linkage Sky Cylinder series products held in Shanghai Center, witnessing the official release of the products.

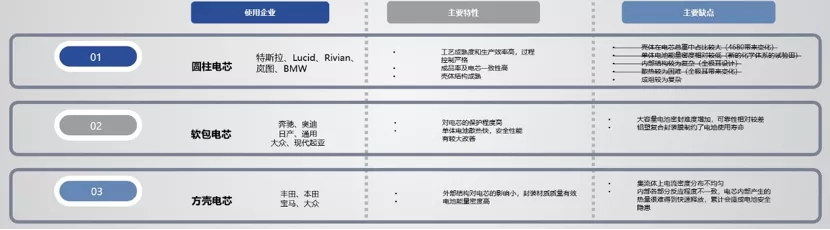

In recent years, the share of cylindrical batteries in China’s power battery industry has actually been decreasing. The only models in mass production worldwide are Tesla (Panasonic 1865, Panasonic and LG 2170, and upcoming 4680), Rivian (2170 SDI), Lucid (2170 LG), and Voyah (2170 SDI). This technological route seems somewhat lonely.

However, the new Linkage Sky products are almost all centered around the cylinder, which is very interesting.

Cylindrical Battery Series

The cylindrical system is a chemical system that accommodates high-nickel and silicon-containing materials and is considered a good container. The main reason is that the energy of the battery cell monomer can be controlled. Through the design of cascading and isolation, it has good safety at the pack level and can ultimately achieve NTP (never thermal runaway) after forming the module/system.

From the perspective of the entire industry trend, the next step to achieve high-energy density and cost reduction at the technical level is only possible by finding solutions in this direction.

Last year, Tesla launched the 46800 cylindrical battery cell at BATTERY DAY. The 46800 can achieve five times the capacity of traditional cells, and the corresponding system integration will also be simplified. In the past two years, major battery manufacturers have all expanded their layouts of large cylindrical cells. Under similar size conditions, each battery company adopts different structural design and functional material, trying to improve thermal conductivity and reduce internal resistance.

However, the size of the 46800 cell alone cannot fully meet all demands. For example, its height can only accommodate Tesla’s short PACK design, which is why there is now a 46950 cell. Considering the mainstream design of PACK for whole vehicle companies, it is also possible to use cylindrical batteries with a height of around 100 in the passenger car field.

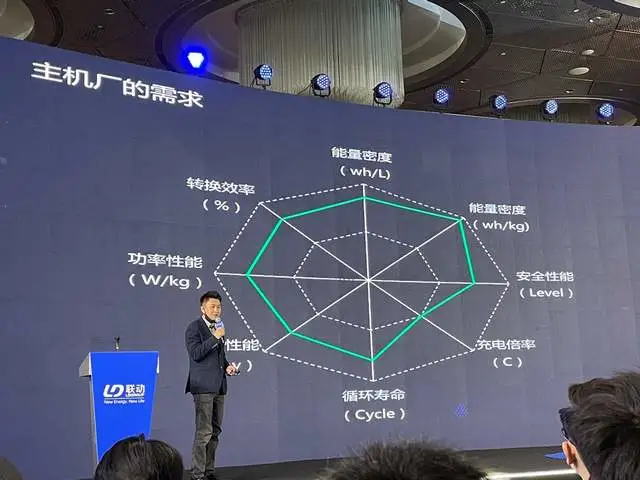

With the rapid development of the industry, the time left for whole-vehicle companies to screen battery cell technology routes has also become shorter.

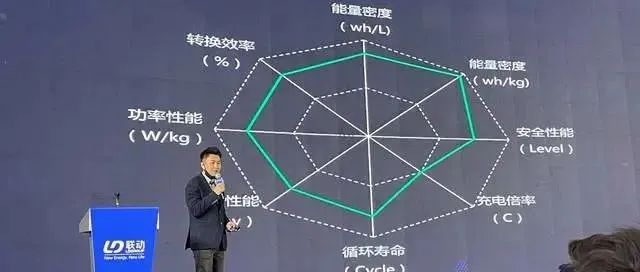

When prioritizing screening requirements, safety is of paramount importance, especially for models that exceed 100,000 in sales.2. Cost: Cost is a significant factor when it comes to switching from high-end 70-90kWh batteries.

