The iteration of plug-in hybrid electric vehicles (PHEV) has gone through 2-3 generations of models both domestically and internationally since 2010, but the development of PHEV batteries still faces certain limitations.

With the platformization and generalization of PHEV models, the battery system now adopts a universal battery module design. The next step is to make the battery system more similar to that of pure electric vehicles, which means placing it at the bottom of the car. Under this placement requirement, the PHEV battery module also needs to have a smaller and flatter module size for more flexible combination.

In 2022, with the use of many domestic PHEV models in this field, the development of PHEV batteries has become an interesting topic.

Regarding the use of 8, 10, 18, 22 and even higher 40kwh lithium iron batteries, Futongda and Heter are currently taking a mainstream approach.

Note: There are not many companies focusing on the development of PHEV battery cells around high-nickel ternary elements.

Futongda Battery

BYD began using lithium iron phosphate battery modules (referred to as small blade) in their own DMI models. Essentially, this is a secondary sealing technology. The cells are encapsulated in a soft pack (an aluminum-plastic film), and the blade cells are enveloped in a hard aluminum shell.

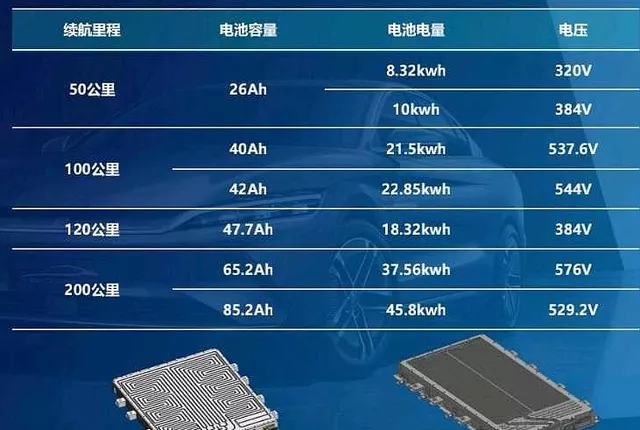

In this sense, design with different capacities (26Ah, 40Ah, 42Ah, 47.7Ah, 65.2Ah and 85.2Ah) and different sizes can actually be achieved. From the current logic, the biggest advantage of the soft pack is that the size can be trimmed. The soft pack cells can be rolled up through an internal support frame and then fixed internally.

As shown in Figures 4 and 5, this interface connects the voltage of each cell, and then connects it to the CMU through a unified connector.

L400 by Honeycomb Energy

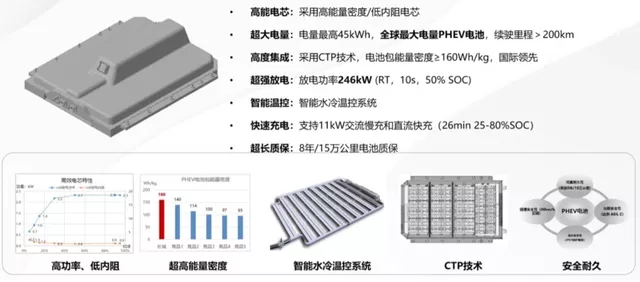

At this year’s Honeycomb Battery Day, the L400 product made its debut. Similar to Freddie, the product uses Lithium Iron Phosphate in PHEV, and introduces a PHEV product that can cover 150-200km of endurance range, with an energy density of 170Wh/kg to 180Wh/kg in cell. It will be in mass production by the end of 2022. This will also reduce the cost compared to ternary lithium batteries, and increase the space utilization by 40%.

In my understanding, this is also a reference to the CTP mode of small blades (which can be made into soft packs or directly into square shells).

This method can replace the battery position of HEV with DHT planned by GWM before, and promote PHEV to serialization.

Note: The previous extended range EREV used a ternary BEV cell, but this time with the introduction of Lithium Iron Phosphate, many cost optimizations have been made under the premise of unchanged battery capacity.

I feel that there has been a significant change in 2021. Before the design between GWM and Honeycomb, it was done around VDA. With rapid changes within one year, the entire technology route has completely reversed.

Summary: I have previously worked with Lao Li on a book called “PHEV Battery System Integration Technology”. Now it seems that the battery cells and overall technical direction centered around VDA have all been overturned in PHEV, representing another direction for PHEV battery in China — focusing on high space utilization rate, and being more useful in PHEV where energy density is not so demanding.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.