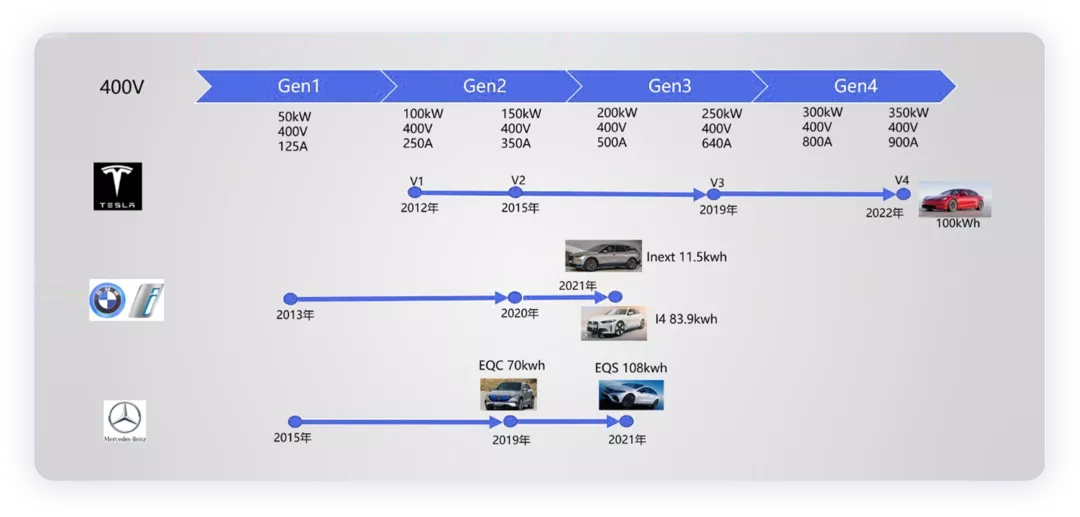

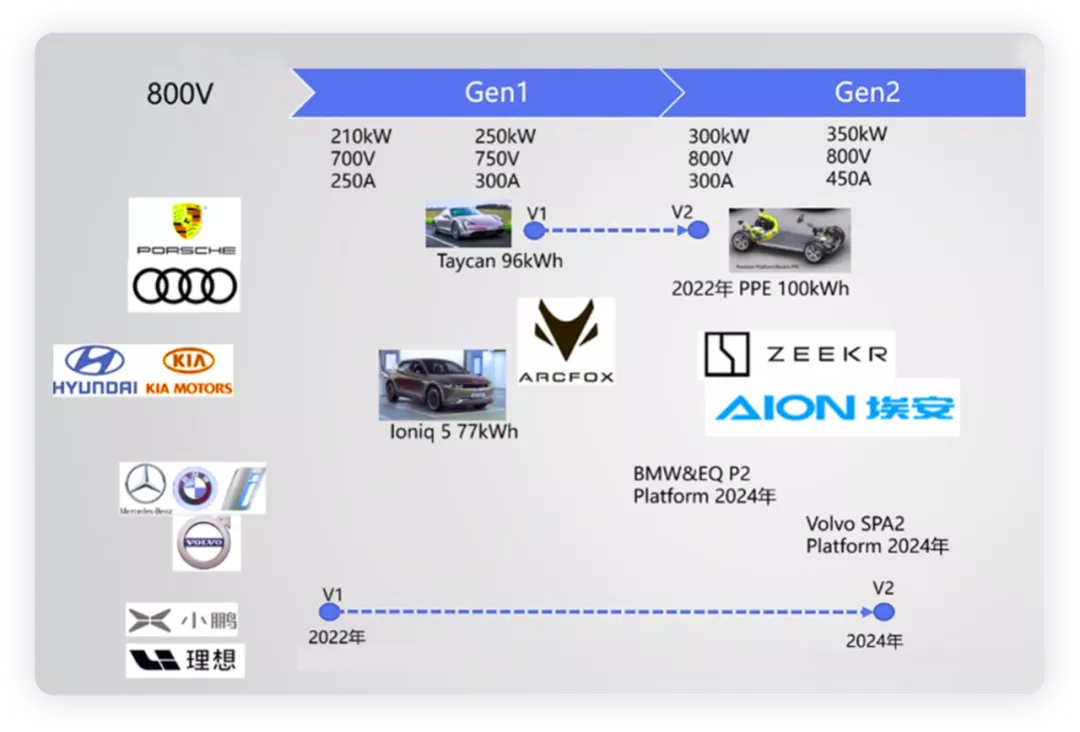

Since the Alpha S vehicle equipped with Huawei’s full-stack high-voltage solution was announced by Beijing Automotive Group’s BJEV at the Shanghai Auto Show, more than ten car companies have either launched or are launching vehicles that are capable of fast charging. The 800V high-voltage architecture has become the core theme of many industry forums in 2021.