- Energy Density: Wh/L is actually an implicit requirement that represents whether the target amount of electricity can be stored in a battery casing, while Wh/kg can effectively reduce the weight of large-capacity batteries and reduce the proportion of battery weight in high-mileage vehicles.

Currently, China’s battery industry has a clear route, which is to develop high-safety and low-cost solutions around lithium iron phosphate, covering 10kWh-80kWh – this is already a very definite direction. However, the energy density of the battery cells is stuck at 190Wh/kg and the system energy density is at around 150Wh/kg, so in order to make further progress, new methods must be relied upon.

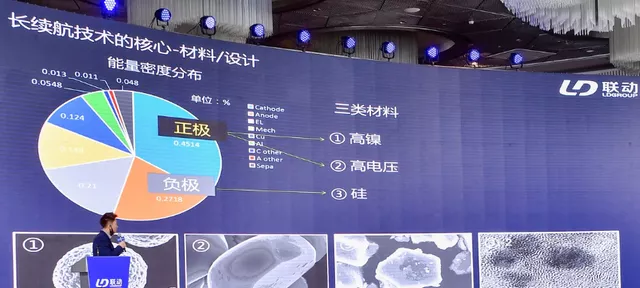

● Energy Density

In terms of single-cell energy density, pouch cells have a relatively high weight energy density (with a very small proportion of structural parts), but there is an issue with regards to packaging and how to isolate thermal runaway problems that may arise when the energy density is high.

The energy density of cylindrical cells is also relatively high, and it can accommodate the latest technology. Compared with square shells, cylindrical cells can effectively accommodate JR utilization, which can improve the percentage by 8% (in terms of expansion, square shells need to reserve space, so the accommodation rate is lower); however, the capacity of cylindrical cells is relatively small, so they are at a disadvantage when compared directly.

Tesla’s solution to this variable is to propose the use of larger cylindrical cells. This is because if one wants to integrate high-nickel, silicon-carbon negative electrode and other technologies that affect safety performance (but can increase battery capacity) into the power battery, without using a cylindrical scheme, the whole technology line will be dragged out, and there will be many systemic cost problems to solve.

From the current logic, the development of positive electrode technology revolves around either high nickel or high voltage, while the negative electrode revolves around high silicon. In China, we have seen the Ni55 high-voltage technology, which is only a transitional strategy and needs to revolve around high nickel to effectively improve cost-effectiveness.

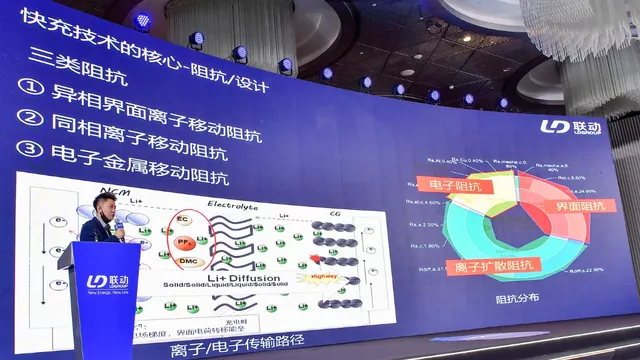

● Fast Charging Time

Fast charging time is a key obstacle to increase the market share of electric vehicles.

There are three main impediments to fast charging: interface impedance, ionic impedance, and electronic impedance.

In fact, achieving high energy density is somewhat contradictory to fast charging, so in this triangle of wanting to achieve long endurance, fast charging, and safety, a relatively stable container is still needed for compromise.

From the rapid development of battery cells, Chinese power battery companies may be disrupted if they do not actively participate in the rapid iteration of large cylinder cells.

Currently, domestic cylindrical battery companies mainly include Lishen and BAK. And by entering the market at this time, CVTC (China Venture Technology Corporation) focuses on high-end cylindrical cells, which is expected to be the next growth point in the industry.

