10-year charging pile, have you seen it before?

Author: Huangshan

On December 1st, the delayed fifth charging pile exhibition was successfully held in Shenzhen for almost one month. Despite the repeated outbreaks of the pandemic, the scale of exhibitors and the popularity of visitors were much better than expected, and the enthusiasm of everyone was not affected by the pandemic at all.

I spent a day and visited all of them, and also had exchanges with many new and old friends. Here is a summary of my exhibition observations:

-

The market is still booming. Not only were there more visitors than usual, but they were also more professional. Moreover, I saw many new companies that I hadn’t heard of before in this industry, which shows that the industry is still on the rise.

-

Export is booming. Benefiting from the global new energy market, especially in Europe, the overall new energy vehicle market in Europe continued to set new highs in the first half of this year, with sales exceeding one million units. In addition, the charging pile subsidies in various European countries are very high. Under the influence of the pandemic, only Chinese suppliers are complete and stable, resulting in a surge in charging pile exports overseas.

-

Product homogenization is serious. Regardless of whether it is an AC or DC charging pile, most companies produce products with serious homogenization in structure and appearance.

-

The price war continues, and there is no lowest, only lower. The price of DC charging piles has dropped below 3 cents per watt, and there was a company that advertised an AC charging pile for only 598 yuan per unit on-site. This vicious circle of price wars will continue for a period of time.

-

Product appearance is generally “ugly”, lacking in design. After looking at so many charging pile products, most of them lack industrial design in appearance, with similar shapes, and low aesthetics. On the other hand, this is also the result of the homogenization-driven price war. Who cares about aesthetics in a price war?

-

Lack of value realization in the use process. Most products simply satisfy the ability to charge, without considering too much about customer needs and scenarios, and why customers should choose their products. At the same time, there is less attention paid to the use experience of the car owners, which is the result of getting caught up in internal competition.

However, I also found some interesting products on-site, such as the DUPOWER new energy’s energy storage and charging integrated charging pile, Weiyu Electric’s semi-integrated DC charging pile, Qudian’s integrated charging and discharging AC gun, Yangguang Power’s IDC120kW integrated charging pile, and Fast Charging’s parking solution.

The product that impressed me the most was Yangguang Power’s 120kW integrated charging pile, which is different from what we usually see in the market.

-

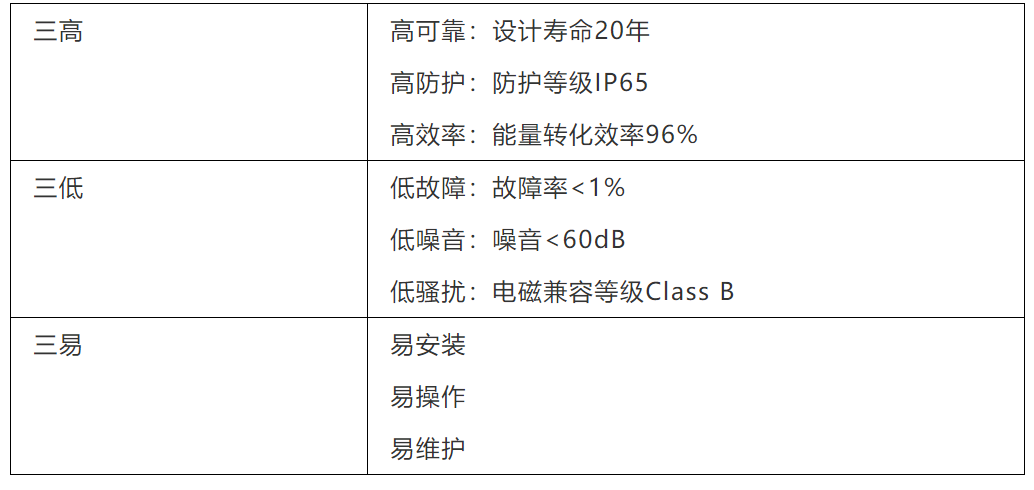

Long service life. This charging pile has a design life of 20 years, and there is no problem with its use for 10 years. No one in the charging pile industry has claimed such a long service life.

-

Small size, high aesthetics. The volume of this pile is much smaller than the commonly seen 120kW DC charging pile in the market, and it has high aesthetics.

-

Integrated structural design. The control and power modules are completely encapsulated in the front of the housing, and the rear has an independent air duct for heat dissipation. This is very different from the commonly seen modular charging piles on the market.

