Small Electric Car Maker XPeng Motor Conducted Highly Difficult Car Body Test in Water Spraying and Cold Environment

This article is reproduced from Autocarweekly on WeChat.

Author: Jing San

XPeng recently did two unique things.

Firstly, in a 200-square-meter stage erected at Beijing 751 Plaza, using over 30 high-pressure nozzles, they continuously sprayed seawater on a small XPeng P7 white car body for 550 hours.

After the test, China Automotive Technology & Research Center conducted the inspection and found no bubbling, edge corrosion, and weld corrosion on the car body. The corrosion level of its front hood, front-wheel surrounding, left and right fender, left and right front door, left and right rear door, left and right side walls, and rear door surface was zero with no corrosion. Only car body parts in the front cabin and the back trunk surface corrosion reached level 1 with rust area less than 0.05%. It’s very robust.

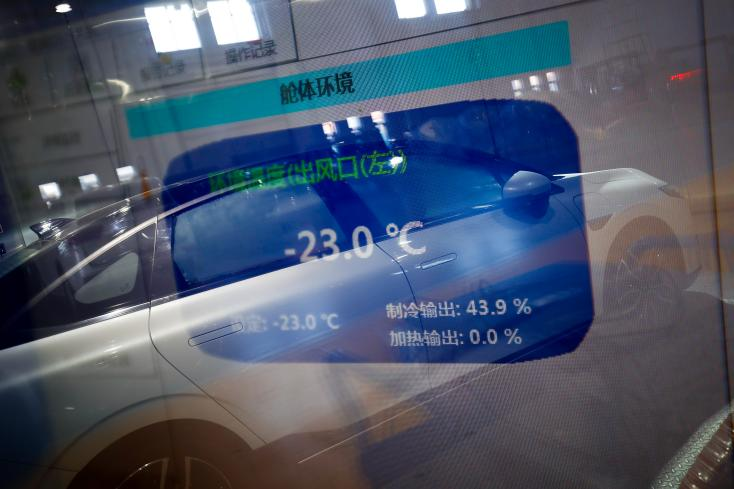

Secondly, in the past few days, they brought a XPeng P5 to CATARC (China Automotive Technology & Research Center), cooled it for 8 hours until the temperature inside and outside the car dropped to -23℃, and then performed low-temperature starting and defrosting after manually frosting the entire car body and windshield. Not only did the XPeng P5 pass the test, but its results were better than the national standard.

You may feel puzzled – isn’t this a test that every household can do? What’s so unique about it?

One of the reasons is the high level of difficulty to achieve.

For example, in the water spraying test, which detects the vehicle body’s electrolytic corrosion resistance, ordinary tests last only one or two days with plain water. XPeng’s test, on the other hand, continued for 23 days of continuous spraying and immersion, with an intensity visibly higher than ordinary tests.

Looking more closely, there are more differences. Ordinary white body tests typically use pure water, and the white body without multi-layer protective shell technology of commodity vehicles is vulnerable to corrosion. XPeng, on the other hand, used seawater directly, which has stronger corrosiveness and electrolysis, and the concentration of electrolyte sprayed on the car body for a day is equivalent to that encountered during normal car use for a year, according to reports.

The car body XPeng displayed is an ordinary car body pulled out of the paint shop at the Zhaoqing factory, which demonstrates the authenticity and applicability of the test results. It means that the XPeng you get has such anti-corrosion capability.

The second reason is that real needs are more important than empty shows, and the latter are already desensitized audiences.

For example, in the cold test, which is incredibly unfriendly to electric vehicles, XPeng used a test temperature of -23℃, which is more severe than the national standard’s -18℃ but necessary. Because realistically speaking from our country’s climate, -18℃ is not enough for many northern cities’ commuting environment, while -23℃ may also be inadequate. Comparatively, it is closer to the real difficulties of winter low-temperature starting and defrosting.

Of course, this is only the tip of the iceberg for XPeng Motors. Theoretical control of the P5’s heat pipe range is between -30℃ to 55℃, which ensures normal battery operation and vehicle start-up in environments above -30℃. It is said that meeting this range will basically meet the needs of over 90% of cities in China.

From this perspective, we can see that XPeng’s development standard is based on real demand, not just getting approval.

Thirdly, it’s all about transparency and impartiality. All tests are monitored and supervised by third-party agencies, even the spray tests are carried out in public. There’s no room for shady practices or blind confidence, and XPeng is firmly confident in its manufacturing quality.