On December 21st, at the 2021 Huawei Intelligent Automotive Solution Eco-Forum, Huawei invited industry partners to discuss how to cooperate to promote the industrialization process of high-voltage fast charging, once again bringing widespread attention to the high-voltage platform.

As the marginal impact of the increase in electric vehicle range begins to decrease, the difference in experience between 600 kilometers to 800 kilometers is not much different from the experience of 300 kilometers to 400 kilometers or 500 kilometers. At the same time, the requirements for volume and weight need to match larger vehicles and is no longer a simple proportional relationship.

Fast charging has become the inevitable direction for the next step in the development of power batteries, and domestic and foreign car companies have begun to envision charging in 5 minutes and adding 200 kilometers of range to meet consumers’ need for rapid charging.

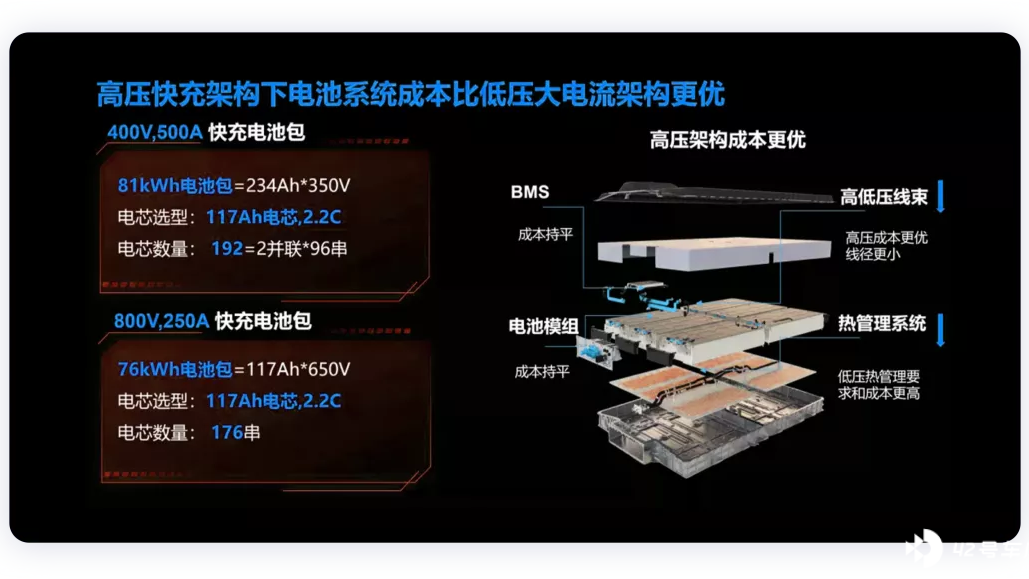

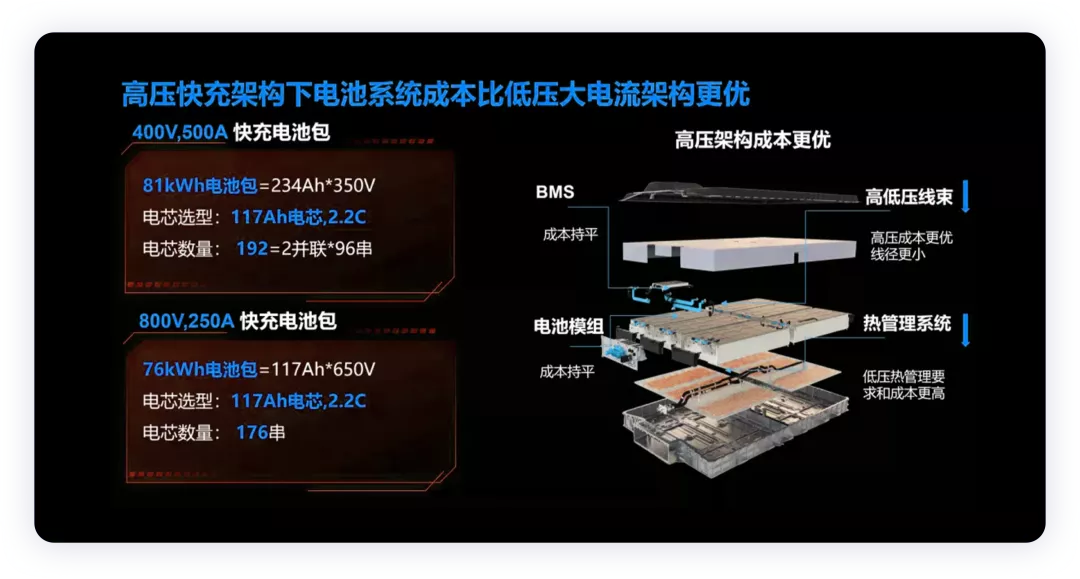

Two ways to increase the charging speed of electric vehicles are to increase the current and/or increase the voltage. Choosing the current path, which involves the tradeoff of thermal losses increasing with higher current, requires consideration of the heat losses in the design of conductive components such as connectors, cables, battery electrical connections, and busbars to avoid overload, overheating, or controlled reduction in charging current. On the other hand, changing the voltage from 400V to 800V is an option for increasing power since the current increase has a limit of around 500A, which reaches a power of approximately 200kW, and involves a systemic improvement for all electrical components. This includes changes in core switching devices and other parts.