SPEED Series Cylindrical Lithium-Ion Battery

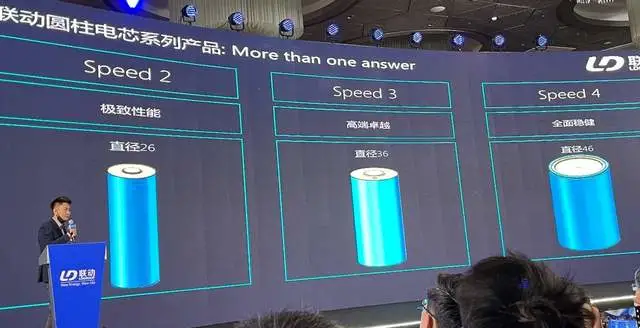

At this press conference, Dr. Yang showcased the latest product development achievement: the SPEED cylindrical lithium-ion battery family, including the previously released SPEED2 series with a diameter of 26mm, the newly released SPEED3 series with a diameter of 37mm, and the SPEED4 series with a diameter of 46mm.

There is a basic design concept: although the cylinder cell may form a certain standard cell in the long term, when currently used by global automakers, it allows the cylindrical cell to have different design options according to the needs of the automakers themselves.

The three schemes of the SPEED series are as follows:

(1) SPEED 2:

Diameter: 26 mm, height: 60-100mm, mass production time: Q4 2022

This battery was released in September 2021. Its main goal is to target high-performance fast-charging power batteries. The energy density of a single cell can reach 260Wh/kg. Charging for 8 minutes can achieve a range of 400 kilometers, and the designed fast charge cycle is more than 800 times. This series is mainly compatible with existing designs.

Fast charging is a prominent feature of this battery, and solving this issue is a multidisciplinary and cross-professional technology. Its performance requires the joint efforts of mechanical, electrical, material, chemical, and control aspects.

(2) SPEED3:

Diameter: 37mm, height: 60-110mm

Due to the adjustability of cylindrical size, and based on the original 26 mm, the adjusted 37 mm SPEED3 battery can not only avoid the multiple challenges faced by 46 mm diameter lithium-ion batteries in manufacturability, heat, force, and structural design but also achieve higher energy density than 26mm lithium-ion batteries, mainly balancing energy density and fast charging capability, suitable for high-end passenger cars.

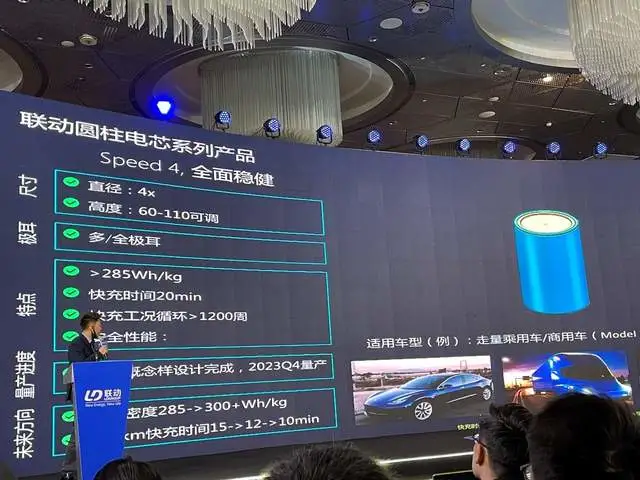

(3) Speed 4 Battery:

(3) Speed 4 Battery:

The SPEED4 series has a dimension of 46 and a height adjustable between 60-110. The design objective is from multi-pole ear to full pole ear. The energy density is greater than 285Wh/kg, with a fast charging time of 20 minutes, and a fast charging condition goal of 1200. It is positioned as a stable system design, pursuing lower cost and comprehensive performance, and is more suitable for ordinary household vehicles.

Summary: Today’s sub-section happens to be about sharing the situation of the 4680, while the linkage considers the layout from the perspective of the technical system. The research and development concept is “more than one answer”. That is, the 46mm cylindrical design is a direction, but not the only answer. Let us have more expectations for cylindrical batteries and provide more directions for the design of the next generation of power batteries.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.