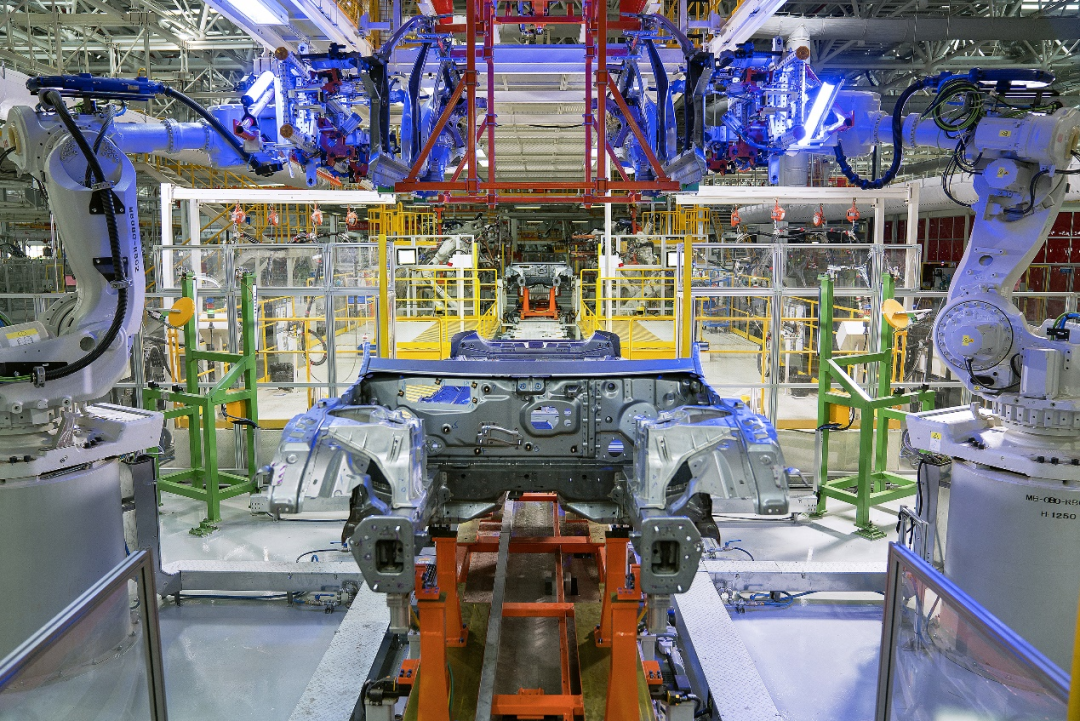

XPeng Manufacturing is no joke.

When it comes to quality, it seems a little out of place to talk about XPeng. After all, we tend to think of it as a tech company, usually ascribing to advanced intelligent technology as the top priority for development and resource allocation. It’s easy to overlook quality, and sometimes we tacitly come to terms with it as a kind of “genius disease.”

However, quality is placed in a very important strategic position for XPeng in many respects.

Firstly, XPeng spares no effort. For example, in order to achieve corrosion resistance, the P7’s body is largely made of anti-corrosion materials, including many aluminum parts such as the aluminum engine cover and cast aluminum shock absorber mount, while over 90% of the body is made of double-layer galvanized steel sheets with a galvanized thickness of 7-12μm, and equipped with the latest generation of CG800 super high-conductivity cathodic electrophoretic paint technology from BASF, which is relatively high in cost.

Furthermore, in places where you wouldn’t even notice it, such as sheet metal welding seams, sheet metal overlapping edges to sheet metal internal openings, strict sealing and closure treatments are performed, and corrosion-resistant wax is sprayed in the depths of the cavity, and the bottom of the car is sprayed with anti-stone chip PVC coating. It’s these details that make the above-mentioned corrosion-proof result possible.

This is just a small part of the corrosion-resistant work. Similar execution specifications run through the manufacturing process.

Secondly, it’s about establishing out-of-scope standards and fine management, so that high quality is fixed in the system as a process and transmitted as a mission and value.

XPeng’s quality is directly managed by CEO Xia Heng himself, and it’s said that the quality team alone has a scale of five to six hundred people, planning to double next year. They hold quality meetings every morning, a CEO meeting every month, and a CEO quality day every quarter, continuously preparing, iteratively improving, and undergoing rigorous evaluations.A car should undergo rigorous testing starting from the product development stage, such as conducting 100 GB (Chinese national standard) and 120 Euro standard cyclic corrosion tests in Hainan to simulate harsh environments such as mud and saltwater roads, with the goal of evaluating and mitigating the risk of surface corrosion, perforation corrosion, and structural corrosion of the whole vehicle under working conditions. There is also cyclic testing, periodic corrosion resistance monitoring, and regular disassembly of the bare body for electrophoretic coating.