The quality of fast charging piles on the market varies greatly, with high failure rates and short lifetimes. What gives Sunshine Power the courage to claim a 10-year lifespan? After a deep discussion with Yang Yuefeng, Vice President of the Charging Business Unit at Sunshine Power, I have some answers.

Why do this?

Why integrate the design? This is the first question that came to mind, what was their research and development logic.

Because currently, traditional fast charging piles mainly use modular and split-type structural design. The so-called modular design uses 20-30kw power modules in parallel and places the control module and power module in the cabinet, while the split-type design places the control module and power module in a rear distribution box with the charging pile only acting as a charging port, where telemetry and remote control by special telecommunication groups are typical.

Yang Yuefeng first did a definition for the integrated charging pile, which is to place all other basic components except for the charging cable, vehicle connector, and human-machine interaction in a closed cabinet, integrate the power conversion unit, and use an independent and heat dissipation system to deal with the heat flux inside the cabinet. This is the charging machine.

As for why this design, the answer is also straightforward. He said, “When we were designing the product, we were thinking about who would buy it? How would they use it? What are the shortcomings of the products on the market? This was the first question we faced during our pre-research. Fast charging piles are generally used for operations and are a production material. This basic attribute requires the product to satisfy “safe and stable, low failure rate, long lifespan, and low maintenance cost” characteristics. We have summed up the key words as “protecting assets and improving returns.””

“Furthermore, Sunshine Power started with PV inverters and has been focusing on power electronic conversion technology for more than 20 years. The technology principles of PV products are similar to those of charging piles. The characteristics of PV products are for outdoor use and must have a long lifespan, generally requiring 25 years, which is similar to the usage scenarios of charging piles. Therefore, the Group’s research and development ideas and technology accumulation has also given us a lot of help and inspiration. Finally, I have been in the power electronics industry for more than 20 years and have a profound understanding of this area,” Yang Yuefeng added two points.

The benefits brought by the integration are also obvious, mainly manifested in three aspects:

To live a long life, there are two major factors to consider: innate genes and the environment. Even with a favorable environment, having poor genes won’t help and vice versa. Therefore, lifespan is determined by genes multiplied by environmental factors, and both factors need to be high in order to achieve a long lifespan. The same goes for creating products, including charging piles.

Yang Yuefeng gave a vivid example of how integrated charging piles achieve a design lifespan of 20 years. It starts with genes at the foundation. All component voltage stress, current stress, thermal stress, and mechanical stress need to be within the range required for lifespan assessment. Reliable theoretical calculation models and testing methods are essential.

Next is the environmental factor. Polluted environments significantly reduce the product’s expected lifespan. For charging piles, it is difficult to eliminate pollutants such as rainwater, dust, and salt mist, so the solution is to create a good small environment. The integrated charging pile adopts an independent wind channel design scheme, isolating internal equipment components from the external environment, fully preventing dust and water vapor from entering, and creating a good small environment for the internal equipment, improving the product’s environmental lifespan coefficient. By simultaneously increasing the genetic lifespan and environmental factors, a high lifespan product is achieved.

With over 20 years of experience in outdoor high-power power supply design and application, Yangguang Power has a comprehensive product lifespan design and evaluation system. It combines research and development capabilities, testing capabilities, supply chain capabilities, manufacturing capabilities, quality management capabilities, etc. The integrated charging piles are developed on a very comprehensive platform, with a strong physique.

Yang Yuefeng continued, “Currently, the technology commonly used is based on communication power supply technology. There is a limit to its lifespan and reliability, making it difficult to break through its ceiling and achieve our goal of reliability and long lifespan.”

The most difficult aspect is still thermal management. Since existing technology is not viable, Yangguang Power had to redesign the product structure of the charging pile. For this, Yang Yuefeng’s team drew on the series-parallel scheme of the group’s photovoltaic inverters and developed a set of HiL simulation tools and a series of auxiliary development tools, which were independently developed and are proprietary secrets.

Everything starts from analog simulation, from the bottom up, layer by layer simulation:

-

Device-level modeling simulation at the bottom layer includes devices, circuits, thermal management, mechanical stress, etc.

-

Whole machine modeling simulation at the intermediate layer includes optimization and protection of the entire machine.

-

Site-level system simulation at the top level includes the fusion and optimized scheduling of the light storage and charging systems.

After completing these simulations, various experiments and verifications will undergo thousands of testing projects, including real-site validation, 100% aging tests, waterproof tests, sand and dust tests, EMC electromagnetic compatibility tests, high and low temperature tests, thermal management tests, etc.