● High-voltage Fast Charging Architecture

For current vehicle upgrades, it is important to improve the fast charging experience while keeping the existing system unchanged. Going from 400V to 800V will bring significant changes, so power upgrades around 400V in the short term are a viable option. When the current is greater, the required cable cross-sectional area for transmitting power at the same voltage level without overheating increases.

The main high-power design currently aims for 200kW, i.e. a continuous 500A current with a duration of around 5 minutes. To match this current, the charging socket inside the vehicle, the high-voltage cable from the charging socket to the battery pack, the fast charging contactor and the main positive and negative contactors, the main fuse, the module wiring harness, and the current-carrying capacity of the cell internal wiring harness need to be increased.

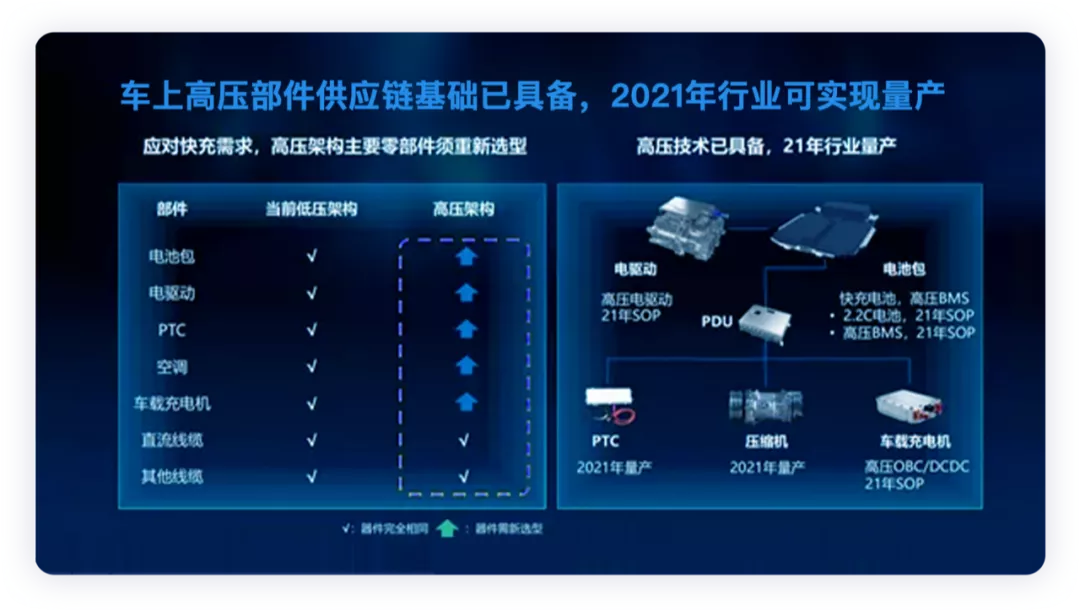

However, in the long term, to achieve 5-10 minute fast charging and create a charging experience similar to refuelling, charging power of over 400kW will be required, and the entire vehicle voltage platform will inevitably evolve towards 800V or higher. Moreover, under high-voltage architecture, the battery system has less heat dissipation, lower difficulty in thermal management, smaller wire harness diameter, and lower cost, all things being equal.