Not all companies can allocate equivalent investments and efforts. Small businesses, low-end products, or limited resources may lead to a trade-off between profitability and cost, while mature and strong companies may manipulate market demands for profit margin.

Ultimately, the level of effort depends on the recognition of high-quality value. Whether it is cutting costs or developing a management system, it is a projection of this value system: Do you firmly believe that consumers deserve high-quality products? All companies are willing to make statements, but not all will act accordingly.

In short, it’s about Chinese manufacturing sincerity that aims to not deceive Chinese customers, and it’s about the faith of XPeng in long-term value, persisting in doing what is difficult and correct.

Many correct things are difficult, and quality is a typical example. With no apparent differentiating features, it is not easy to distinguish between good or bad, nor does it have emotional connections, so consumers may find it hard to perceive quality differences, which may make it challenging for companies to see short-term returns.

As for XPeng, the main sales market currently focuses on the south, with the top five sales regions in Guangdong, Zhejiang, Jiangsu, Shanghai, and Sichuan. From the perspective of maximizing utility, the extreme cold test might be a bit problematic as it may not yield the best results. However, that does not prevent the XPeng P5 from still surpassing the standard calibration or from making every effort to improve winter range performance.

For example, the XPeng P5 is fully equipped with a heat pump air conditioner. The benefit is that the COP (coefficient of performance) is greater than 1 when the temperature is above -10℃, meaning that a 1 kW power output can generate more than 1 kW of heat, which can significantly reduce energy consumption compared to traditional PTC heating, with purportedly about a 15\% improvement in range performance.

Of course, the disadvantage is also evident: the cost is too high. Currently, the added value of the heat pump system compared to a conventional air conditioning system averages between 1,200 and 1,500 yuan, which is almost the profit margin of a traditional compact car. As such, the installation rate of heat pump air conditioners in domestically sold electric vehicles was less than 5\% last year. The XPeng P5, as a pure electric car priced at 200,000 yuan, was surprisingly the first of its class to be equipped with this feature; meanwhile, it still retains another set of traditional water heating air-conditioning to cope with extremely low temperatures below -10℃, using high power output to ensure rapid heating.“`markdown

These considerations are not the greatest common divisor of right now. XPeng is also not stagnant but providing redundancy and maintaining quality iteration to expand product boundaries, which is the right thing to do and a necessary responsibility for a pioneering enterprise facing the grand challenge of popularizing electric vehicle consumption and transforming the intelligent industry. If we only make simple choices that are most in line with current interests, we will not have the energy to go to the future.

When you mention XPeng, what do you think of?

Of course, not being stingy with love and persisting in difficulty while being correct also doesn’t mean being so lonely without feedback.

For example, XPeng P7 won the first place in the medium-sized pure electric market attractiveness index in J.D. Power’s China New Energy Products Attractiveness Index Study (NEV-APEAL) this year. In August, it also won C-NCAP five-star rating with a score of 89.4%, far exceeding the industry average.

There is also the XPeng G3, which ranked first in the quality ranking of new energy vehicles in the compact car category in J.D. Power’s China New Energy Vehicle Initial Quality Study (NEV-IQS) this year.

The double awards have made XPeng’s quality resonate loudly, but more solid certification comes from the market. As of October this year, XPeng has delivered more than 100,000 vehicles cumulatively and is growing at a rate of more than 15,000 vehicles per month. Most people’s choice of XPeng may be driven by cool design and intelligence, but ultimately, the order cannot be placed without trust in quality.

The increase in scale is also a new threshold, which means that XPeng has completed the initial market validation and run the product logic. The next challenge lies in the upgrade of its own operation and management, as well as facing a larger population, more diversified needs, and more severe consumer scrutiny as the penetration rate of electric vehicles exceeds 20%. XPeng needs to constantly self-prove whether it has the ability to meet the rapidly expanding market, whether it is stable, consistent, and can maintain sufficient reliability even in a complex environment. These two tests are the process of self-proofing: whether XPeng has the qualifications to become mainstream.

XPeng carried out a brand new round in November, aiming to transform from a leader in intelligent vehicles to an explorer of future travel. This is actually a signal of transformation to cope with the game upgrade. He XPeng said, “I hope that when you mention XPeng, you will realize that this is a company that maintains exploration and adheres to a sustainable path.”

Quality is also included in the exploration. He XPeng explained that the entire future transportation must have better quality, which comes from technological innovation, process innovation, and better development of the entire supply chain.

“`

From Intelligence to Quality, from single long board to diversified composite competitiveness, behind which runs XPeng’s clear thinking on future development, and it is also a declaration to the market that intelligent automobiles are not just a dream, but also a future implemented with quality. XPeng is ready.