The difference between an integrated charging pile and a traditional modular DC charging pile is that the control module and power module of the traditional modular DC charge pile are placed separately; the control module and other switch components are in front of the machine cabinet, and the power module is stacked one by one on the side or back of the cabinet.Integrated pile is to completely seal the control module and power module electronic components in front of the cabinet, with an independent heat dissipation air duct at the back of the cabinet. Due to the structure design of front and back isolation, the benefit is the water resistance level increased to IP65, and the entire machine can be directly washed with water, while also protecting electronic components from external pollution, effectively improving stability and lifespan.

“After integration, another benefit is the reduction in wire routing and connector count, which are also factors that ensure stability and longevity. Therefore, in simple terms, all factors that may affect stability and lifespan are controlled one by one,” said Yang Yuefeng.

The most challenging issue in the R&D process is thermal management, which is actually a problem faced by all power-related products. Poor thermal management can accelerate component aging, thereby increasing failure rates and affecting the final product lifespan. Regarding this, Yang Yuefeng stated in the interview that the simulation accuracy was difficult at the beginning, followed by continuous optimization during the process, and ultimately they adopted an independent air duct for forced cooling.

Different from the structure of module and overall heat dissipation of traditional charging piles, the integrated design of Sunlight Power leads to a very smooth air duct for cooling, with only one set of DC cooling fans located in the middle position, making the noise lower, the cost lower, and the efficiency greatly improved during the operation of the charging pile.

Before the interview, I had communicated with many industry friends about the integrated solution, and two issues were of the most concern. First, the after-sales cost, because it is integrated, once a problem occurs, whether it is easy to repair or not and whether the cost will be high or not. Second, the expandability issue, as charging piles are developing towards higher power, can this integrated solution be expanded? Can it support higher power in the future?

Yang Yuefeng provided answers to these two questions. Firstly, he believes that if problems occur frequently, it proves that the product design has failed. Charging piles should be plug-and-play and require little maintenance, at most washed if it gets dirty. If it really breaks down, Sunlight Power will provide a standby new machine, and repair the broken machine before reinstalling it for the customer.

Secondly, regarding the expandability issue, it is currently impossible to increase the charging power through module expansion in the existing generation of solutions. However, in the integrated product lineup, Sunlight Power is also developing charging piles with higher power.

At the same time, Yang Yuefeng believes that the charging power will not be increased indefinitely. Currently, 120kW can adapt to mainstream models, and 200kW charging power will be a more suitable power range in the future.

Will integration be a trend?

As the saying goes, one man is not a team, and one tree does not make a forest. Will the integrated technology route chosen by Sunlight Power be the development trend in the future?The answer given by Yang Yuefeng is affirmative. He believes that the future charging station must be developed towards higher power, higher energy density, smarter, more user-friendly, and more aesthetically pleasing, just like our household appliances. Think about how televisions have developed from being bulky in the past to being super thin now.

To achieve this integration, it is certain to be a trend in technology roadmaps. Currently, Sungrow is already leading and participating in the development of integrated charging station standards.

In terms of evaluating the advancedness of this integrated product, Yang Yuefeng believes that this should be the world’s first 120kW integrated charging station, and Sungrow has applied for a global patent.

If someone else wants to design something similar, Yang Yuefeng thinks that first, he must master the power electronic technology, followed by the technology of the entire station, and requires a large amount of capital investment. Sungrow’s investment in this equipment is close to one billion yuan, and with the research and development colleagues of the Central Research Institute, we have invested a research and development team of more than 100 people, and it took two years to develop.

When it comes to potential competitors, Yang Yuefeng’s answer surprised me.

“I think the real competitors are in Shenzhen, where there are many talents, many companies, and a strong entrepreneurial spirit. International companies don’t need to be considered too much. I have worked in foreign companies and understand their situation. Another reason is that the Chinese people have already done a very good job in the application of power electronics.” From Yang Yuefeng’s answer and eyes, I saw his conviction.

Sungrow seems to be a new force that crosses borders, but in fact, they have been researching and developing charging piles since 2016. So far, they have a dedicated R&D team of more than 80 people, which is a typical strategy of keeping a low profile and accumulating strengths.

Now, Sungrow’s 120kW integrated pile has started mass production and has been launched in multiple places. Ultimately, customers and time will give the answer to whether a product is good or bad.

Sungrow’s in-depth thinking and innovation in technology roadmaps are worth learning from. Leading change is sometimes not visible by competitors. Cross-border challengers are the most frightening because they adopt a completely different way of thinking, whether it is a dimensionality reduction attack or using next-generation products to compete against current products. These are the only way for challengers to make their mark.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.