In this field, apart from vehicle manufacturers, Huawei is particularly active and has developed an 800V system as a full-stack high-voltage platform solution. This includes on-board charger (OBC) for vehicle charging, battery management and powertrain, high-voltage modules beneath the vehicle, and the 15-minute 30% -80% charging solution released this year, with a 7.5-minute solution coming to the market in two years and a 5-minute solution achievable by 2025.

In terms of battery safety, we have developed an AI BMS solution for cloud-based battery safety, combining big data, electrochemical mechanism models, and AI models. Based on AI algorithm training and continuous iteration through digital twin coupling, this solution improves algorithm effectiveness, achieves faster, more accurate prediction of battery thermal runaway, and ensures battery safety.

In terms of battery safety, we have developed an AI BMS solution for cloud-based battery safety, combining big data, electrochemical mechanism models, and AI models. Based on AI algorithm training and continuous iteration through digital twin coupling, this solution improves algorithm effectiveness, achieves faster, more accurate prediction of battery thermal runaway, and ensures battery safety.

Currently, there is a severe shortage of high voltage DC stations that can match fast charging electric vehicles with 800V or more. During the initial promotion phase of high voltage architecture, boosting functions may need to be equipped on the vehicle end to solve the problem of boosting from 400V to 800V.

The challenges and opportunities brought by the 800V system are diverse, and there are several opportunities:

-

From the voltage topology perspective, it is possible to achieve a gradient configuration of the same battery cell, which means it can be differentiated into high-voltage/high-spec and low-voltage/low-spec configurations.

-

From the current direction, starting from 350A, 500A, and even 600A in the future, it can support fast charging and continuously improve power.

-

The introduction of SiC can improve the efficiency of the overall power electronics and reduce the volume.

In addition, the investment in charging infrastructure is another important piece of the puzzle in the overall industry. Currently, major auto companies such as Volkswagen, Tesla, and General Motors are building their own fast charging networks. In terms of facilities, they have begun considering the establishment of charging facilities that meet the future 800V demand. Huawei has started designing charging modules that are compatible with 200V to 1000V, based on the efficient output of two 500V series circuits under full load.

In practical applications, the 800V high-voltage platform also brings many challenges to electric drive, such as insulation, bearing corrosion, and EMC issues. Huawei has made many attempts in this regard, systemically solving these problems through core innovative technologies such as patented high-voltage connectors, patented bearing flow control and breakdown structure, and EMC software and hardware suppression. For example, in the 800V system, bearing corrosion has always been a difficult problem for industry electric drive products. While bearing corrosion may not occur in motors under 400V, the probability of motor bearing corrosion will directly increase under 800V systems.Firstly, we need to pay attention to the axial voltage generated by the common mode current in the electric drive system. In the electric vehicle, the axial voltage of the drive motor is mainly based on “capacitive voltage”. Its source is the common mode voltage generated by PWM control, which is divided by layers of parasitic capacitors and finally distributed to the two ends of the bearing in a certain proportion. The mechanism of high-frequency induced axial voltage includes the asymmetry of parasitic capacitance between stator winding and machine casing in the stator winding and machine casing, the change of leakage current between the winding and machine casing in the common mode circuit, and the equivalent current change of common mode current and the corresponding induced magnetic flux on the motor shaft.

Through innovative “Franklin” drainage technology, the current of the voltage on the bearing up to 60V-80V can be led out, which can solve the impact on the pressure resistance performance of the lubricating film between the bearings and greatly reduce the risk of bearing failure.

Summary: Major automakers have begun to increase their investment in 800V high voltage, although there are still some challenges in high voltage architecture. Overall, 800V high voltage architecture will become the mainstream platform for the next generation of electric vehicles, and 2022 will be the first year of 800V system in China.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.